-

CoreXY Mechanism

04/25/2021 at 14:35 • 0 commentsCoreXY Mechanism

![CoreXY Mechanism CoreXY Mechanism]()

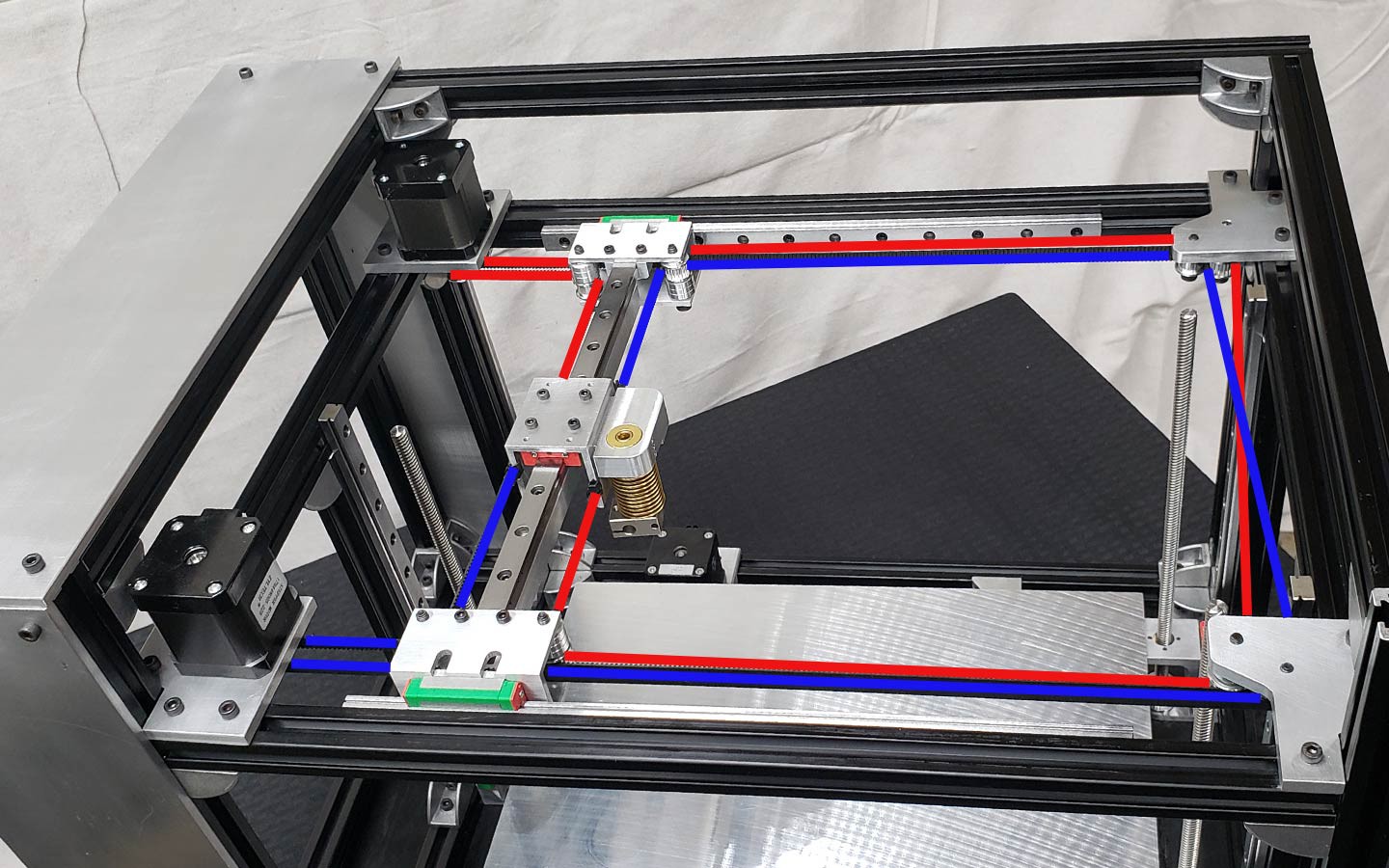

CoreXY Mechanism CoreXY Kinematics

The corexy parallel kinematics mean's that the motors are the largest source of inertia within the system, and are stationary. This means rapid acceleration because the two stepper motors provide a means of moving both axes independently or simultaneously. The major benefit of the design is that the motors remain in a static position.

