THE PROBLEM

In the field of animal research, the traditional method of capturing small animals often relies on traditional pitfall traps. These traps typically consist of a container such as a bucket that serves to capture the animal and long tarps attached to each side to create a funnel-shaped structure to guide the animal into the trap.

However, this approach poses significant challenges and potential risks to the captured animals. One major concern is that the captured animal remains trapped inside the trap once captured, making it vulnerable to attacks by other animals in the vicinity. In addition, adverse weather conditions such as heavy rain can flood the trap and increase the risk of drowning for the captured animal if it cannot be checked in time.

Another disadvantage of this trapping method is that it relies on animals voluntarily entering the container, which not every animal is tempted to do. This poses a significant challenge for researchers, as some animals may not fall for the trap and may fail to enter the intended container, resulting in missed opportunities to study and monitor these shy creatures.

The Openthing 2 RepTrap is intended to address this problem and provide an alternative to traditional methods.

THE SOLUTION

Conventional motion sensors rely on temperature difference detection using infrared sensors. The environment is divided into small segments, and the temperature difference from one segment to another is detected when a warm object moves through the sensor's field of view. Due to the segmentation and the requirement for a distinct temperature difference from the surroundings, these objects need to have a certain size and temperature contrast to be detected. Reptiles such as frogs, lizards, or snakes usually have minimal temperature differences compared to their surroundings and are not large enough to trigger the sensor's segments.

