Preview:

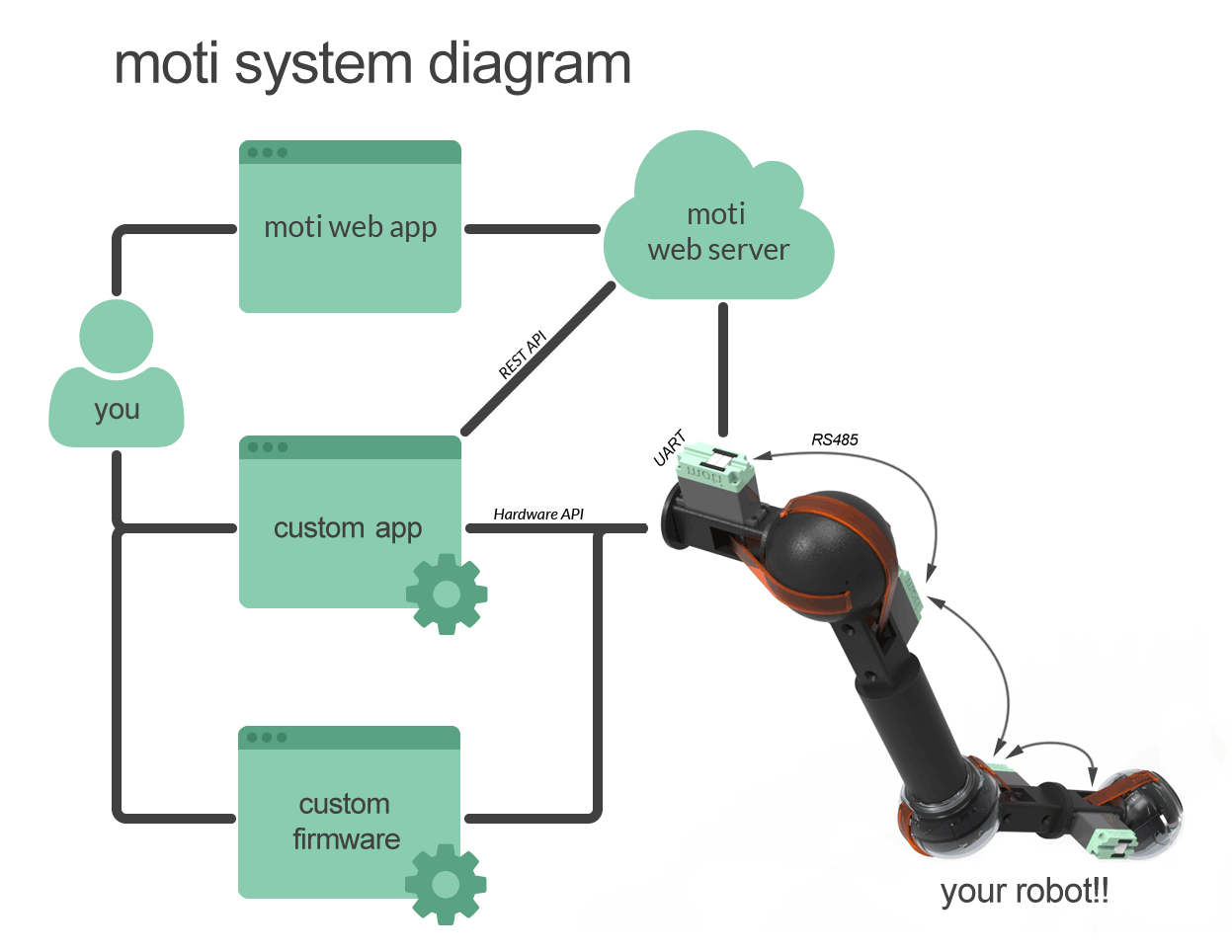

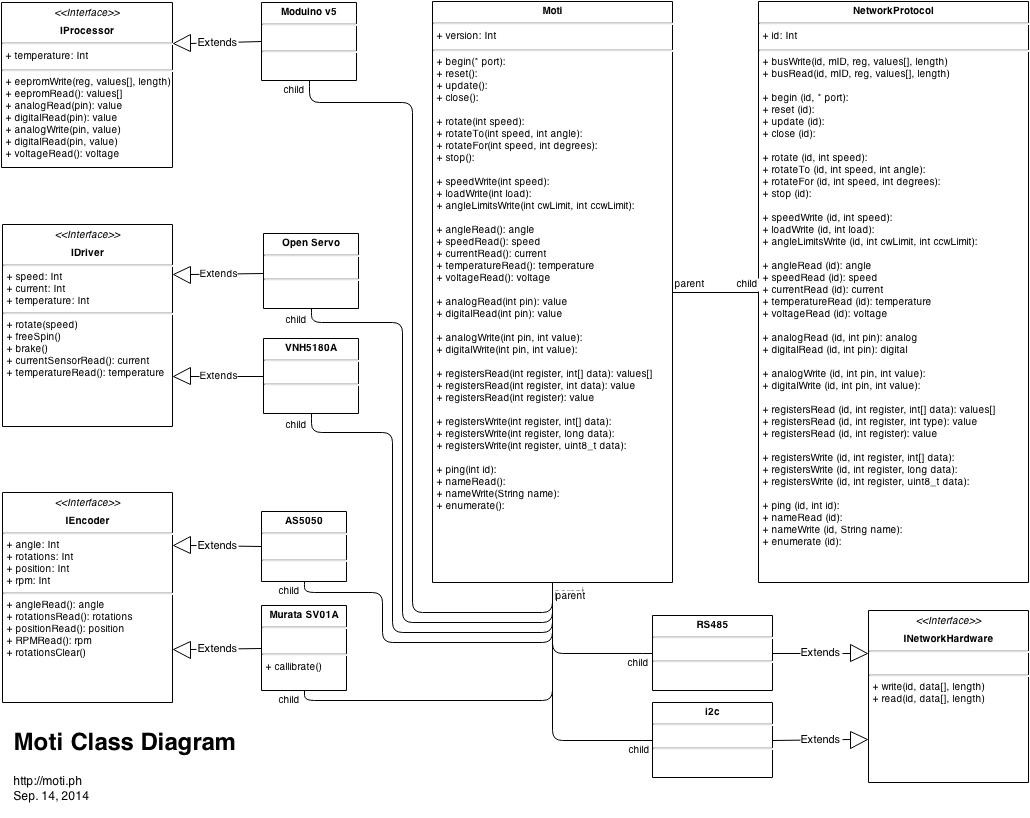

What the system diagram illustrates is that you can use our prebuilt web app to recognize, monitor, remote control & program your robot. Alternatively, you can build your own app (or use someone else's) that is customized for your application. Thirdly, you can program the motis directly to create an autonomous system.

Nicholas Stedman

Nicholas Stedman

Cees Meijer

Cees Meijer

Morning.Star

Morning.Star

Yannis

Yannis

Capt. Flatus O'Flaherty ☠

Capt. Flatus O'Flaherty ☠

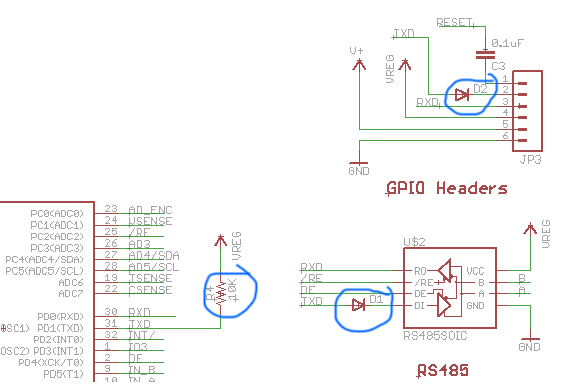

Hi @Nicholas Stedman What is the status of your project? . The continues motion is grate. I am really interesting on building it and plug it into our M0CUBE controller. Our new GRBLHAL Universal controller have RS485 on board (among others EtherNET, CANbus).

https://hackaday.io/project/171770-m10cube/log/202098-m10cube-pico-cnc

So it will be nice to start experimenting in the robotics field among others. I subscribed for a newsletter but project looks dead. Pity if that is so. It has grate potentials. One can be substituting the expensive CPU you are using with R2040.

So please I like very much to help in any way.