Modules design

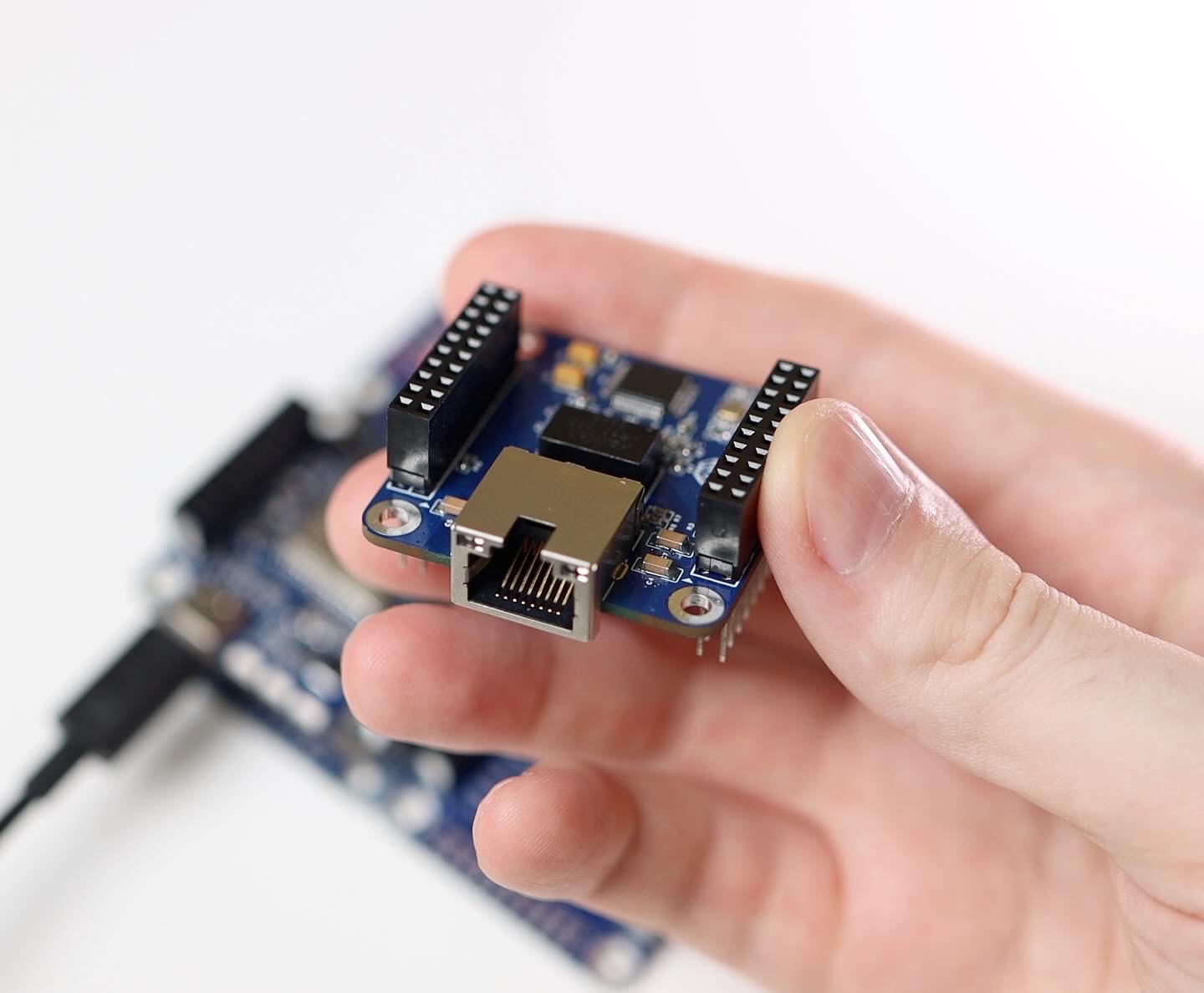

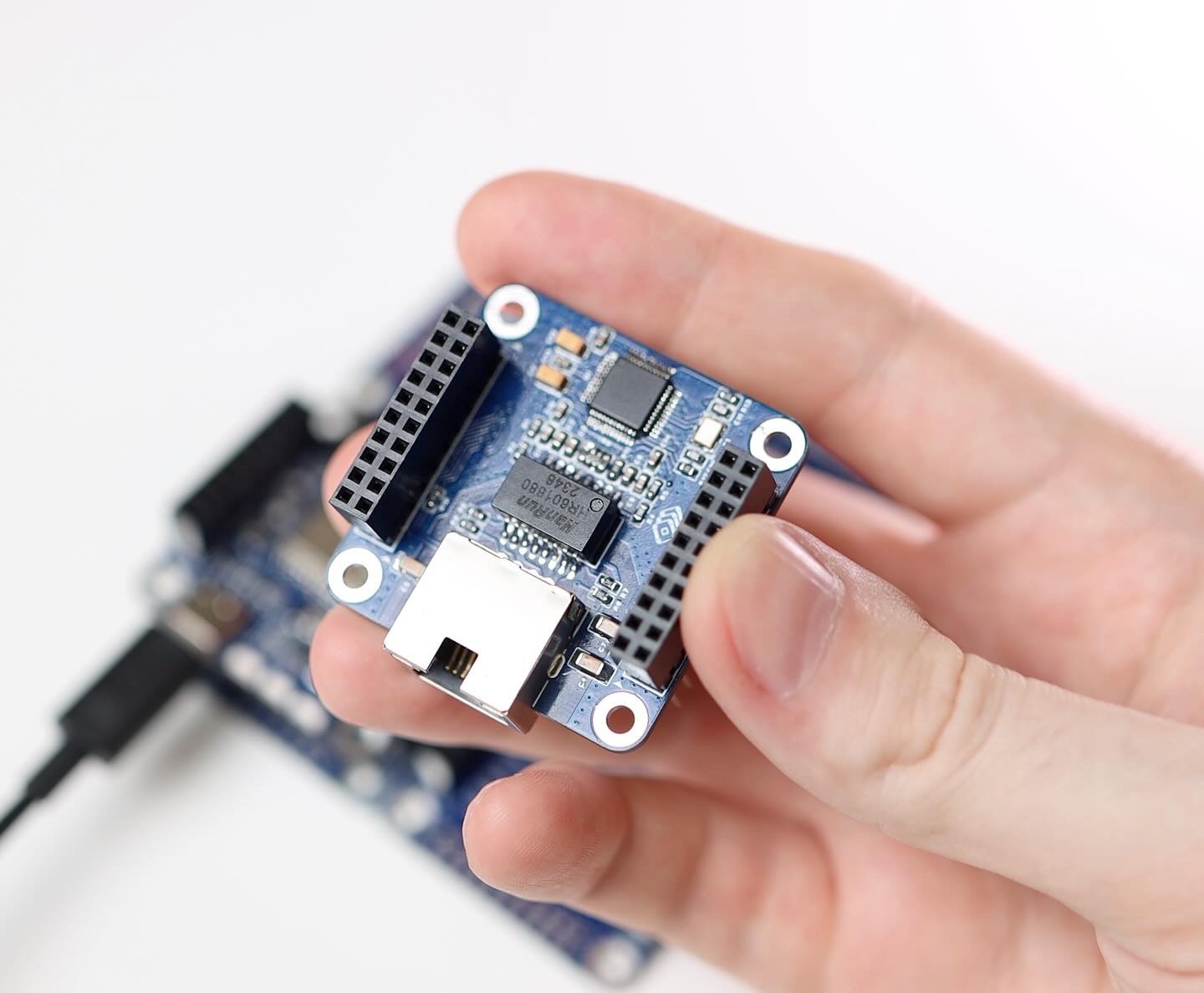

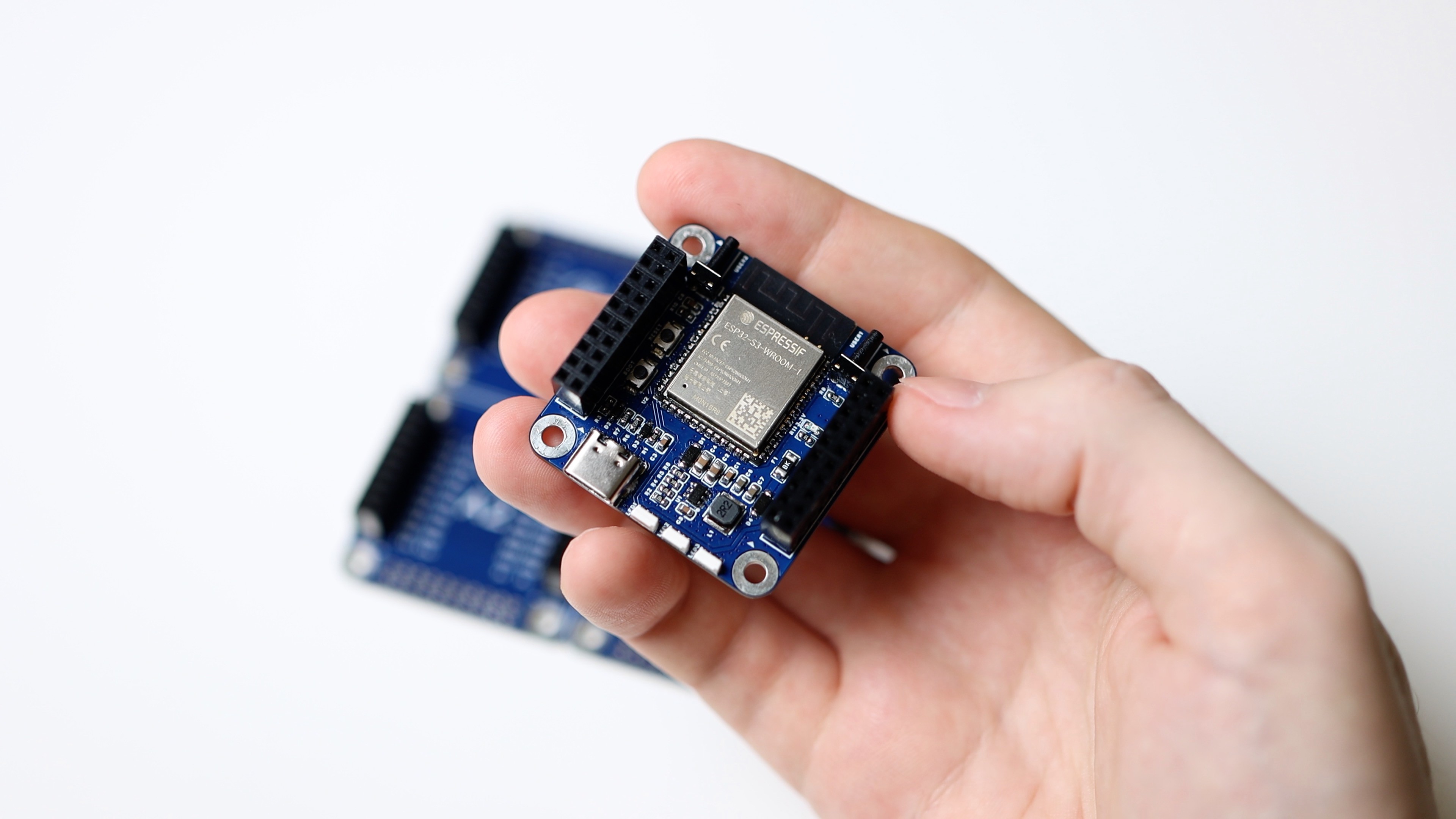

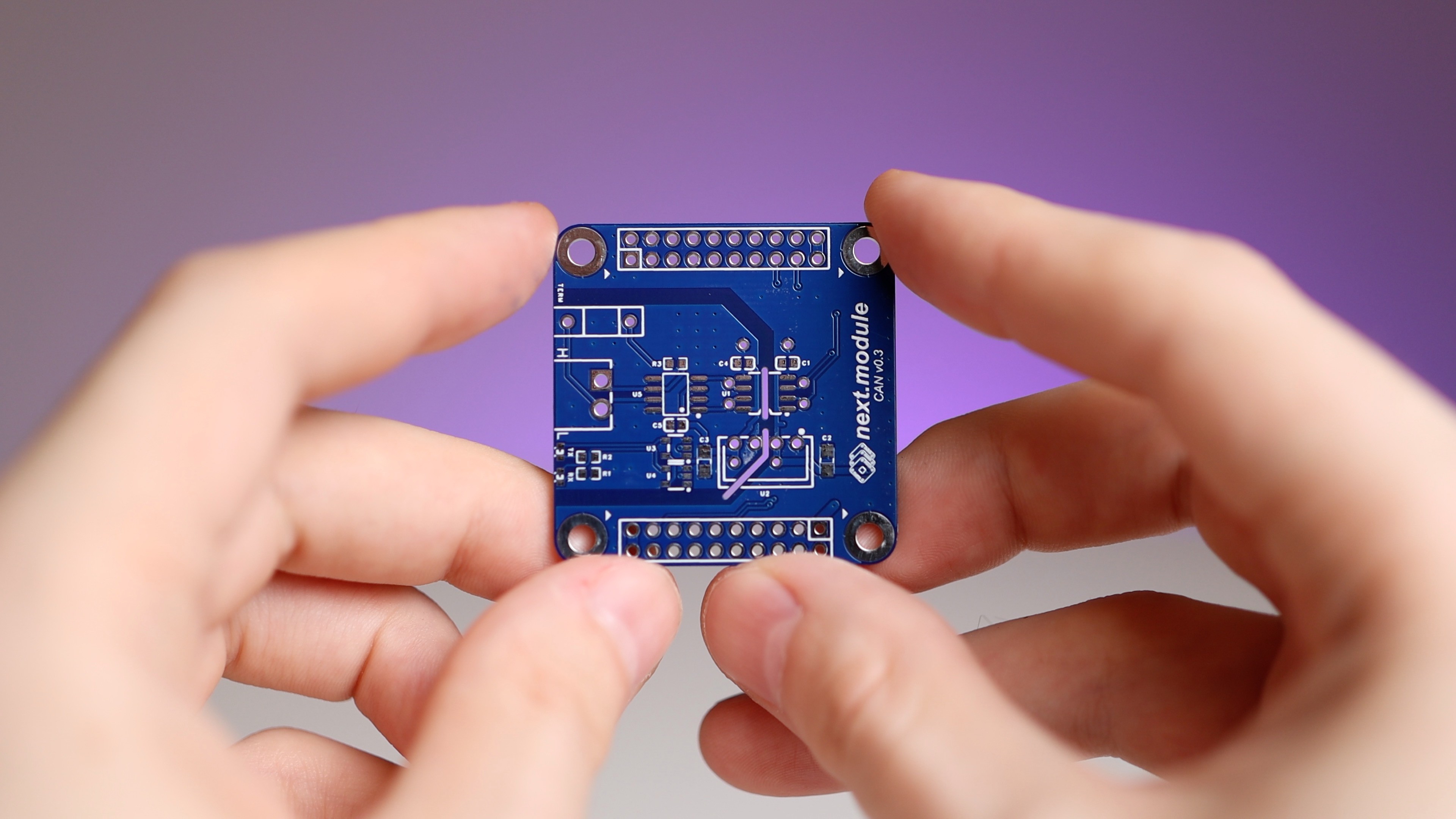