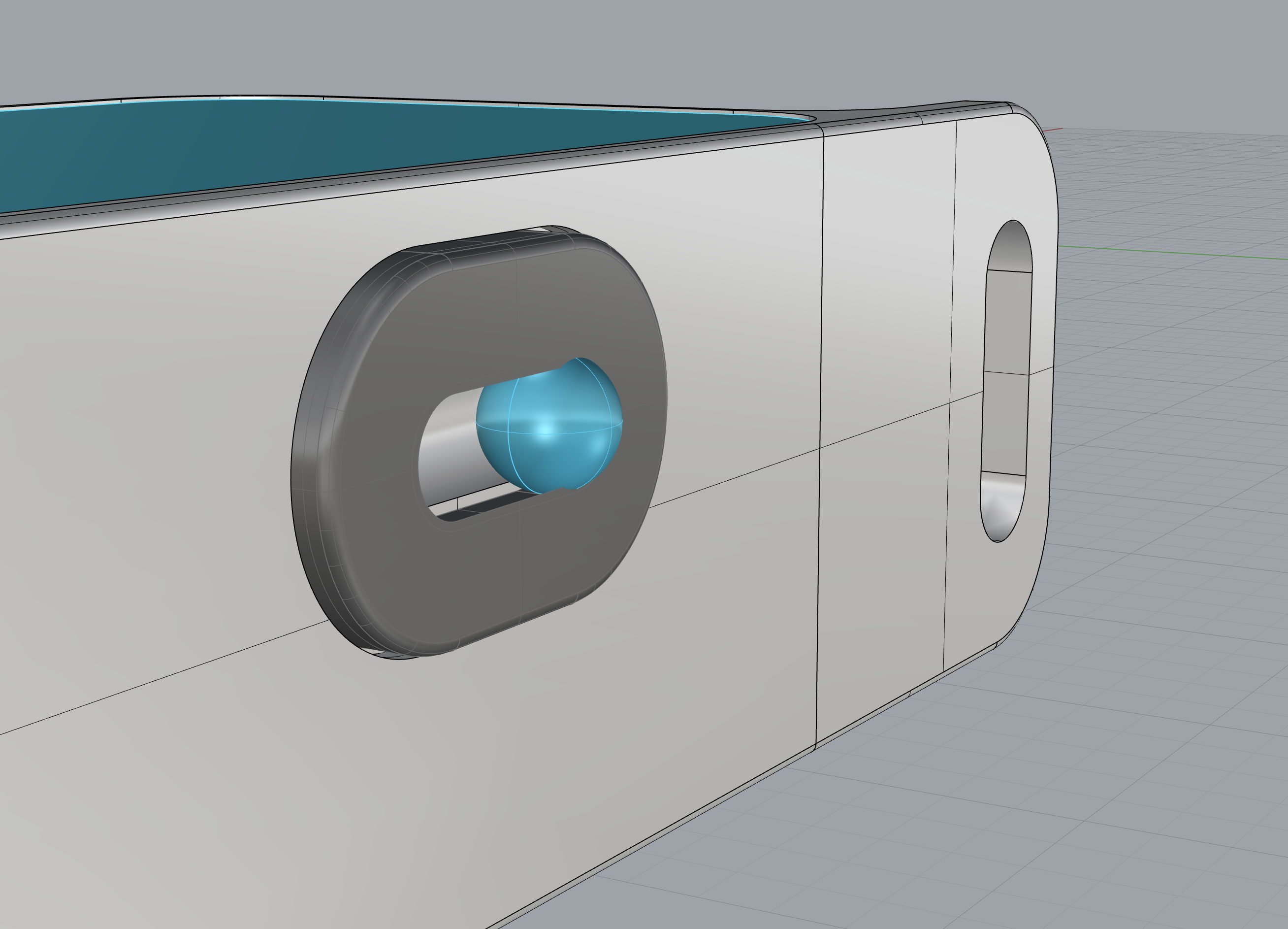

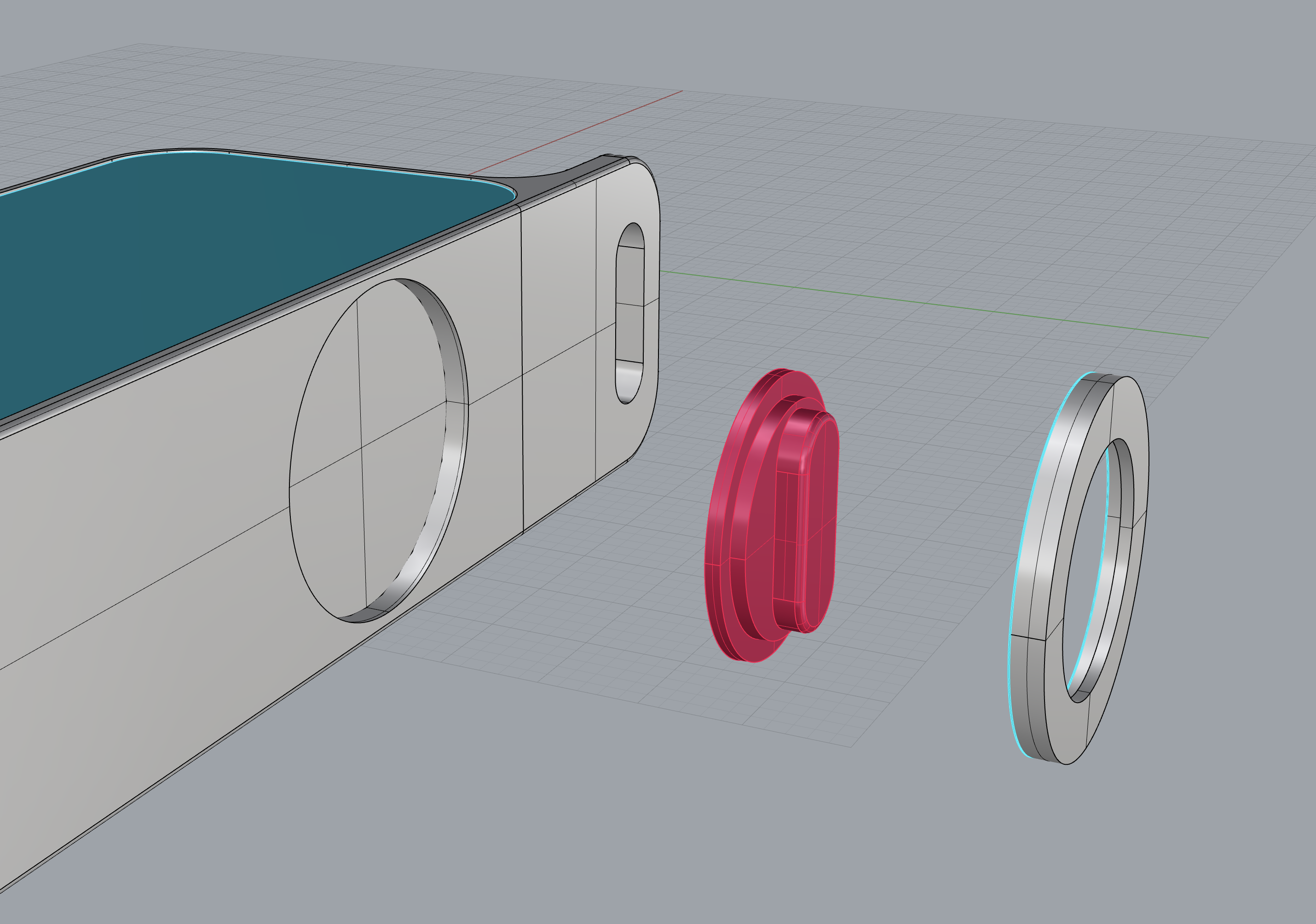

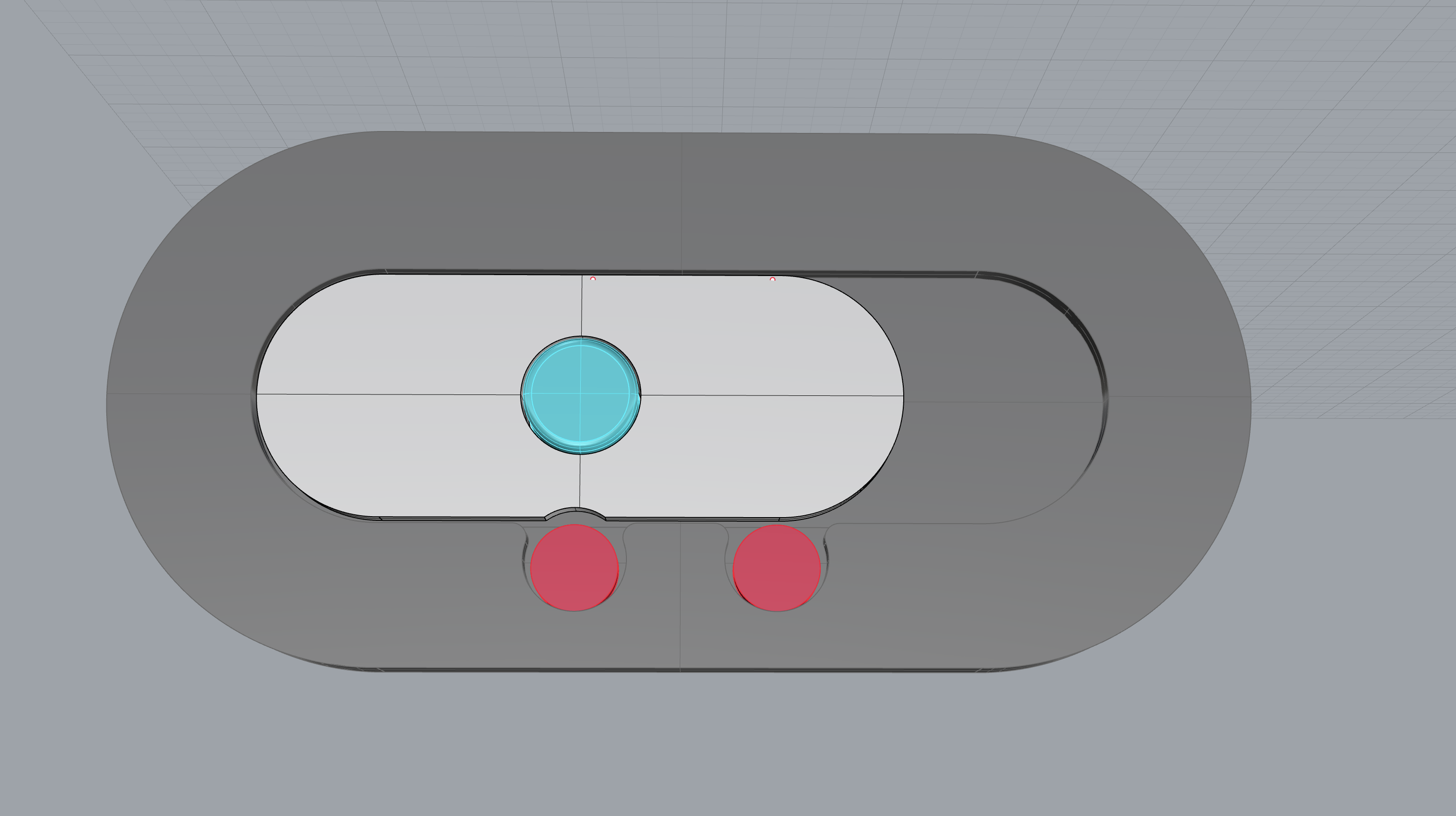

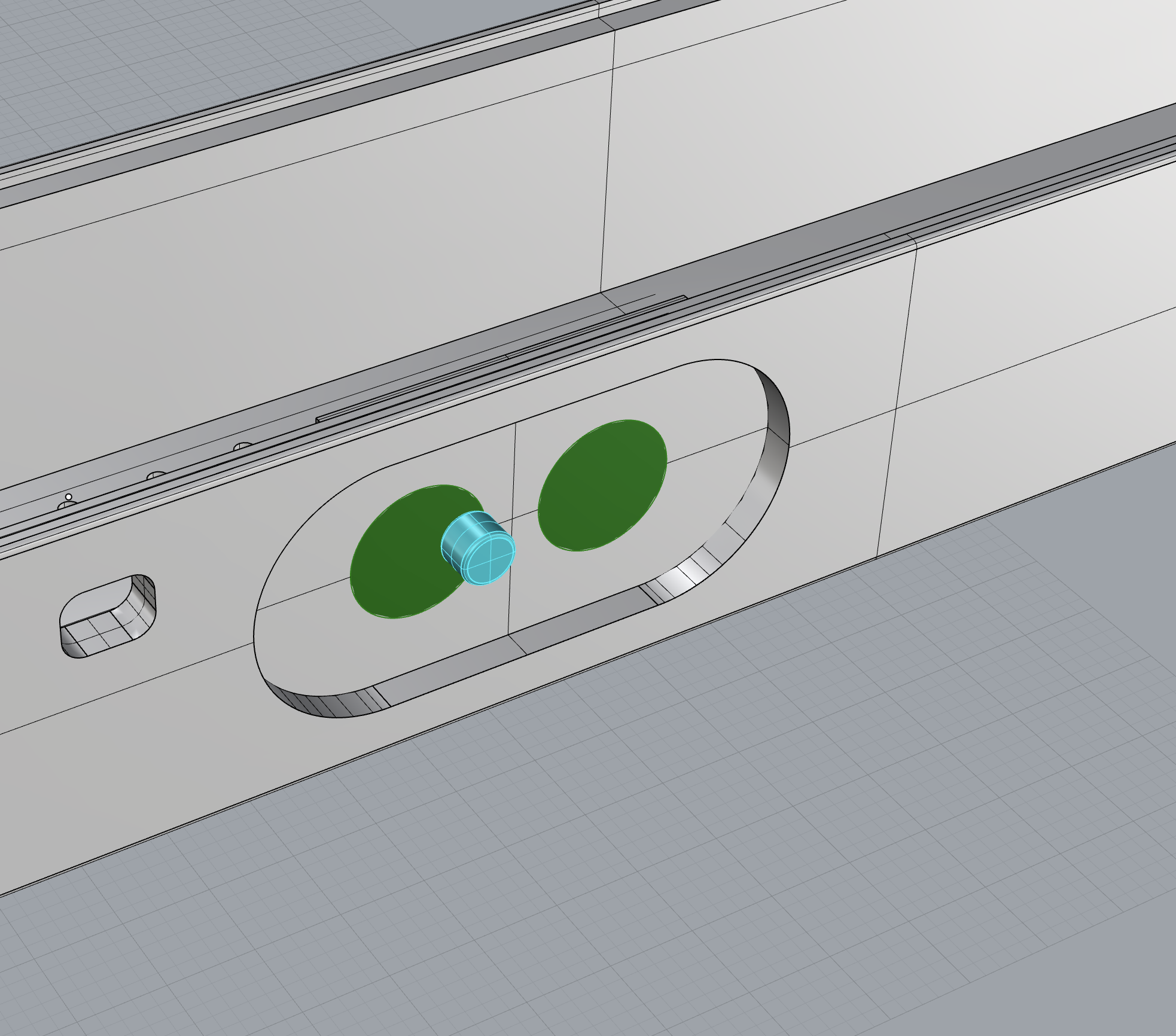