The corexy kinematics is a complex motion system where X or Y motors move together or opposite of each other to move the carriage from left to right or towards or away . If you were to move just one motor you would see the print head move diagonal.. If the two motors move opposite of each other the print head will move along the X-axis, If the two motors move in the same direction the carriage will move along the Y-axis.

Belt Path

A printer’s motors can be offset at different heights so that the belt routing runs a straight belt path and doesn't have to be twisted. But this belt routing path would also mean that on one side of the gantry the belt would have the teeth on the side of the idler wheel which wouldn’t run as smooth and could lead to artifacts within printed parts.

Motor Movement

- Both Motors Move Clockwise >> Carriage Moves Left

- Both Motors Move Counter Clockwise>> Carriage Moves Right

- Both Motors Move Opposite of Each Other>> Carriage Moves Toward & Away

- One Motor Moves>> Carriage Moves Diagonal

Also See:

-

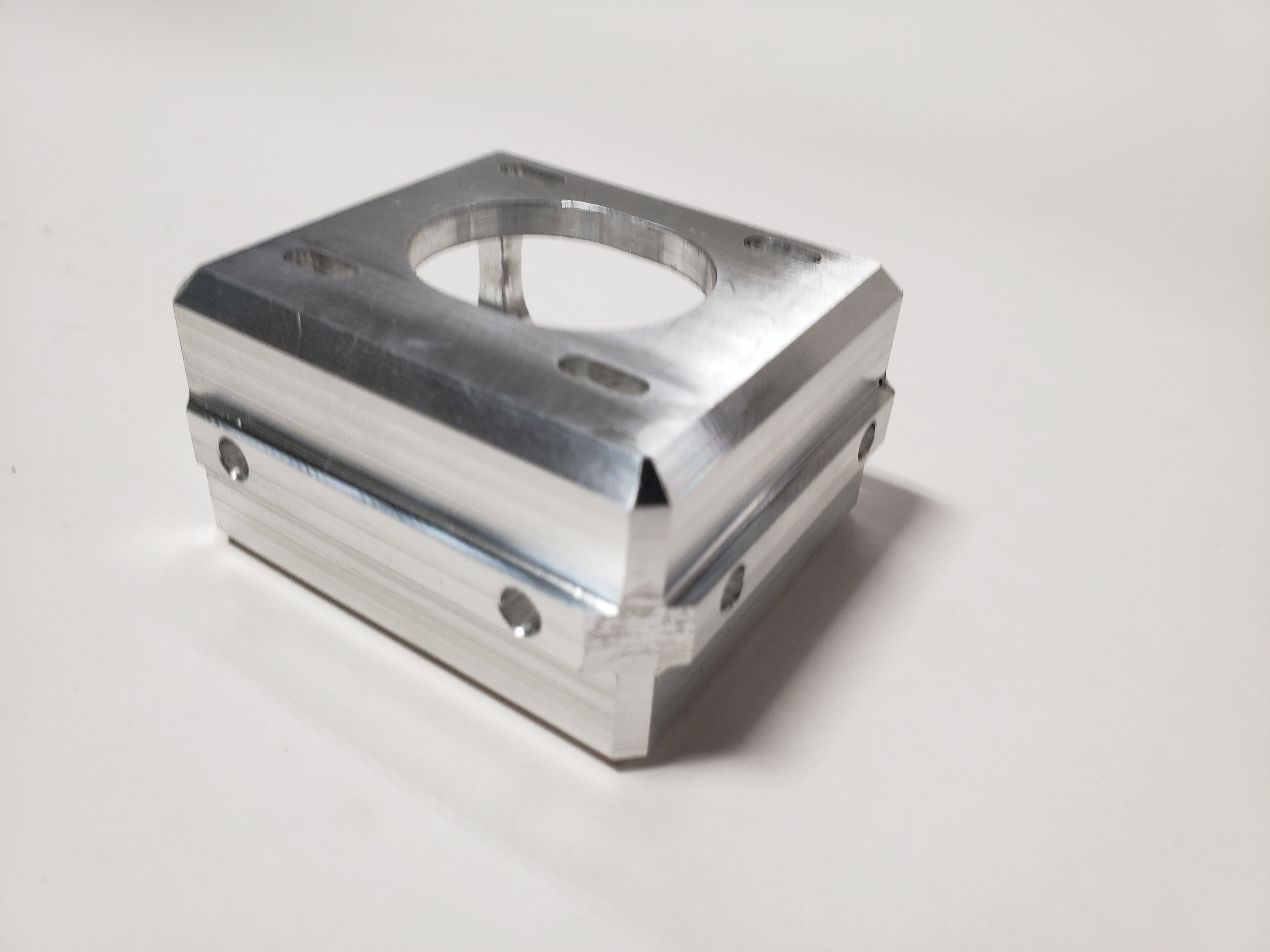

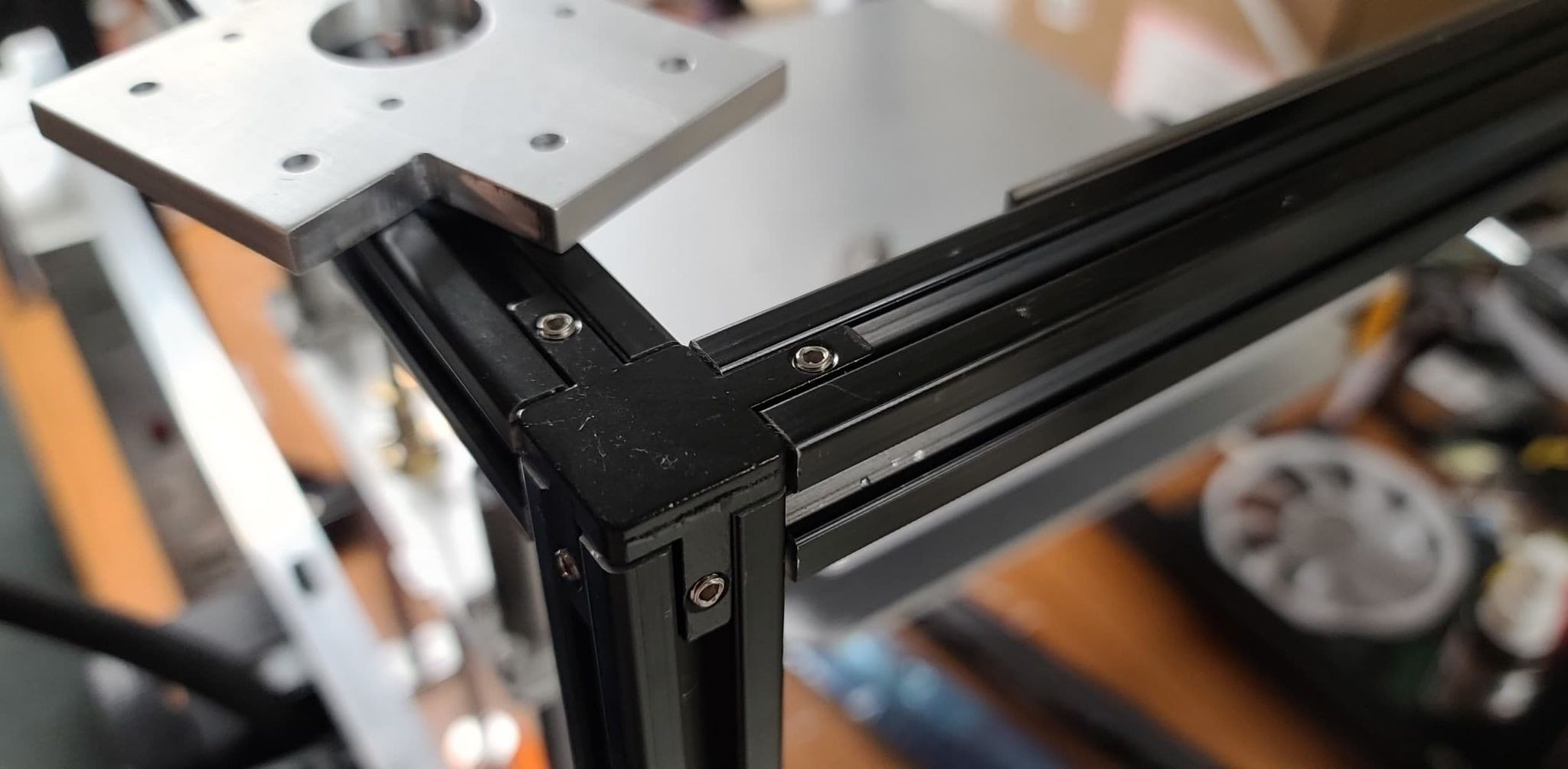

CoreXY Motor Mounts

03/24/2021 at 02:14 • 0 commentsI've been working on a modular and scalable corexy design called the SolidCore for over a year now. The plan is to have a platform or ecosystem of parts that can be used on any 3d printer that uses 2020 frame extrusion. The original motor plate had a 20mm cut out to seat in the corner of the frame. One of the problems I ran into was that many of the frames use square corner brackets that don't have the clearance needed in order to mount the motor plate mount. So I'm designing a motor mount that mounts within the inside of the frame instead of on top of the frame.

![]()

![]()

Before

![]()

