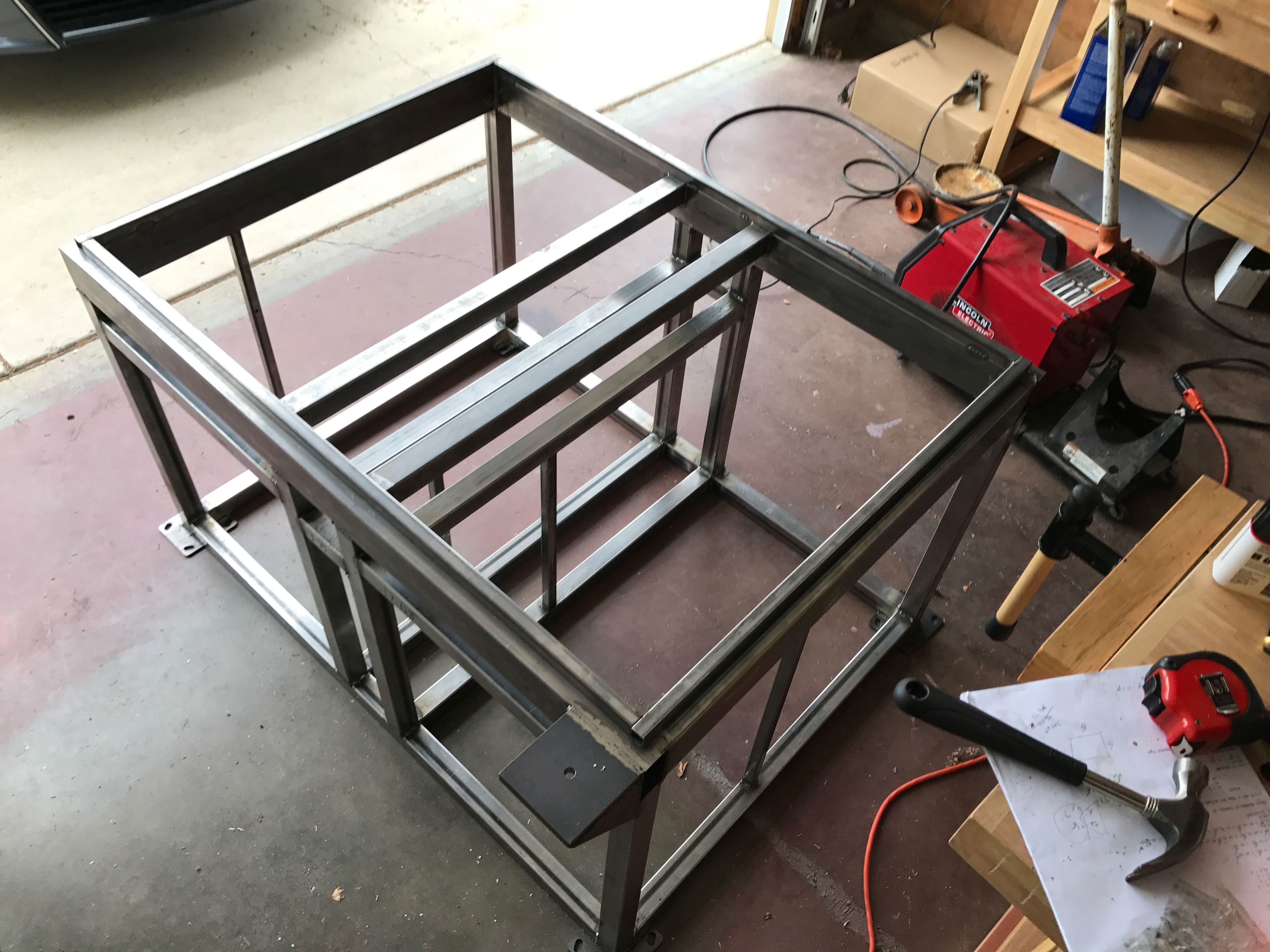

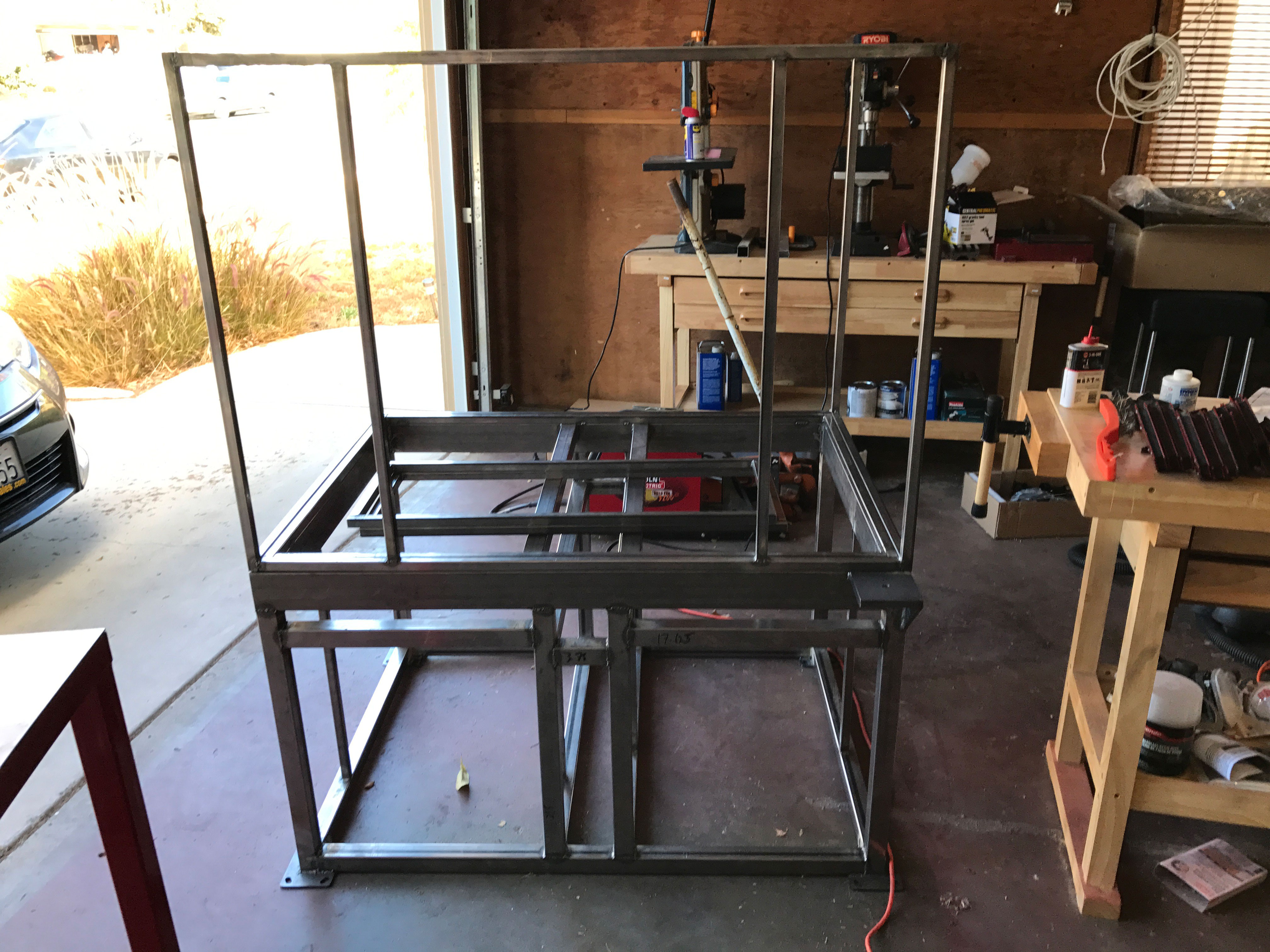

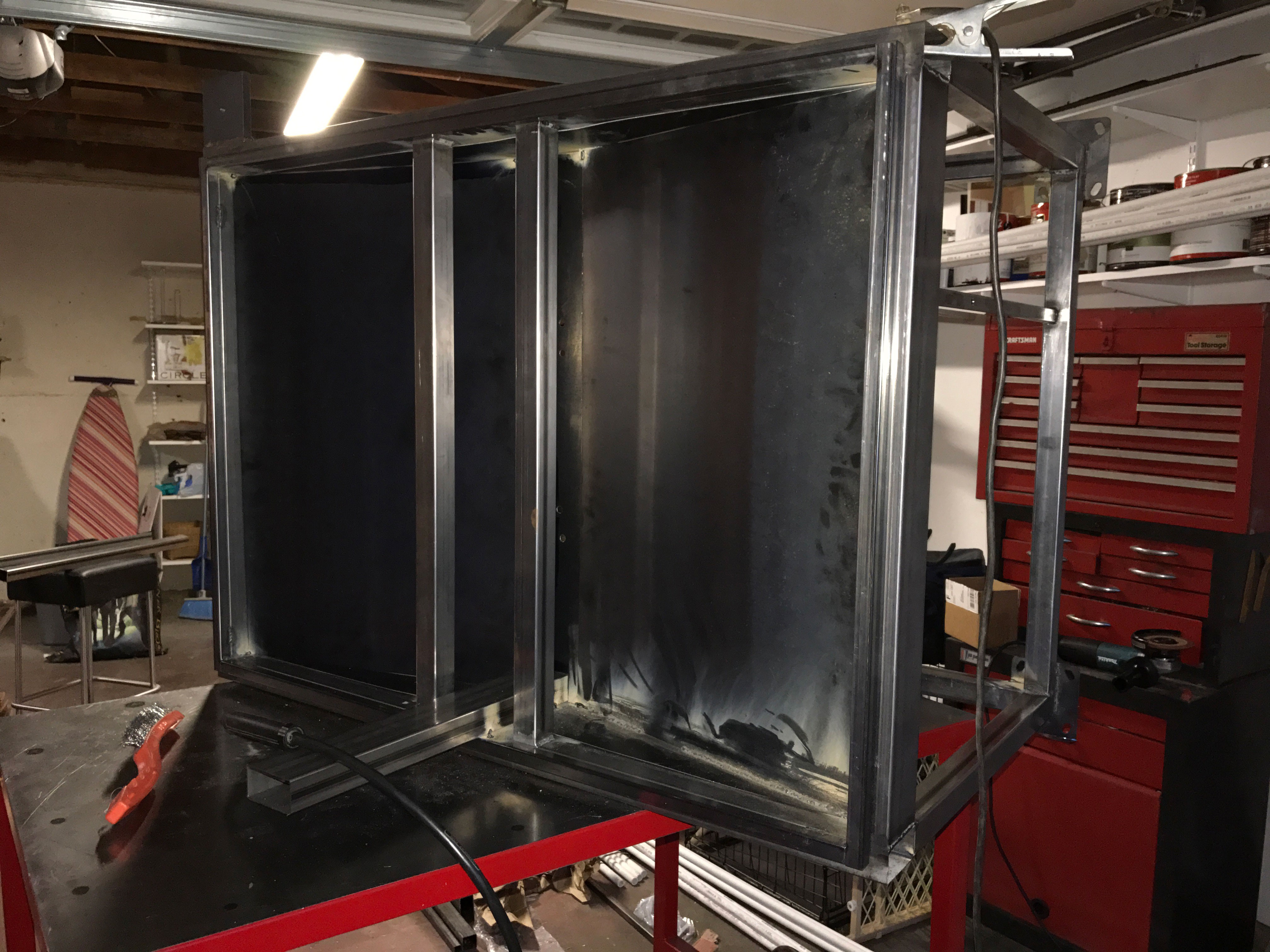

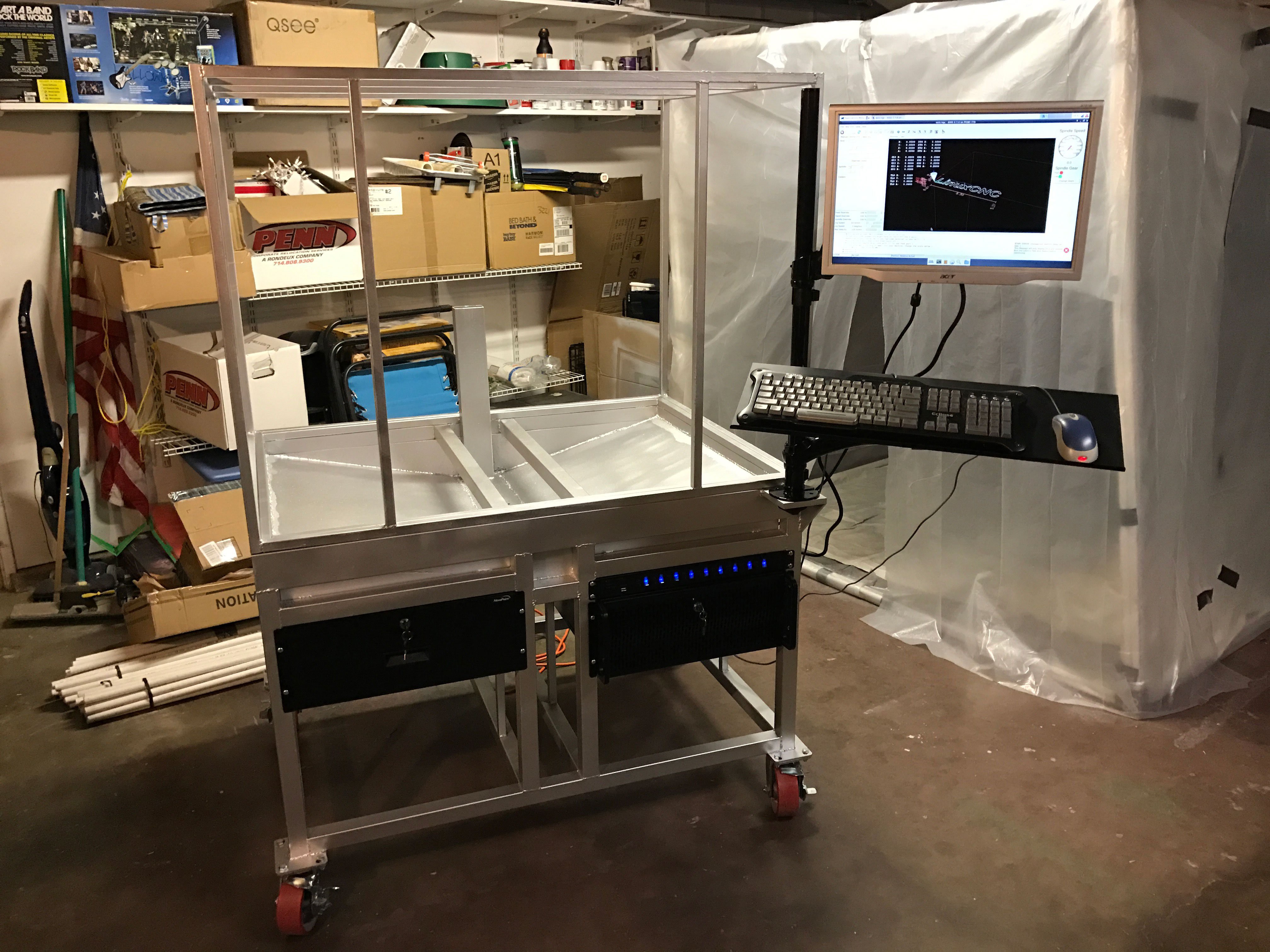

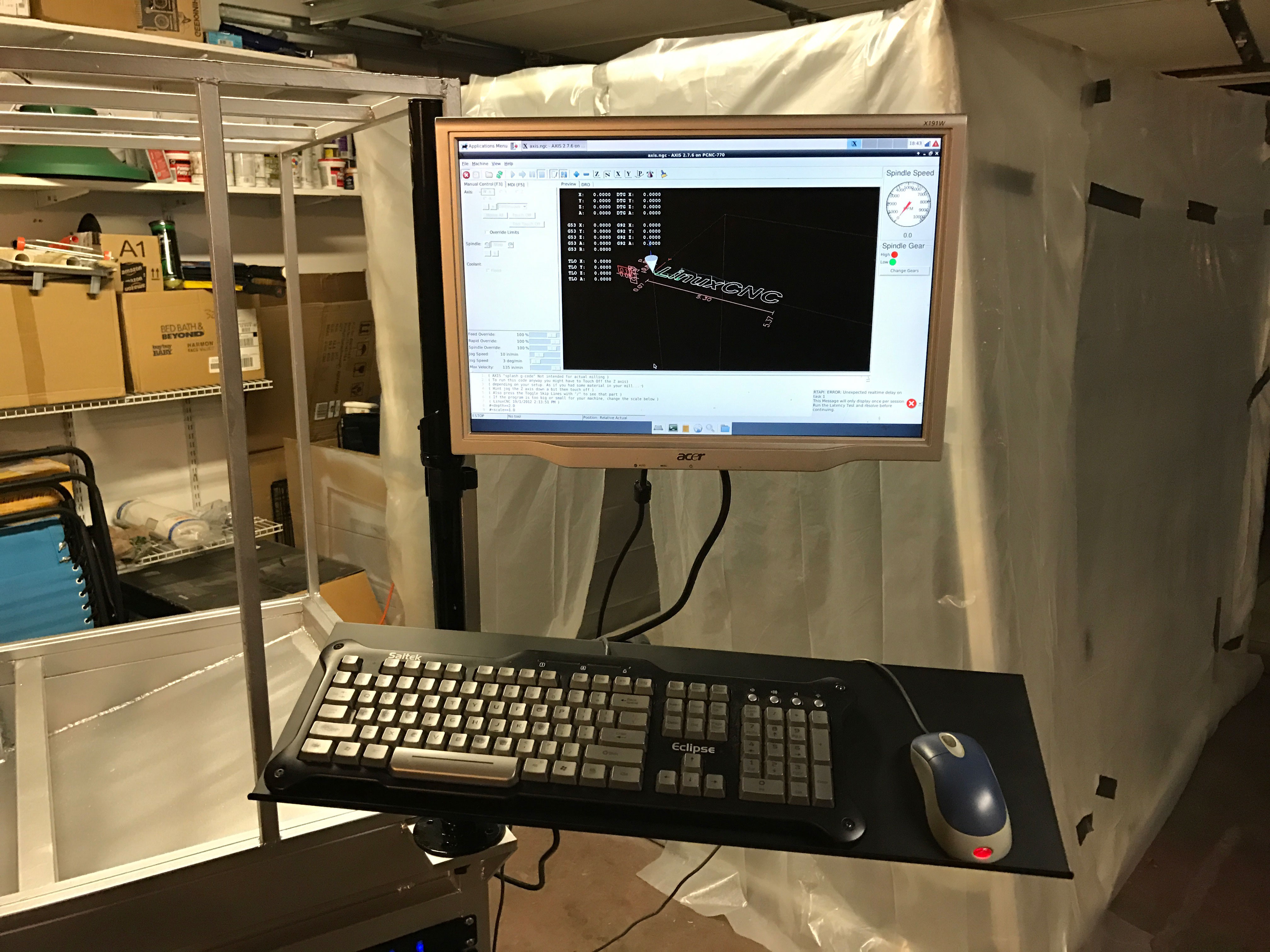

