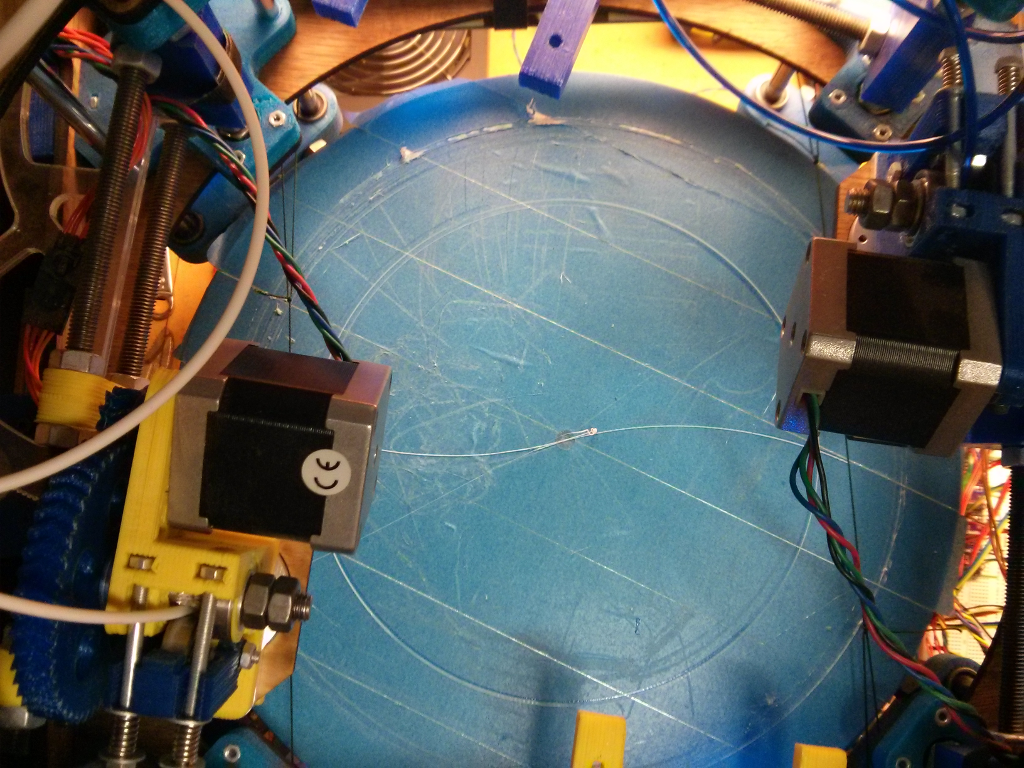

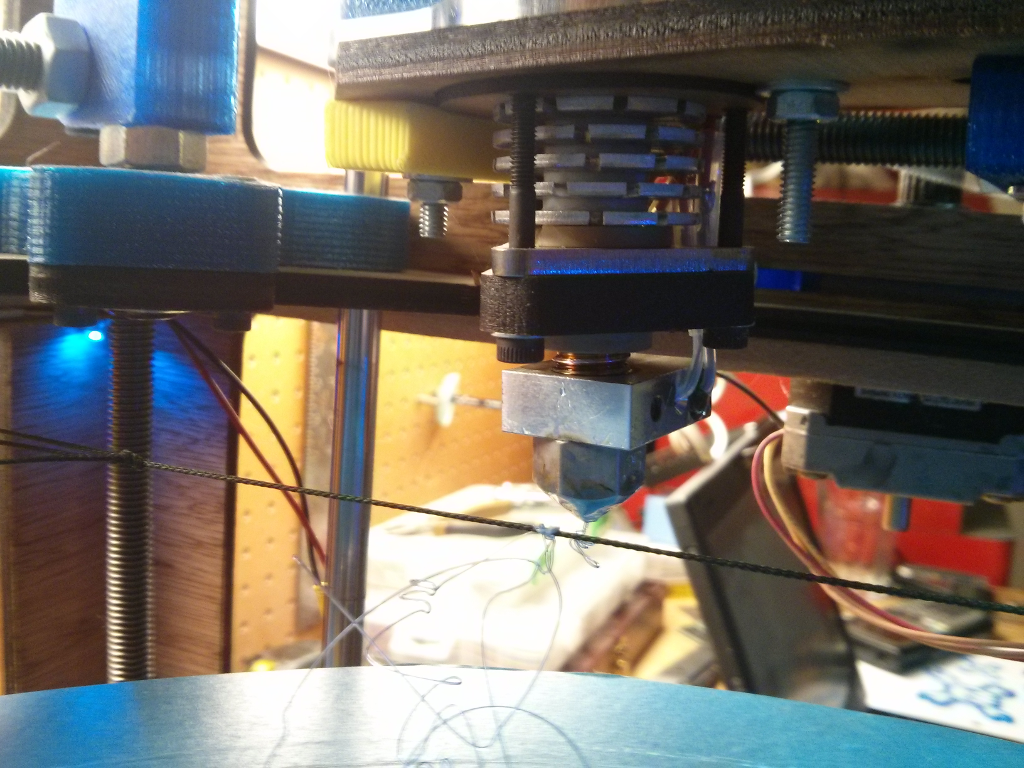

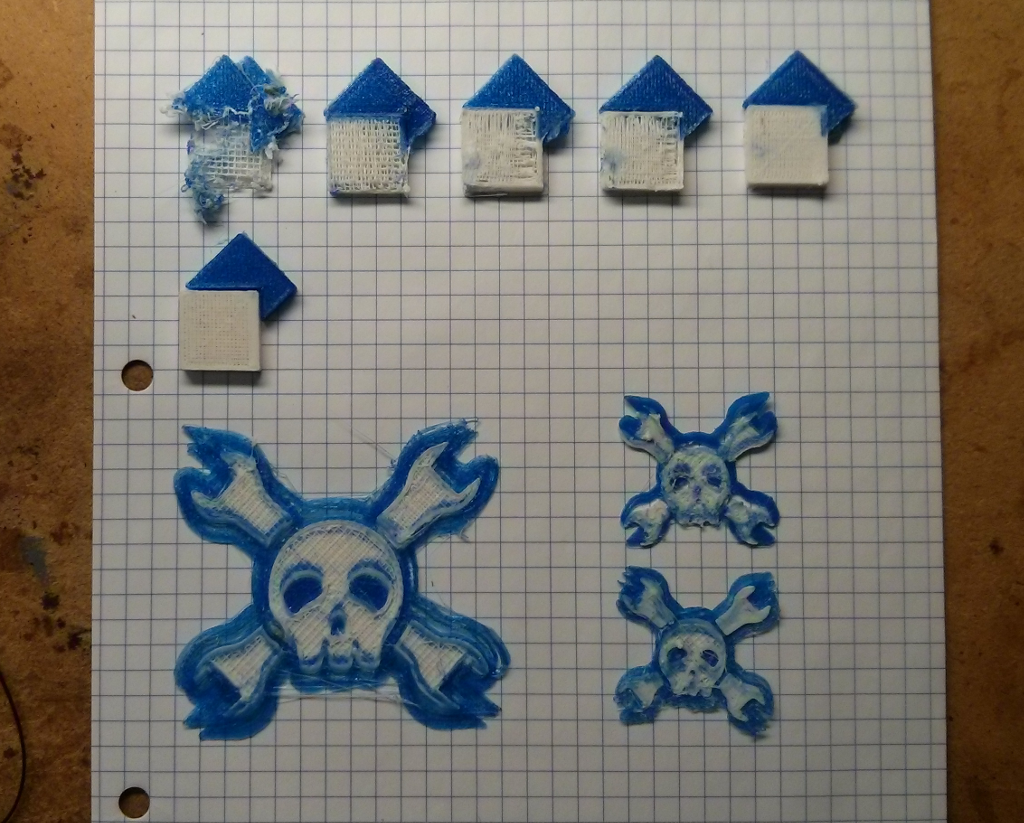

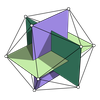

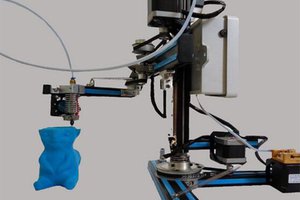

With most 3D printers, adding more extruders makes the machine slower and reduces the build volume. The Theta Printer overcomes this by using polar coordinates. A polar printer works kind of like an old fashioned record player. Your objects are printed onto a platter which spins. The advantage is that you can have many print heads. Each extruder is on the end of an arm which swings in and out. The spinning platter is called the ϴ ("theta") axis and the swinging arm is called the R axis. Together these replace the normal X and Y coordinates you're used to. A polar printer has a couple of advantages over normal cartesian 3D printers.

