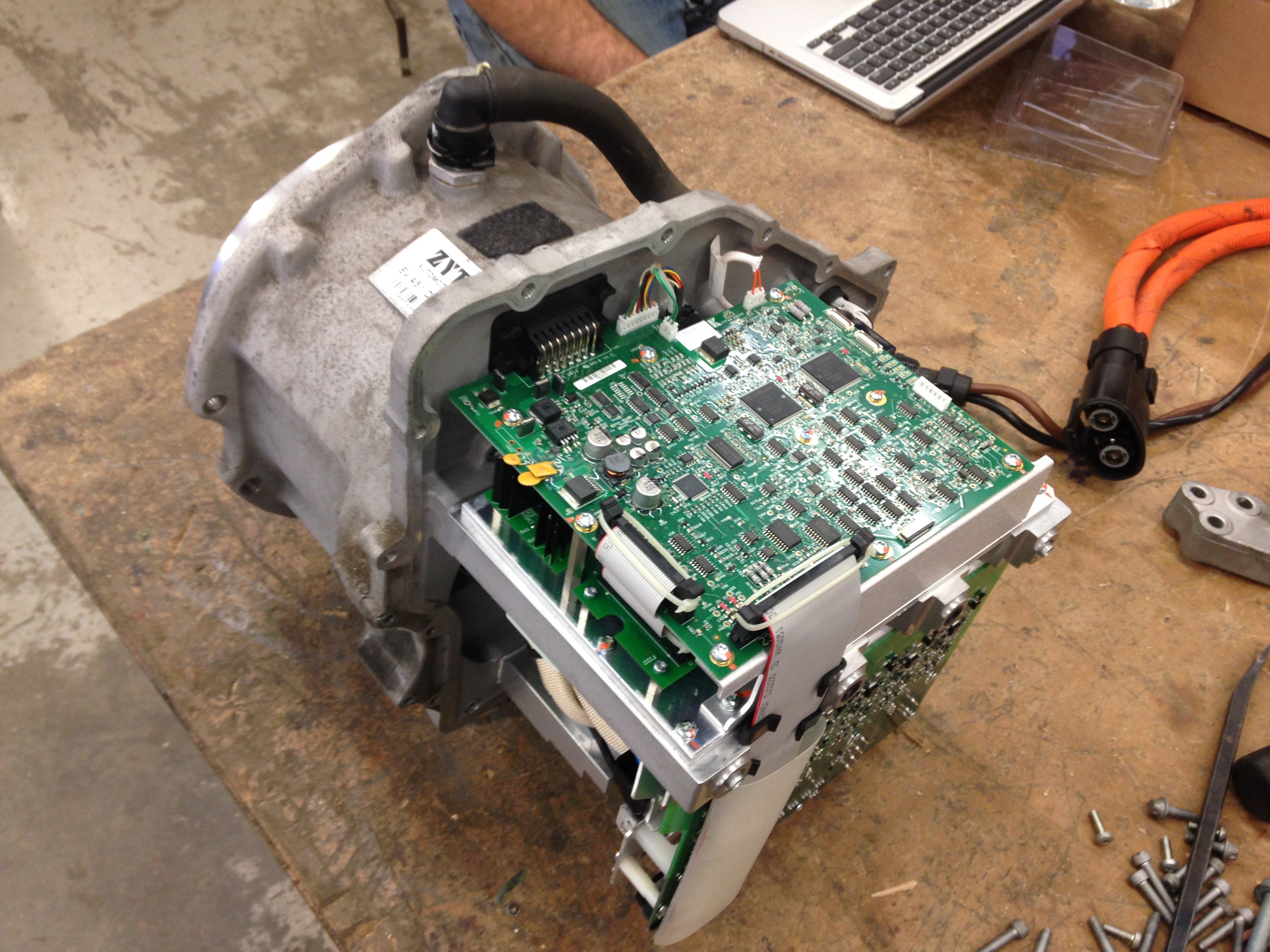

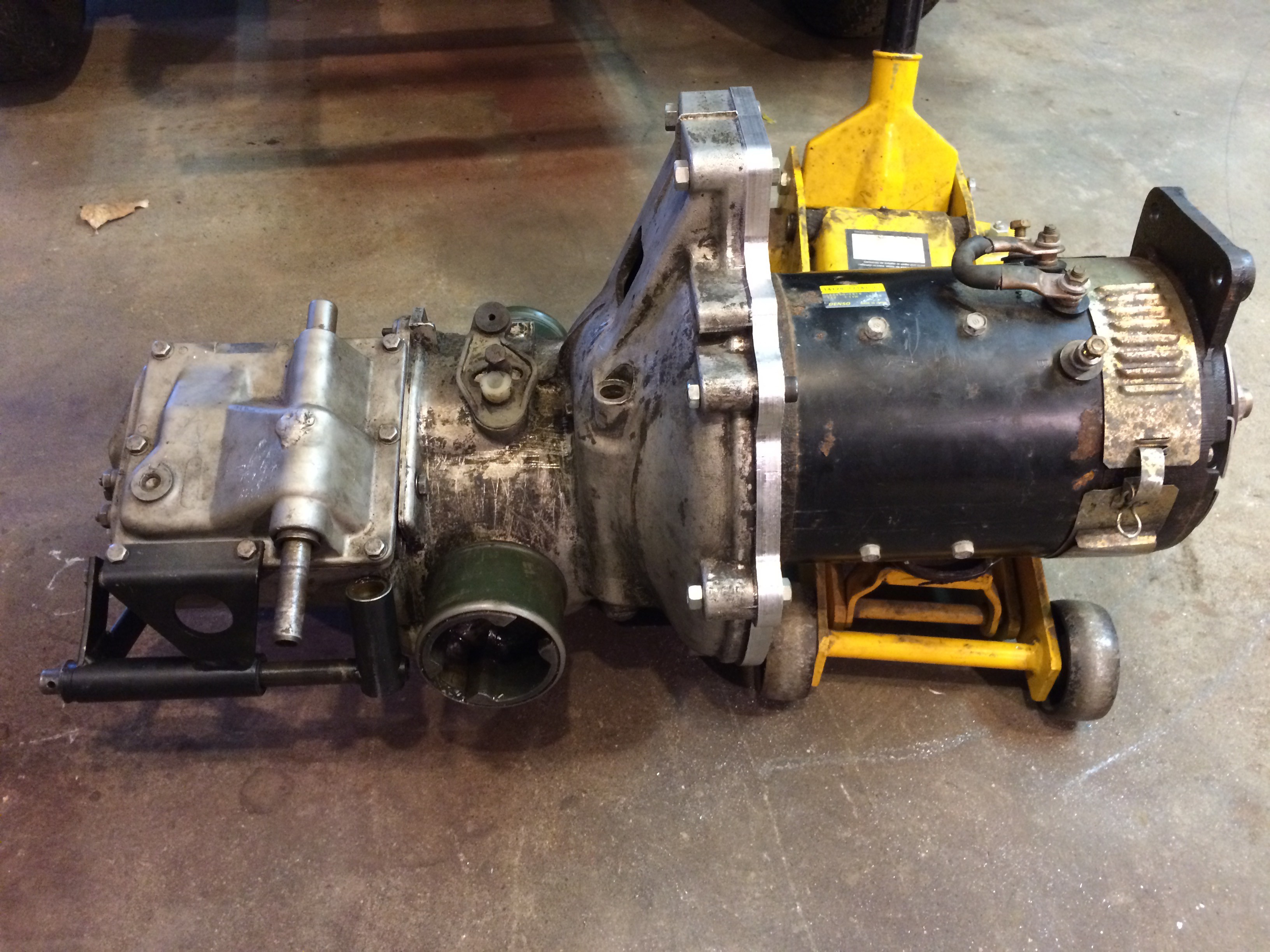

I am using an electric Smart Car motor/controller and charger, as well as some big relays, safety cut offs, crash switch and the water pump from the same era electric Smart Cars. I think there is great potential for the use of OEM parts in electric conversions. These parts are incredibly cheep. I purchased the motor/controller for $250.00 plus shipping. This reduces costs without reducing quality. These are really nice parts and will make for a powerful and dependable EV. The largest hurdle to overcome is hacking the motor/controller and charger (that's why it's so cheep). These components are controlled with proprietary CAN data that I need to get my hands on.

Despite this major difficulty that I may or may not be able to overcome, the ideas that I am exploring are valid/interesting/constructive. If I can't hack it, someone else soon will.

