Parts to upgrade from 4-in to 8-in

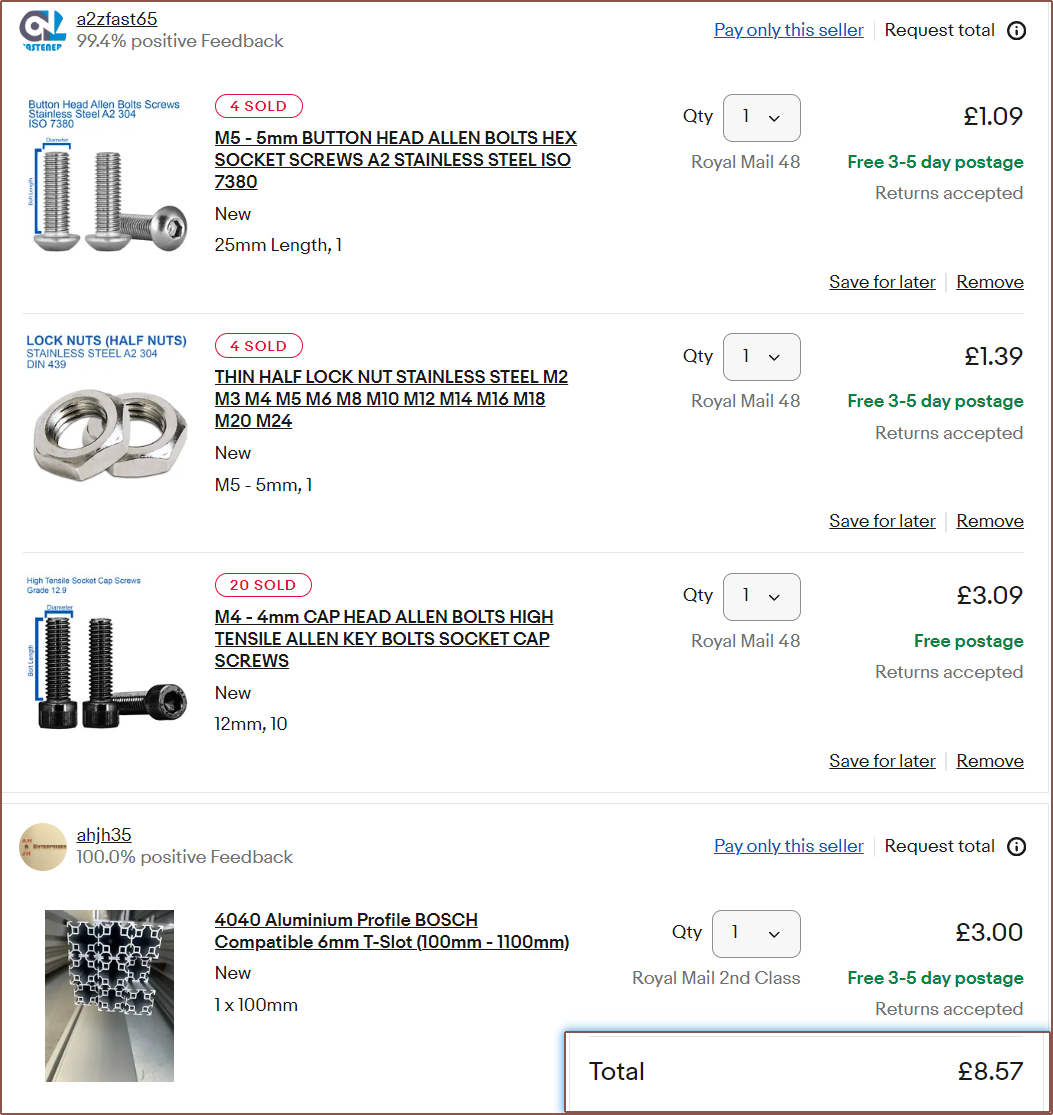

Ebay

I just need 12mm M4's for the clamp plate and I'll be replacing the 2040 100mm extrusion with 4040mm as I plan to use Nema17s that are half the thickness (and hopefully weight) as the 4 steppers I have now and use mirrored BMGs. I also need clearance from that X-gantry bolt that sticks out. More about that below.