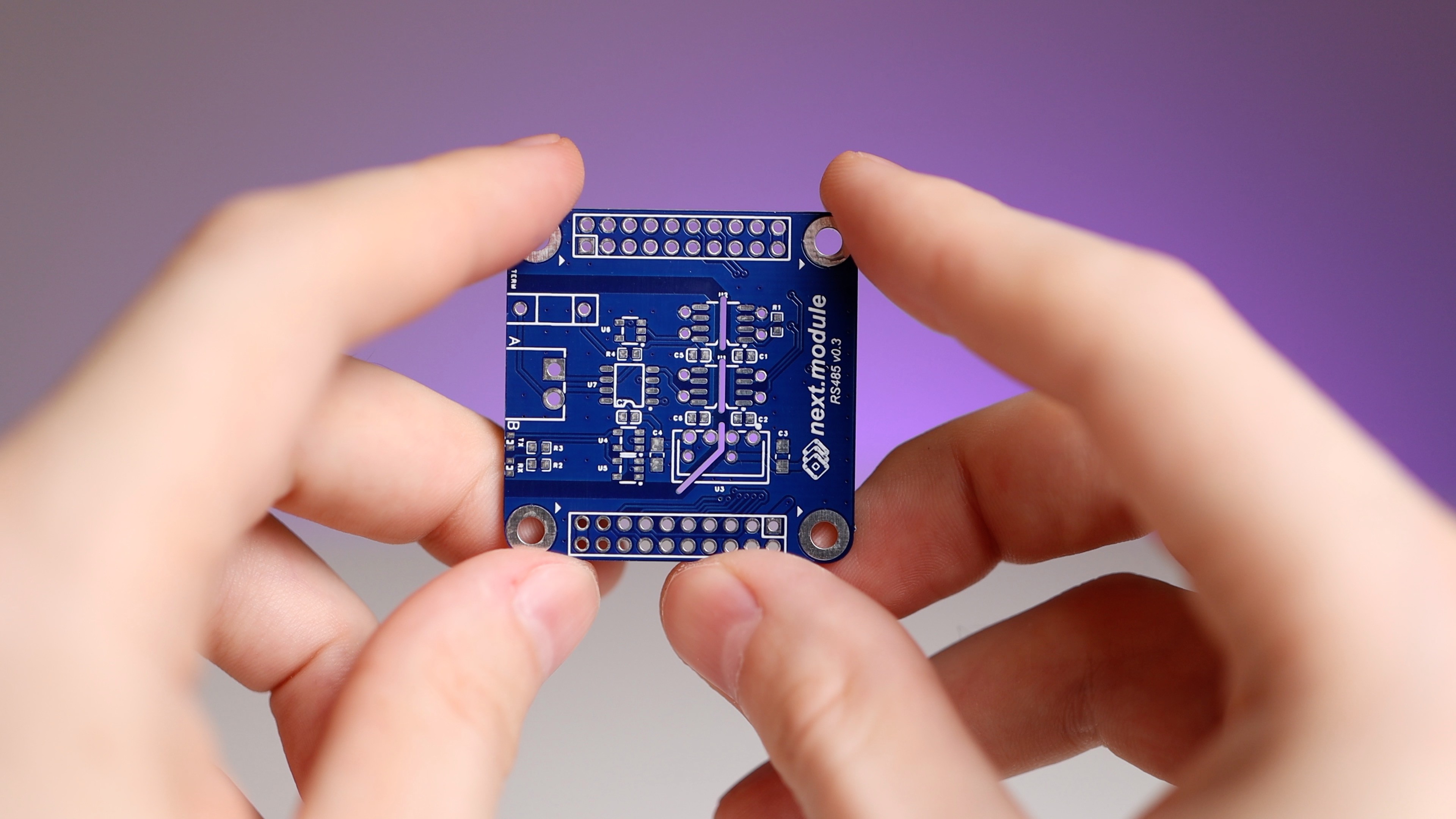

I have always wanted to use small modules. As much as possible and reasonable in terms of fitting all the components of a fully functional