In the industry, they use 13.56mhz for all plasma things, a free ISM band. But all the 13mhz equipment is so expensive.

In the industry, they use 13.56mhz for all plasma things, a free ISM band. But all the 13mhz equipment is so expensive.

And about the only thing 10 meters is good for right now, lol

And about the only thing 10 meters is good for right now, lol

Yeah, RIP

Yeah, RIP

![]() Give it a few years! (hopefully)

Give it a few years! (hopefully)

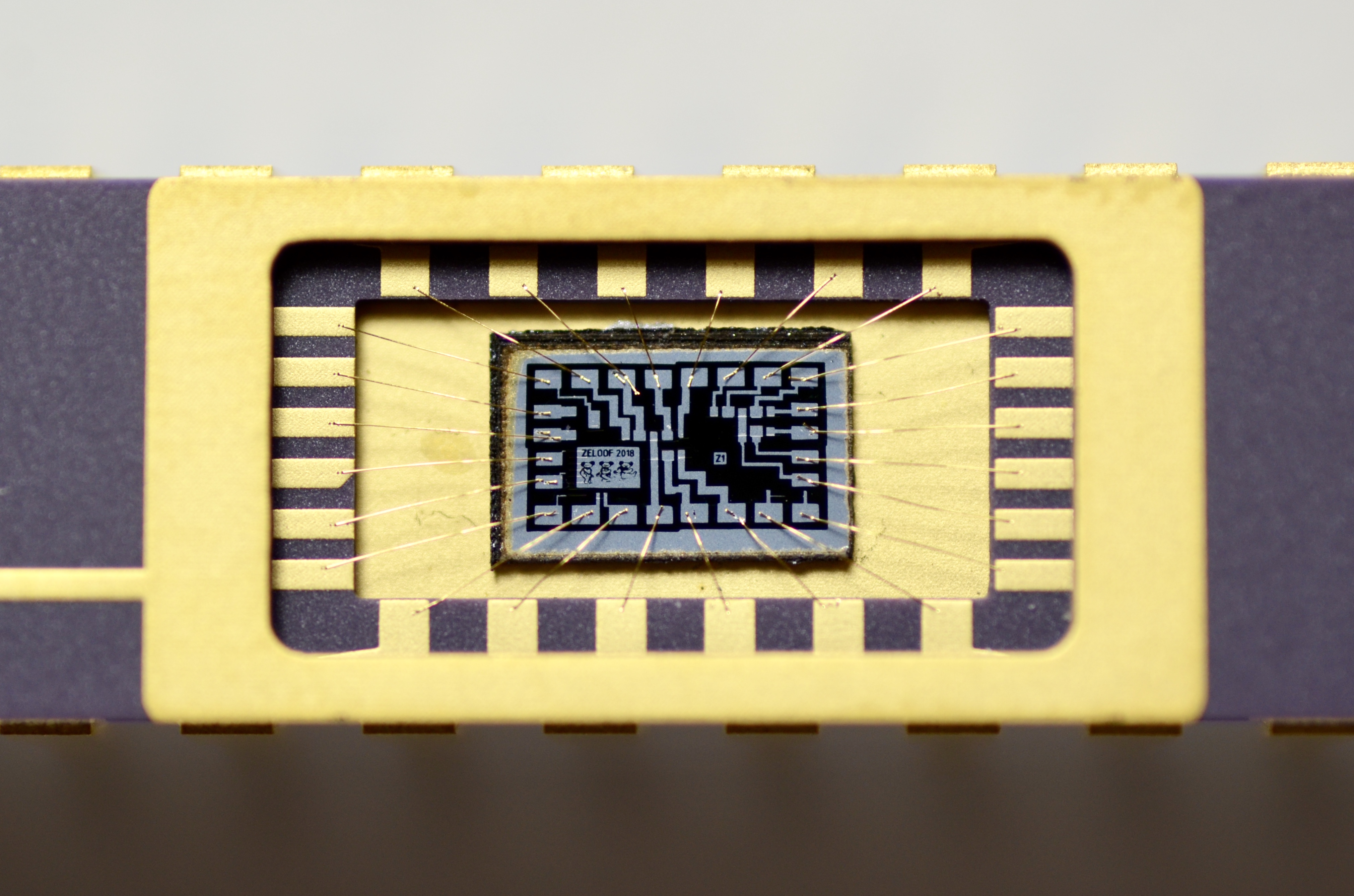

![]() @Sam Zeloof what would one expect to spend on a setup like your's

@Sam Zeloof what would one expect to spend on a setup like your's

I don't think the next solar upswing is going to be much to write home about, but maybe.

I don't think the next solar upswing is going to be much to write home about, but maybe.