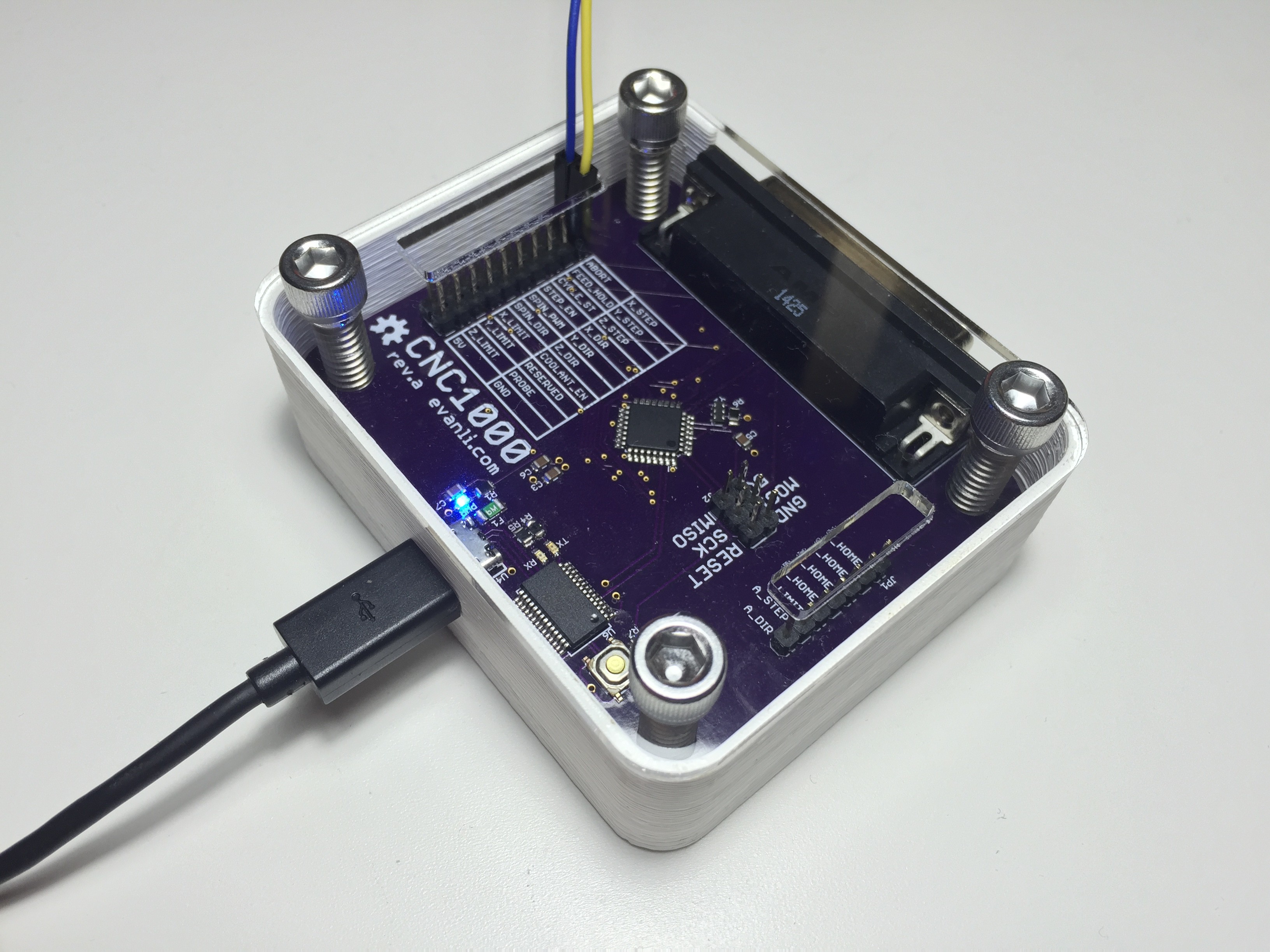

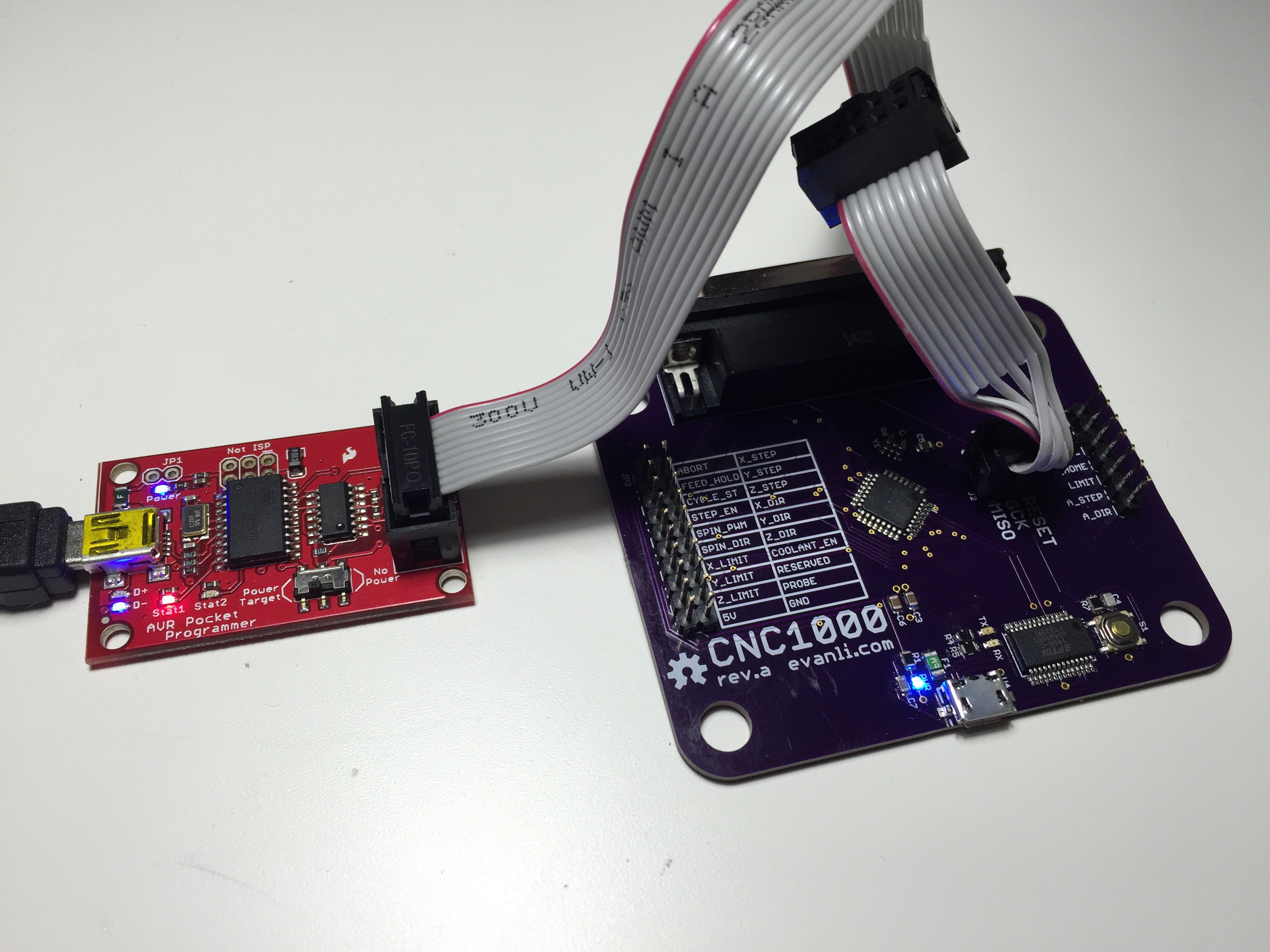

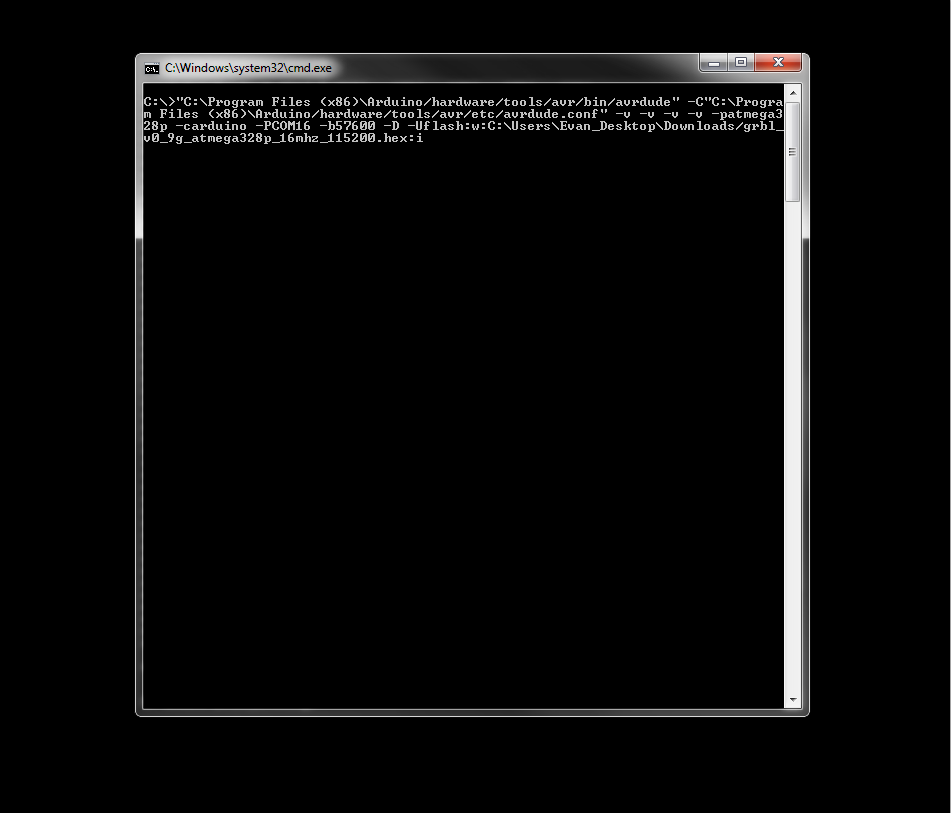

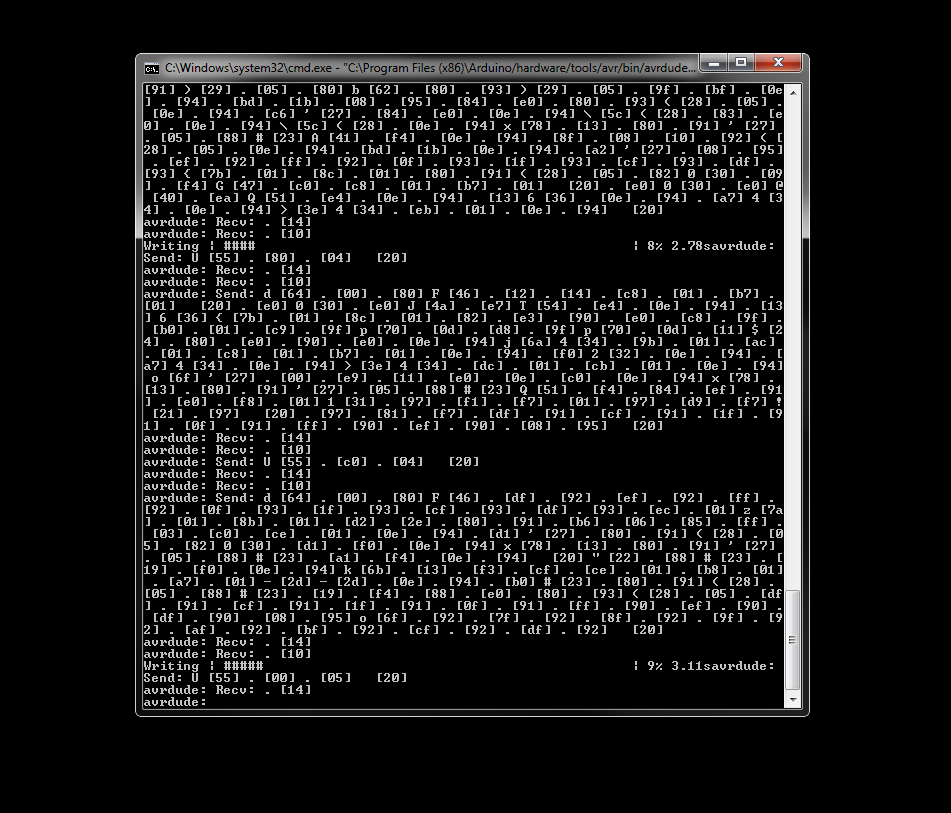

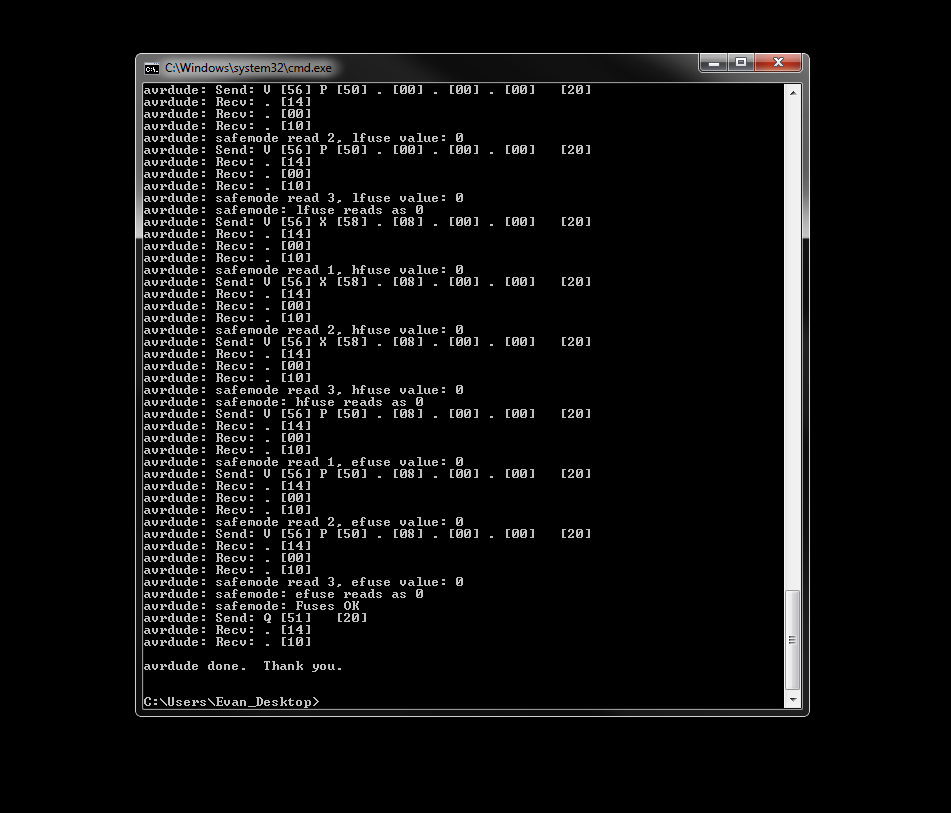