assembly on them. Ideally 50x50mm or even smaller.

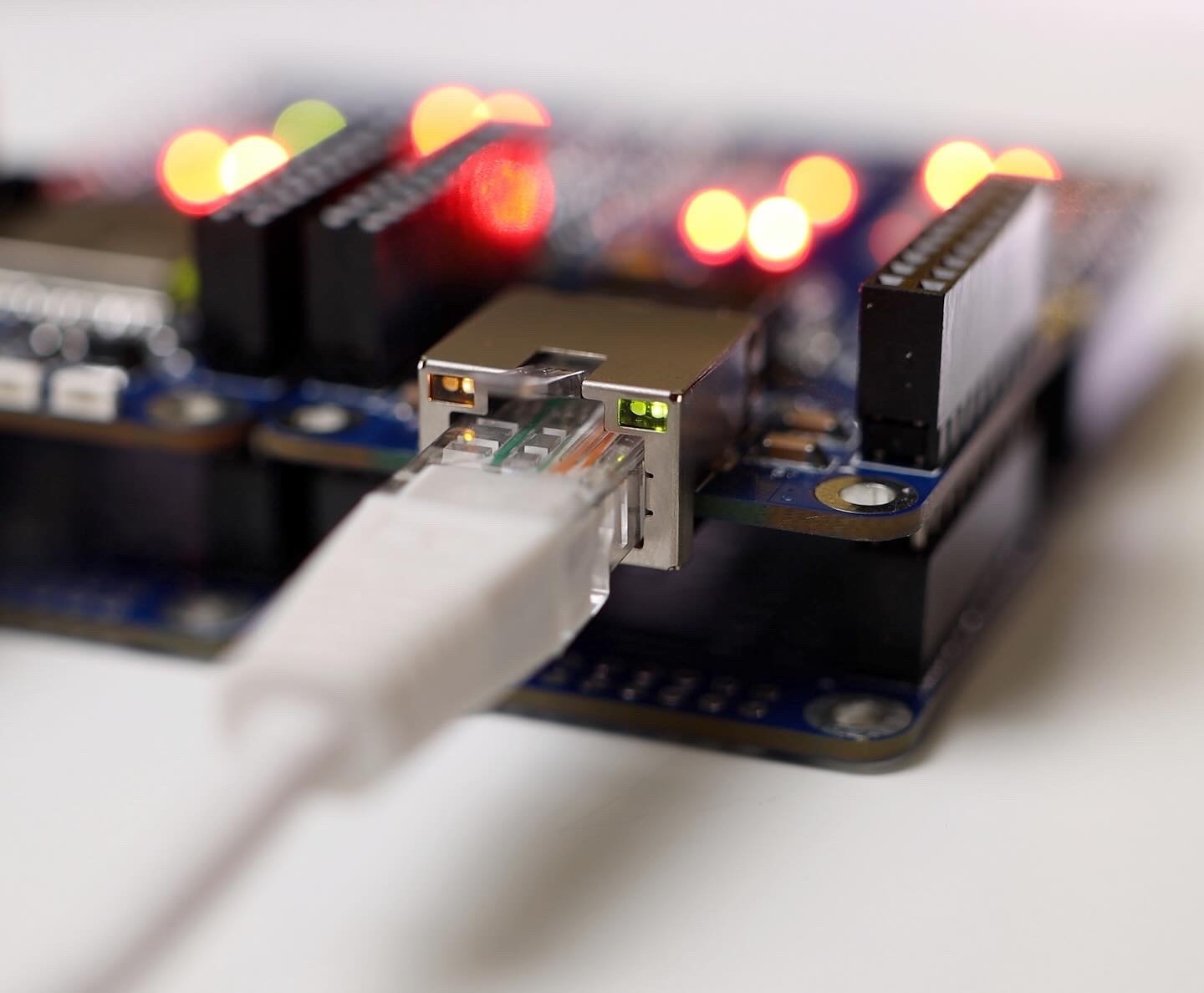

The electrical connections between the modules must be reliable, the modules must be firmly attached together to prevent the structure from coming apart with any careless movement on the table. Additionally, the contacts need to be reliable to ensure that they do not fail.