Hard to estimate, I picked up things like a SEM which aren't strictly necessary, but in hindsight you can make basic ICs (probing only or flip chip, no wire bonding) in the low thousands of dollars without stressing too much

Hard to estimate, I picked up things like a SEM which aren't strictly necessary, but in hindsight you can make basic ICs (probing only or flip chip, no wire bonding) in the low thousands of dollars without stressing too much

That's pretty approachable. Hmm....

That's pretty approachable. Hmm....

@nixie_guy on twitter is doing amazing things, made his own diffusion furnace and a small acrylic vacuum chamber for sputtering copper, all of that costs in the hundreds of dollars

@nixie_guy on twitter is doing amazing things, made his own diffusion furnace and a small acrylic vacuum chamber for sputtering copper, all of that costs in the hundreds of dollars

![]() @Sam Zeloof how much did you pay for the SEM

@Sam Zeloof how much did you pay for the SEM

One question: Now that you have access to "real" fab equipment, do you ever find yourself saying, "Man, I wish I had my xxxx instead of this fancy thing"?

One question: Now that you have access to "real" fab equipment, do you ever find yourself saying, "Man, I wish I had my xxxx instead of this fancy thing"?

can confirm. sputtering is cheap. most expensive part by far is the vacuum pump(s). the rest can be done in a mason jar

can confirm. sputtering is cheap. most expensive part by far is the vacuum pump(s). the rest can be done in a mason jar

@itsallgoodjames not much, it was thrown out by the university of south carolina and was broken. Look on ebay, the hardest part is transporting them

@itsallgoodjames not much, it was thrown out by the university of south carolina and was broken. Look on ebay, the hardest part is transporting them

@thethoughtemporium - No implosions yet? The comments on that article I wrote seemed to think you were doomed for using plain old jars.

@thethoughtemporium - No implosions yet? The comments on that article I wrote seemed to think you were doomed for using plain old jars.

![]() Is it possibly to use standard refrigerator pump for sputtering?

Is it possibly to use standard refrigerator pump for sputtering?

@Dan Maloney the "real" fab equipment is so nice and I'm lucky to have the amount of freedom at school that I do, but it is different than working in your own lab for sure. Harder to get away with stupid ideas and missuses of tools!

@Dan Maloney the "real" fab equipment is so nice and I'm lucky to have the amount of freedom at school that I do, but it is different than working in your own lab for sure. Harder to get away with stupid ideas and missuses of tools!

@moh.mohx1000 no. even a decent mechanical pump isn't really that great on it's own. ideally you need a proper 2stage rotary vane pump, and then some secondary pump. diffusion pumps are classic, but im looking into titanium getter pumps as they are buildable in theory

@moh.mohx1000 no. even a decent mechanical pump isn't really that great on it's own. ideally you need a proper 2stage rotary vane pump, and then some secondary pump. diffusion pumps are classic, but im looking into titanium getter pumps as they are buildable in theory

@thethoughtemporium you mentioned in your vid that this pump didn't work for sputtering https://www.amazon.com/ZENY-Single-Stage-Economy-Conditioner-Refrigerant/dp/B012CFTYX4/ref=sr_1_4?keywords=vacuum+pump&qid=1565812353&s=gateway&sr=8-4 I actually had the same pump on a small chamber, with nice vacuum fittings and no leaks. Got down below 500mTorr and made nice plasma, probably enough for rough sputtering. I was impressed. But its probably harder without a stainless steel chamber, you need a real vac pump I guess.

@thethoughtemporium you mentioned in your vid that this pump didn't work for sputtering https://www.amazon.com/ZENY-Single-Stage-Economy-Conditioner-Refrigerant/dp/B012CFTYX4/ref=sr_1_4?keywords=vacuum+pump&qid=1565812353&s=gateway&sr=8-4 I actually had the same pump on a small chamber, with nice vacuum fittings and no leaks. Got down below 500mTorr and made nice plasma, probably enough for rough sputtering. I was impressed. But its probably harder without a stainless steel chamber, you need a real vac pump I guess.

+1 yeah, real sputtering systems have multiple turbo pumps or crypo pumps to bring the chamber to UHV (nice and clean) before sputtering at ~50 to 100 mTorr

+1 yeah, real sputtering systems have multiple turbo pumps or crypo pumps to bring the chamber to UHV (nice and clean) before sputtering at ~50 to 100 mTorr

things will sputter at 500mtorr but you'll hate your existence the whole time. it's so bloody slow and the coatings are porous as all hell. only time i sputtered that high was when i coated a still damp hornet that took a while to dry under vacuum/plasma

things will sputter at 500mtorr but you'll hate your existence the whole time. it's so bloody slow and the coatings are porous as all hell. only time i sputtered that high was when i coated a still damp hornet that took a while to dry under vacuum/plasma

