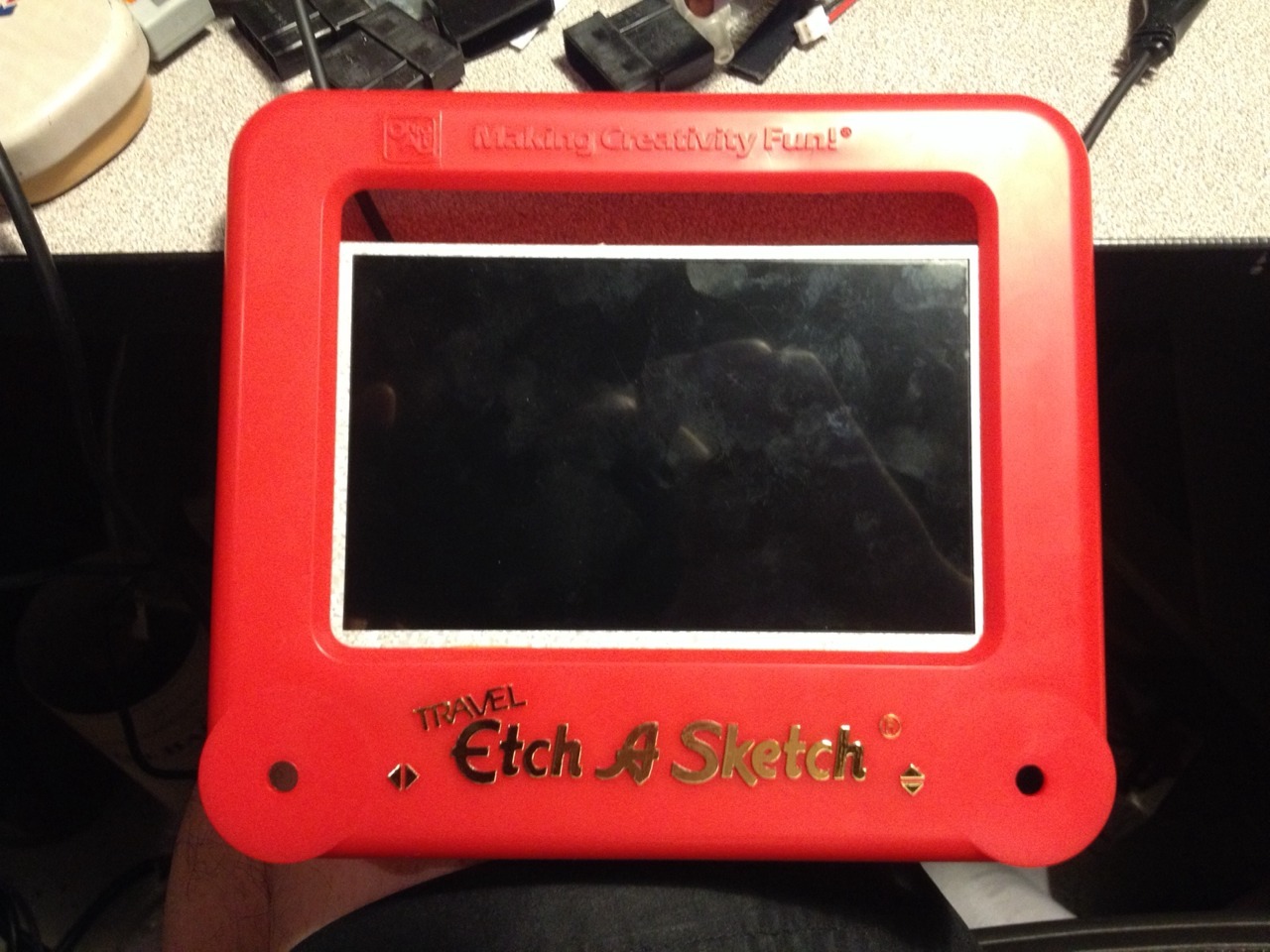

So I had this idea to make my CNC machine approachable for kids. I thought about various methods to do this. My brother-in-law showcased his Fireball v90 CNC router at a local mini maker faire and had the machine running cutting out keychains to give out. It was cool and the booth was crowded the whole day. Kids seemed mesmerized watching it cut out the shapes. I wanted to make something interactive, and thought about toys that they have that are similar to the CNC. The etch a sketch immediately came to mind. It's a control interface that kids can intuitively understand, is simple to operate, and comes in a non threatening red plastic case. The project continues to grow in complexity, but only on my side not in the interface. The user interface is going to be as close to the original as I can make it. I've even got plans to have the system reset be done by turning the controller upside down and shaking it. Stretch goals include having the reset feed out the paper from a continuous roll, sign it with a URL for more info and maybe the date or event name, cut it out off give to the user and reset itself for the next user. It's not quite all there yet, but I'll document it all here as I go.

Etch-a-CNC

An etch a sketch type controller for CNC machinery

lj

lj

lawnmowerlatte

lawnmowerlatte

Thornhill!

Thornhill!

David Boucher

David Boucher

Ted

Ted

Looking for gcodes for engravings

We are looking for gcodes for engraving to put on our web site:

http://endurancerobots.com/products/laser-cutters-accessory/gcode-samples-for-engraving-2/

we already have some on Endurance web site. So feel free to send gcodes so we can

upload them