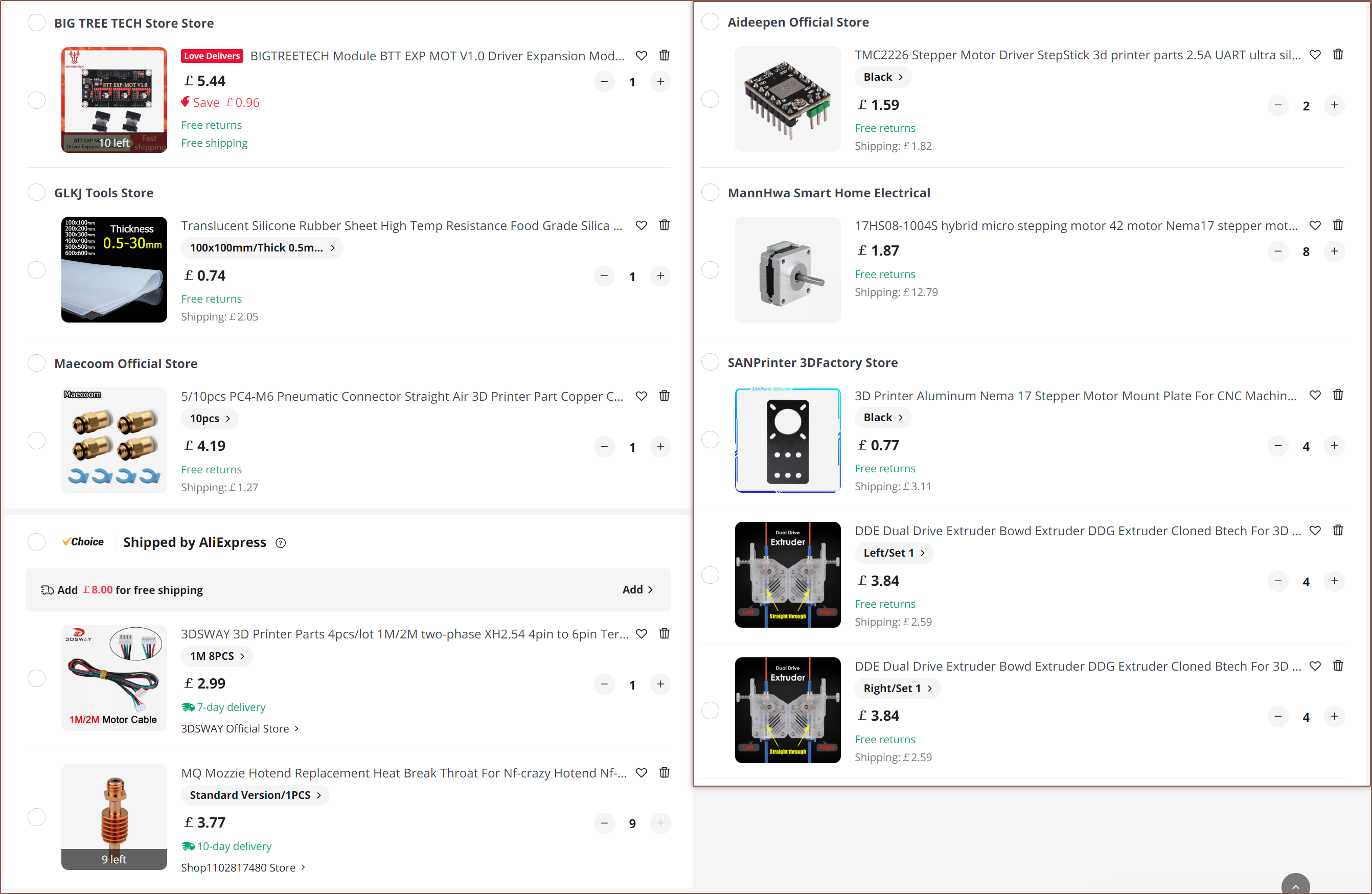

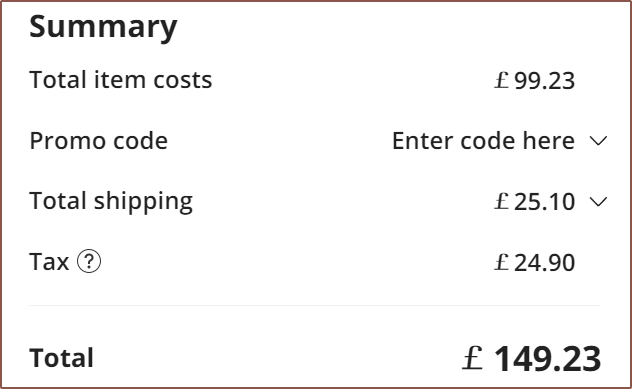

AliExpress

Some quick things first. I've only got 6x2209s so I need to get another 2 stepper drivers for the extruders (and the 2226s are the same thing in a different, larger package that theoretically dissipates heat better). I couldn't see any cable at all in any of the motor images so I just added 8pcs of cables in the basket (which are also the right connector, instead of Dupont that 3 of the 4 motors use).

