So I've addressed the potential of

- insufficient cold-end cooling by just using a 6028 blower instead of a traditional 4010 axial fan

- material leaks during printing by using expanding ball plugs and an undercut to the M6 heatbreak threads

- uneven coating by using a centrifugal inlet design

and now I'm wondering what to do in the expectedly likely situation where one or more materials just aren't used for extended periods of time.

As Deckingman, an FFF hobbyist that's been at this multi-material problem for longer than I have, pointed out (somewhere on the internet but I forget where), no amount of cold-end cooling is going to prevent heat from simply conducting up the material itself. Another thing he mentioned that I didn't know about is that PLA hydolyzes. Not exactly sure what that is, but research suggests that it's a kind of degradation of the material, which isn't good for business.

His flagship hotend is a 6-in 1-out multi-material hotend:

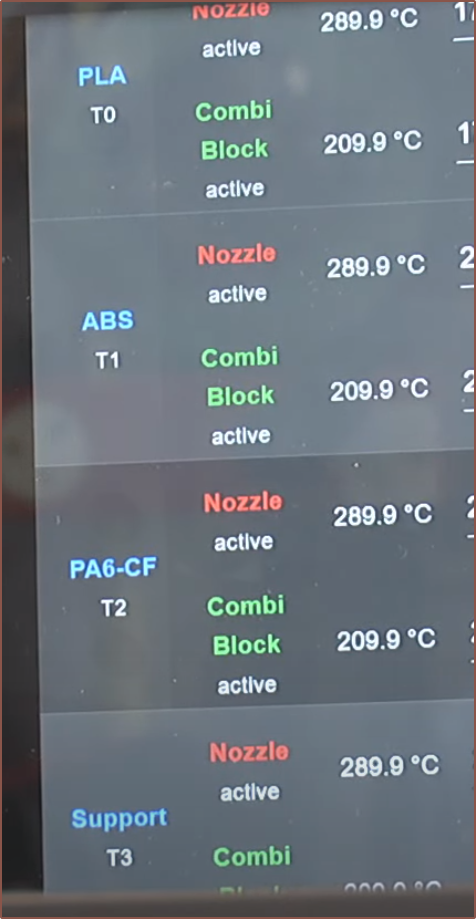

It looks massive and complex, but it can be split into 3 distinct sections: water-cooled cold end, combining block and heating block. Essentially, it sounds like the combining block is the only difference (in theory) from his design and a water cooled hotend:

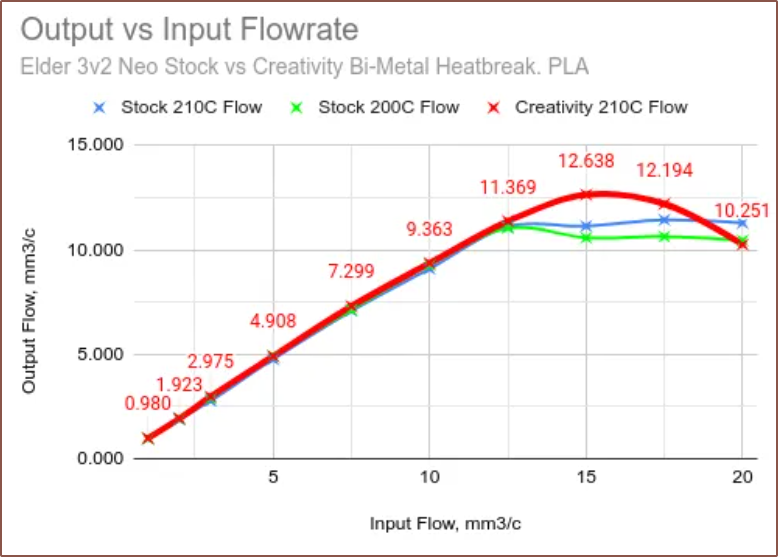

It sounds like all the tested materials (such as CF Nylon, TPU and ABS) can get through the combination chamber whilst it's hovering around 210C (see image below). This allows PTFE lined heatbreaks to still be used. My only concern is with PBT, which has a higher Tg and lower print temperature than most.

