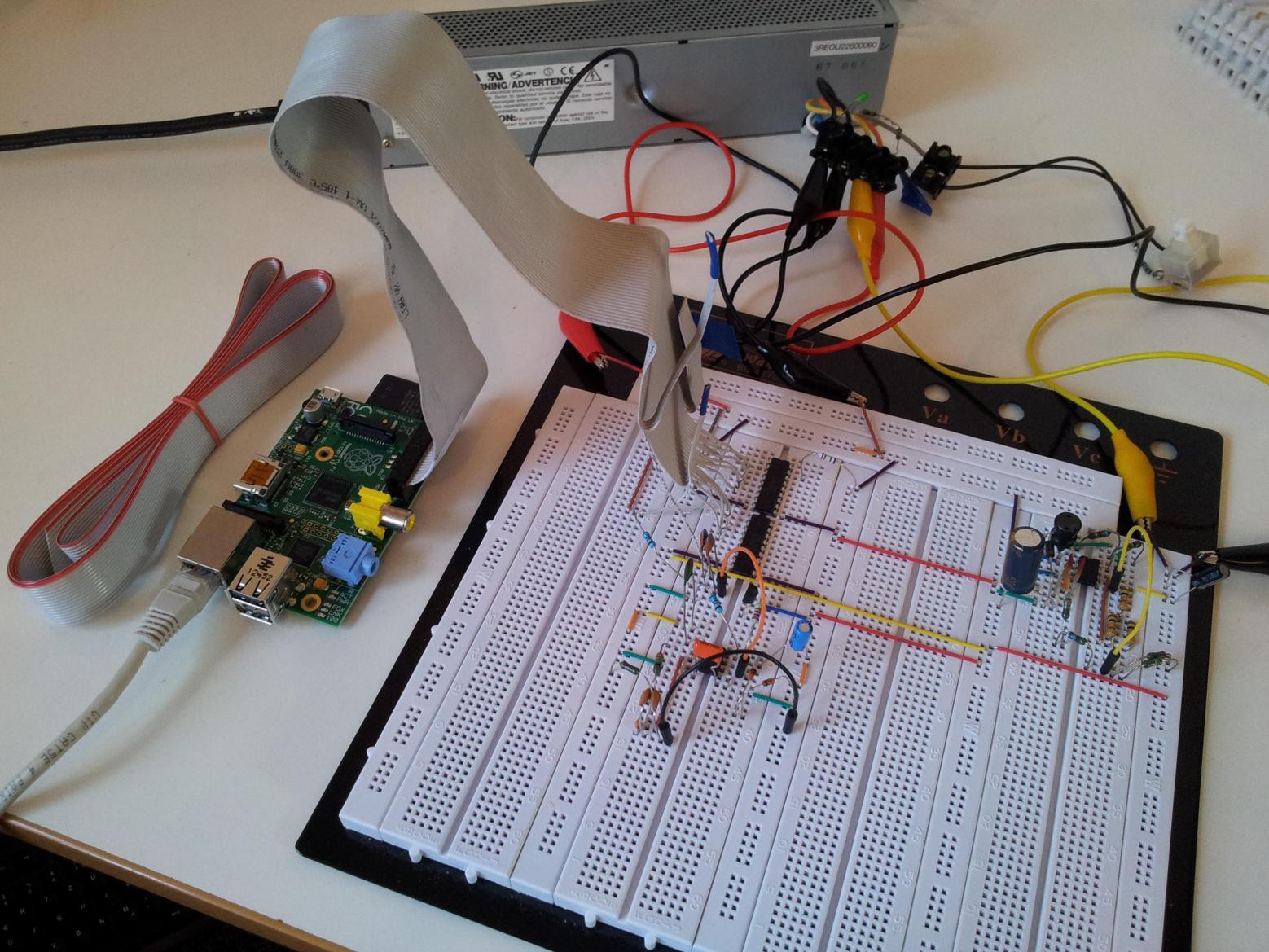