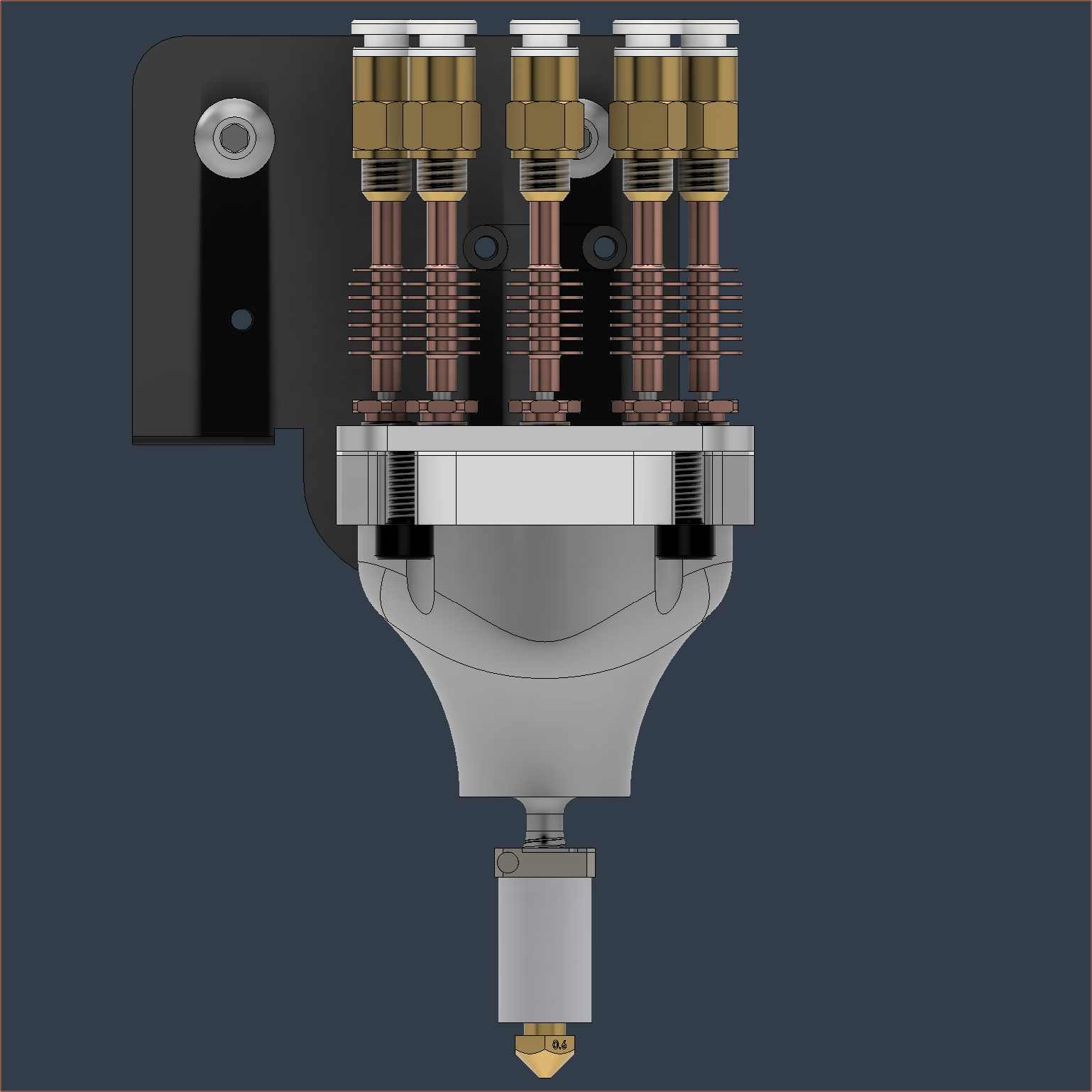

Let me start with the PTFE tube situation. I can't use compression fittings unless I want to also increase the distance between heatsinks, thus both a larger hotend and higher costs. The KJH-04-M6 bowden couplers were the only ones that also have the same 8mm across-flats hex. They conveniently also have a 2.8mm exit hole which should pair perfectly with the estimated 2.65mm tops of the heatsinks. I found a good image to use as a reference for CAD and modelled it:

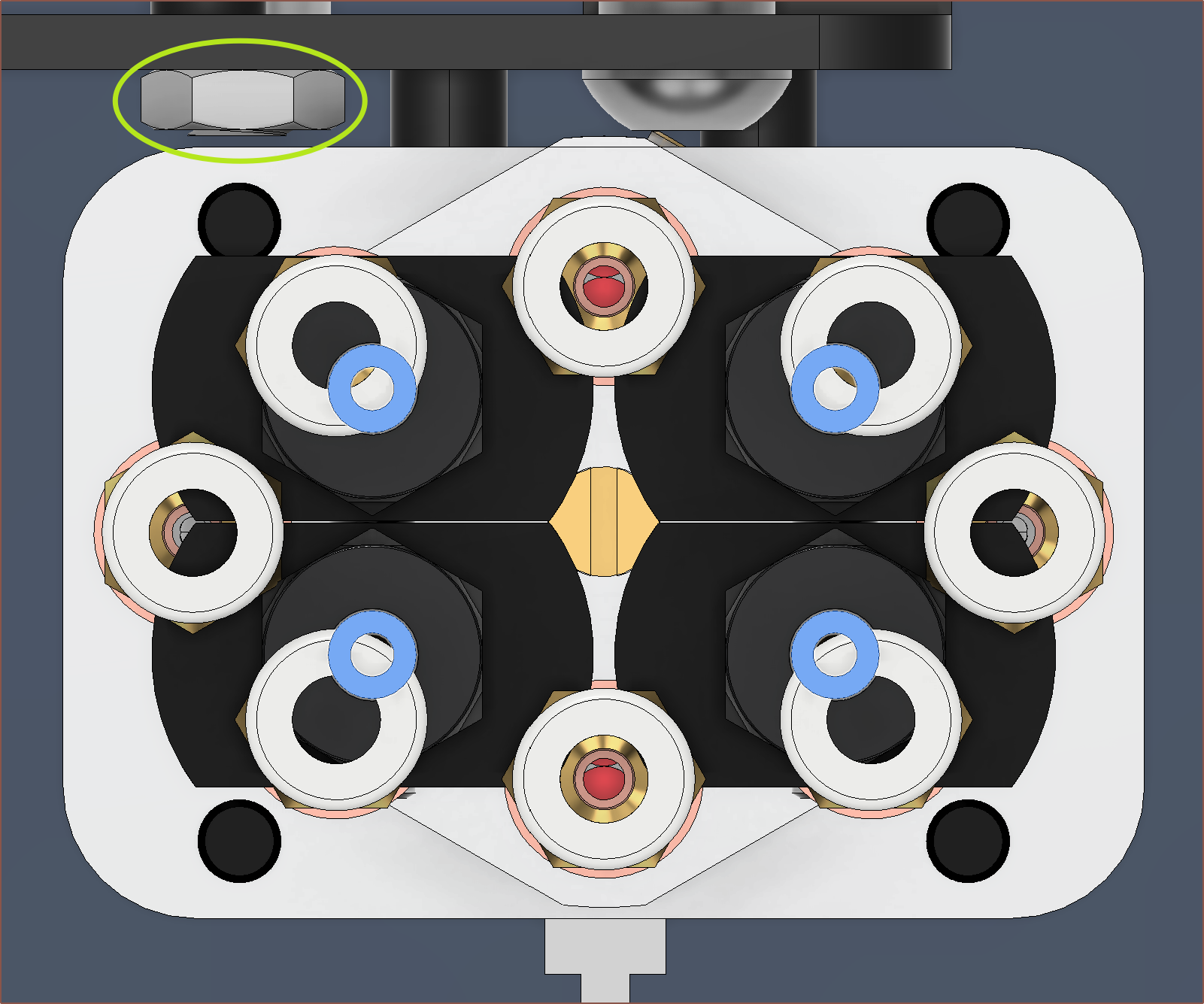

If you want to see the difference, look at the below image with the 4-in inputs highlighted in blue. It's almost as if the extra 4 inputs were just squished inbetween the original 4. Also notice the bolt circled in line green. With a M5x25 bolt and a DIN439 thin bolt, I believe I can get the space I need to mount the hotend with minimal loss of Y.

For the extruder, I've gone with 4pcs of both left and right of the "DDE" extruder because they're half the price I was expecting to pay for more BMGs, they look nice (cool diagonal lines and no "extruder" sticker), they're translucent (so I should potentially be able to see the filament pass through when loading/unloading), they come in both left and right variants (unlike some similarly priced BMGs) and it's from a reputable AliExpress store that I believe make high quality stuff.