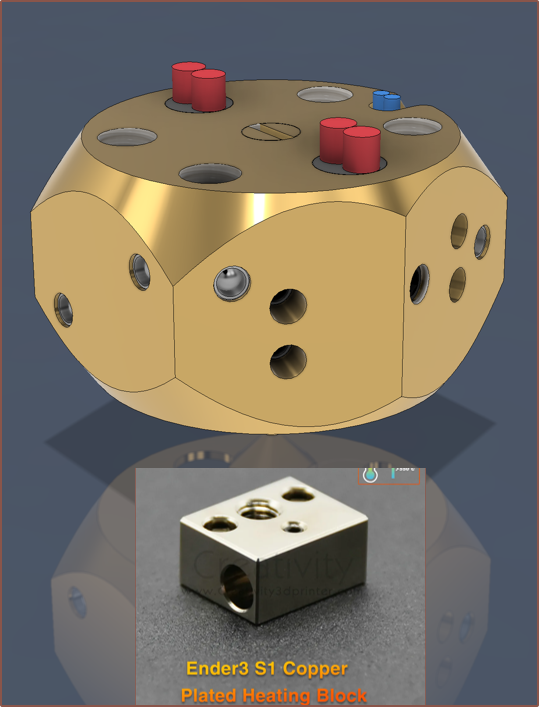

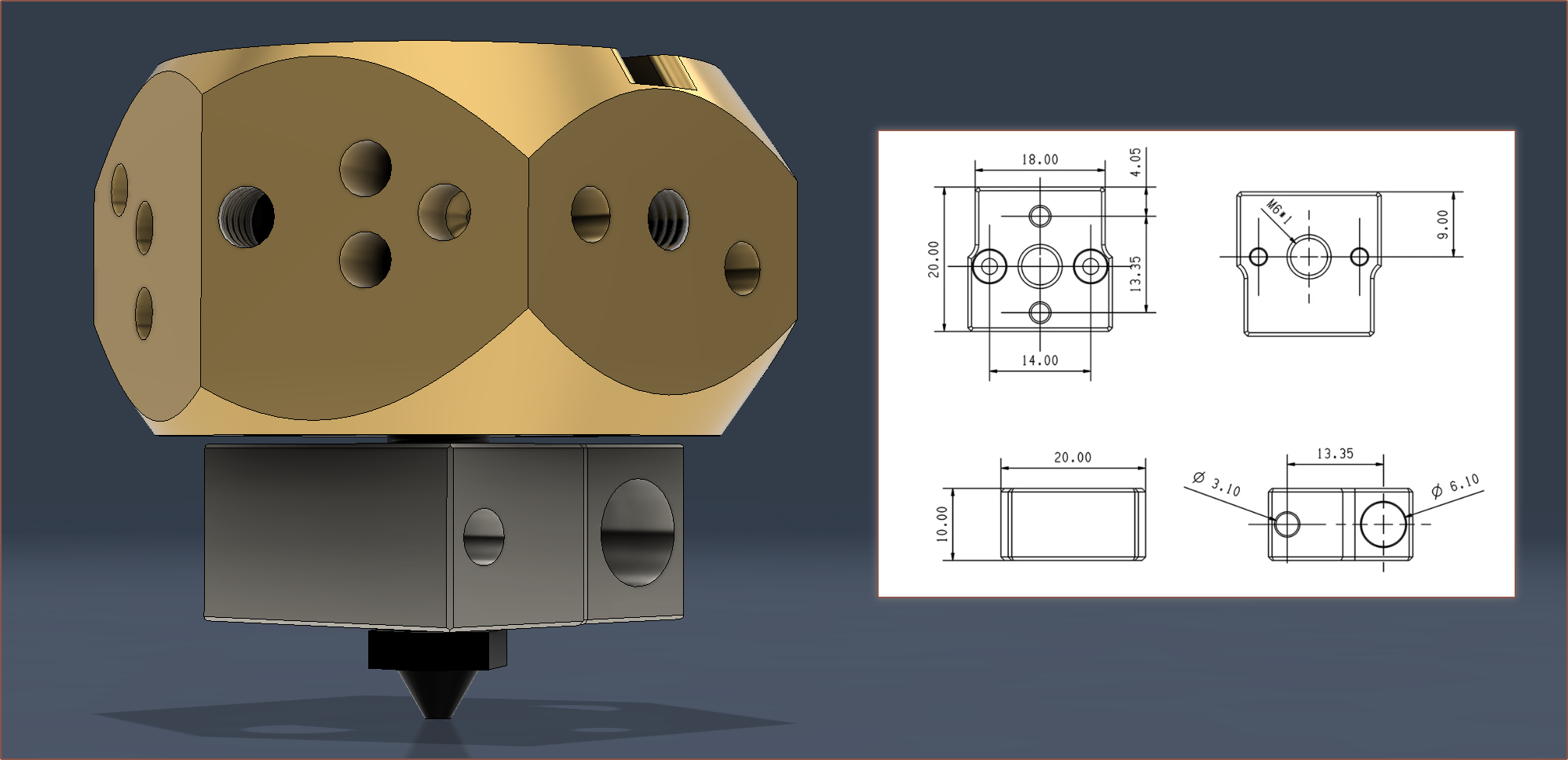

For the coaxial heatblock, it sounds like all I do is take a standard brass or copper heater block (that supports 1 handed nozzle changes) and I put it where the exit of the coaxial heatblock is:

They're like £5 on AliExpress. I would've liked to see a block with a cartridge thermistor but ATM I can't find one.

Scrolls down to bottom of the very next page

Hey hey hey!

