Video explanation of RetroPopulator:

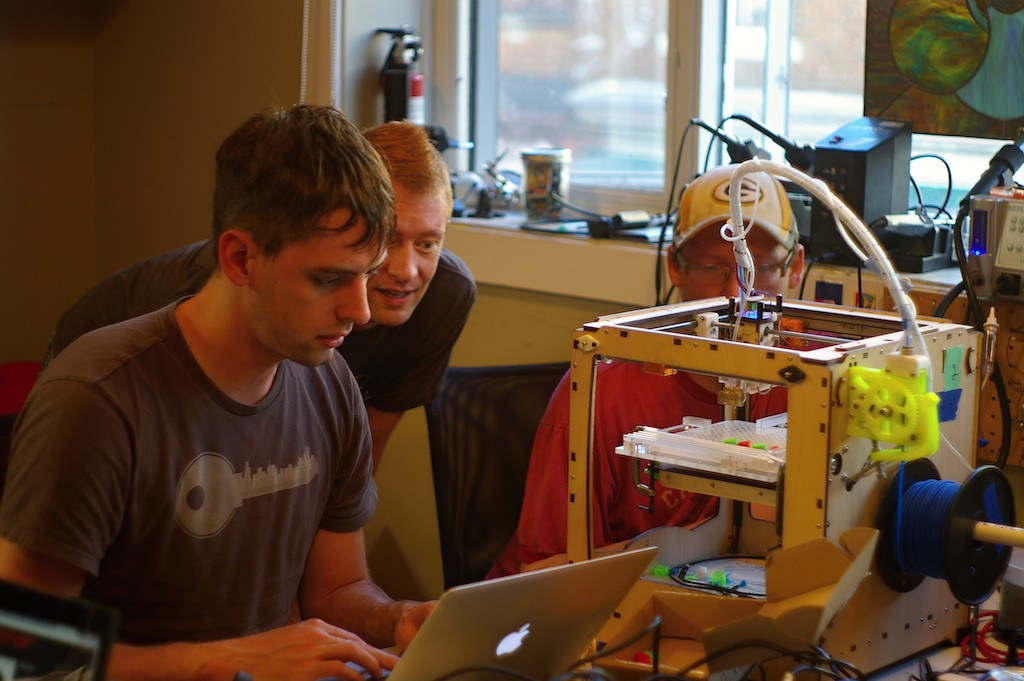

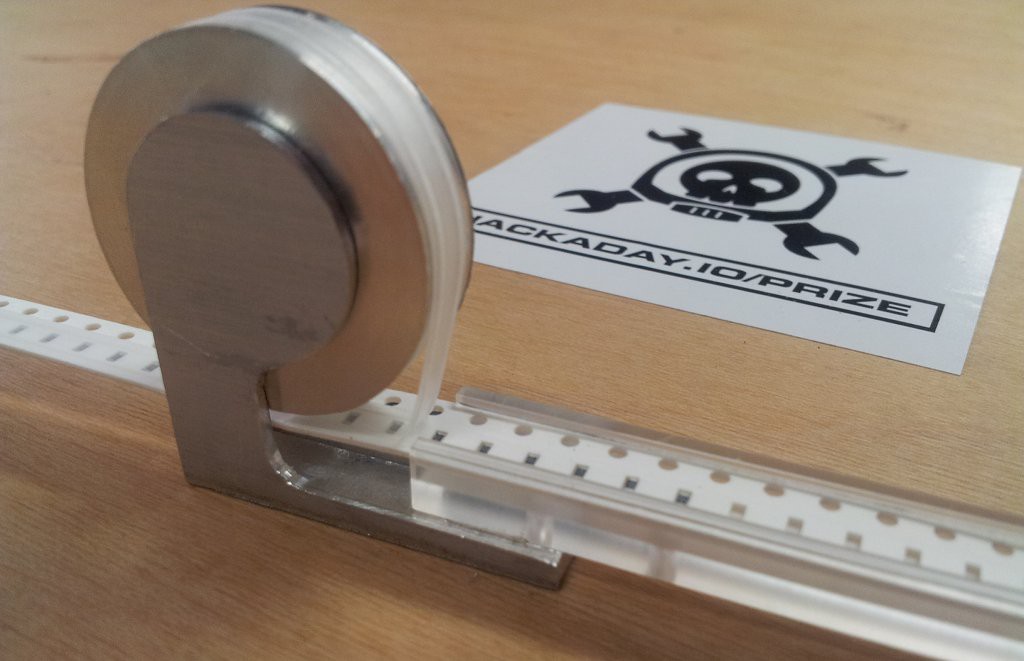

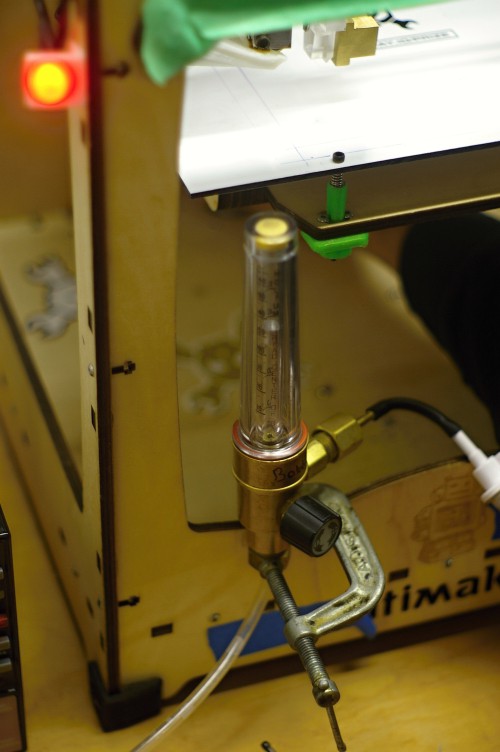

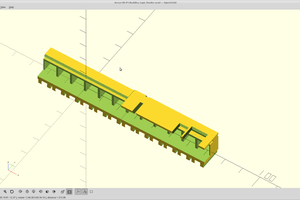

Version 1.0 : Essentially complete now. CNC milled acrylic base plate, with milled tape holders. Vacuum syringe for picking up parts, vacuum supplied by SMT rework station. Milled nozzle mount which attaches to the side of the existing extruder. Z-axis rezero jig to easily change re-zero height. 3D printed cam-lock parts to holds boards in place on 10mm peg-grid base. Code parses a yml file for board & tape placement info, and then an eagle .brd file directly for part types and locations. It generate a gcode file which goes from pick to place location for all of the parts which can be populated. Support for multiple boards. Demo of RetroPopulator in operation, with multiple components and multiple boards:

Connected Device

The RetroPopulator connects mechanically to a 3D printer, which in turns connects to a computer. For our software we use Tegh, a wifi 3D printer client/server application D1plo1d's been building. For now we're using it locally on a single laptop, but ultimately it will allow us to access the RetroPopulator from our laptops anywhere in the lab and extra ultimately, the world, which is awesome! The ability to quickly load the RetroPopulator jig into a 3D printer, combined with wifi accessibility via Tegh, makes the RetroPopulator perfect for a modern connected workspace like hacklab.to or Ultimate Workshop.

Future Plans

Version 2.0: currently in planning/design. Addition of tape advancement, including plastic cover peeling. Addition of a second nozzle which will do solder paste dispensing. Software will have 'position confirm' feature where it will move to the corner of each board, and the first component on each tape, so that you can verify key locations directly before running the entire job.

Version 3.0: part rotation. Numerous other things we'll learn about as we do V2.0, no doubt...

Licensing

We're fully open source! Our PopCAM and Tegh Daemon software are licensed under GPL3. The Tegh GUI is licensed under MIT. Our hardware designs are licensed under MIT as well. All text, images and videos CC-BY V4.0.

