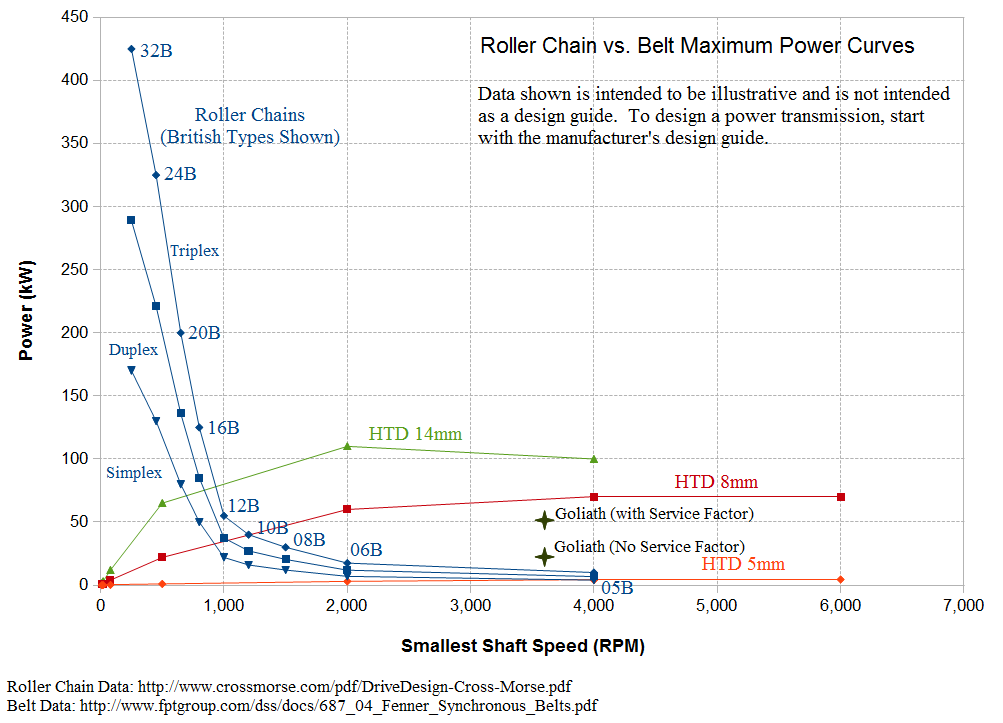

The last time I wrote I was getting ready to add additional pulleys to try to deal with the belt oscillations. Over the Thanksgiving break, I had some time to think about it some more and came up with some alternatives. One of the first things I did was go back to the initial design guides I used to decide whether or not to use belts. I decided this time to take some time to create a graphic that illustrates the the design space between roller chain and belts.

The graphic above shows the maximum power capabilities for both Roller Chain and High Torque Drive (HTD) belts. While I've only plotted British Standard Chains (vs ANSI), the properties are the same. The three curves for chains show simplex, duplex and triplex (one, two and three strands). The different points called out are for the different chain sizes (05B being the smallest to 32B the largest) For belts, three different pitches of HTD belts are also shown.

The graphic shows that at lower RPMs, roller chain has a far superior power capacity than HTD belts. As the RPM increases, the maximum power capability of roller chain decays exponentially, in contrast the HTD belt power capability increases. Above 1000 RPM, 14mm pitch have the most power capability and above 1200 RPM, 8mm pitch HTD belts are superior in power capability than roller chain.

Also plotted is the point where Goliath operates, with a maximum power of 30 Hp (22.37 kW) at 3600 RPM. However, when designing a power transmission system a service factor has to be applied. In this case I choose a service factor of 2.3. This means that the belt system should be designed for 51.5 kW at 3600 RPM. This is clearly well beyond the capability of roller chains.

So back to what needs to be done with Goliath. Over Thanksgiving I decided that it'd be appropriate to upgrade the belts from 20 mm wide to 30 mm wide. This would give a belt that is 50% stiffer and help reduce the oscillations. I also revisited the design guides and a 30 mm wide belt would be able to withstand the worst service factor listed (2.3). Since a 30 mm wide belt requires new pulleys, I'm also going to get larger diameter pulleys (40 teeth vs. 32 teeth). This will increase the power capacity and help prevent any teeth from skipping.

So I've ordered the new pulleys and a new single sided belt. The hardware should be here early next week. I'll test things out with just the single sided belt, and if that works then I'll order the more expensive double sided belt. If the bigger belts still have oscillation issues, I should at least be in a better position when I start adding more pulleys.

Peter McCloud

Peter McCloud

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.