![]() and a pinning gauge for pressure measuring

and a pinning gauge for pressure measuring

haha sounds about right. I mainly do thermal evaporation in my chamber, which can be as fast as 100Å/s , orders of magnitude faster than sputtering

haha sounds about right. I mainly do thermal evaporation in my chamber, which can be as fast as 100Å/s , orders of magnitude faster than sputtering

also, and i found this out the hard way, do not attempt to sputter aluminum/titanium unless you've got a good vacuum system. the oxide layer that builds up prevents material from sputtering. anything else should work fine though. just tried carbon coatings the other day. may have managed diamond like carbon but will need to check it with a raman spec to confirm

also, and i found this out the hard way, do not attempt to sputter aluminum/titanium unless you've got a good vacuum system. the oxide layer that builds up prevents material from sputtering. anything else should work fine though. just tried carbon coatings the other day. may have managed diamond like carbon but will need to check it with a raman spec to confirm

![]() is the sputtering of the thermal evaporation easier?

is the sputtering of the thermal evaporation easier?

im about to be swtiching to thermal, least for titanium. a nice hot titanium wire should sputter readily compared to trying to magnetron sputter it. least that's the impression i got from the literature

im about to be swtiching to thermal, least for titanium. a nice hot titanium wire should sputter readily compared to trying to magnetron sputter it. least that's the impression i got from the literature

Interesting, good to know. Thermal evaporation of titanium is so nice, as its wetting it acts as a Ti getter pump and sucks the chamber pressure down. Every other metal (mostly) raises the chamber pressure due to out gassing

Interesting, good to know. Thermal evaporation of titanium is so nice, as its wetting it acts as a Ti getter pump and sucks the chamber pressure down. Every other metal (mostly) raises the chamber pressure due to out gassing

Id say you should start with sputtering if making your first chamber, evaporation requires a turbo or diffusion pump

Id say you should start with sputtering if making your first chamber, evaporation requires a turbo or diffusion pump

![]() is a microwave magnetron at all related to a sputtering magnetron?

is a microwave magnetron at all related to a sputtering magnetron?

yeah vaguely, uses crossed electric and magnetic fields to contain something

yeah vaguely, uses crossed electric and magnetic fields to contain something

im planning to add a second chamber to my system just to spray titanium as a getter pump for exactly that reason. cheapest high vacuum pump you can make essentially

im planning to add a second chamber to my system just to spray titanium as a getter pump for exactly that reason. cheapest high vacuum pump you can make essentially

http://sam.zeloof.xyz/titanium-sublimation-pump/

Titanium Sublimation Pump

A quick attempt making a titanium sublimation pump. Ti welding rod was bent into a coil around aluminum round stock and placed across 30-50 amps in high vacuum yielding successful results. Chamber was roughed down to 20mTorr then pumped with turbo to 1e-5 and briefly baked out.

for sure!

for sure!

i just picked up some thin titanium wire rather than welding rods so i can use 3-5 amps instead of 50

i just picked up some thin titanium wire rather than welding rods so i can use 3-5 amps instead of 50

i think the main consideration with those is you want lots of surface area around the hot titanium

i think the main consideration with those is you want lots of surface area around the hot titanium

Good idea, wind them into a coil maybe

Good idea, wind them into a coil maybe

![]() guessing it wouldent be possible to use a microwave magnetron for sputtering?

guessing it wouldent be possible to use a microwave magnetron for sputtering?

actually you could, but it's a different beast

actually you could, but it's a different beast

magnetrons put out wayyyyy too much power for the most part

magnetrons put out wayyyyy too much power for the most part

Possibly, theyre so powerful you could make a nasty plasma for plasma cleaning, etching, or a fusor

Possibly, theyre so powerful you could make a nasty plasma for plasma cleaning, etching, or a fusor

![]() good to know

good to know

Well, we got seriously down into the weeds here with the physics of fabbing chips. This was outstanding stuff, and I hate to wrap it up, but it's that time. Sam, feel free to stay on and field questions if you like, but for now I'll just say thanks for taking time out of your summer vacation to talk shop with us. I really enjoyed it.

Well, we got seriously down into the weeds here with the physics of fabbing chips. This was outstanding stuff, and I hate to wrap it up, but it's that time. Sam, feel free to stay on and field questions if you like, but for now I'll just say thanks for taking time out of your summer vacation to talk shop with us. I really enjoyed it.

Remember that we'll be talking to Arko, a robot engineer at JPL next week: https://hackaday.io/event/166178-life-at-jpl-hack-chat

im actually tinkering with running a microwave magnetron at 12w or so. all you need to do is sub out the usual cap for ones of lower capacitance and it works like a charm

im actually tinkering with running a microwave magnetron at 12w or so. all you need to do is sub out the usual cap for ones of lower capacitance and it works like a charm

Thanks Dan, and everyone, that was great

Thanks Dan, and everyone, that was great

![]() thanks for the help

thanks for the help

@thethoughtemporium interesting, i didn't know that was possible but I guess it makes sense

@thethoughtemporium interesting, i didn't know that was possible but I guess it makes sense

Lutetium

Lutetium

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.