The old SolidCore motor and idler mounts worked great but limited the number of frame extrusion bracket options.

![]()

![]()

Many of the new frame brackets or connectors use an endcap style connector.

After

![]()

![]()

Frame Rigidity

![]()

I was planning on scaling up to a 3030 mm frame extrusion on the next larger corexy build. With the components mounting within the frame adds more rigidity to the frame.

![]()

![]()

![]()

![]()

![]()

Download 3D Model

-

CoreXY Belt Path: Crossed Belts vs Stacked Belts

02/19/2021 at 00:45 • 0 commentsCoreXY Belt Path

![]()

CoreXY Diagram

Belt Path Crossing

While the SolidCore 3D Printer design had a lot of influence from the Railcore's design, which also has the "x" shape belt path that some say “serves no purpose.” True, but you see the quality prints that the Railcore community is putting out. The print quality of the RailCore is AMAZING! Although the belts don't have to cross if the pulleys are at different z-levels. I originally thought that the difference between the hbot core xy design was that the corexy belts crossing segment.

We already designed and built the SolidCore with the crossed belt path so we're going to stick with it for now. Later on after many performance tests I'll try out some other design configurations to test out any changes.

Hbot vs CoreXY

The difference between hbot and corexy is that hbot has a single belt on a single plane, corexy can have either two non-intersecting planes or a single plane with pulley idlers on different levels which keeps the belts from rubbing.

While the Hypercube has the stacked belts on different planes configuration unlike the SolidCore corexy configuration "x" crossed belts.

Stacked Pulleys