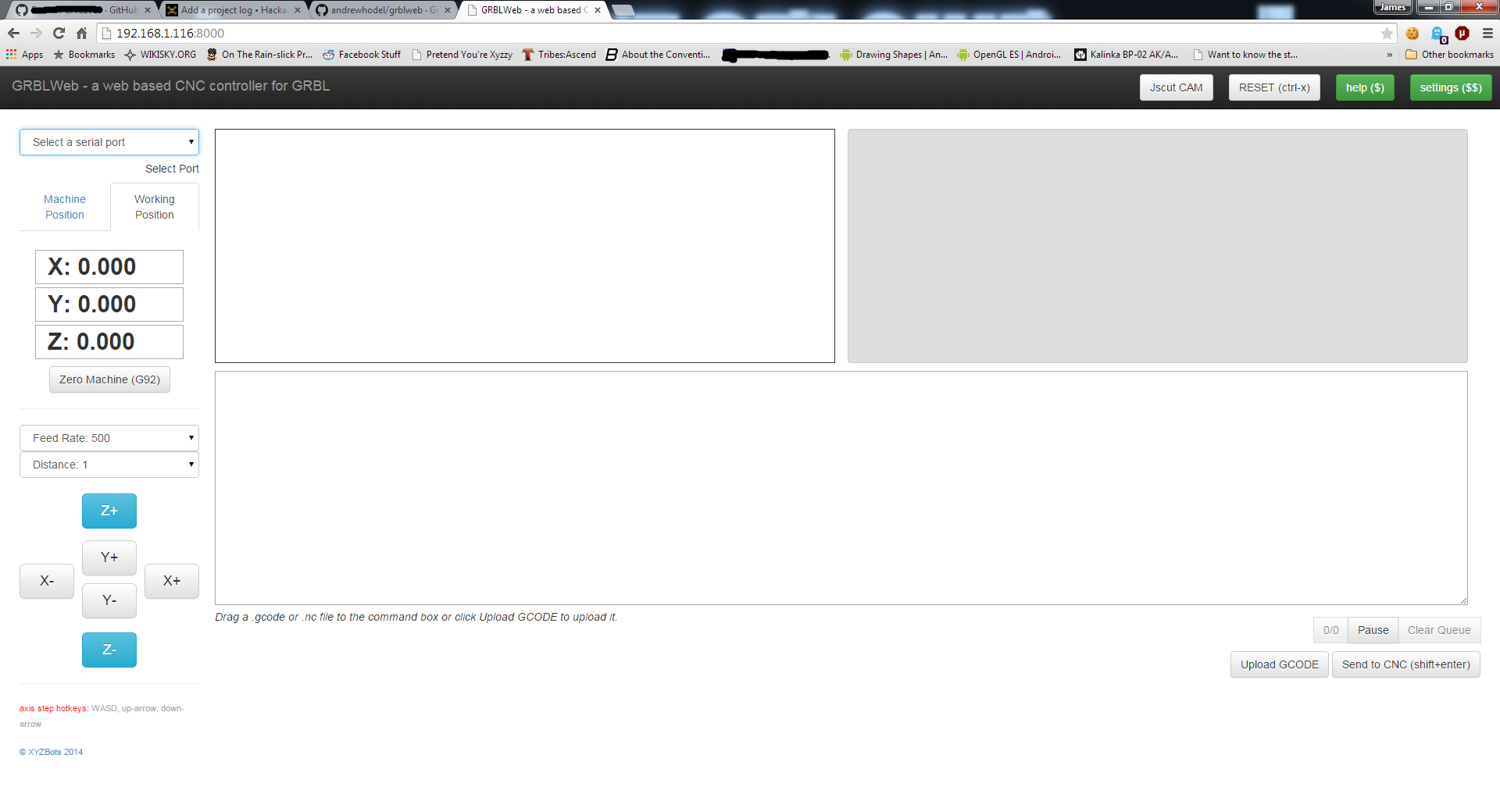

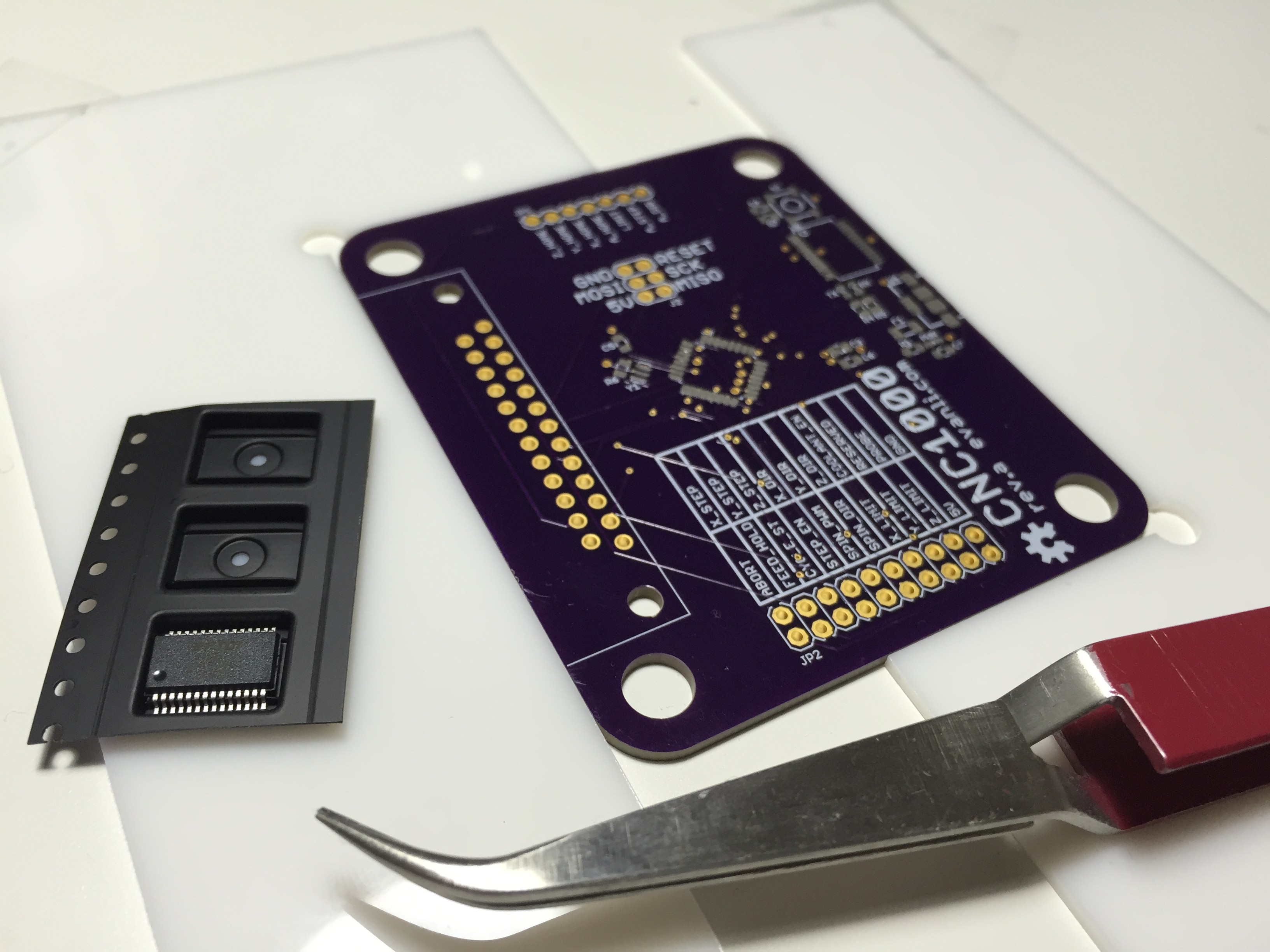

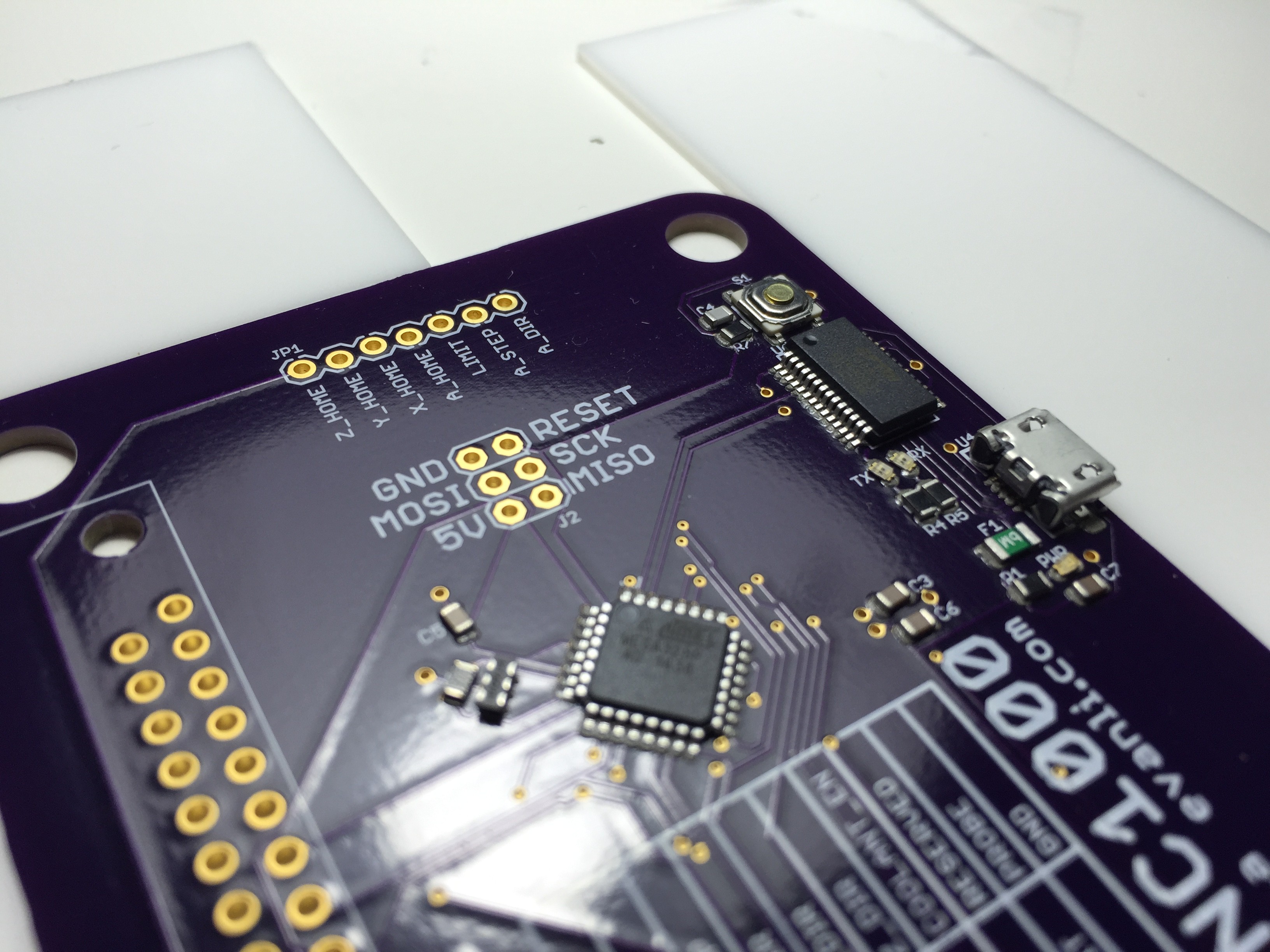

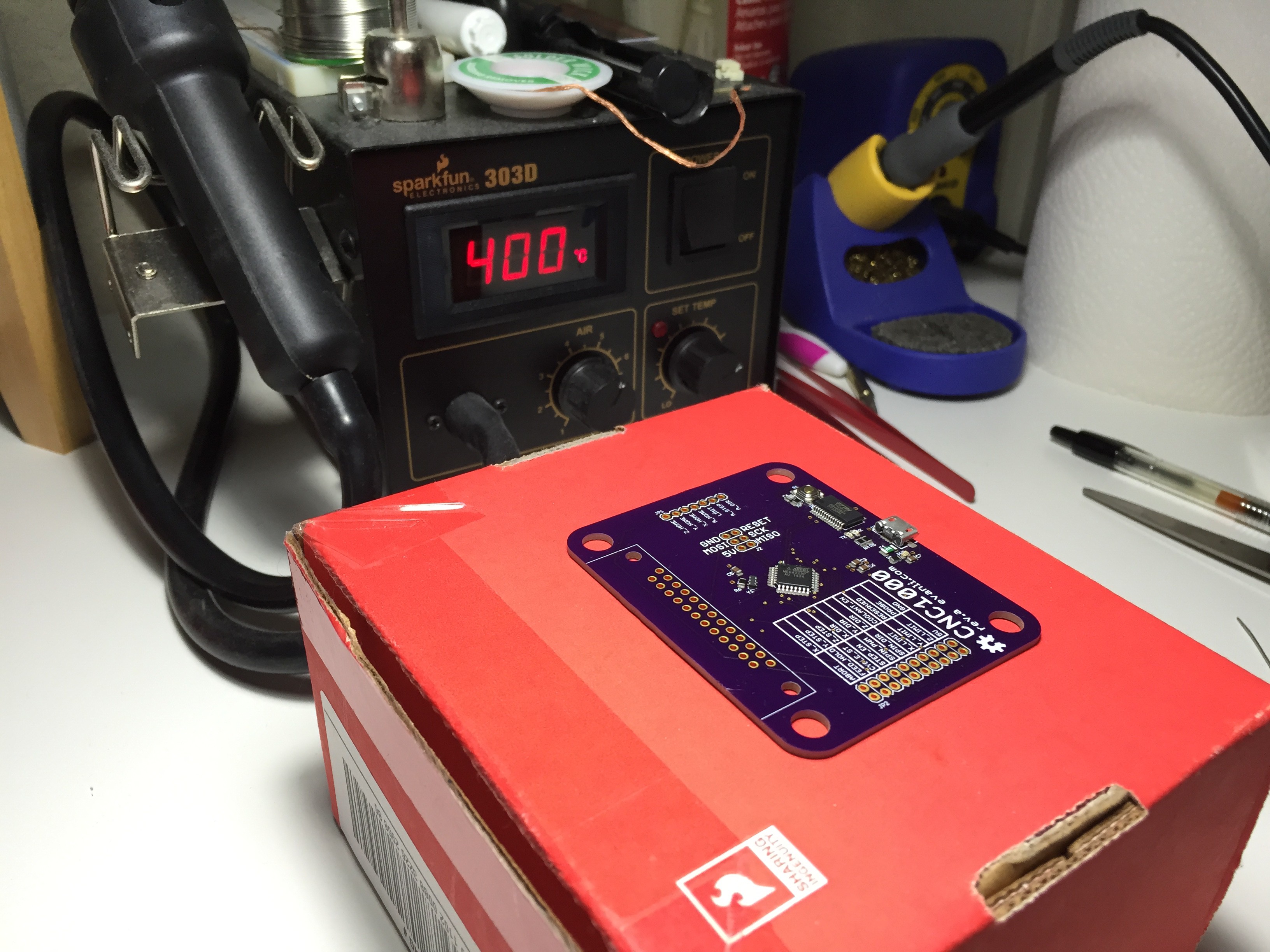