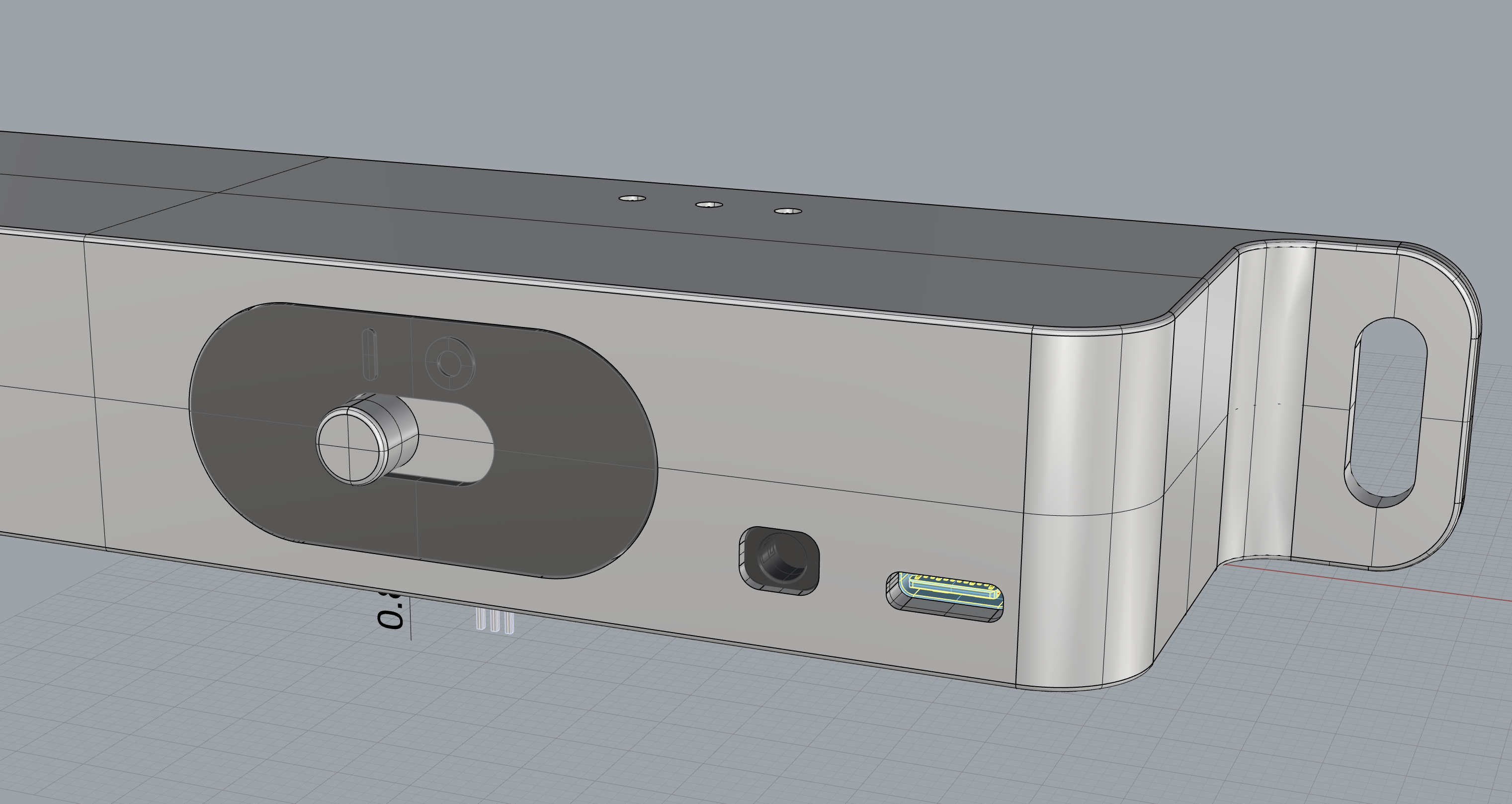

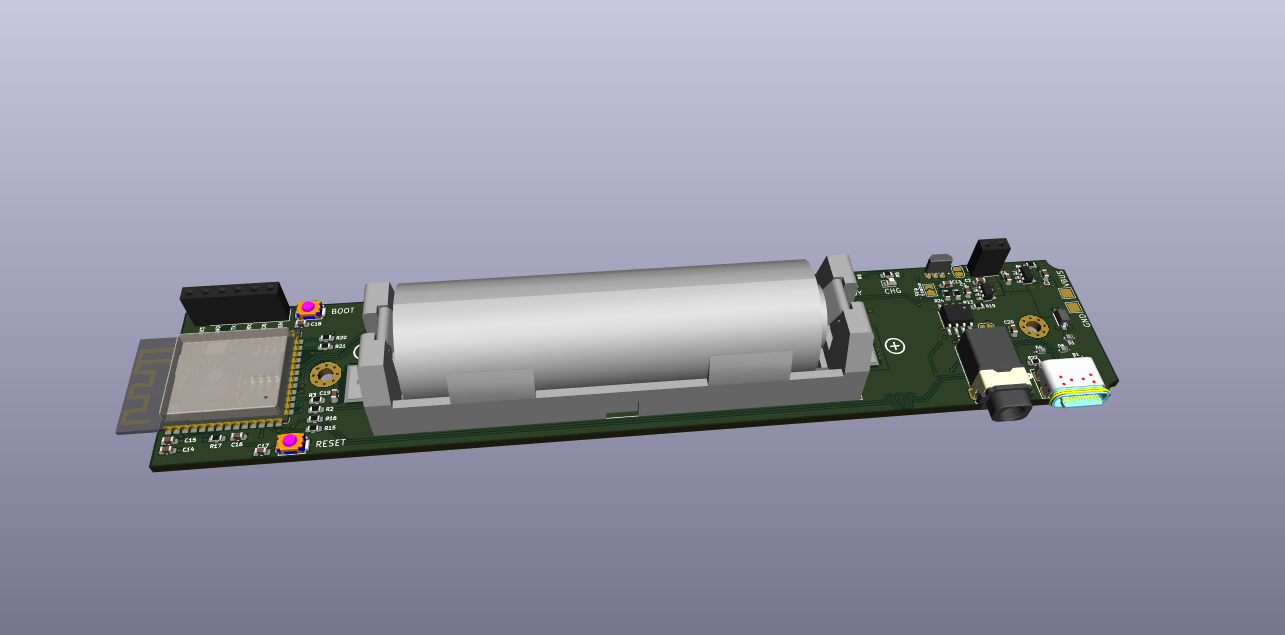

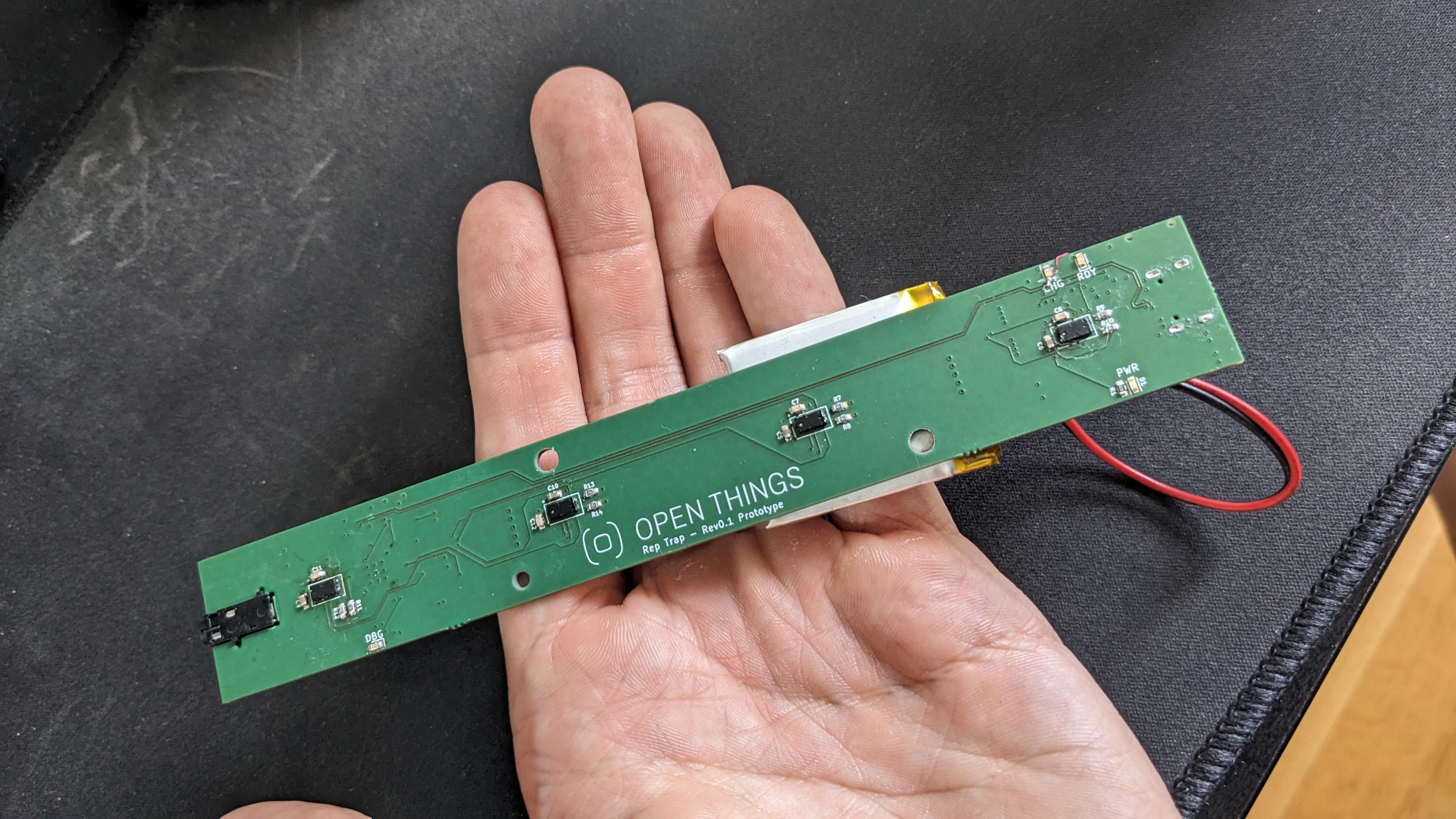

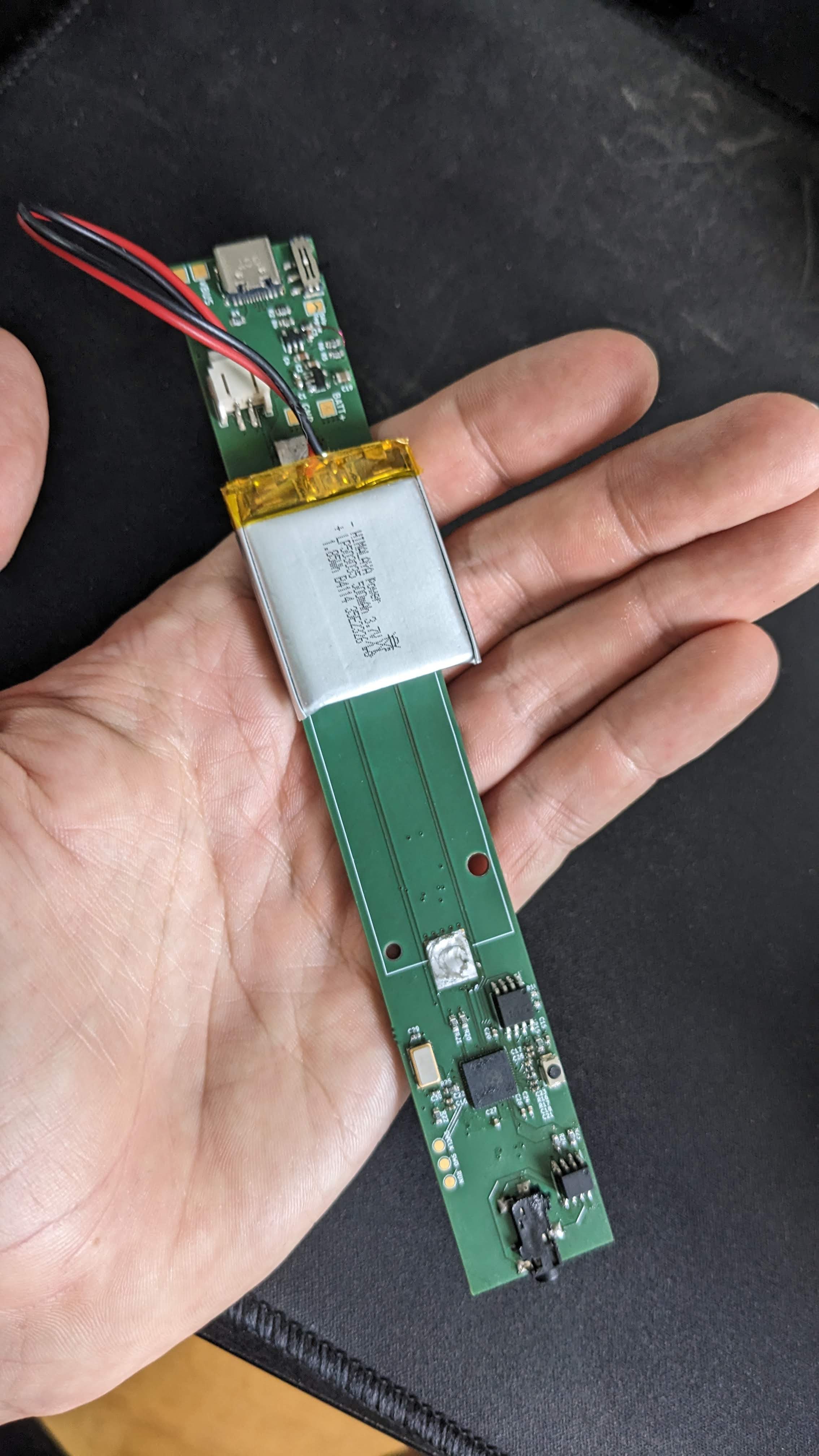

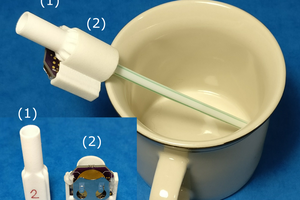

Our approach does not focus on motion but rather on the height of an animal, regardless of whether it is warm or cold-blooded. The RepTrap monitors the distance in front of the device using infrared laser sensors. When the height under the sensor changes, the sensor detects it and sends a signal to activate the camera. Installation only requires setting up a gate-like structure that the sensor can monitor, eliminating the need for holes and buckets.

This installation can remain unattended at a location for several days without putting animals at risk. The animals are not confined, reducing exposure to risks such as rainwater or other predators. With this solution, this type of trap can also be set up in remote locations where daily trap checks may not be feasible.

Mirko

Mirko

Bud Bennett

Bud Bennett

electrobob

electrobob

jflaschberger

jflaschberger