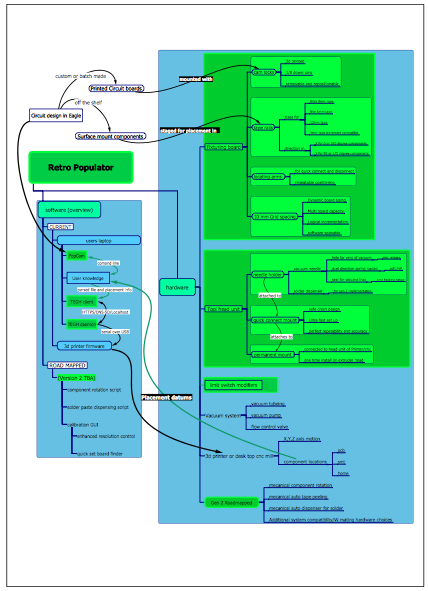

System Design Doc

Charles has done up a nice brain-map of the RetroPopulator, download full-size PDF, or see a small version here:

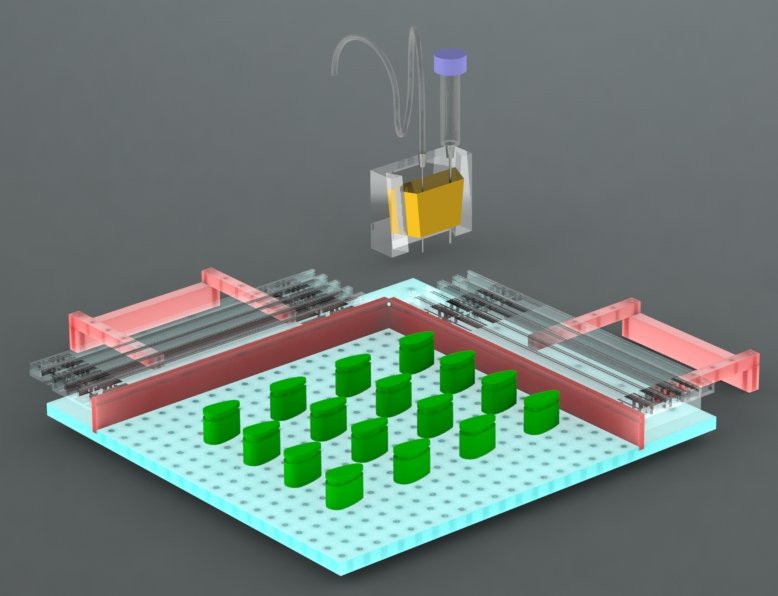

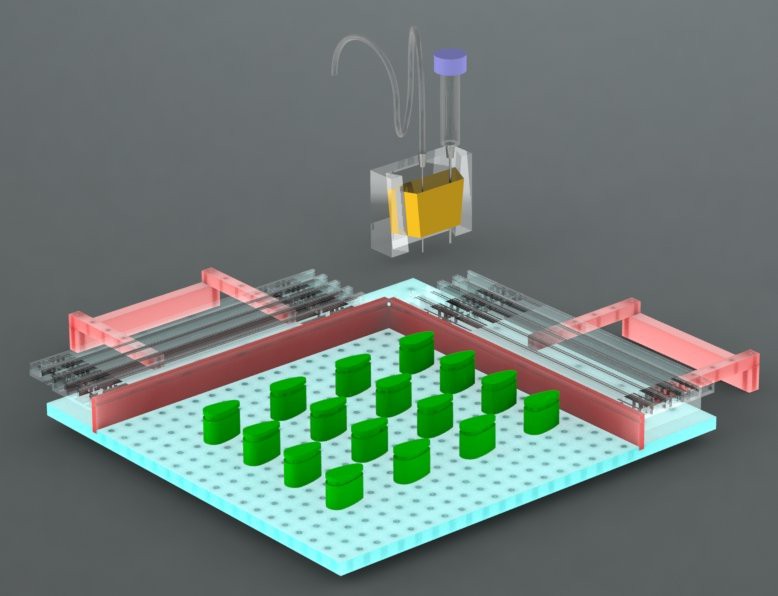

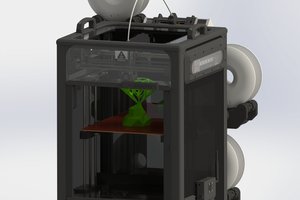

Artist's Rendition:

Finally, please sign up to our mailing list! We'll be sending out details on a monthly basis, and of course we'll let you know when the Retro Populator is actually available for sale (or for kickstarter pledge).

Eric Boyd

Eric Boyd

Daren Schwenke

Daren Schwenke

Michal Wojciechowski

Michal Wojciechowski

Nelson Bairos

Nelson Bairos

xpDIY

xpDIY

I really like the idea of having 2 perpendicular sets of tape feeders rather than head rotation