Here I'll try to explain the beginins of the project, a bit of background of where I'm coming from, the idea, and where I'm trying to go with this project.

As a student, building a Reprap is a cost and time intensive undertaking. I find the concept of a self replicating very interesting. Not having much money to spare led to my interest in highly printable Repraps as a means of reducing cost by printing many parts of the motion system. I was very tempted to build a GUS Simpson and was also looking at delta printers of which a large cost is the linear bearings. I didn't like how the GUS Simpson uses two special bearings. What about building a traditional delta style printer?

Searching on the Internet I found that there have been attempts at creating a traditional delta printer (e.g, RappiDelta, PolyBot), but they were either not well documented, or had low resolution, or were otherwise incomplete (I couldn't find functional firmware), and so I started my last project, the Icepick Delta.

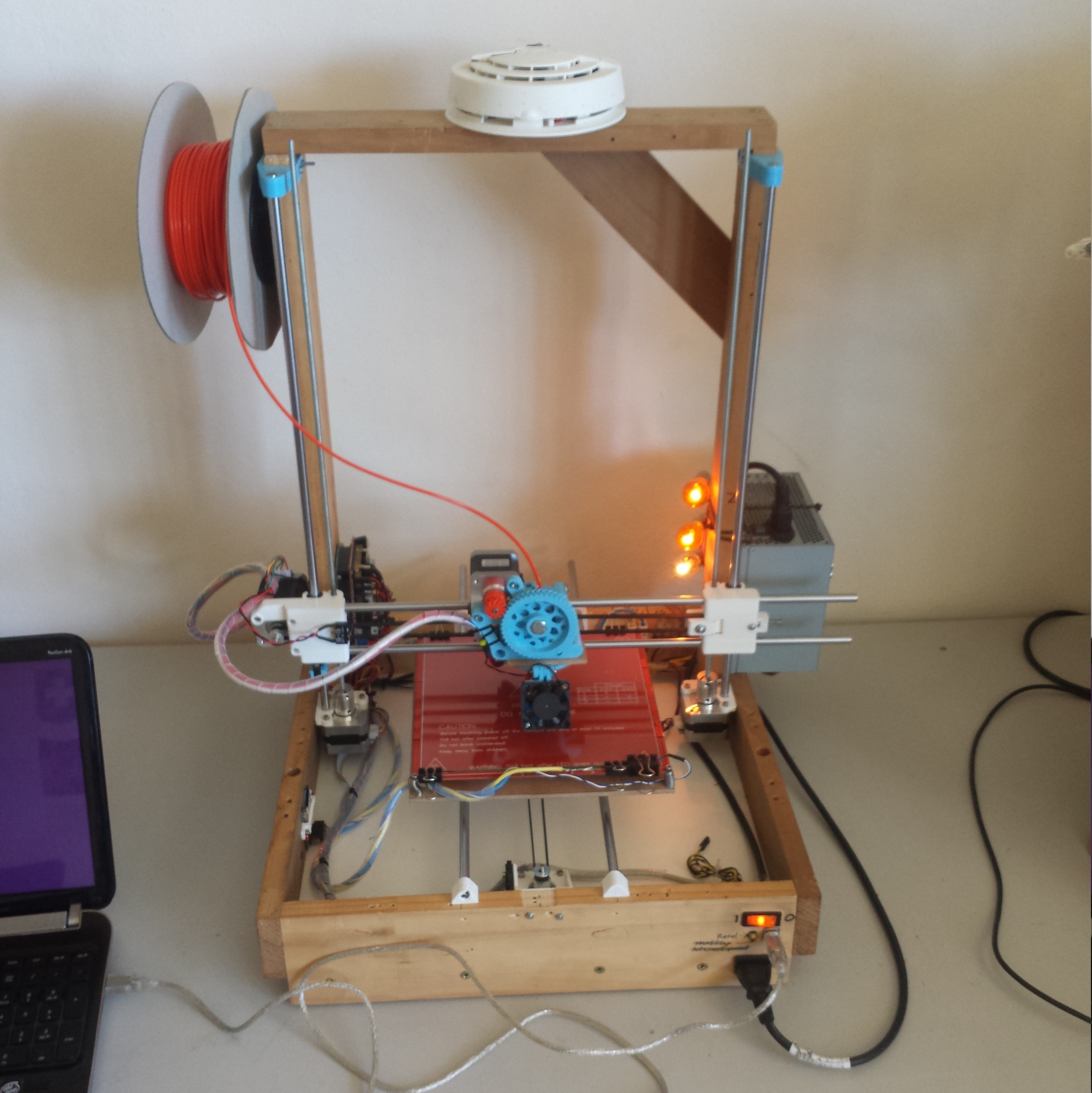

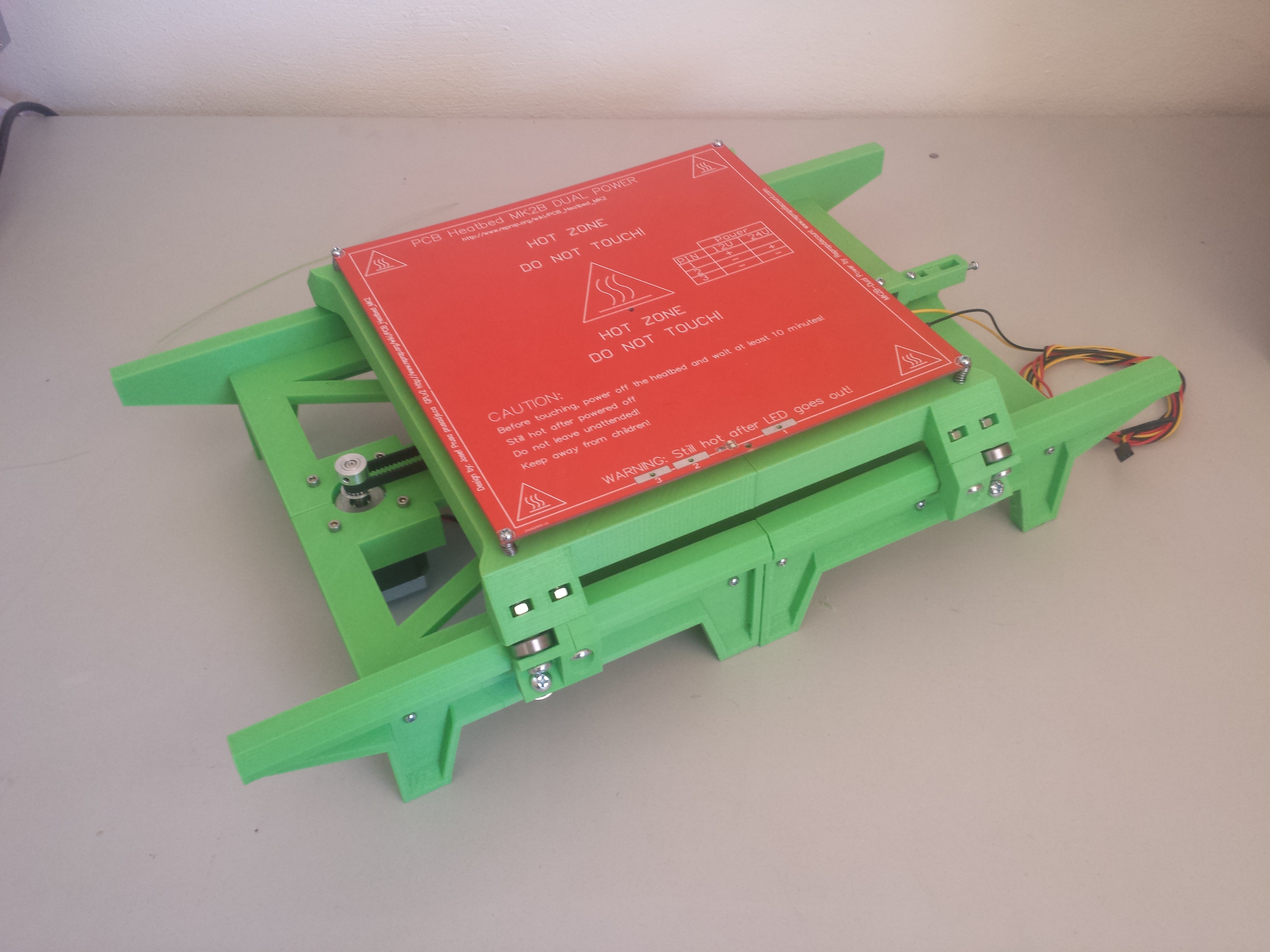

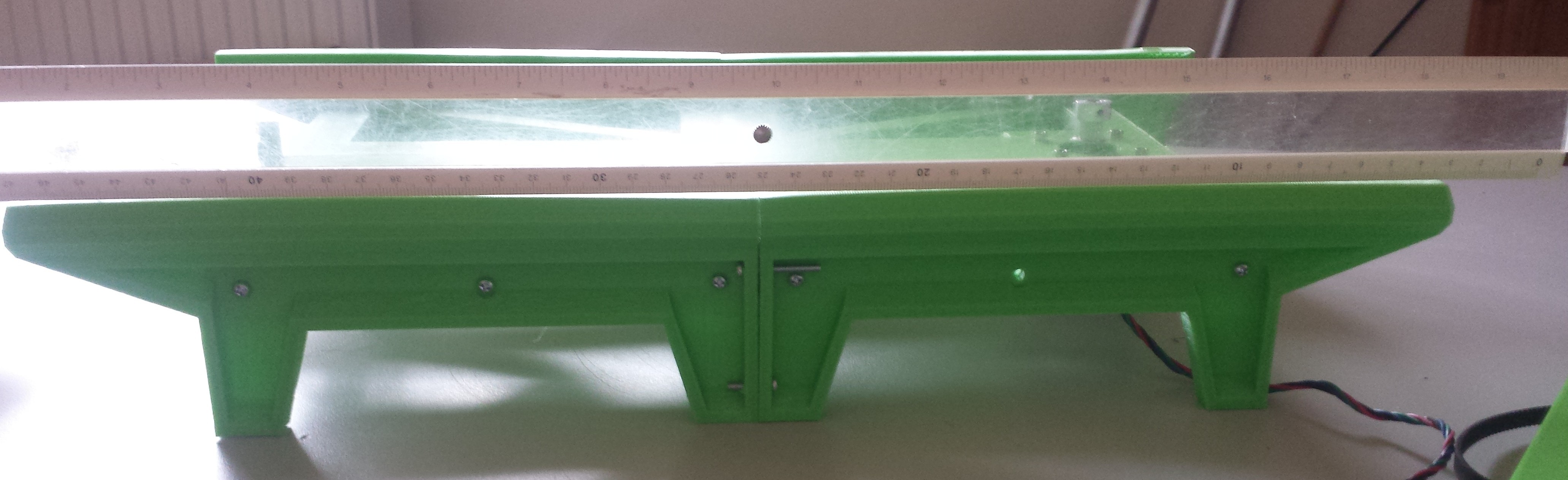

The Icepick Delta has been a success to some extent. It did not require a linear motion system, and therefor was cheaper to build. Some of the issues are as outlined below:

- Calibration is very difficult. Measuring an arm, and entering it in the firmware incorrectly by 0.5 mm will be a quiet a problem.

- The arms and end effector sockets have to be spaced exactly 120 degrees from one another.

- The end-stop distances are critical, there are three to calibrate. If one of these is calibrated incorrectly, parts are made dimensionally inaccurate, e.g. warped, wider as it gets taller, or other weird nonlinear transformations.

- Low repeatability, (banding in prints)

- It cannot self replicate: After days of calibration and fiddling it was printing dimensionally correctly apart from everything being 4% too short in the z-axis.

- The Arduino Mega with a custom version of Marlin firmware could only calculate 40 delta segments per second.

All in all it makes for a very cool looking, low cost minimalistic printer in terms of hardware usage, but it is very difficult to build and not suitable for a beginner. Lessons learned here will help with the Reprap Neumann project for sure.

I came to the conclusion that the GUS Simpson is a very impressive piece of engineering and is simply much better implementation of a highly printable delta printer. The GUS Simpson is practically an inverted delta which removes the need for large frame like the IcePick Delta uses.

