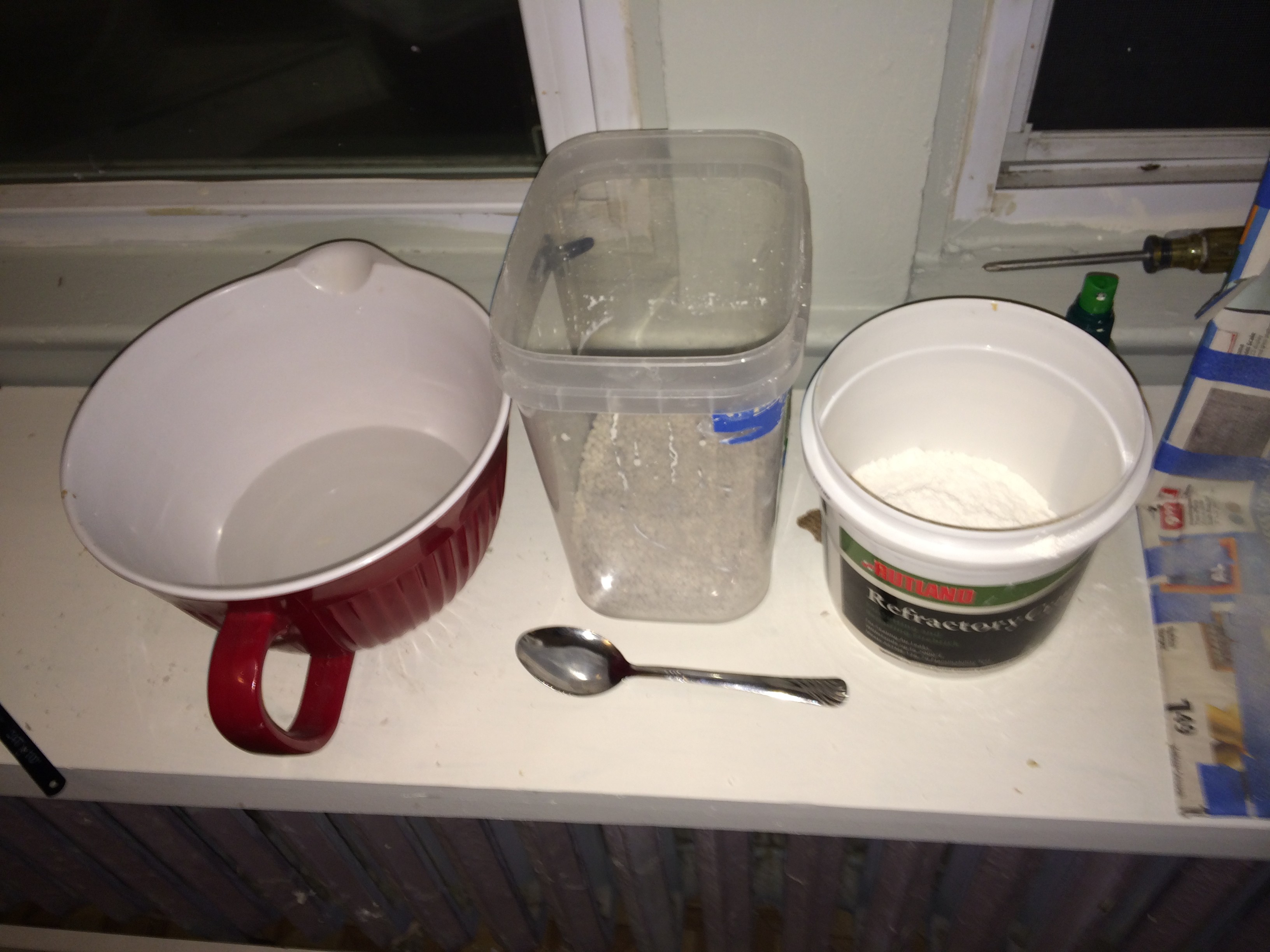

Materials:

Investment [mold]: Equal parts of Perlite / Plaster of Paris / Water

Something to stir with and a bowl to stir in

Old plastic Tupperware

Vibration table of sorts [to remove the air bubbles from the container]

It took about 3.5 cups of each ingredient equally in order to fill our mold.