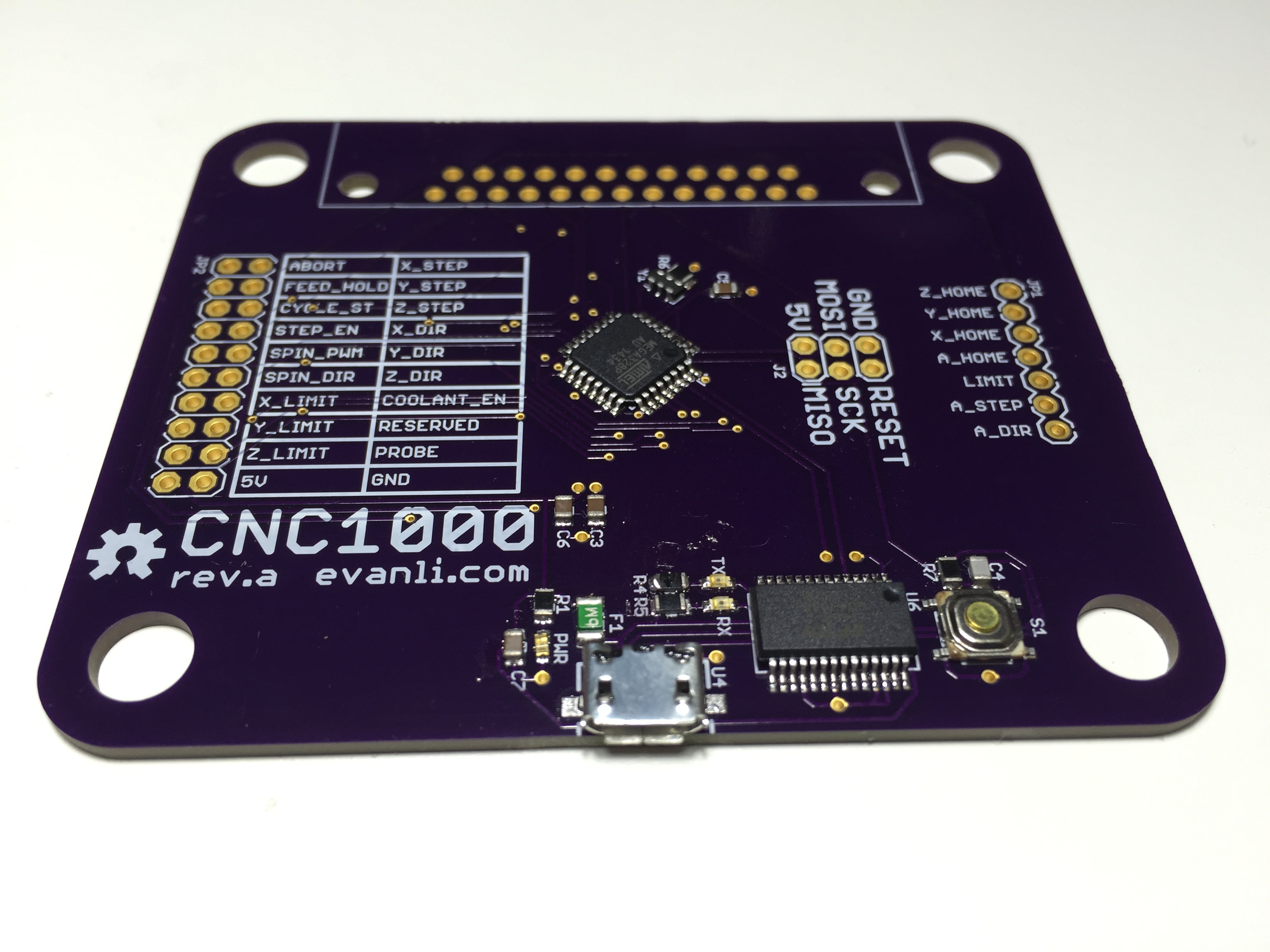

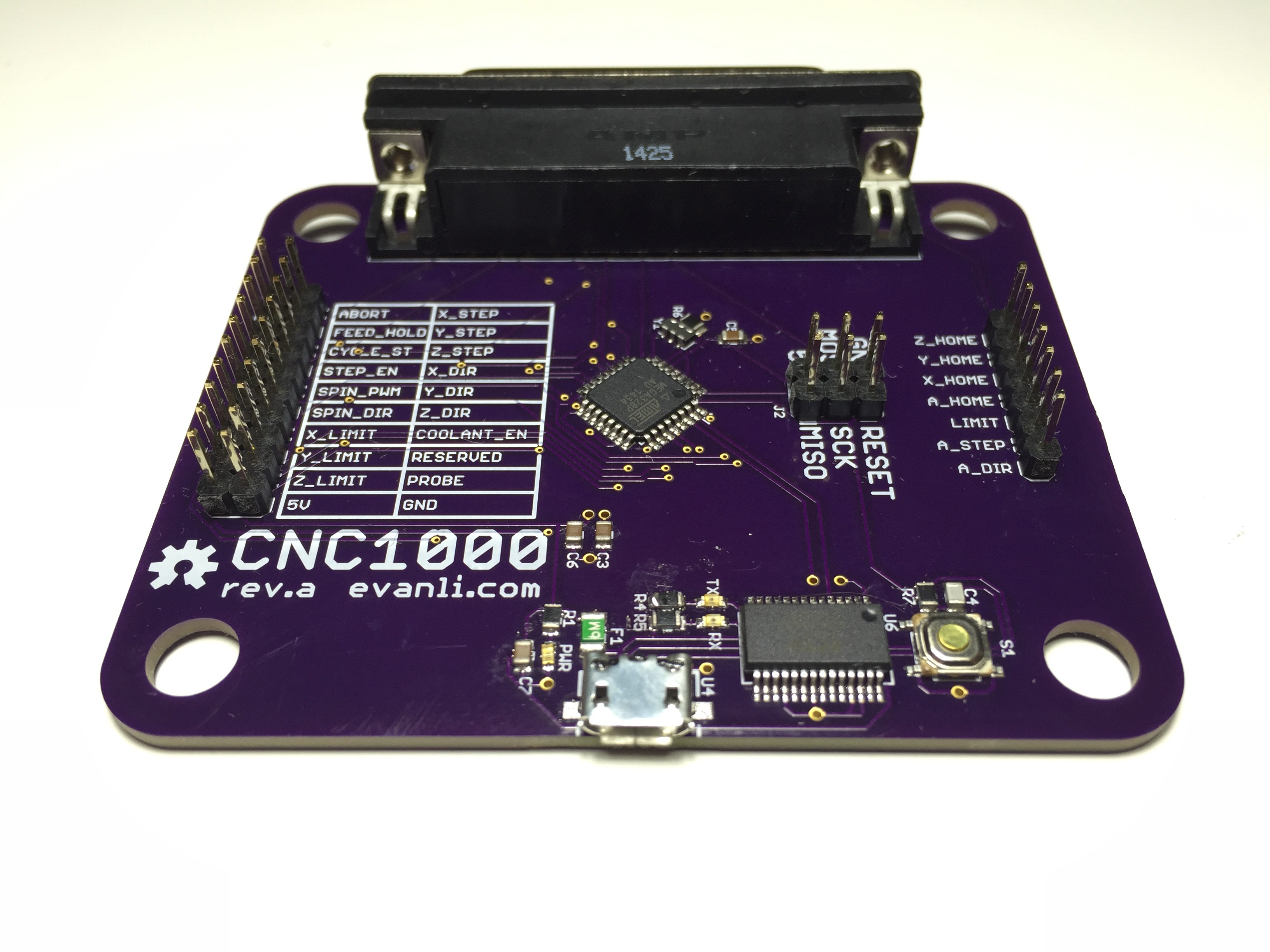

The plan is to replace the parallel port interface on the stepper driver with a microcontroller running GRBL. The mill can than be run from a USB interface on any computer rather than a increasingly rare parallel port. Also planned are some incremental upgrades to the hardware on the mill, such as spindle control, and a flood coolant system.

Servicing and Upgrading a Harbor Freight Mini Mill

Years ago, I converted a Harbor Freight mini mill to a CNC using a CNCFusion kit and stepper controllers from HobbyCNC. Time to fix it!