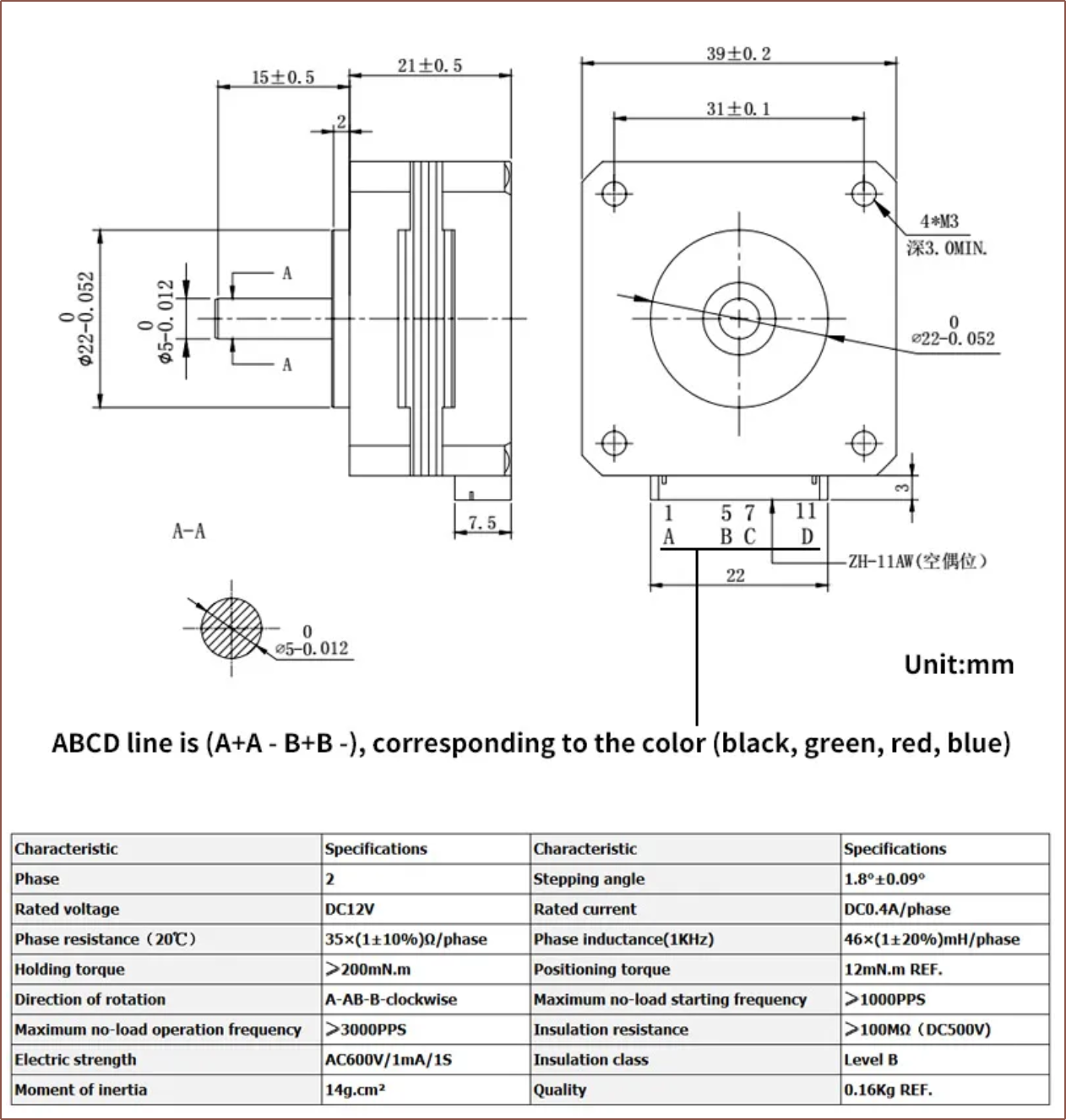

The extruders are to be powered by 0.4A Nema17 motors at the lowest price I've ever seen for Nema 17s. Since the BMGs 3x the torque and the amount of force required to extrude at higher speeds seems to increase exponentially anyway (meaning that a 2X stronger motor may only increase throughput by 1.4X, for example), I think they'd be ideal for moving filament. I'm planning to run them at 300mA, which is half the current I've run the current extruders. Other than the shaft being a