Offsetting the stepper motors with stacked belt path pulleys may give the belts a clean run and simplify belt alignment. A printer's motors can be offset at different heights so that the belt routing runs a straight belt path and don't have to be twisted. But this belt routing path would also mean that on one side of the gantry the belt would have the teeth on the side of the idler wheel which wouldn't run as smooth and could lead to artifacts within printed parts.

SolidCore and RailCore Crossing Belt Segments

![]()

While many frown upon the crossed belts configuration found on the Railcore or SolidCore due to the y-axis could possibly bind if the y-axis isn't completely perpendicular to each other.

Linear Rail: Supported vs Unsupported

I'm using a crossbar made from u-shaped aluminum extrusion. Depending on the rail length if the y-axis has an unsupported linear rail it could possibly lead to deflection. The load of the belt paths have to be balanced along the running plane with the pulleys. An unbalanced load can lead to the belts trying to slip off the pulleys and premature wear of the bearings.

This user joined on 08/04/2016.

My Pages

Things I've Built

WorkHorse 3D Printer

The WorkHorse 3D Printer is a large scale XYZ-Axis lead screw driven printer with a fixed bed

Projects I Like & Follow

In this project, I make a big size 3d printer 400 x 400 x 400 mm for a collage project.

Share this profile

ShareBits

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Shane Hooper

Shane Hooper

Lutetium

Lutetium Dominik Meffert

Dominik Meffert Andrey

Andrey Amadon Faul

Amadon Faul Simon Wirz

Simon Wirz SarkstiR

SarkstiR rockfishon

rockfishon Shiny

Shiny Desi Engineer

Desi Engineer Nickcasio

Nickcasio Sarah Petkus

Sarah Petkus Fairhopeguy

Fairhopeguy Roy Berntsen

Roy Berntsen Himanshu Sharma

Himanshu Sharma Eric Cantrell

Eric Cantrell Chris Amanse

Chris Amanse eeRoots

eeRoots