- Less moving mass means better acceleration

- Finer resolution, especially near the center

- Multiple toolheads without reducing build area

The spinning platform makes this machine ideal for integrating a 3D scanner. In addition, you can easily swap out an extruder for a mill or any other tool, making the Theta Printer the perfect all-in-one fabrication machine.

Specs

- 4 Extruders (Currently Greg's Wade Reloaded w/ Budaschnozzle 2.0 3mm/0.35mm)

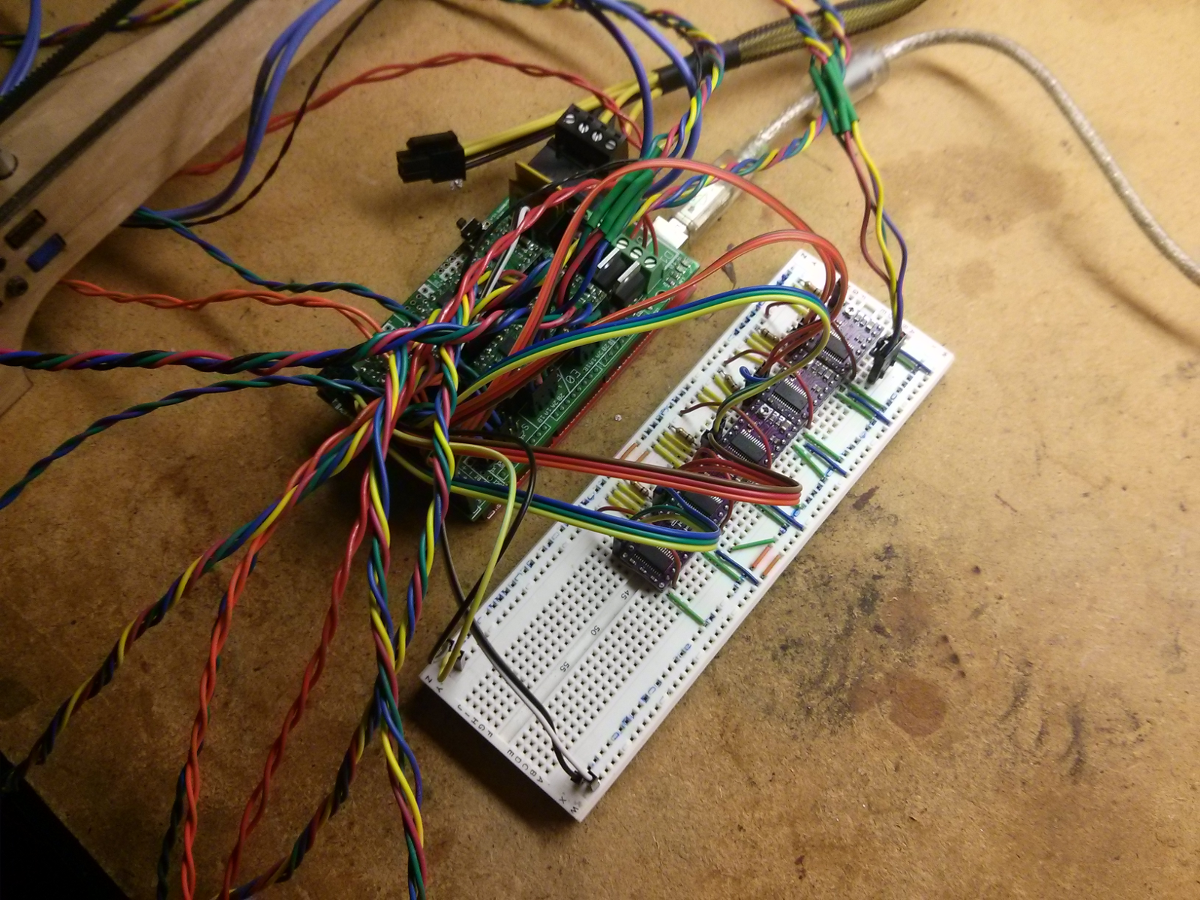

- Decapede Electronics, for driving 10 stepper motors

- Heated Bed

- Build Platter Diameter: 12"

- Z Height: 150mm

- Maximum Speed: 40 °/s

- Resolution: 190 microsteps/° (1/16 microstepping)

This machine is completely open source, under whatever license the RepRap project uses.

The complete parts list is on GitHub.

Tyler Anderson

Tyler Anderson

Mark Rehorst

Mark Rehorst

Jeremy

Jeremy

RobotDigg ME

RobotDigg ME

TTN

TTN

Do you have assembled unit? we could try our 3.5W and 5.6W lasers to install on this device...