Evan Li

Evan Li

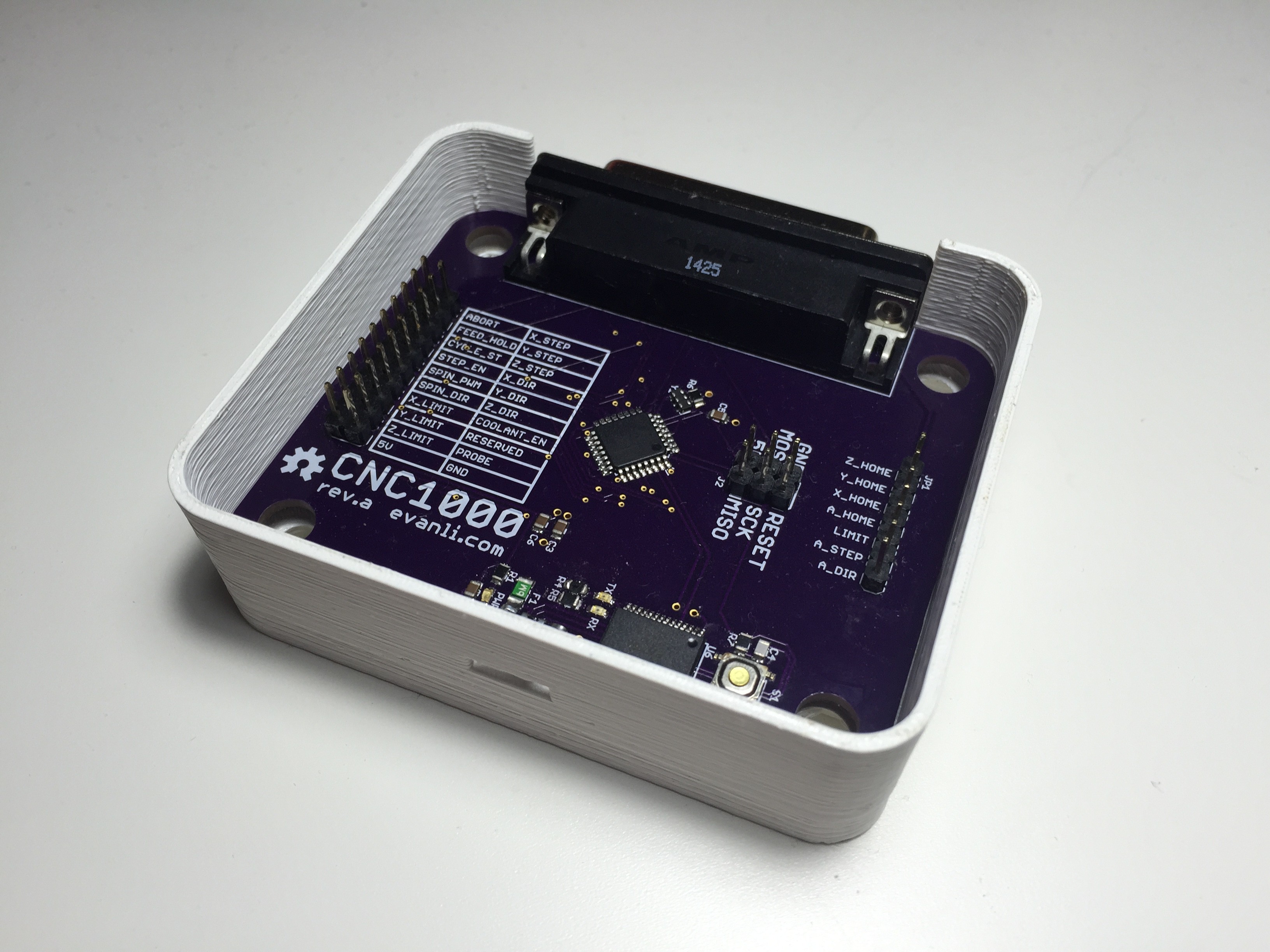

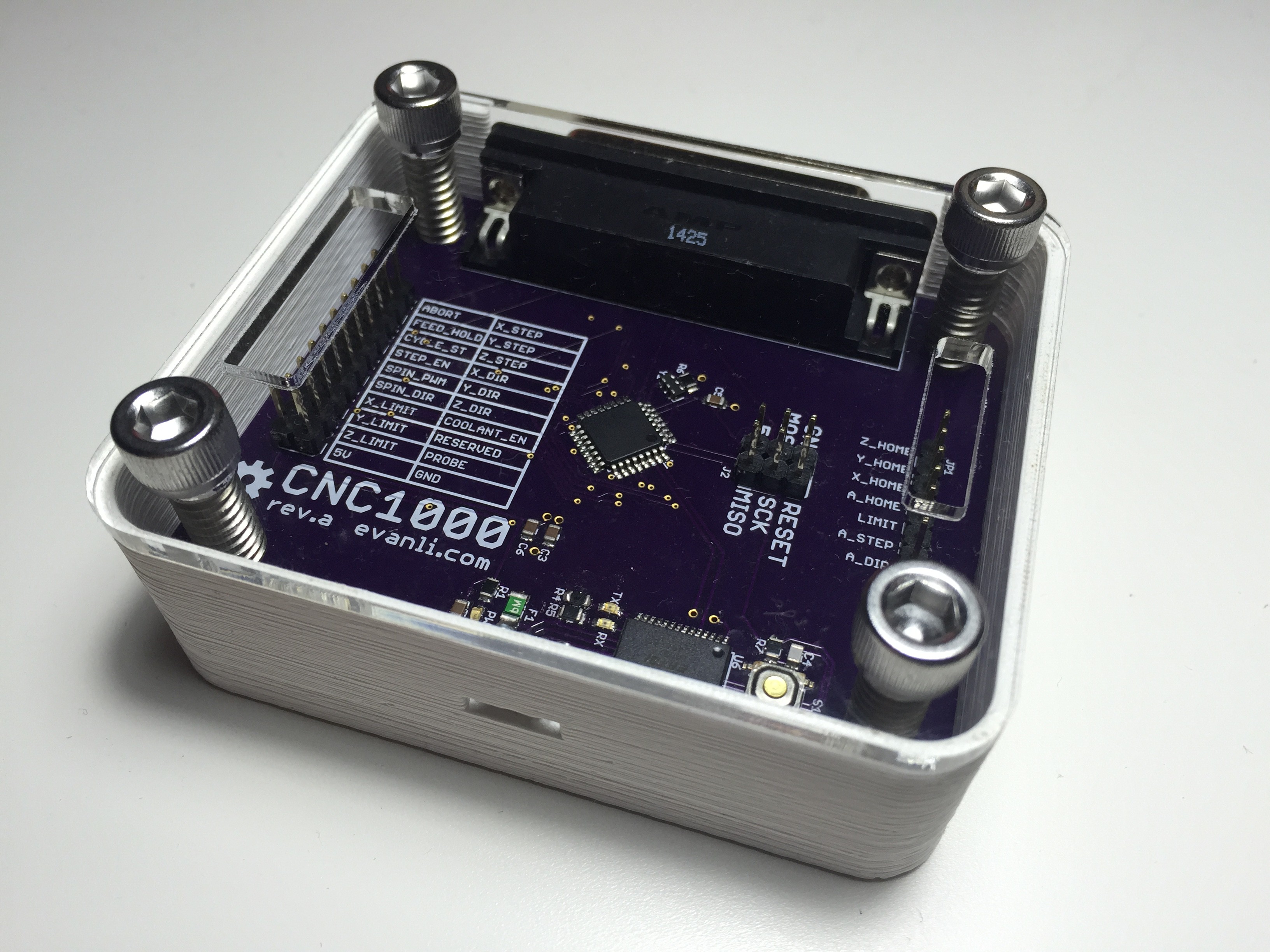

The model has tolerances for my 3D printer incorporated into it, so it fits like a glove.

The model has tolerances for my 3D printer incorporated into it, so it fits like a glove.

