Alright so here is what i think i need:

A tribo powder coating gun modified for a smaller stream of material.

A scanning electron gun similar to what is in a cathode ray tube.

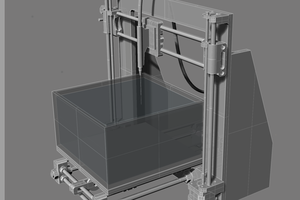

A vacuum chamber

A focusing coil and direction coil for guiding the particles out of the tribo gun.

A signal generator to draw me a circle to test with.

A rotary vane 2 stage vacuum pump.

A radiant heat source

Basically the electron beam and particles are directed to the same location.

The beam creates a negative charge on the surface and the particle sticks to that location.

A radiant heat source could help stick the materials together/fuse them?

I'll see how long it takes me to source the parts.

Chaz

Chaz

brtv-z

brtv-z

Michael

Michael

PointyOintment

PointyOintment

Tinkers Projects

Tinkers Projects