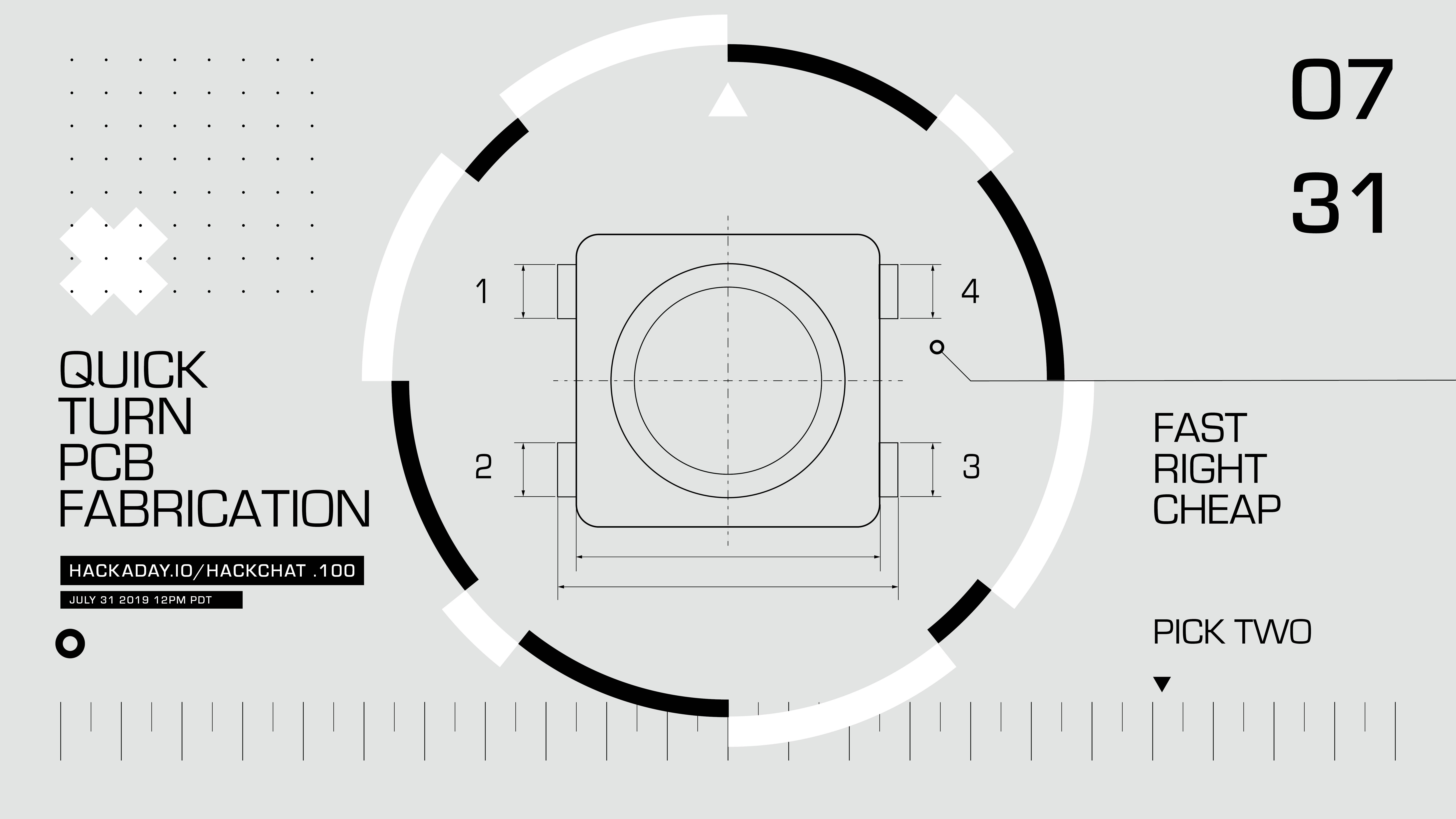

Mihir Shah will host the Quick-Turn PCB Fabrication Hack Chat on July 31, 2019.

Time zones got you down? Here's a handy time converter!

We've all become used to designing a PCB and having it magically appear at our doorstep - after a fashion. Modern PCB fabs rely on economies of scale to deliver your design cheaply, at the expense of time - the time it takes to put enough orders onto a panel, and the time it takes to ship the finished boards from Far, Far Away.

We've all become used to designing a PCB and having it magically appear at our doorstep - after a fashion. Modern PCB fabs rely on economies of scale to deliver your design cheaply, at the expense of time - the time it takes to put enough orders onto a panel, and the time it takes to ship the finished boards from Far, Far Away.

Not everyone has that kind of time to burn, though. Hobbyists who want rapid turnaround can etch their own boards, but that won't generally fly for manufacturers. That's where quick-turn fabs come in. These manufacturers specialize in getting boards to their customers as quickly as possible, helping them deal with sudden design changes or supporting specialty applications for customers.

It's a niche industry, but an important one, and Royal Circuits is at the forefront. Mihir Shah is Director of Special Projects there, and he's deep into the business of getting PCBs to customers as quickly as possible. He'll drop by the Hack Chat to answer all your questions about how the quick-turn industry fits into the electronics manufacturing ecosystem, and to show off some of the tools of the future that they're developing and investing in to streamline PCB design and analysis - from DebuggAR to PCBLayout.com, and more..

And we're doing a livestream! Tune into https://www.youtube.com/watch?v=UghcHq9nssg

OK all, let's get started. Let's welcome Mihir from Royal Circuits to talk about quick-turn fabrication. We'll be doing this a little differently as Mihir points out, so you'll want to tune into the livestream now.

OK all, let's get started. Let's welcome Mihir from Royal Circuits to talk about quick-turn fabrication. We'll be doing this a little differently as Mihir points out, so you'll want to tune into the livestream now.