plain O instead of a D, I think this solution is ideal as it means that I can place all 8 filaments on the same side of the printer.

Marlin

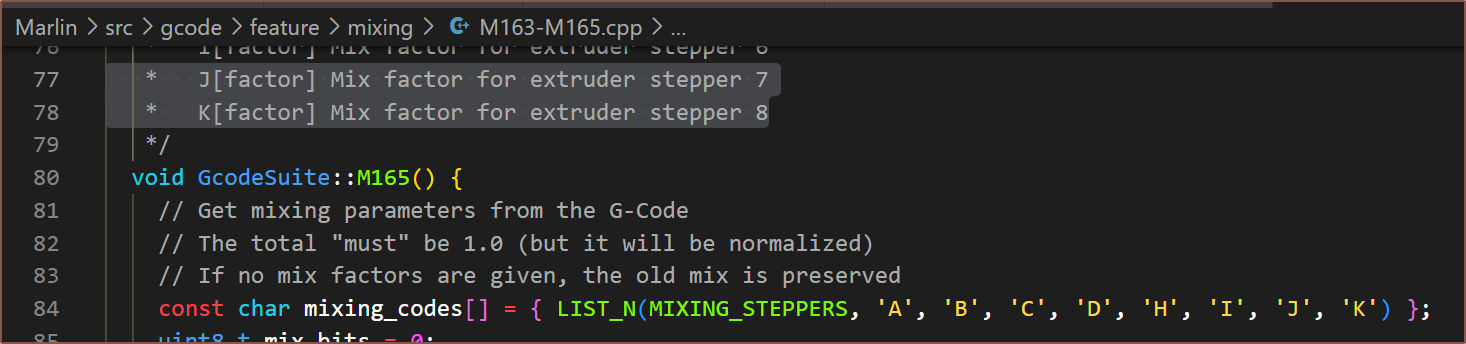

For some reason, Marlin supports 8 extruders. I've looked around and I don't think a single printer comes close to that number, so it's very convenient that the Marlin devs are looking ahead. For some reason though, M165 officially only supports 6 of the 8 extruders, even though mixing hotends support the full 8. It's a very easy patch though:

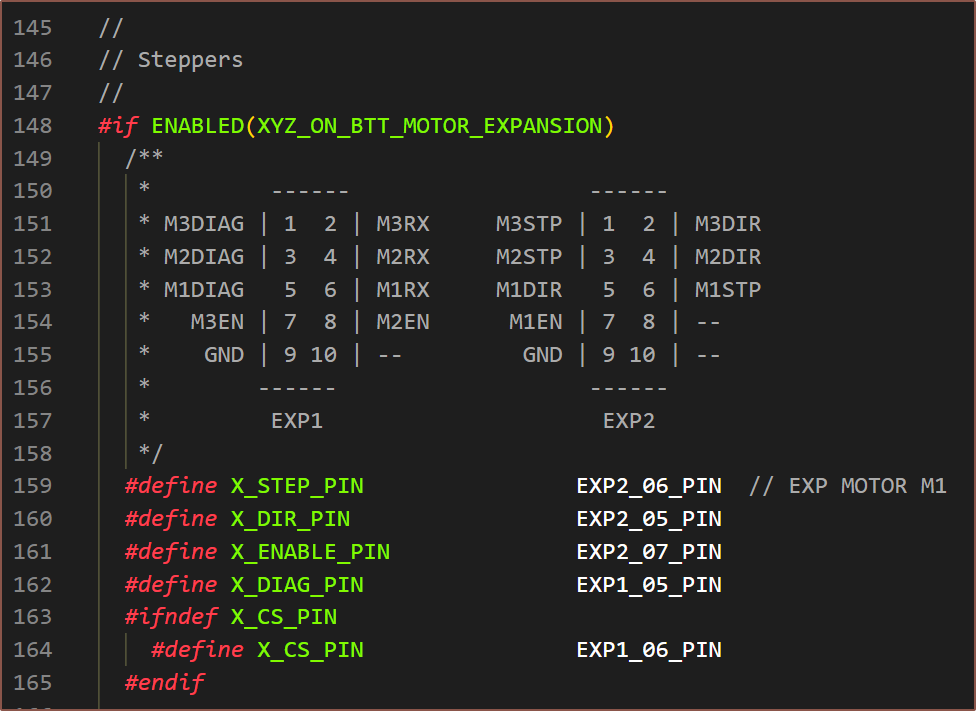

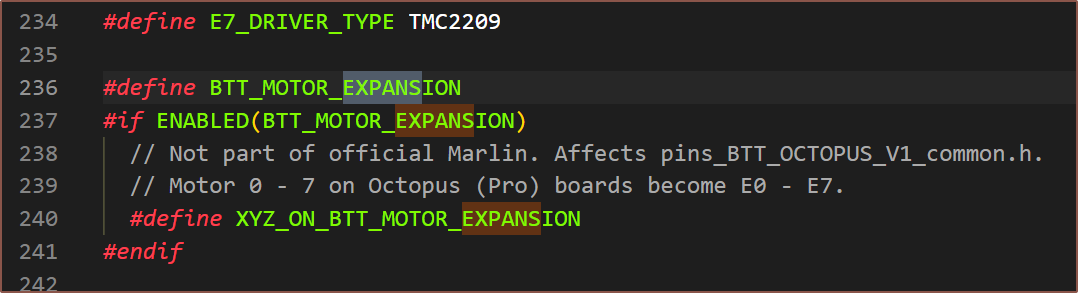

What was a bit more tedious to implement was the pin reconfiguration so that all the extruders were on the Octopus Pro and XYZ was on the EXP MOT. The trip-ups mainly stemmed from TMC related pin setup of DIAG or UART pins being in separate parts of the file and not with the stepper definitions, thus I had to move them.

Under all the stepper driver definitions, I've added a few lines in the config:

Obviously, I'll have to turn off all LCD features and rely on the touch screen interface.

Conclusion

It does seem that, if starting from a typical £399 FFF 3D printer in the CR-10/Ender 3 style, upgrading to this 8-in-1-out is going to be something in the ballpark of another £300. However, I think that the value is still there if there was a hypothetical listing of an 8-extruder printer priced at £699 if the hotend works as intended with features such as:

- allowing for a spectrum of colours without having to buy a spool each time

- the potential for increased mechanical properties such as increased inter-layer strength, potentially allowing ABS to be printed in the open without delamination.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.