Now, what I wasn't expecting is how much hotend advancement has happened while I was preoccupied with all my other projects.

There's now a hotend that's like the Trianglelab ceramic one, but it has 2 screws to bolt into the heatsink to facilitate 1-handed nozzle changes:

There are now copper nozzles with hardened steel inserts:

There are now nano-coated heatbreaks, which may be useful to prevent clogs:

For the connection between the coaxial hotend and the additional hotend, a possible strategy could be to take the Ender3 S1 heatbreak, fillet 2 sides for a wrench and add M6 threads to it.

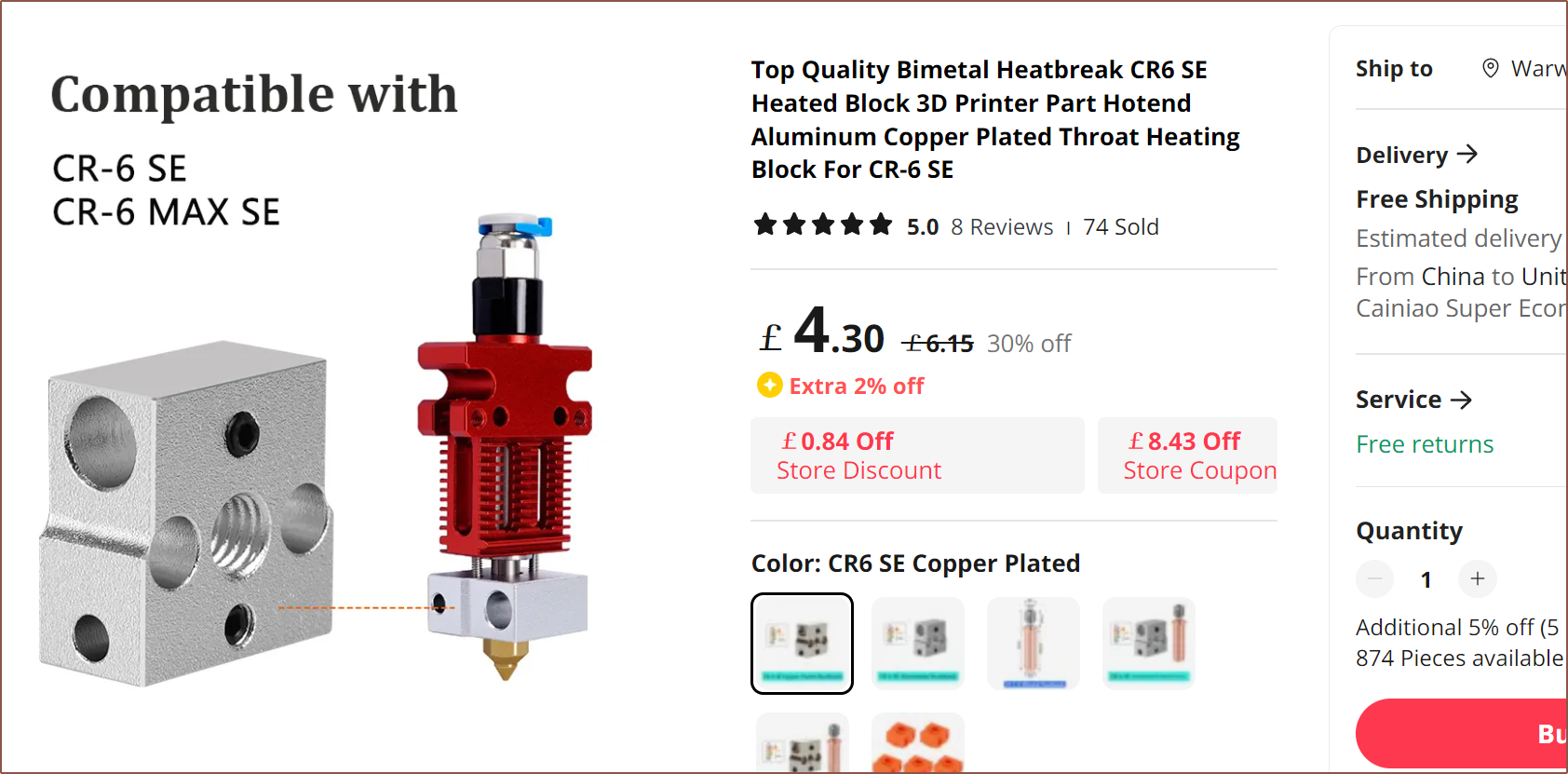

Alternatively, a volcano nozzle is used instead and any heat block short enough to fit inbetween the end of the nozzle and the bottom of the coaxial heatblock is used. A hardened steel nozzle should probably be used as it'll conduct heat less. The block would have to be 10mm or thinner, considering that the CR-6 SE block only has 0.5mm a side of space!

The brass heatblock is 143g and the copper heatblock is 24g.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.