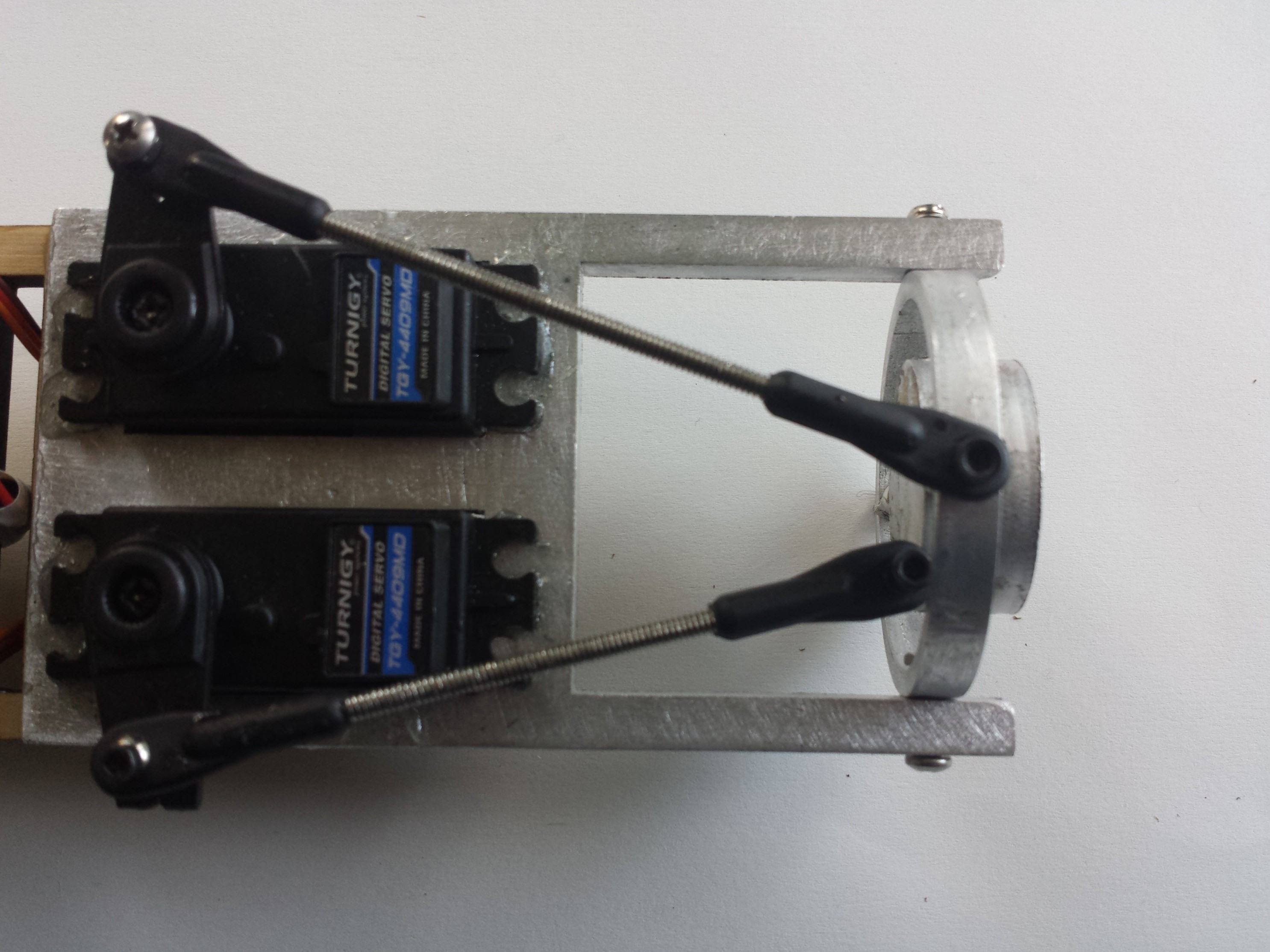

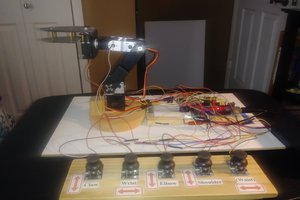

This code will enable the gimbal to make sure the nose is always facing up, meaning that the rocket will always face up without the need for fins. When combining this code with a rocket with a gradual thrust curve, you will essentially get a hover and a landing:

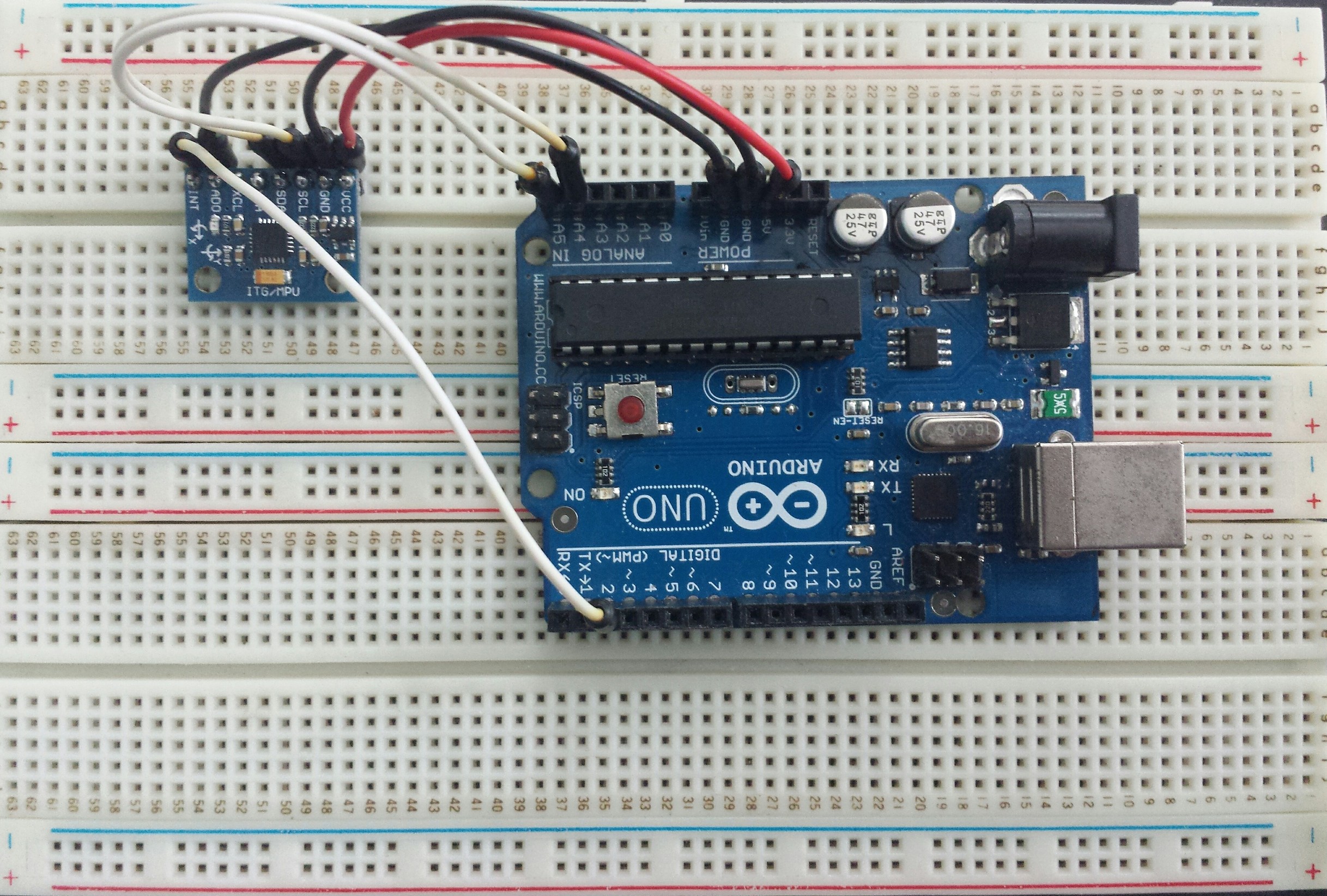

#include "Wire.h" // allows communication to i2c devices connected to arduino

#include "I2Cdev.h" // I2Connection library (communication to serial port)

#include "MPU6050.h" // IMU library

#include "Servo.h" // servo control library

MPU6050 mpu; //defines the chip as a MPU so it can be called in the future

int16_t ax, ay, az; // x y z orientation values from accelerometer

int16_t gx, gy, gz; // x y z orientation values from gyrscope

///////////////////////////////////////////////////////////////////////////////////////

Servo outer;

Servo inner;

///////////////////////////////////////////////////////////////////////////////////////

int valo; // outer val

int prevValo; // outer prev val

///////////////////////////////////////////////////////////////////////////////////////

int vali; //inner val

int prevVali; //outer prev val

///////////////////////////////////////////////////////////////////////////////////////

//initializes the IMU

void setup()

{

Wire.begin();

Serial.begin(38400);

Serial.println("Initialize MPU");

mpu.initialize();

Serial.println(mpu.testConnection() ? "Connected" : "Connection failed");

outer.attach(9); //servo on pin 9 for large ring y

inner.attach(10);//servo on pin 10 for small ring x

}

///////////////////////////////////////////////////////////////////////////////////////

void loop()

{

mpu.getMotion6(&ax, &ay, &az, &gx, &gy, &gz);

valo = map(ax, -17000, 17000, 179, 0);

if (valo != prevValo)

{

outer.write(valo);

prevValo = valo;

}

vali = map(ay, -17000, 17000, 179, 0);

if (vali != prevVali)

{

inner.write(vali);

prevVali = vali;

}

}

///////////////////////////////////////////////////////////////////////////////////////