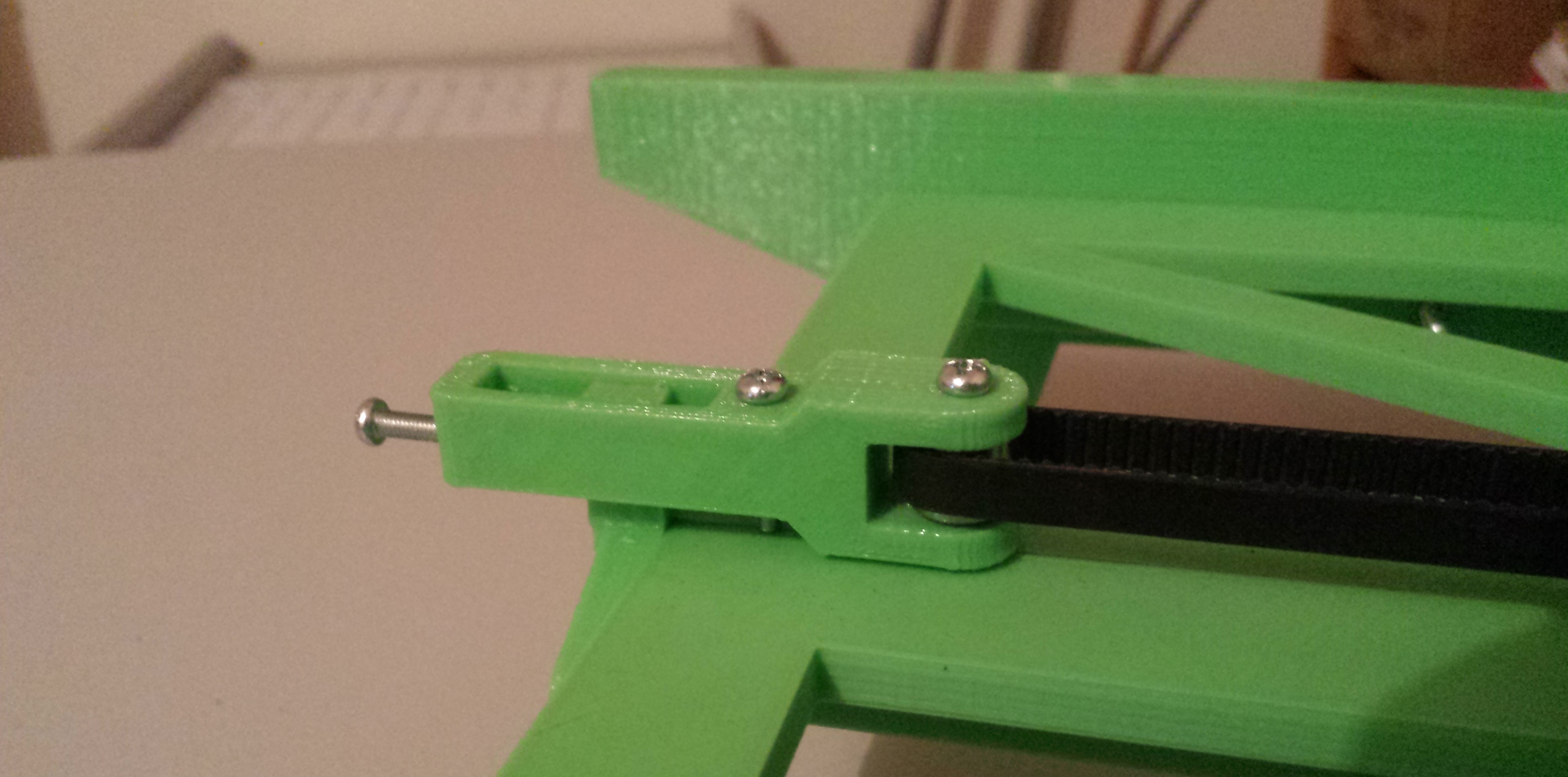

Still the problem remains: How can a Reprap be made, so that it can create its own motion system, and still maintain dimensional accuracy when replicating?

I spent a lot of time looking at other designs, trying to come up with an original solution. Some are rather beautiful and elegant pieces of engineering. In my opinion notably: the GUS Simpson, Reprap Morgan and Wally. I eventually came to the conclusion that there are no such Reprap's as of now that can print its own motion system while remaining dimensionally accurate or easy to calibrate as it replicates from generation to generation.

As an example, what if I had an Icepick Delta, a Reprap Morgan or a Reprap Wally printer and the pulley radius has a slight error in the pulley, the next copy of the machine that is printed will now have more than the original error in the radius of the new pulley. As the machines produce copies of itself, are printed this error will increase exponentially. This is a core issue that must be tackled.

