First let me apologize for the pictures, I was too lazy to grab my DSLR so my "trusty" Samsung Galaxy S2 had to be enough.

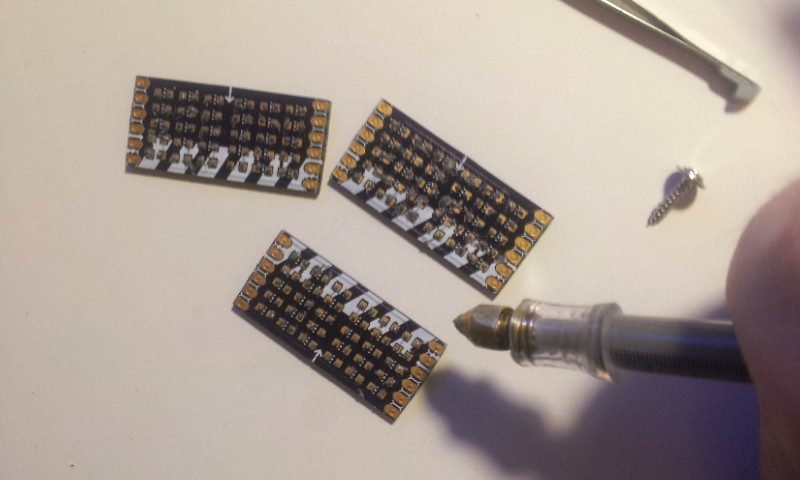

So let's dive into my adventure with SMD soldering with a toaster oven. I had all I would need to test this method myself. The boards were send by OSHPark, my cyan LEDs I've ordered years(!) ago and the solder paste. But my syringe wasn't actually a syringe you would expect but one with a 3mm opening - d'uh - let's not hit 1x2mm spots with that. So I got creative with a 3D printing nozzle - which made quite a mess but worked probably better than without.

Then I went on putting solder paste on 180 spots with this crude device.What a boring task. But hey, all for science!

I had to get those LEDs out of the strip and figured out how they are oriented. But once I tried, they almost every time jumped out and I had to first find them and then check the polarity again. Hours later it was time for my trusty toaster oven. I have no special controller nor a temperature sensor - just a google search where I found this page http://www.openhardware.net/Misc_Stuff/ToasterSMD/ and figured I would have to turn the oven on for about 3 1/2 minutes. I'm sorry science.

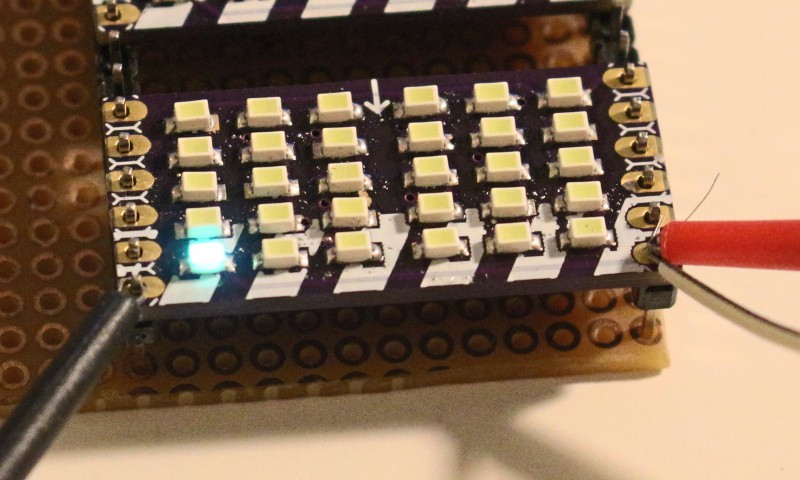

I'm kind of jumping to the end here, because I did them one by one and took no photos. They are not perfectly aligned through the process but far better then I could have soldering them by hand ;) That's actually from my DSLR because I switched while writing.

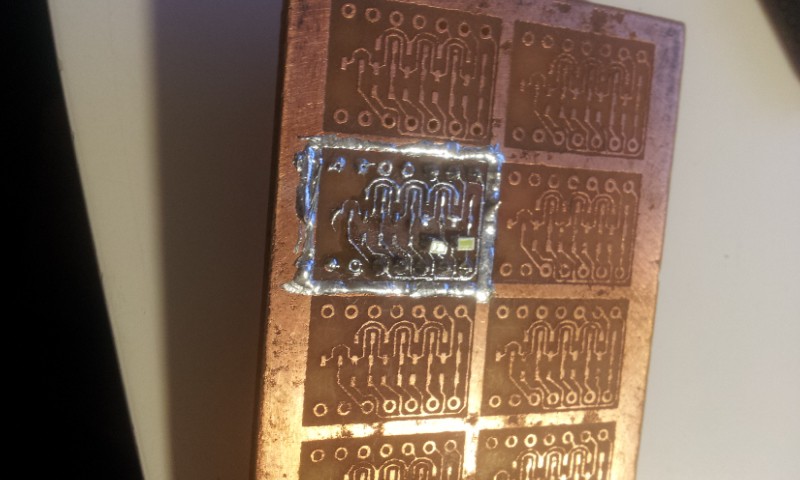

And this is my first attempt from years ago, which demotivated me for some time now. This board is self etched and pre tinned by hand - soldering those LEDs was nearly impossible.

Next up will be color coded pin headers for the cathode and anode rows, since I always forget what is what. Yes, lame, I know. But wait, that doesn't even matter with those little guys. Damn. Never mind, I mix up cathodes and anodes. So what.

davedarko

davedarko

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Maybe you could do something with a squeegy? The grid-pattern might lend itself to that nicely.

Are you sure? yes | no

oh it did - not perfectly but that just may be because of the uneven distribution of solder paste. I could not really tell if it was too much or not enough because it was a mess.

Are you sure? yes | no

I've never used the stuff, personally... those 100pin TQFPs suck to do with an iron and sucker, but I've gotten OK at it. Something about the paste I bought, it never seems to melt, it's like a flux that doesn't burn-off embedded with particles of something that doesn't melt. I thought I was doing something wrong, but I've seen vids of others and it seems to work fine. And wicks? Sheesh... most people seem to love the stuff, but I can't ever seem to get it to work right. Would sound like my iron's not powerful enough, but this thing's a beast when turned all the way up... (dja see my message that I always seem to find the odd-cases in things that others do all the time?)

That said, I saw a video once of someone doing TQFPs with paste, and it looked so easy it was unbelievable. No masks, no nothing, just laid it on *across* all the pins with lots of pre-flux, and let surface-tension do the rest... didn't even align the dang chip, the surface-tension took care of that too! It took a little tiny bit of wicking of the excess in a few places, but not much. But what I meant about squeegying was that maybe you could just lay it on thinly over the entire board, then use like the edge of a credit-card to scrape it out from between, rather than applying to each pad individually... Or, mask it like a painter, with thin strips of tape, and peel it off before placing the components :)

Are you sure? yes | no

I always managed to solder the wick onto the stuff instead of getting rid of the solder... so don't ask me about them ;) Those videos are awesome, I've watched quite a few now! The credit-card trick might have worked as well - trying that next time - but I was worried about the polarization of the LEDs too much to think of that. Thanks for the tips!

Are you sure? yes | no

wow, that looks professional... maybe it's time I quit soldering by hand...

Are you sure? yes | no

it was such a relief when I got them out of the oven and all LEDs were still functional and the solderjoints looked good! A solder paste mask would have been great - applying it manually took a lot of time and I would have been almost as fast soldering it by hand. But the Led form factor and case made it impossible.

Are you sure? yes | no