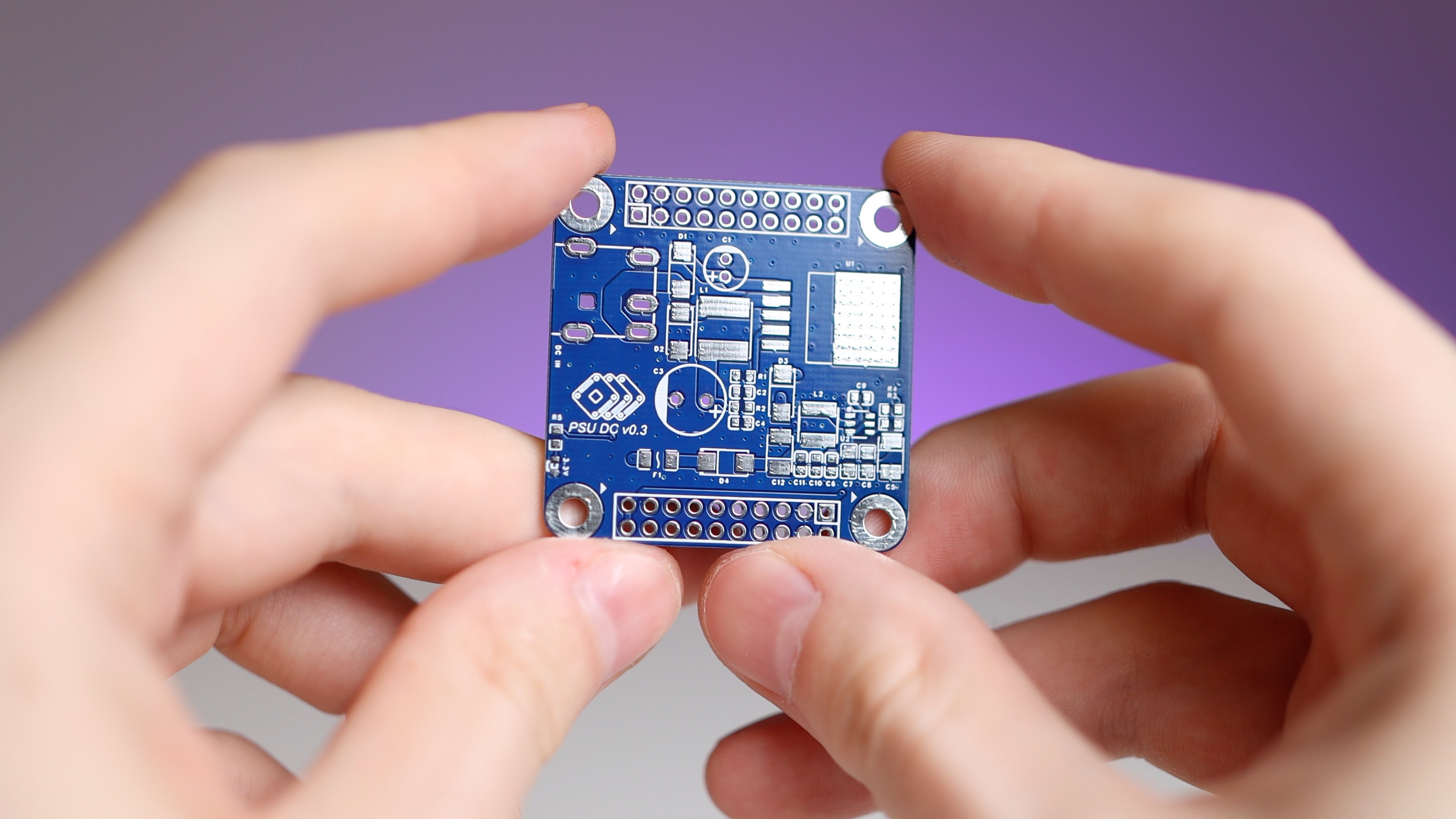

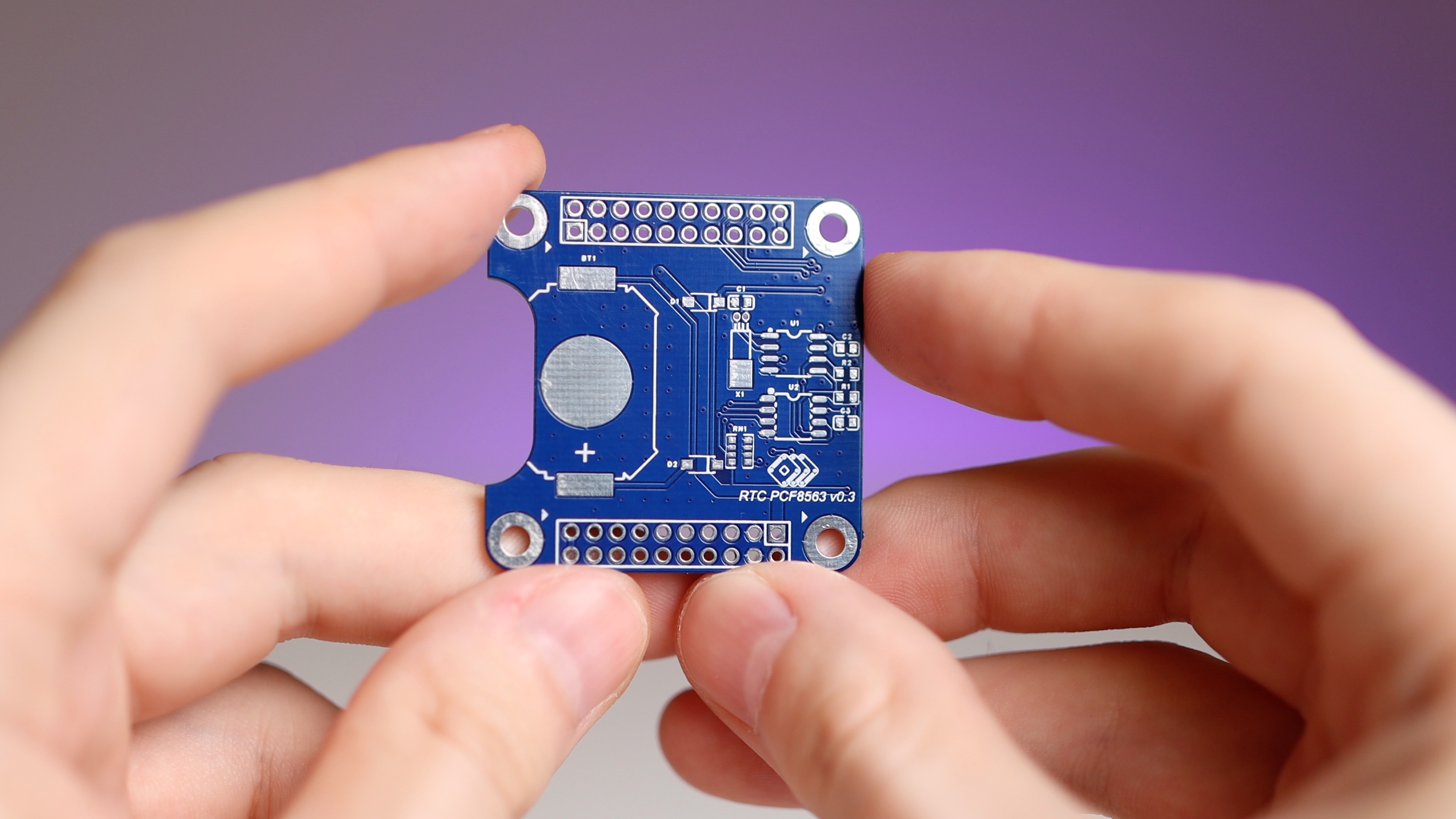