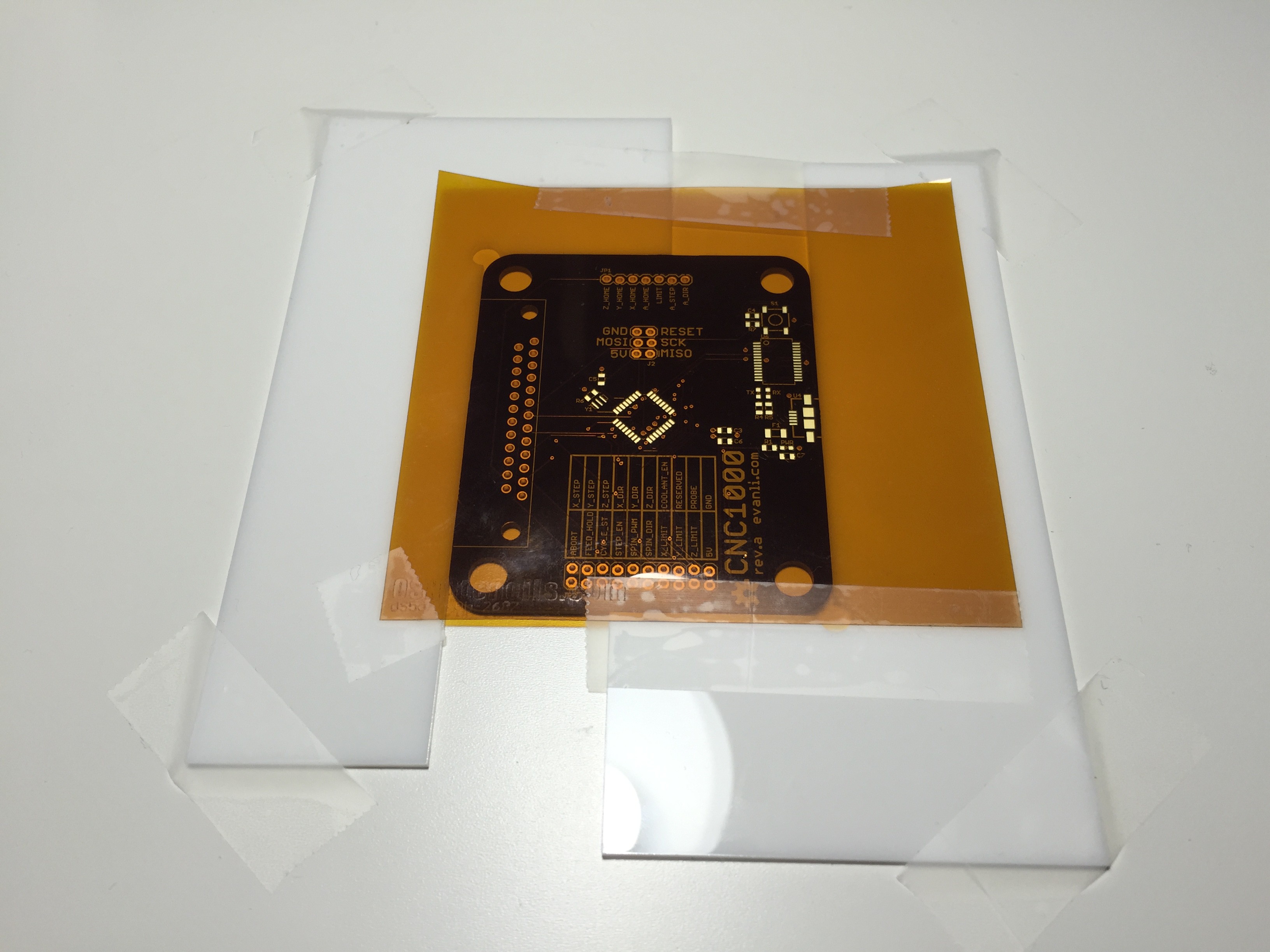

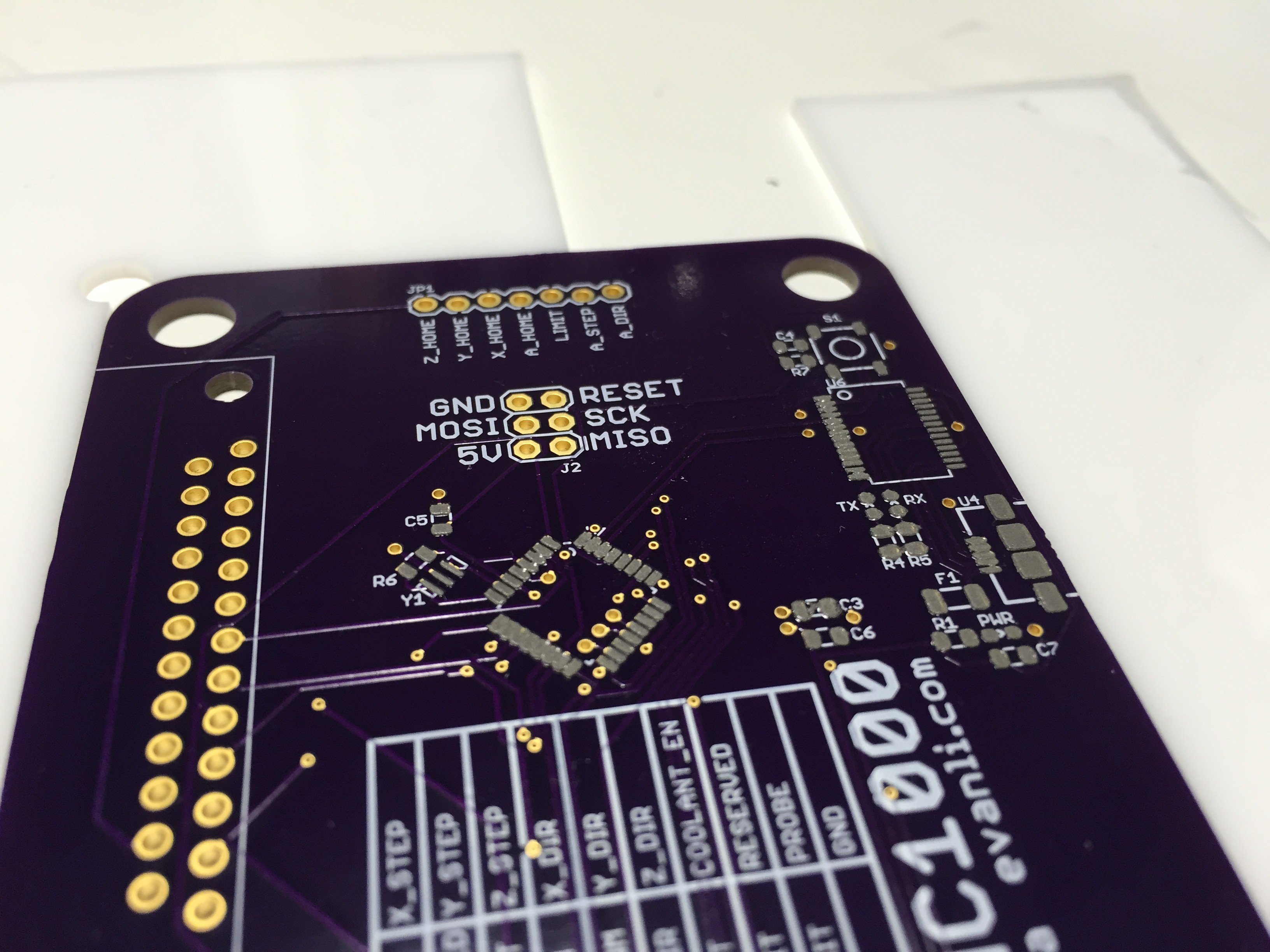

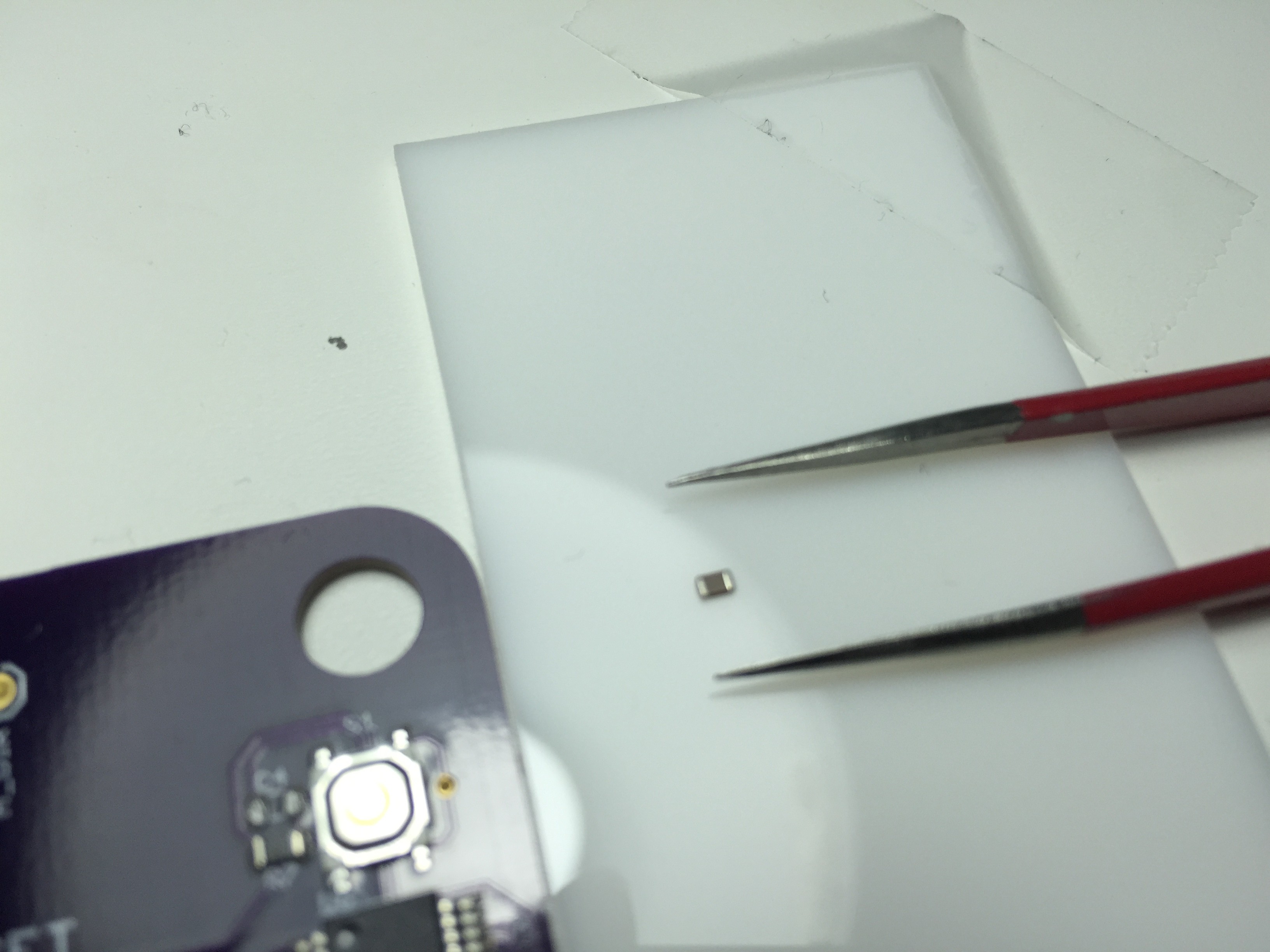

Putting on solder paste is always a delicate task. Basically I just taped the PCB in place with some acrylic L shapes. The stencil is aligned and secured in place with more tape.

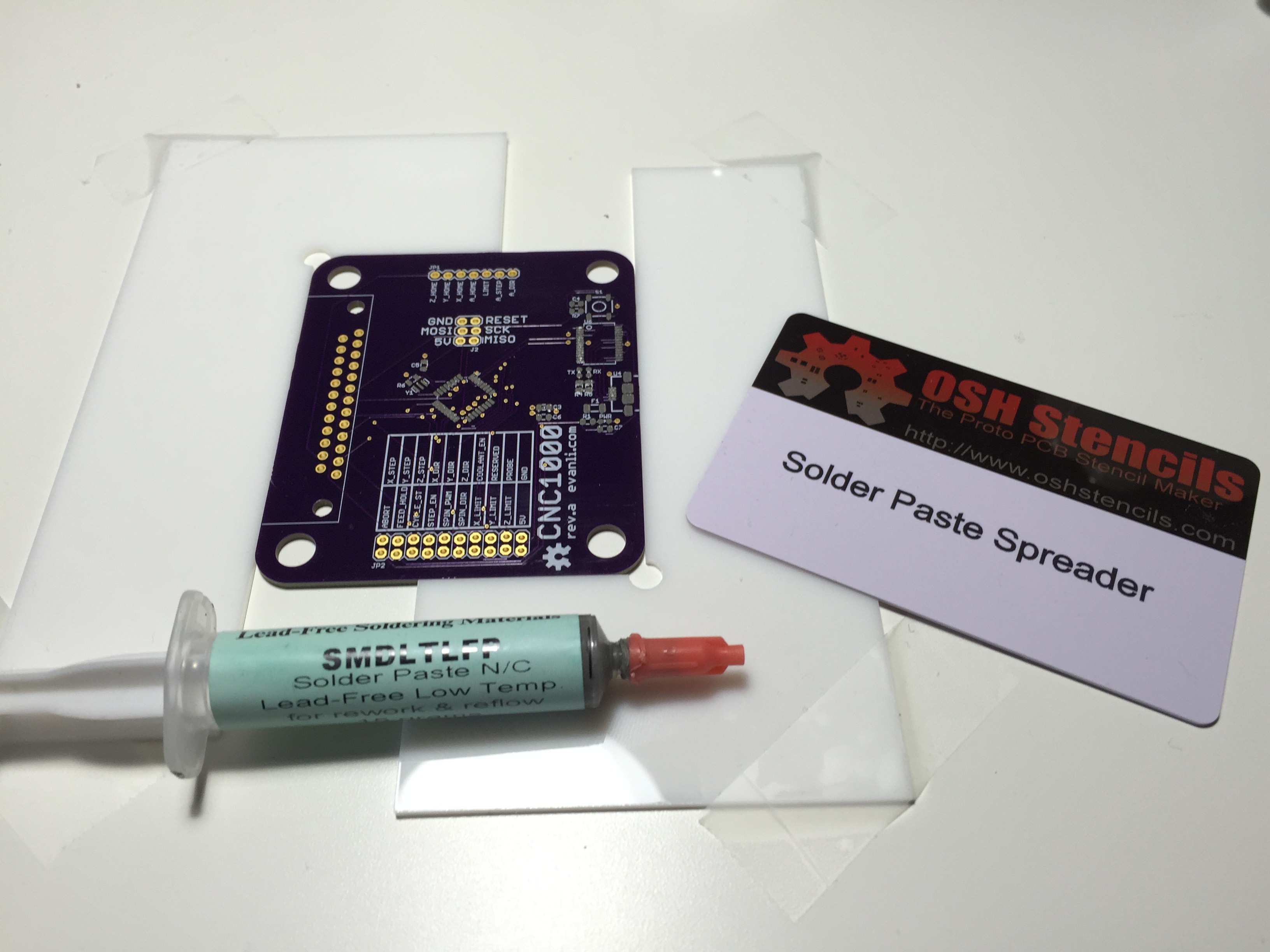

Putting on solder paste is always a delicate task. Basically I just taped the PCB in place with some acrylic L shapes. The stencil is aligned and secured in place with more tape.  Dump some solder paste on and spread it with a convenient card from OSH Stencil.

Dump some solder paste on and spread it with a convenient card from OSH Stencil.

Timo Birnschein

Timo Birnschein

dar.ryl

dar.ryl

Thomas Bladykas

Thomas Bladykas

J.C. Nelson

J.C. Nelson