The ideas that fuel this project are centered on ecological sustainability and social responsibility. Utilizing used parts is good for everyone! It saves money and keeps old stuff out of the waste stream. It feels like dumpster diving for gold. But this stuff is around. Damaged EVs go to the junkyard with lots of good parts in them. As the proliferation of EVs grows, more parts will be available, so let's make use of them!

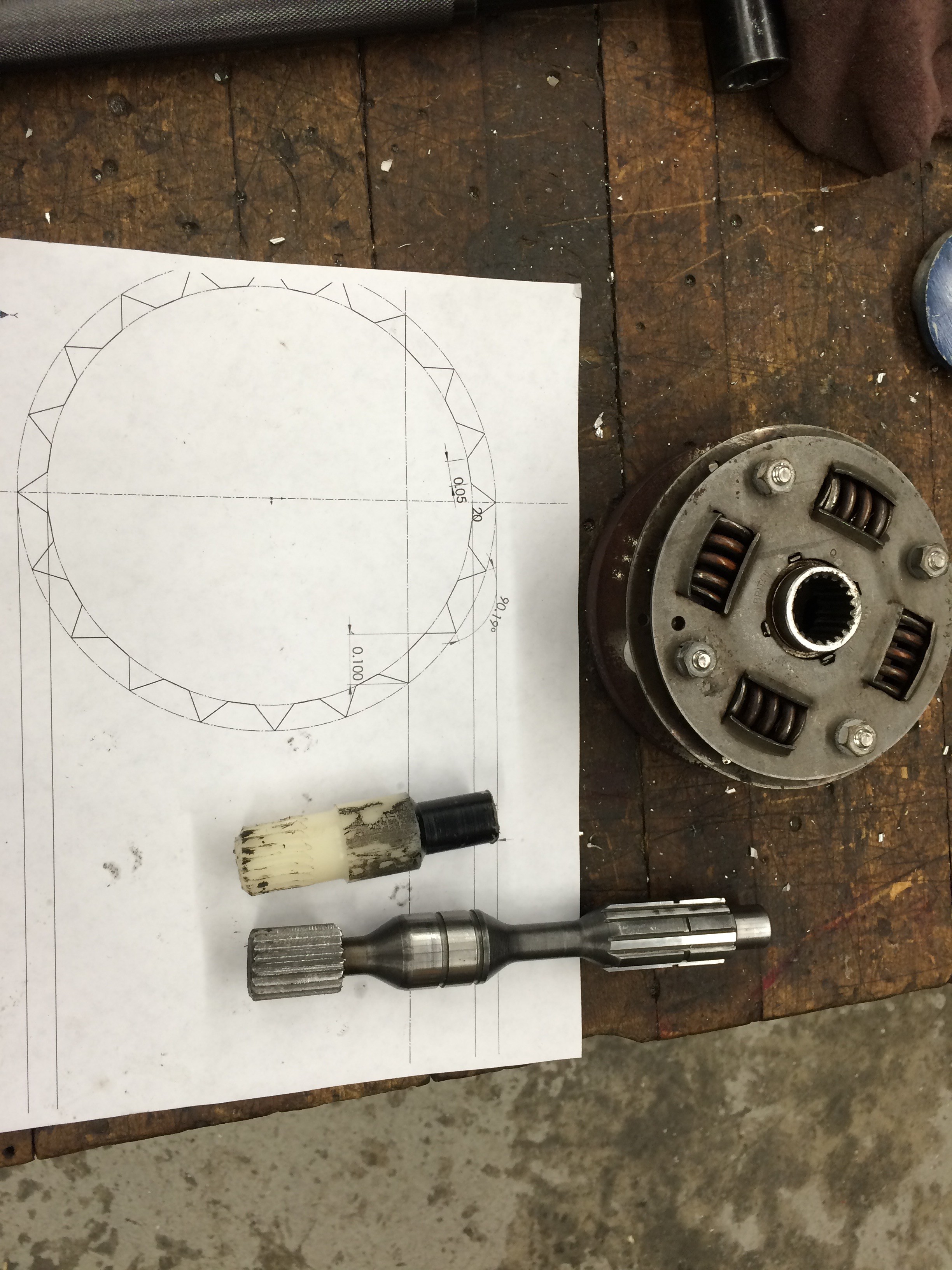

Ok, I'm rambling. This will be a cool project. Stay tuned and I will post CAD files of the adapter plate that you can modify to fit your transmission if you want to use this motor! Contact EV West, they might still have some of these on hand.

