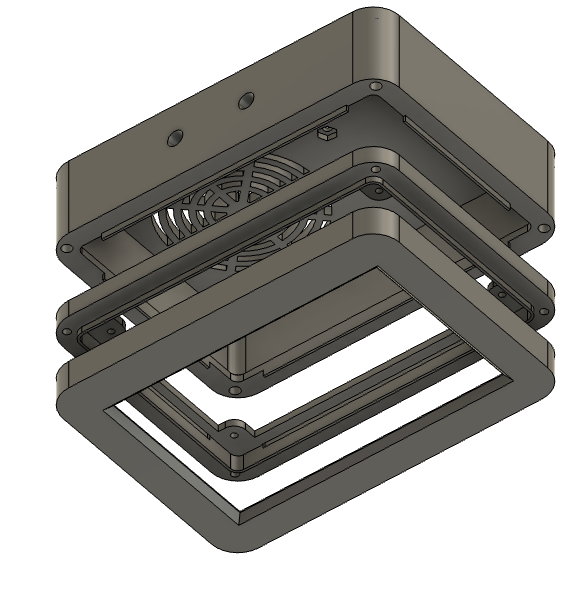

This project is a Raspberry Pi CM4-based, portable, touchscreen computer for remotely controlling settings on modern cinema cameras. It utilizes 900mhz HaLow communication for wireless bridging, connected to the Ethernet port of whatever camera is in use. The goal is for it to be robust, slick, and professional-looking.

Camera Control Tablet

RPi-based cyberdeck tablet with a 900mhz WiFi HaLow radio built in

max

max

J. Peterson

J. Peterson