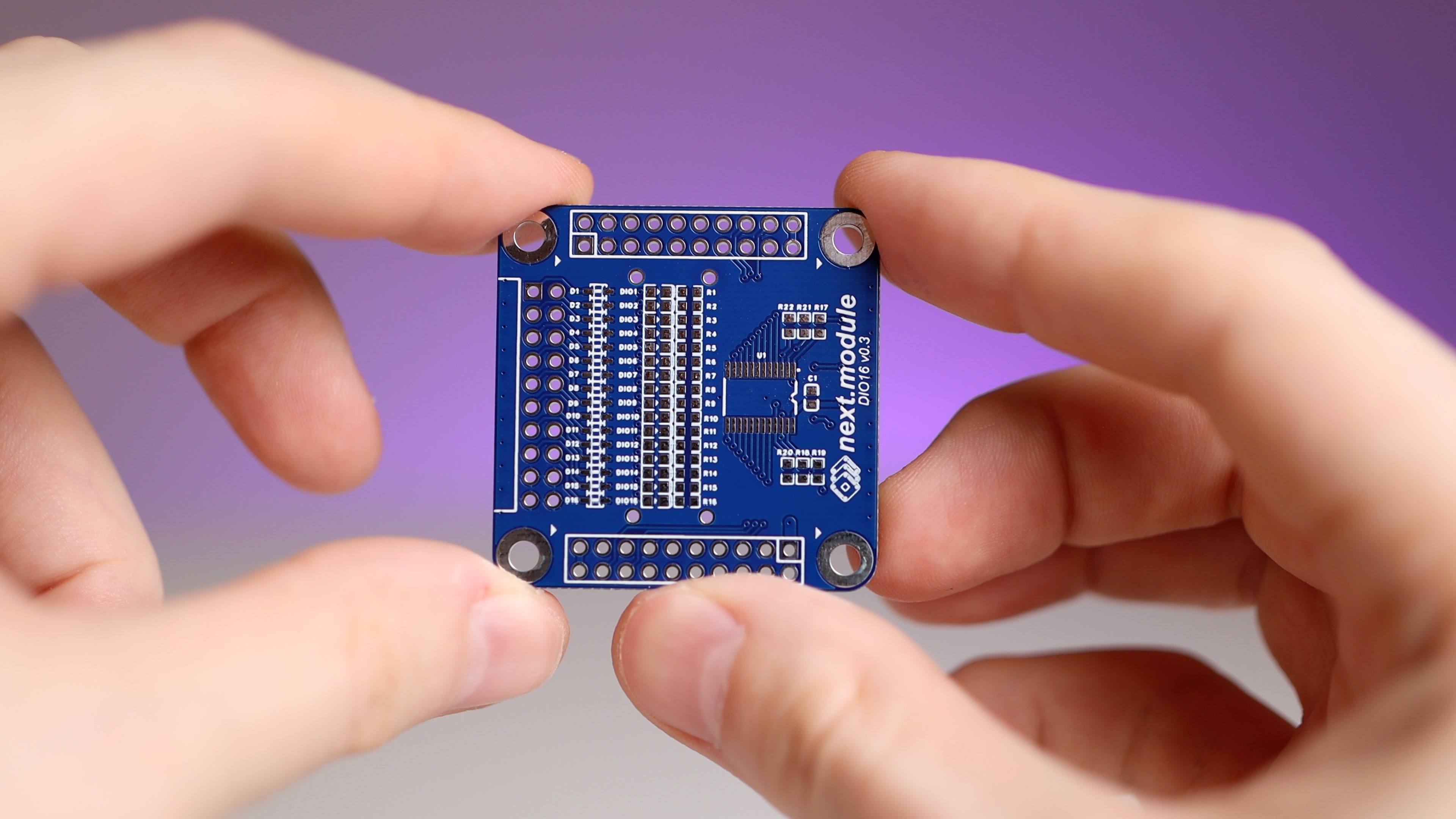

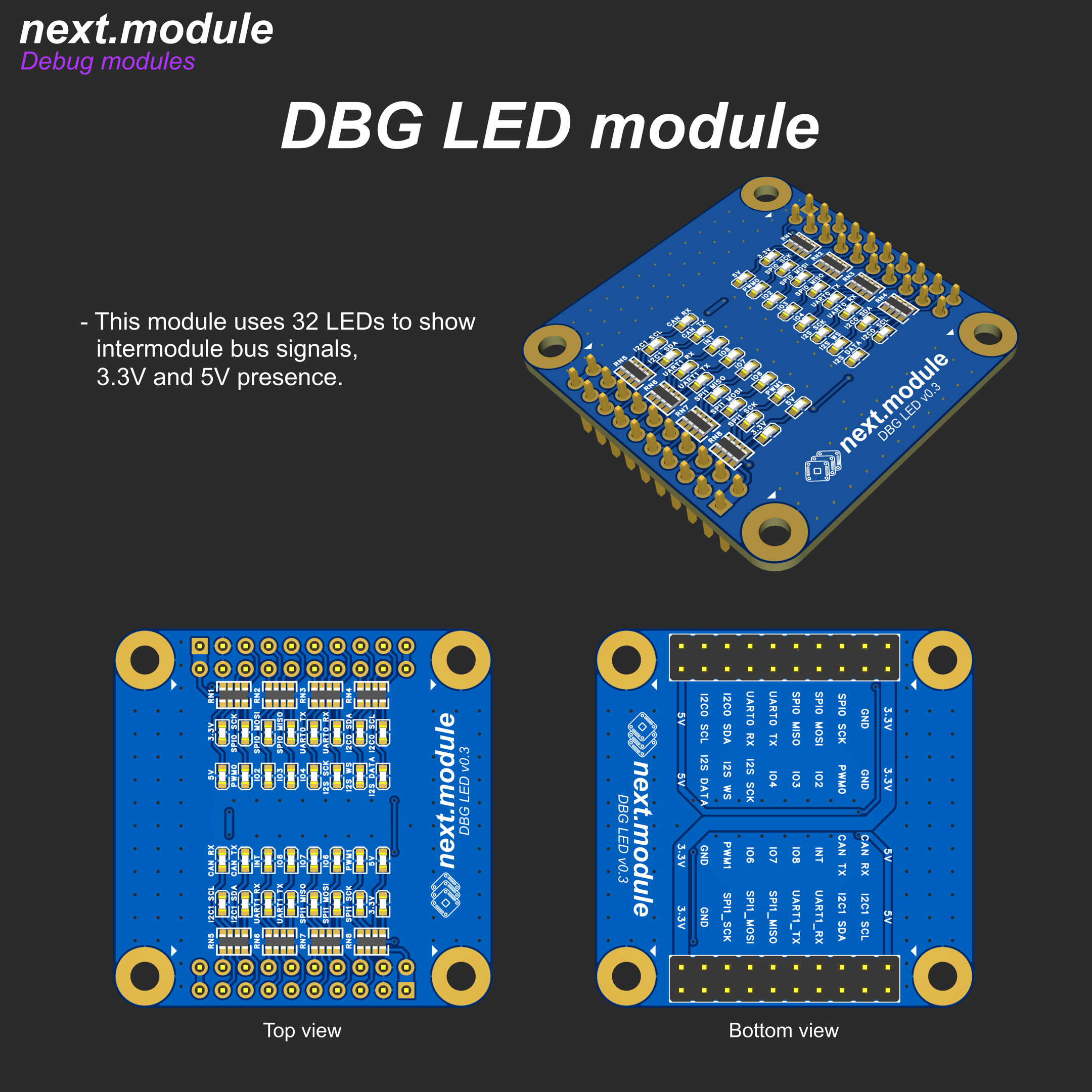

To address these concerns, I have designed the printed circuit board for the module in this way.