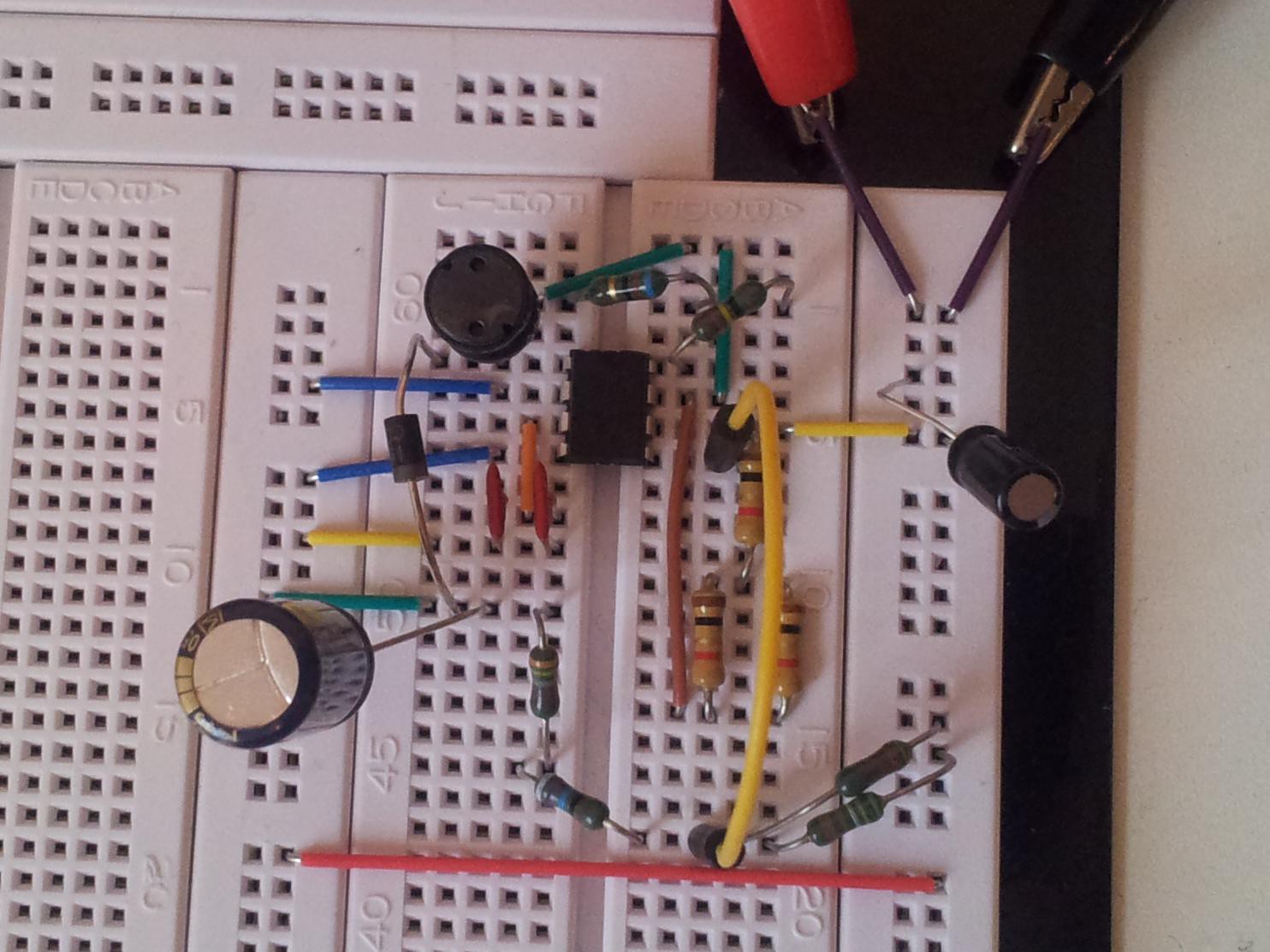

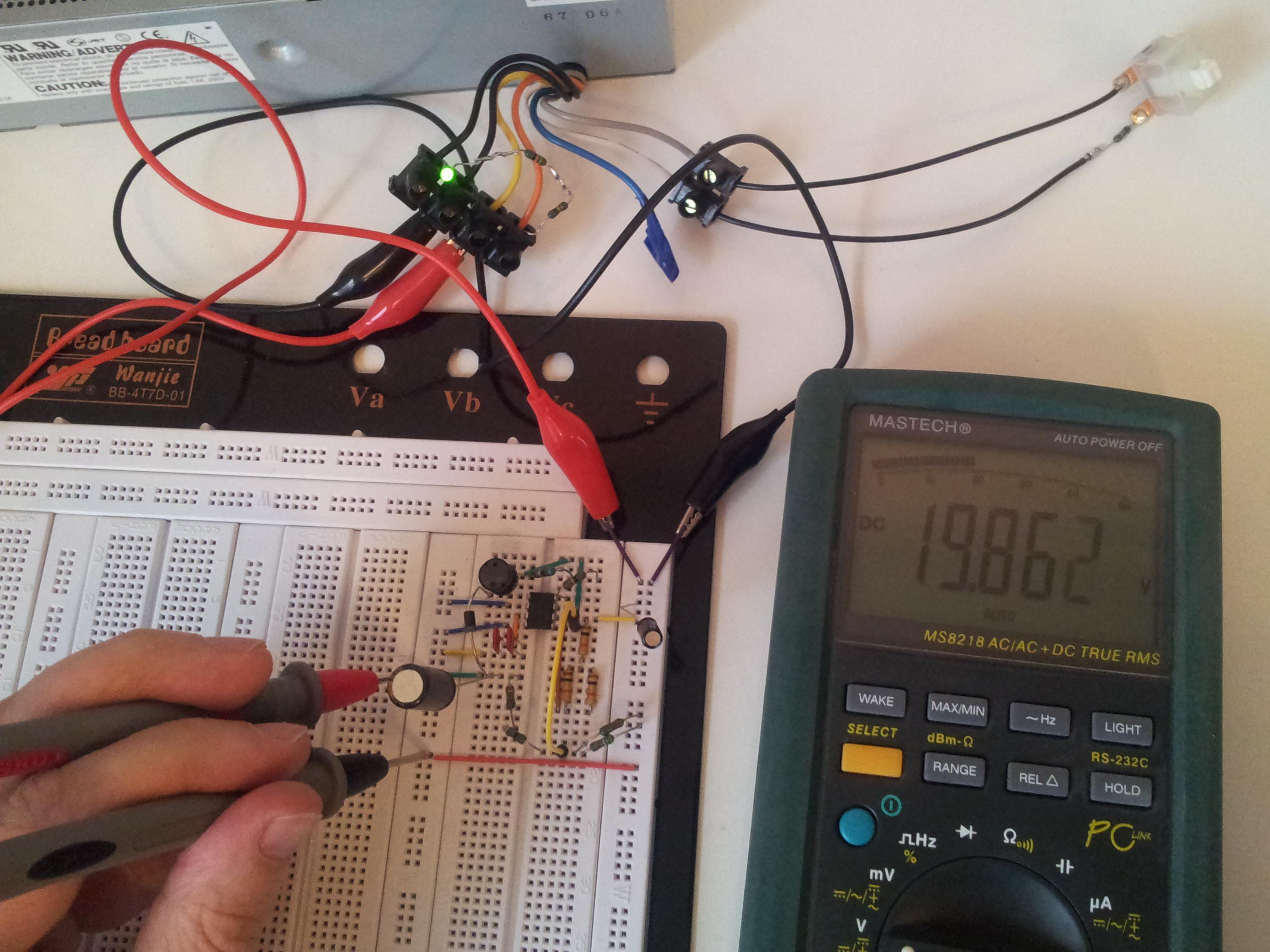

I will start with a simple setup as a proof of concept:

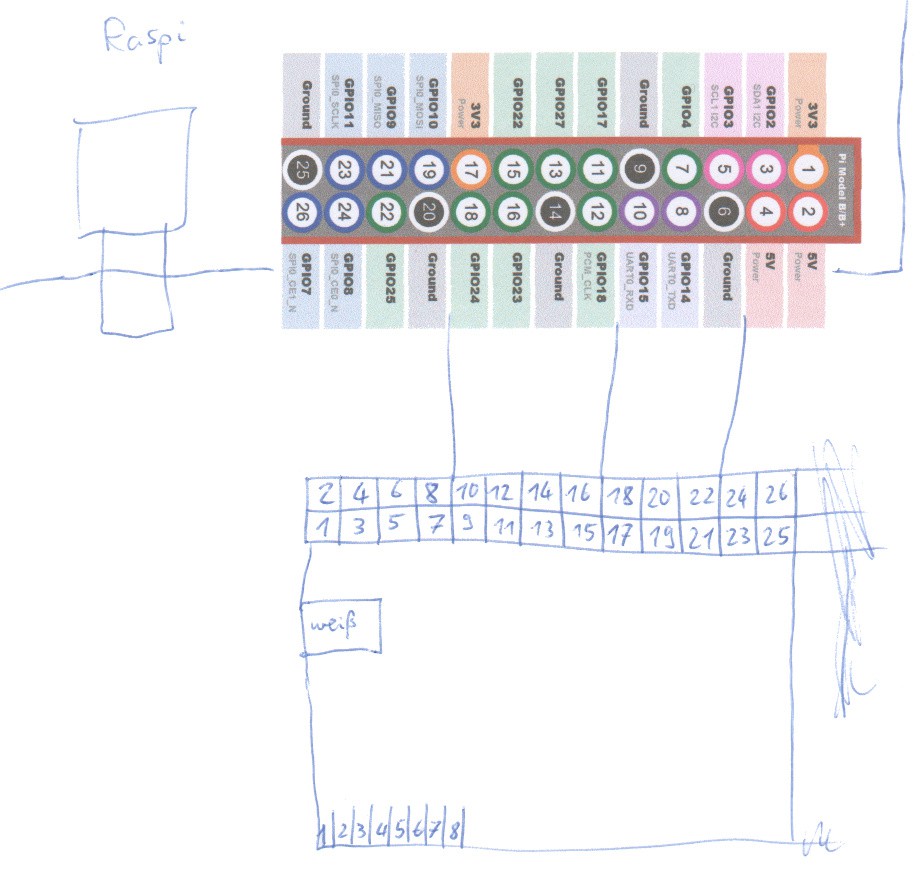

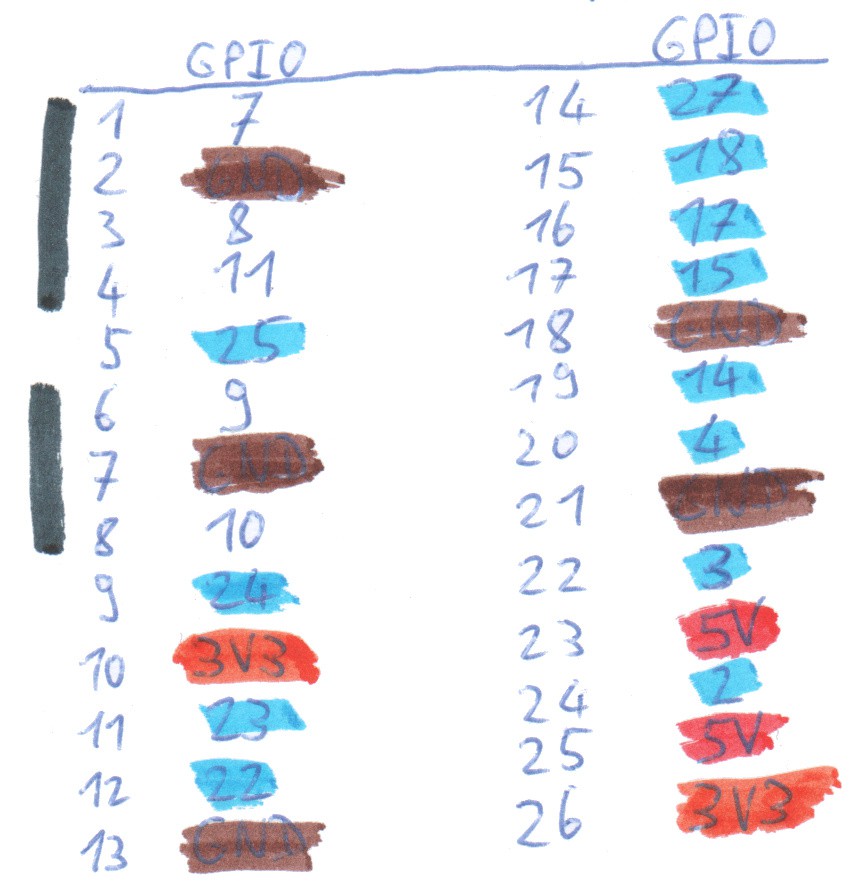

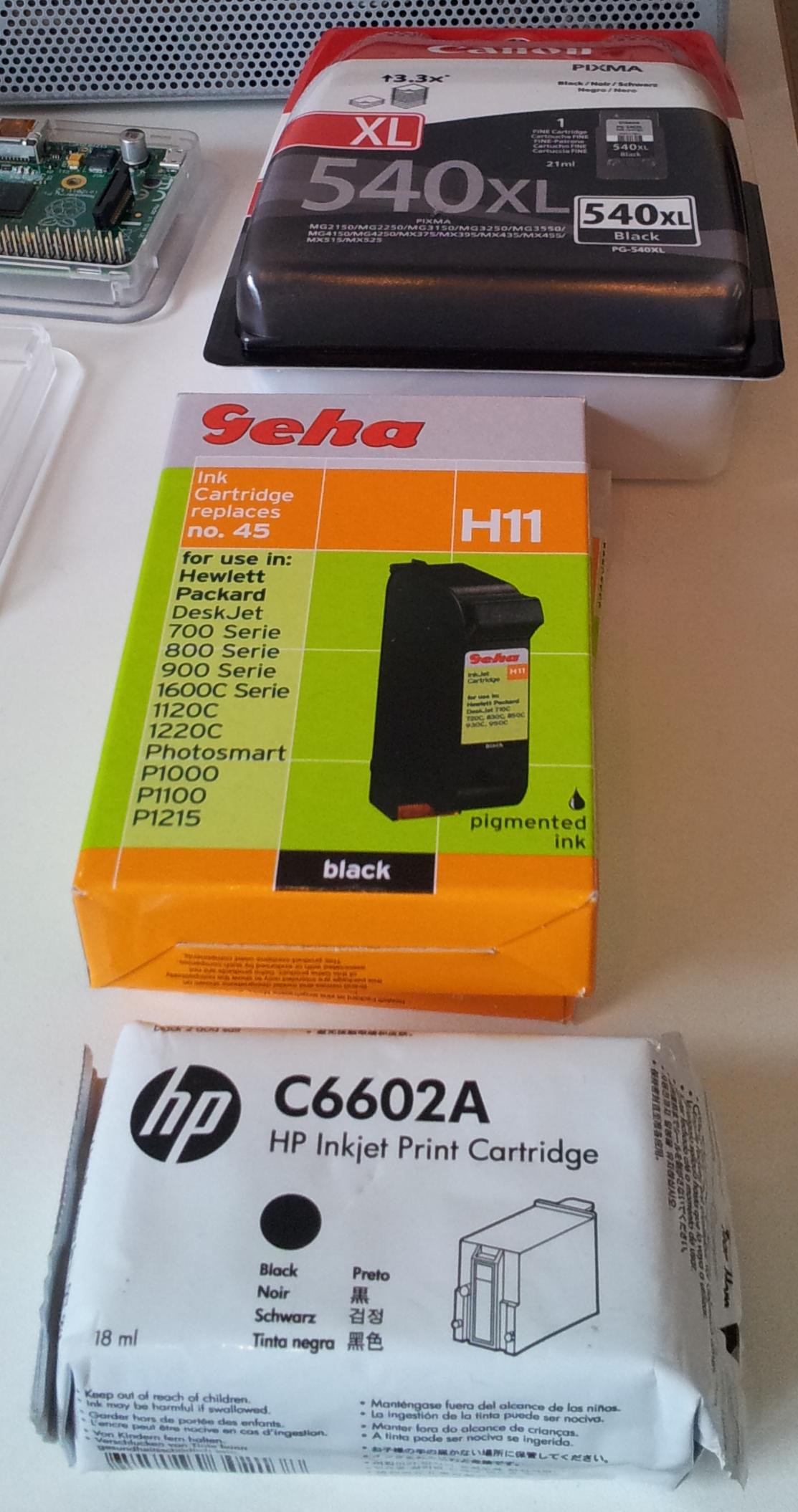

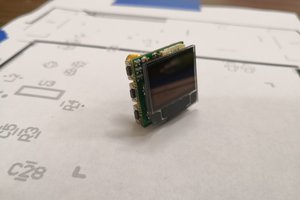

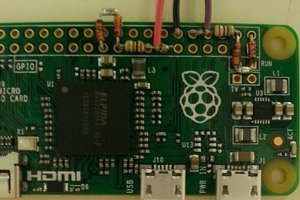

A Raspberry Pi is used as controller and later substituted by a more embedded solution (which is yet to be determined). The printhead is moved by a linear slide, which is harvested from an old CD-ROM drive. The Digital Stamp is initially powered by an