This project has taken an unexpected turn recently. I'm temporarily using a forklift motor and an old Kelly controller. Hopefully I'll be able to go back to the smart car system (I really want to be liquid-cooled) but for now I'm making some compromises to fit a schedule and budget.

Adam Curtis

Adam Curtis

Mount to this surface. Triangle and tab

Mount to this surface. Triangle and tab

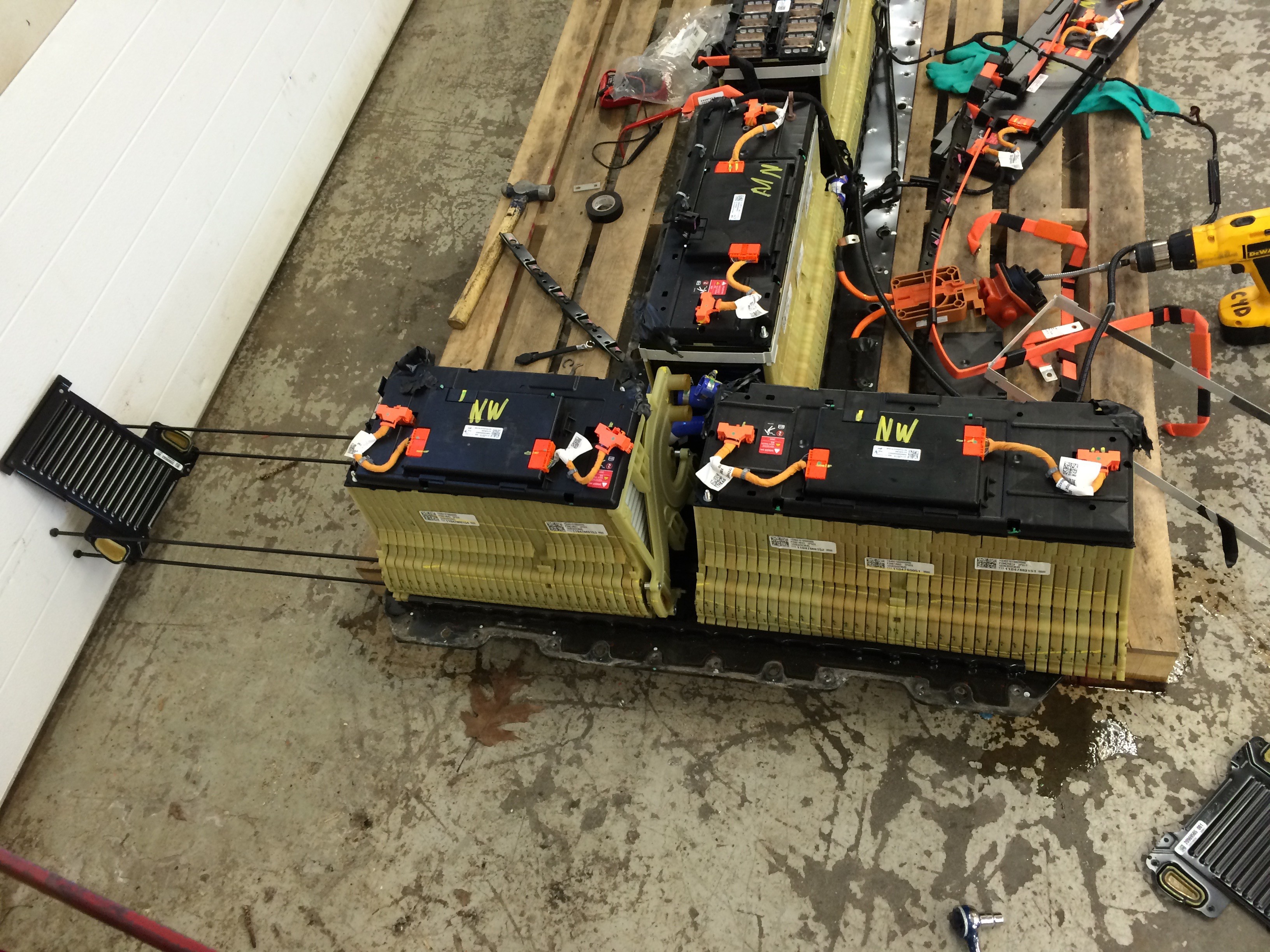

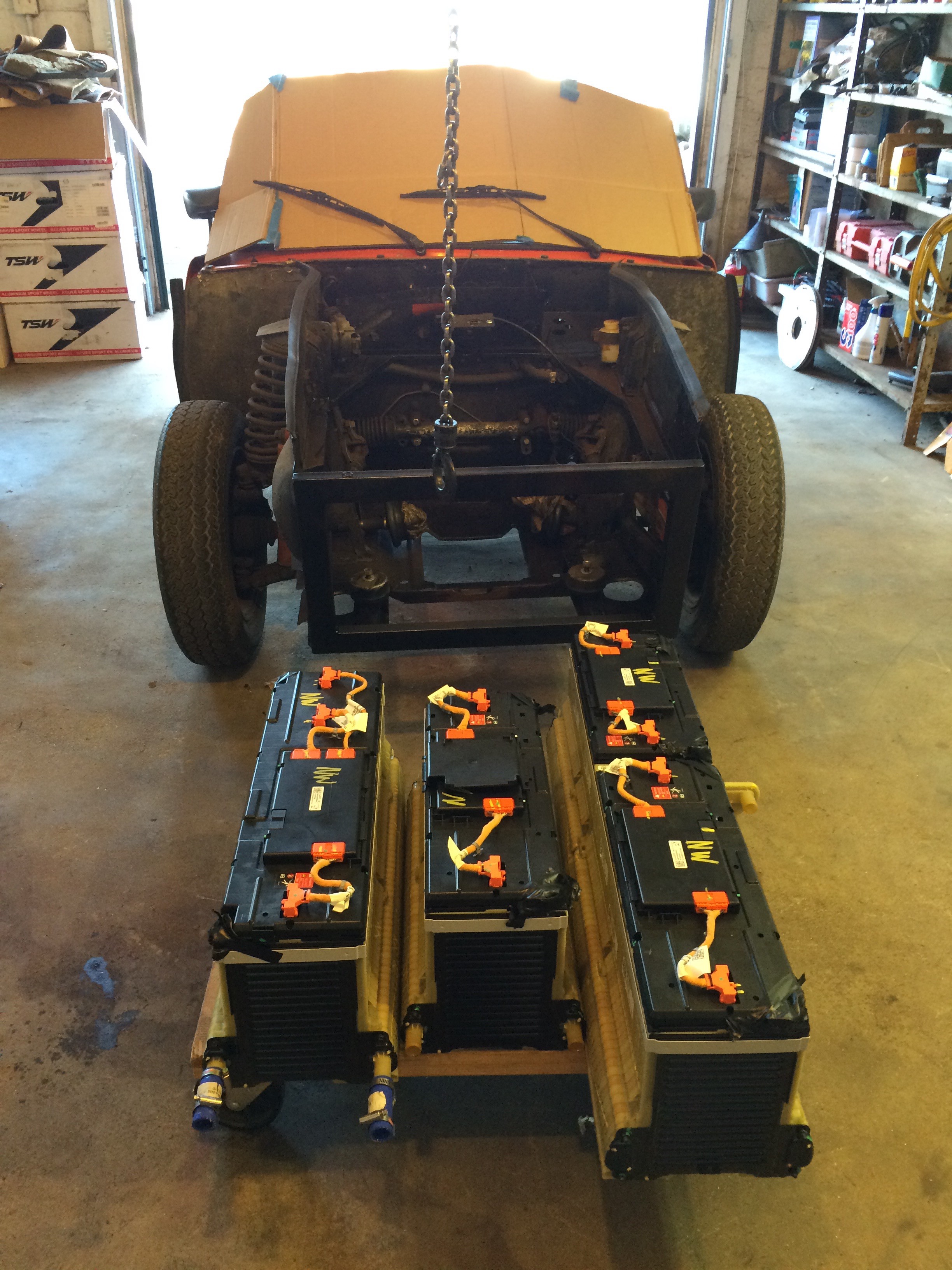

Here's the batteries resting in the engine bay above the motor and transmission. See any problems? I'll make a metal battery mount that bolts into the engine bay and tranny/engine mounts.