Sagar

Sagar

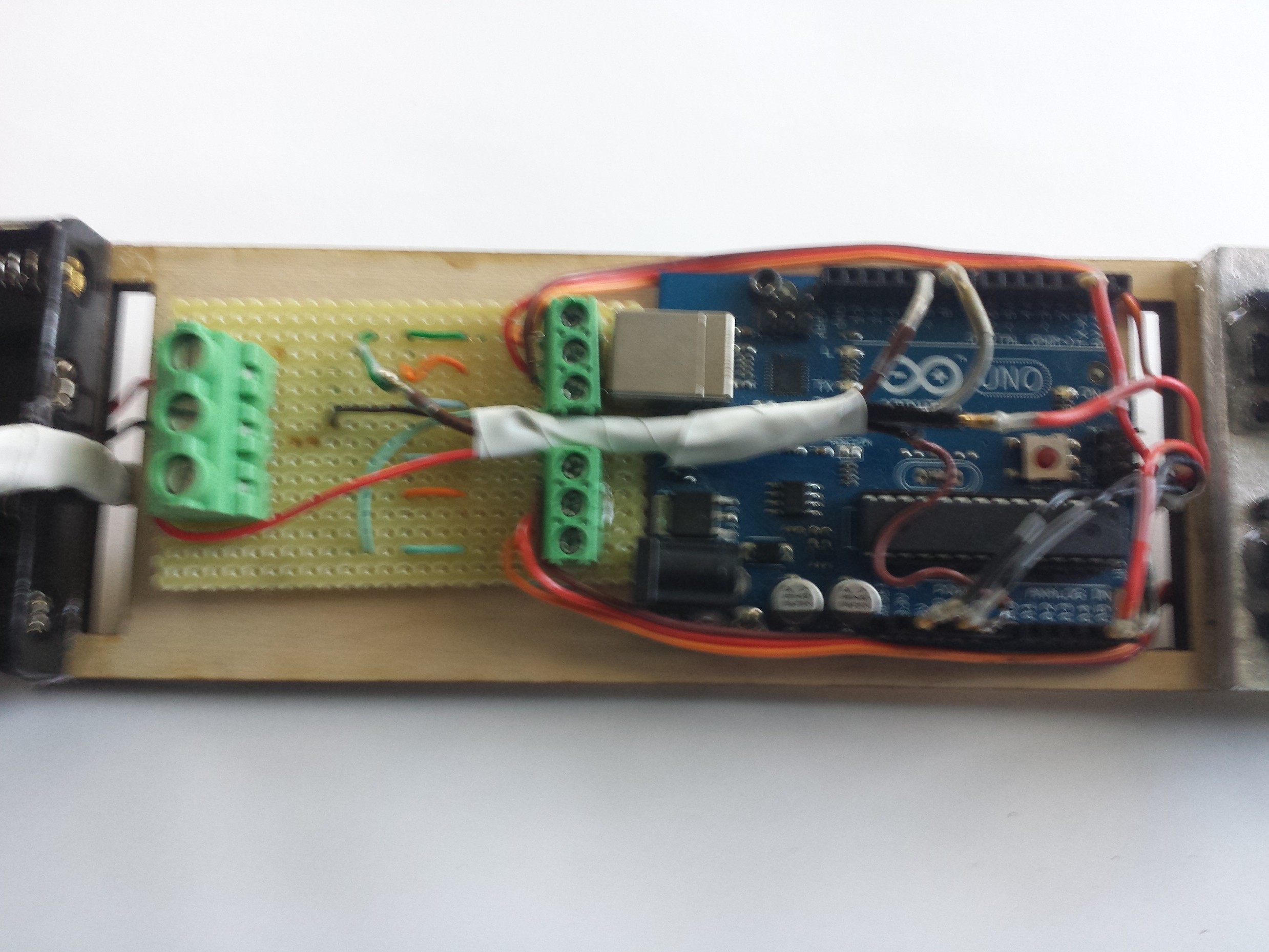

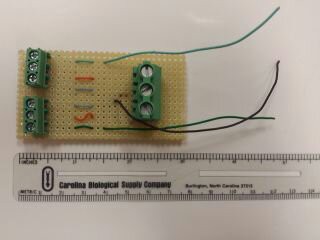

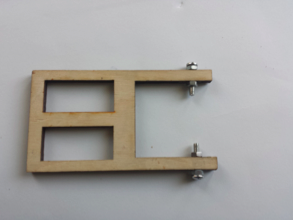

The servos connect to the screw terminals on the left hand side, while the batter goes on the bigger terminal, the 3 wires connect to arduino and are (ground, PWN9, and PWN10)

The servos connect to the screw terminals on the left hand side, while the batter goes on the bigger terminal, the 3 wires connect to arduino and are (ground, PWN9, and PWN10)

Cees Meijer

Cees Meijer

amr.mostaafaa

amr.mostaafaa

Steven Kibler

Steven Kibler

G. Rosa

G. Rosa

Looks like an old project, but what the heck... The arduino has no where close to enough bandwidth to self stabilize during the burn phase of the flight. You should use rocksim to verify that after burnout the thrust vectoring chassis can still influence stability... I doubt it.