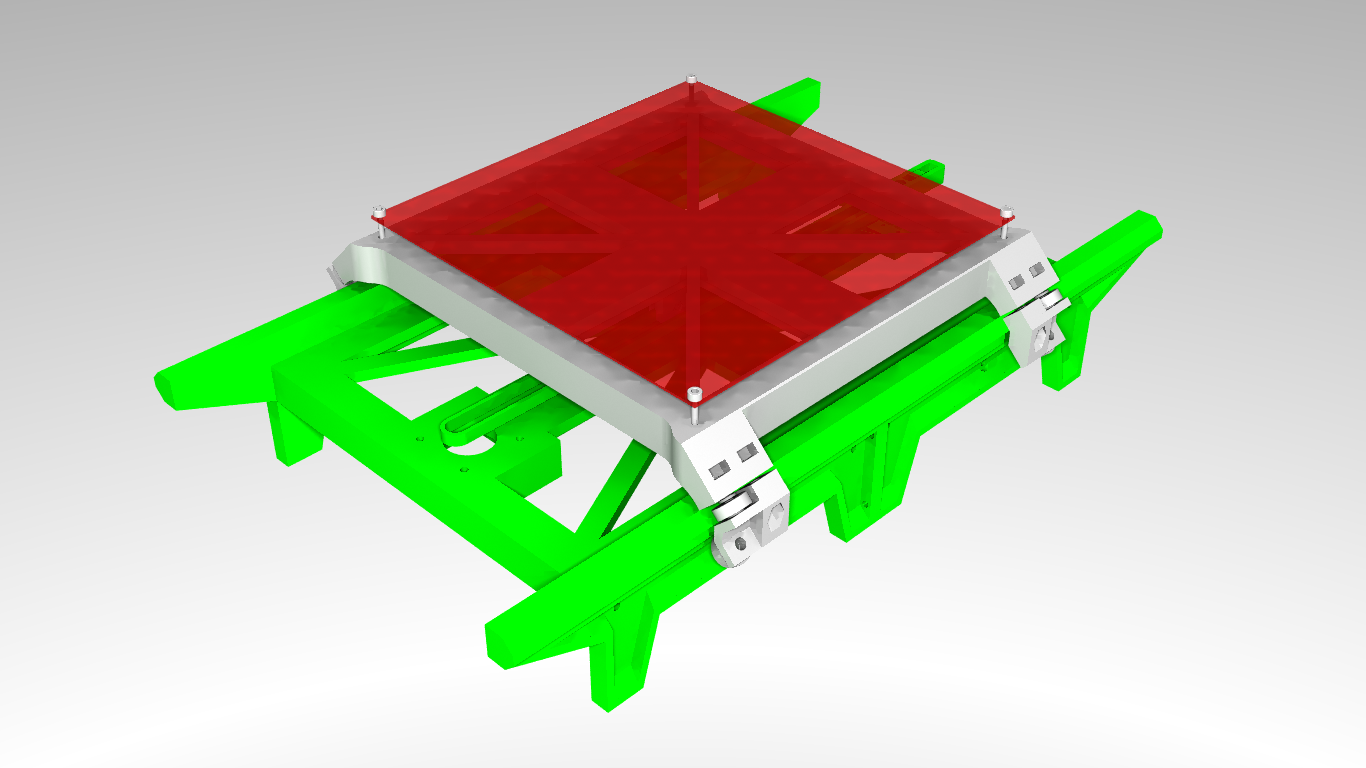

Reprap Neumann aims to tackle this core problem by using a very simple design. The problem on the afore mentioned printers that when there is an error, it is magnified. As explained before, the radius of the printer arms are larger than the radius of that pulley that was being used. To achieve a demagnification of error size, the radius of the point of rotation must be larger than the radius of rotation of the print bed. Although I do not think this is practical with the afore mentioned printers,...

Read more » TTN

TTN I'm using FreeCad 0.15 and povray for rendering. Both are free, open source and are available

I'm using FreeCad 0.15 and povray for rendering. Both are free, open source and are available

Benchoff

Benchoff

Malte Schrader

Malte Schrader

heinz

heinz