Here's the batteries resting in the engine bay above the motor and transmission. See any problems? I'll make a metal battery mount that bolts into the engine bay and tranny/engine mounts.

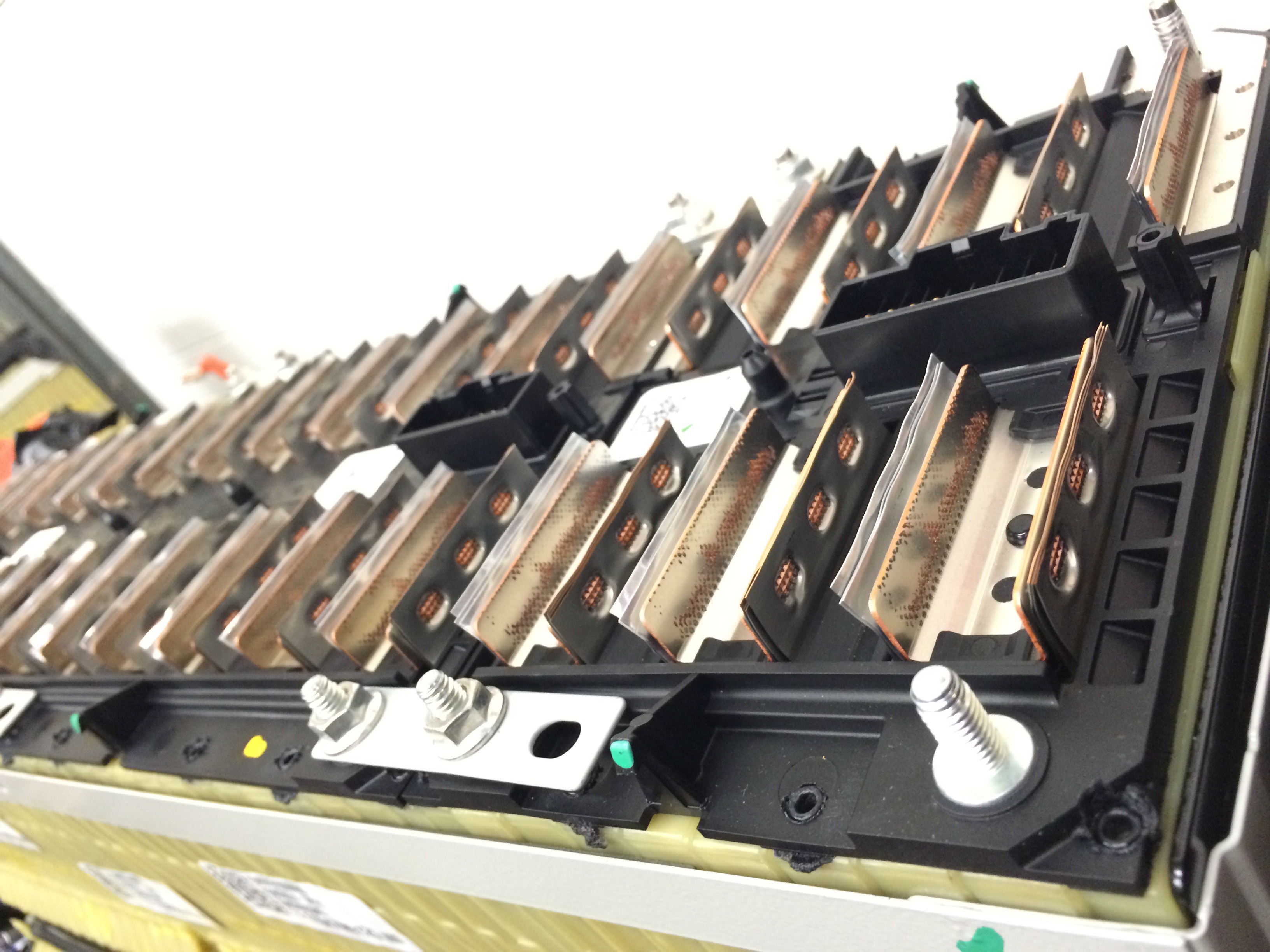

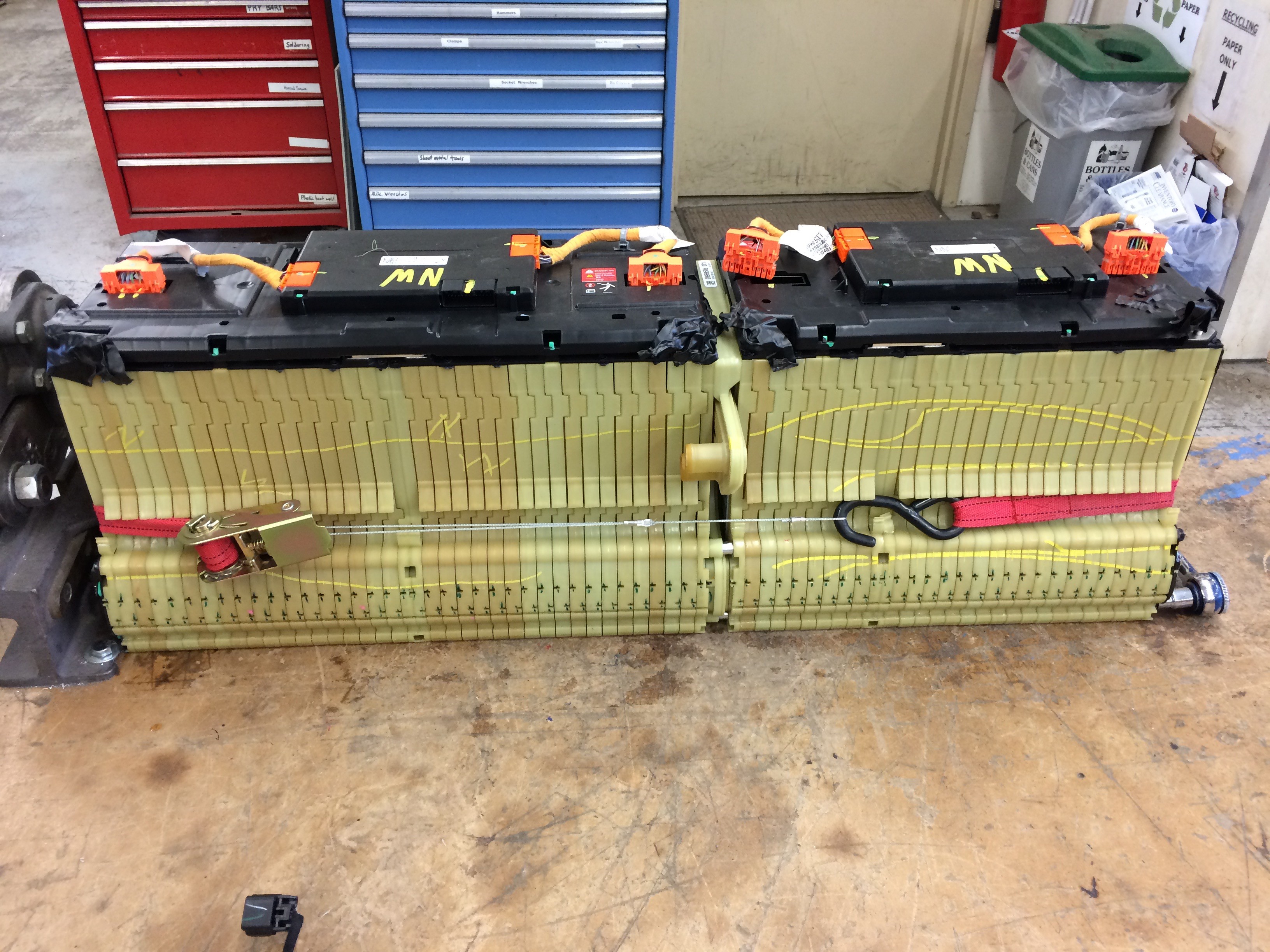

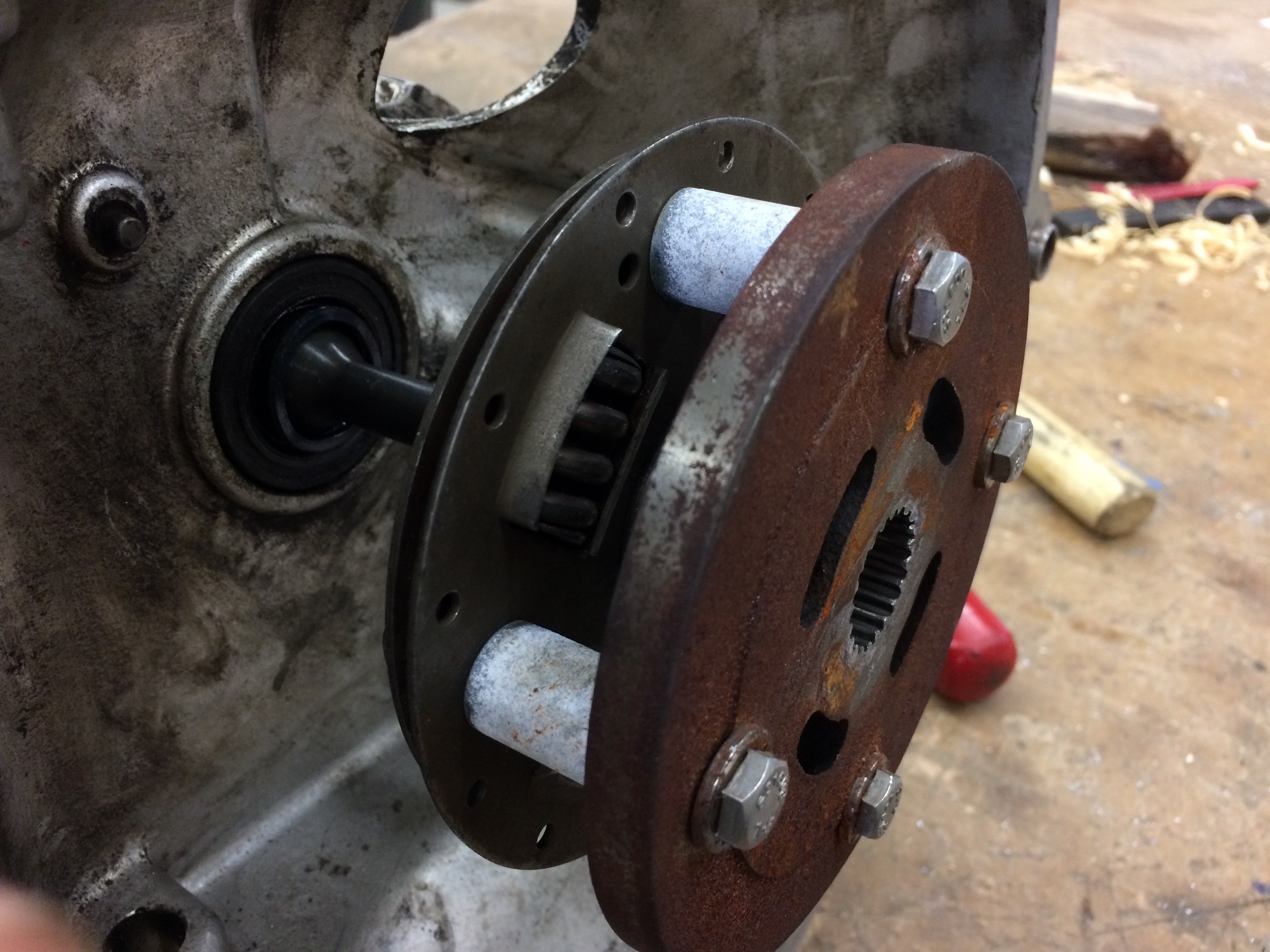

These huge bricks are held together with glue, steel bands and 3 foot screws. I wanted to see what the cooling system was like so I started taking this apart down to cell level. As soon as I loosed the 4 bolts that hold the black endplates together coolant started leaking out from every cell. Here's what the 4 bolts look like.

These huge bricks are held together with glue, steel bands and 3 foot screws. I wanted to see what the cooling system was like so I started taking this apart down to cell level. As soon as I loosed the 4 bolts that hold the black endplates together coolant started leaking out from every cell. Here's what the 4 bolts look like.

Ryan

Ryan

Quinn

Quinn

Awesome project. I want to tackle a EV conversion and am just at the stage of reading as much as I can.