ATX or similar power supply. A small selection of ink cartridges is there to be tested.

Overall goals:

- Small

- Easy to handle

- Wifi

- USB

- Local data storage

- Good printing speed & quality

- Real time clock or frequent time synchronization

Are you curious about something, do you found a mistake, or do you have questions? Please write a comment.

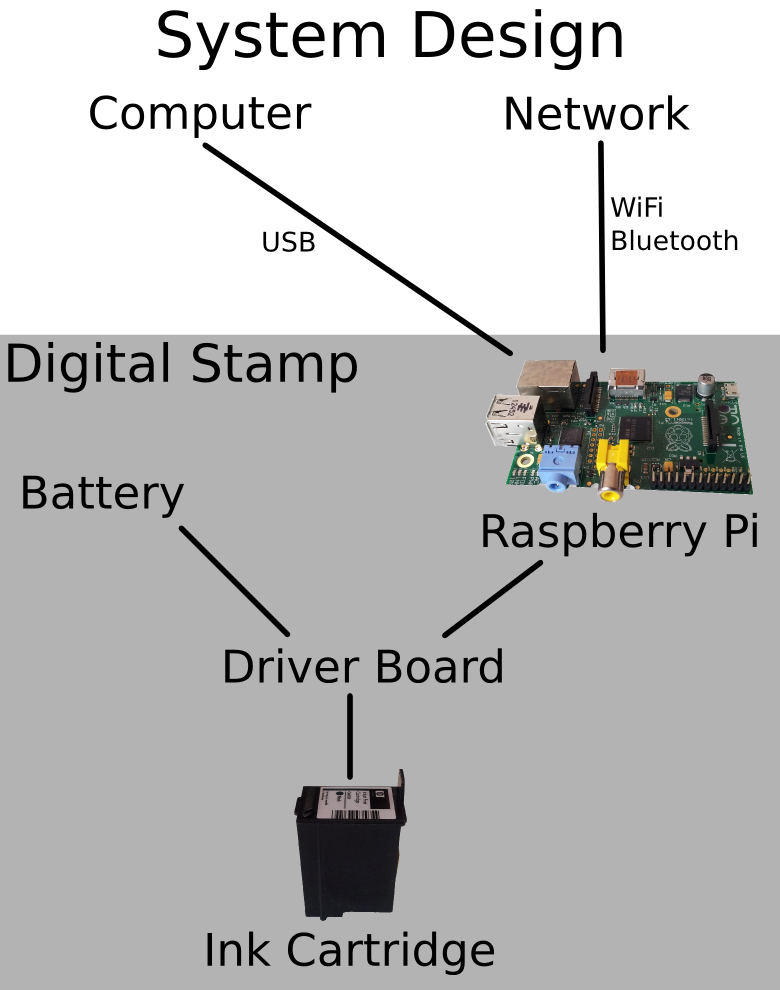

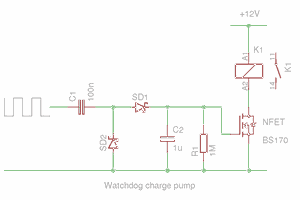

The system design document:

Licenses: For my own work (text and pictures) I use the

Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

If you need another license, feel free to contact me.

Here's my concept video:

Timo

Timo

Mark Omo

Mark Omo

Yann Guidon / YGDES

Yann Guidon / YGDES

Brainy.Baboon

Brainy.Baboon

Thank you so much for this informative blog. I'll be in contact with <a href="https://www.cycjetcoder.com/inkjet-coding-machine/">Inkjet Coding Machine</a>