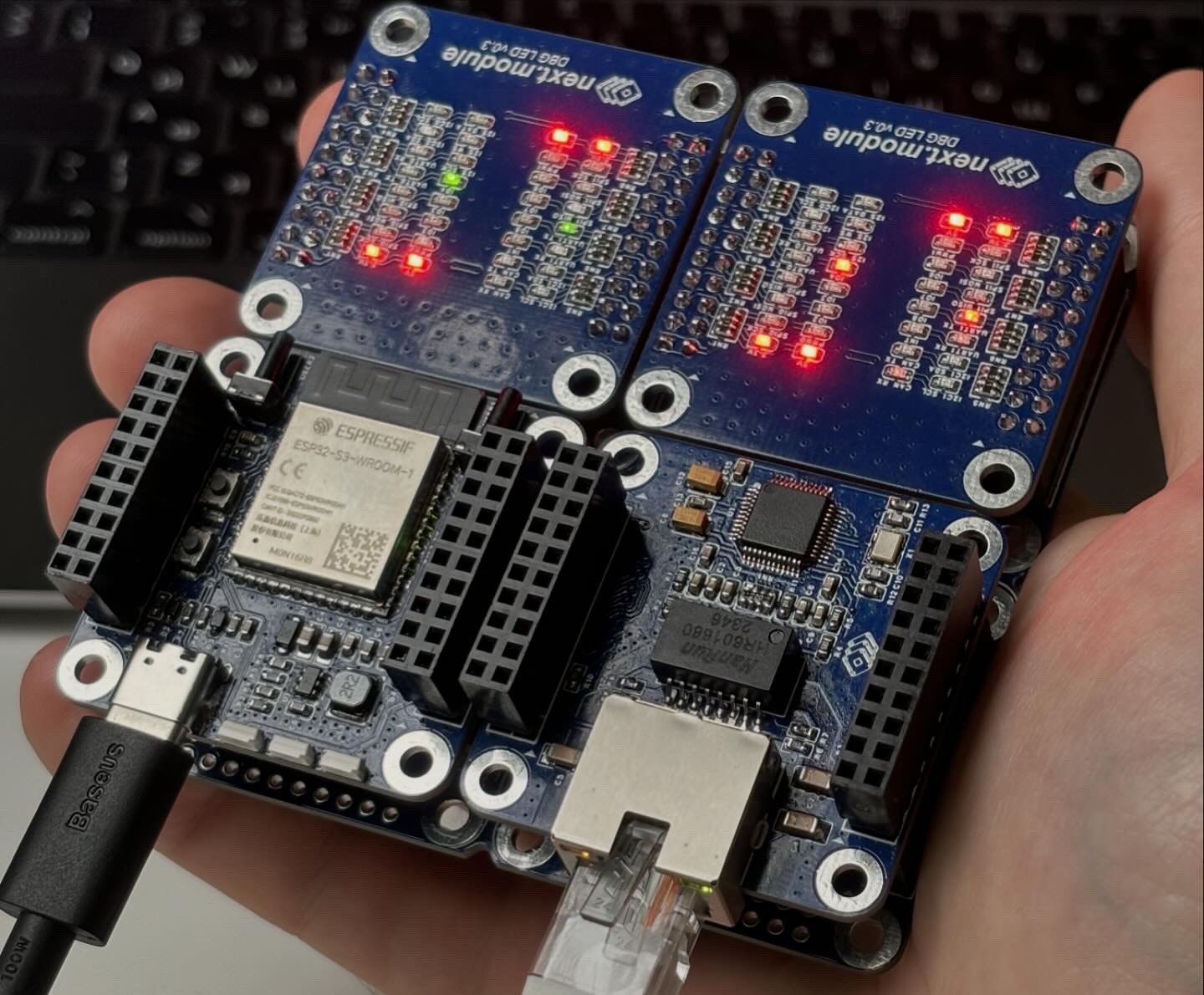

Expanding the assembly vertically is good, but horizontal expansion is still necessary. Otherwise, with a large number of modules, we will end up with a narrow and unstable rack. Horizontal expansion is also possible using HUB boards. That is, in one of the rows, a larger HUB board is placed, which has a multiple of the module's dimensions (for example, 2x1, 1x2, 2x2, 3x2, etc.). It has all the same inter-module connectors at the top and bottom and mounting holes as conventional modules. Such HUBs allow you to run multiple modules from different racks in parallel and connect them physically.

The main disadvantages of this solution are that the HUB takes up one tier in the assembly and the mechanical connection between racks is weaker than if there were no HUBs.

Modules placement in the case

Connectors for external connections are located with a 2 mm protrusion beyond the board. This is necessary so that the connectors of the device are not recessed into the case and do not stick out of it. A case with a wall thickness of 1.6 mm can be 3D printed. The remaining 0.4 mm gap is the space between the board and the case wall.

Brass stands, which are used to attach modules to each other, can also be used to assemble modules in a case. The M3 screw can be used to fasten the module rack to the chassis. Another option is to use M3 injection nuts:

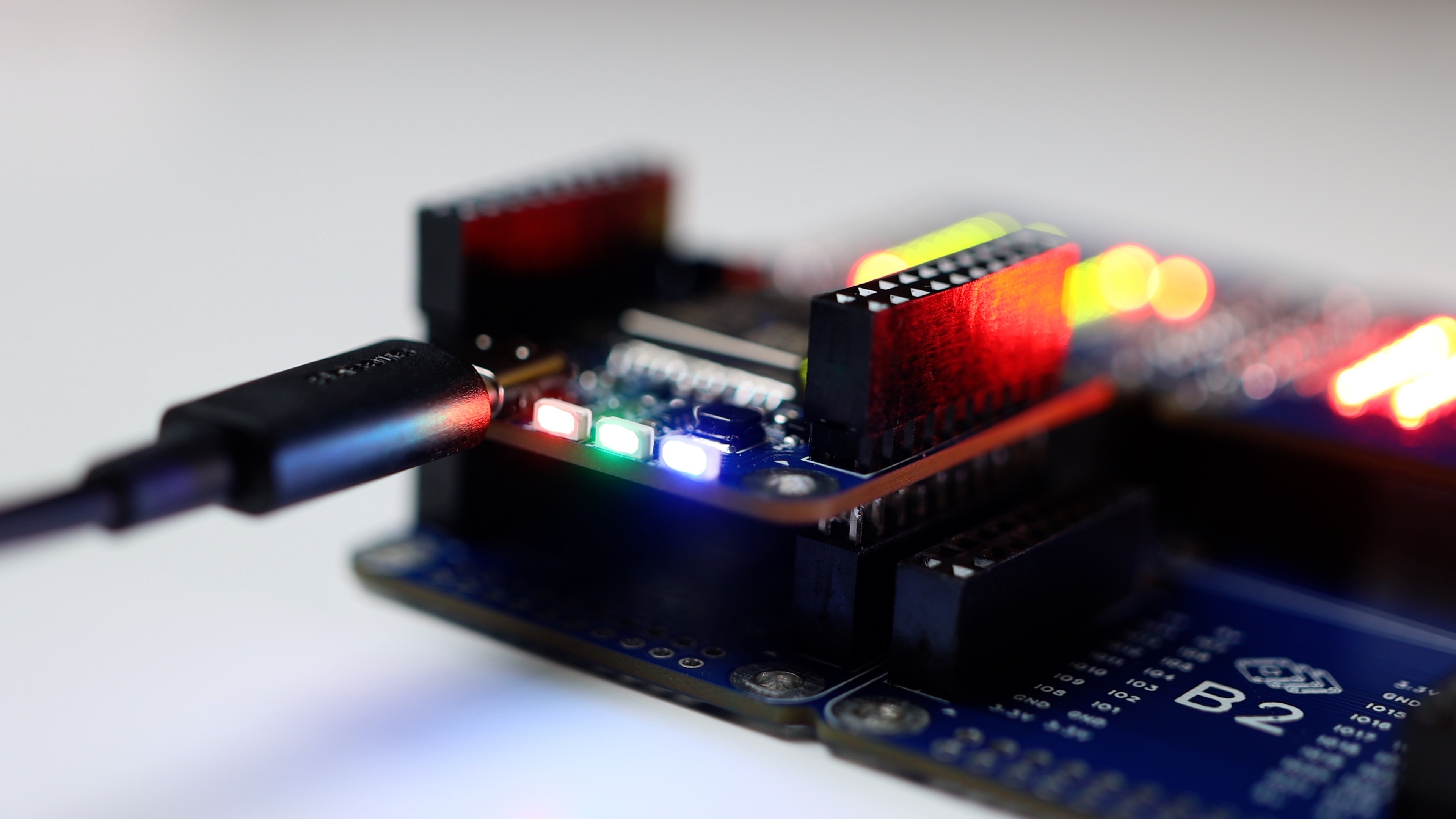

Then, the first level module is applied, the first level stands are screwed in, the second level module is applied, etc. In a cut it looks like this:

Subscribe and share

The project is currently in active development. If you are interested in the idea, please subscribe to the project and share it with your friends who may also be interested.

Now you can find news about next.module project in the "Project Logs" section.

Ruslan

Ruslan

Richard

Richard

Hexabitz

Hexabitz

Silícios Lab

Silícios Lab

It's a shame the screen one isn't pin compatible with your boards. I might see If I have the skills to edit it to be pin compatible. I suspect not, but I'll have a look.