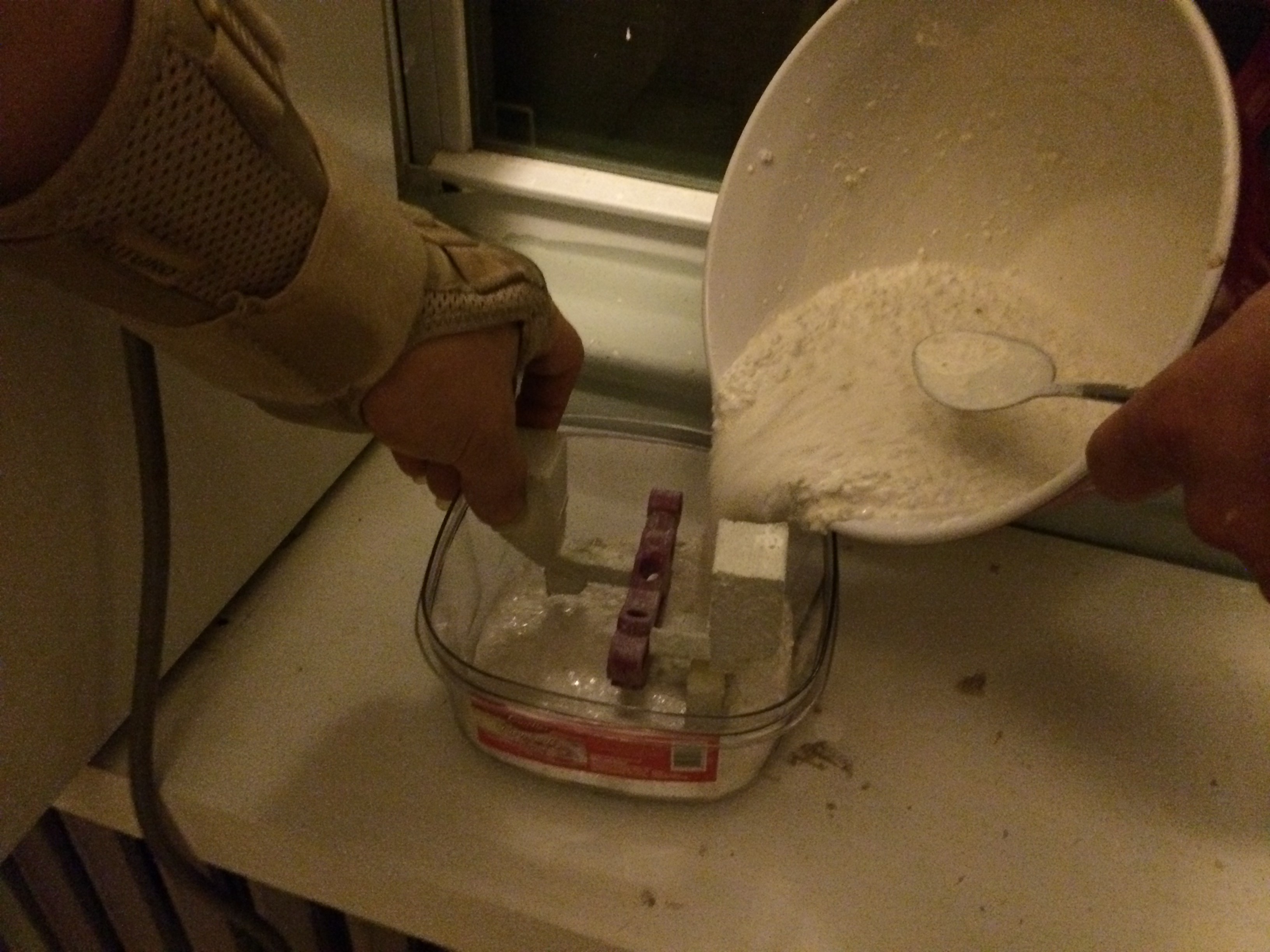

Mix "investment": equal parts perlite + plaster of paris + water. Mix dry ingredients before adding one part water (equal to the perlite or the plaster). Investment should have the consistency of thick soup (think: pancake batter). Do not stop stirring for more than 15 seconds after you add water or the investment will harden. Stir until ready to pour, then pour quickly! You're looking for a thick soupy consistency like pancake batter.

Pour a little investment into the container to server as a 'floor' for the object to rest on.

Place the object on top of the investment.

Cover the object with the remainder of your investment, until the object is no longer visible.

You will want to vibrate the mold with the container so that the air bubbles inside can escape. We might try to use a laundry machine next time and see how that goes.

We added a little weight atop of our mold while the investment hardened. Set for ~ 1 hour.

We added a little weight atop of our mold while the investment hardened. Set for ~ 1 hour.

We had accidentally got Tupperware that was too firm it caused a problem to remove the settled mold.

Use older / plastic Tupperware that has flex and wiggle in it so that after the 'investment' has settled you can remove it easier :)

Julia Longtin

Julia Longtin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.