Hi everyone, welcome to the Hack Chat. We're excited to have @Mohit Bhoite | मोहित भोईटे today to talk about his wonderful circuit sculptures. If you haven't seen them, you should check them out at https://www.bhoite.com/sculptures/

Welcome Mohit! Can you maybe kick us off with a little about yourself and how you got into circuit sculpture?

Hello everyone, thank you @Dan Maloney for hosting me today! and thank you @Aleksandar Bradic for that amazing poster design, and title.

Hello everyone, thank you @Dan Maloney for hosting me today! and thank you @Aleksandar Bradic for that amazing poster design, and title.

hi @Mohit Bhoite | मोहित भोईटे

hi @Mohit Bhoite | मोहित भोईटे

I work as senior hardware engineer at Particle, where I help design and build our flagship IoT modules and dev kits. I'm also a maker at heart, and in my free time, I dabble in a lot of projects - free-formed circuit sculptures, robotics, electronics, woodworking, etc.

I work as senior hardware engineer at Particle, where I help design and build our flagship IoT modules and dev kits. I'm also a maker at heart, and in my free time, I dabble in a lot of projects - free-formed circuit sculptures, robotics, electronics, woodworking, etc.

Yes, love the posters that @Aleksandar Bradic does!

Yes, love the posters that @Aleksandar Bradic does!

have we started? Cause I really wanna know how you manage to bend those thick wires so perfectly?!

have we started? Cause I really wanna know how you manage to bend those thick wires so perfectly?!

My first introduction to freeform electronics came though BEAM robotics as a teenager

My first introduction to freeform electronics came though BEAM robotics as a teenager

@Paul Stoffregen just regular flat nose pliers, and patience! It very straight forward if you give it a try

@Paul Stoffregen just regular flat nose pliers, and patience! It very straight forward if you give it a try

I use these pliers, if anyone is interested: Xuron 485 https://xuron.com/index.php/main/consumer_products/5/38

I use these pliers, if anyone is interested: Xuron 485 https://xuron.com/index.php/main/consumer_products/5/38

but, really any regular good pliers would do the trick

but, really any regular good pliers would do the trick

I have pliers... but where do I buy that superhuman patience?!

I have pliers... but where do I buy that superhuman patience?!

have you tried jewelers pliers? there are some with round ends that work really well

have you tried jewelers pliers? there are some with round ends that work really well

lol, thats kind of you to say

lol, thats kind of you to say

![]() do you use any fixtures to align components? i saw in your gallery that you had 3D printed fixtures holding LEDs

do you use any fixtures to align components? i saw in your gallery that you had 3D printed fixtures holding LEDs

I'd imagine the serrations on the jaws of most pliers would mar the wires. True?

I'd imagine the serrations on the jaws of most pliers would mar the wires. True?

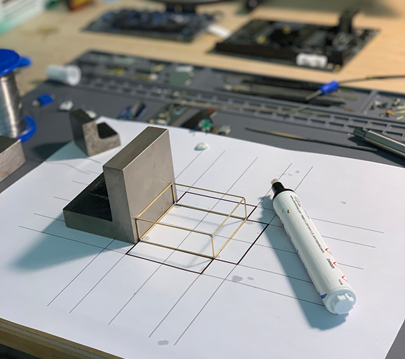

I use mechanics square to align the right angles, essentially tapping the rods to it while soldering

I use mechanics square to align the right angles, essentially tapping the rods to it while soldering

^ I really like these for precision wire bending

^ I really like these for precision wire bending

@Dan Maloney yes, they would. The flat needle pliers are what we would want to use.

@Dan Maloney yes, they would. The flat needle pliers are what we would want to use.

![]() Is there audio in this chat?

Is there audio in this chat?

how often do you incorporate your sculpting work into you actual engineering test circuitry - outside of the obvious commonalities like soldering and working with leaded parts.

how often do you incorporate your sculpting work into you actual engineering test circuitry - outside of the obvious commonalities like soldering and working with leaded parts.

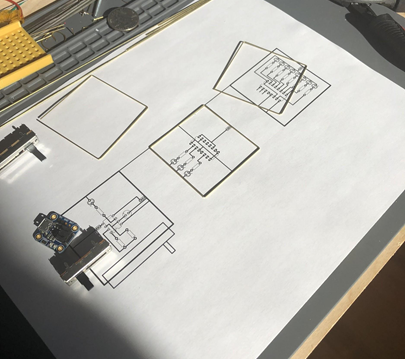

I usually draw template using either Fusion 360 or Adobe Illustrator, and take a print out.

I usually draw template using either Fusion 360 or Adobe Illustrator, and take a print out.

@Chris Sullivan - No, text only. I'll have a transcript available at the end

@Chris Sullivan - No, text only. I'll have a transcript available at the end

@mumi all the time! But I don't focus on making it look pretty - then its purely functional

@mumi all the time! But I don't focus on making it look pretty - then its purely functional

Its more like dead-bug style soldering then

Its more like dead-bug style soldering then

so it's not like you somehow end up with a 14 inch tall r2d2 sculpture on your bench by the time you're done mocking up a power supply?

so it's not like you somehow end up with a 14 inch tall r2d2 sculpture on your bench by the time you're done mocking up a power supply?

I wish!

I wish!

or a penny farthing

or a penny farthing

What does your basic materials list include? I assume that's brass rod as opposed to coiled wire...

What does your basic materials list include? I assume that's brass rod as opposed to coiled wire...

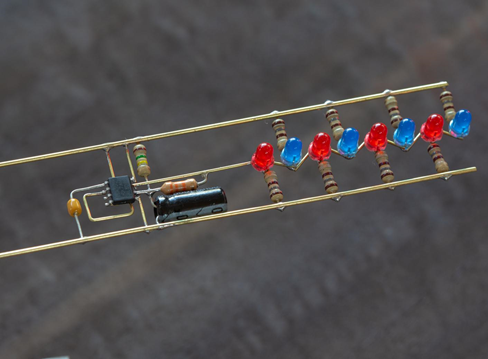

For brass I use 0.5mm, 0.8mm rods from ACE hardware (they are made by K&S metals)

For brass I use 0.5mm, 0.8mm rods from ACE hardware (they are made by K&S metals)

WES51 soldering iron

No clean solder flux: https://www.digikey.com/product-detail/en/chemtronics/CW8400/CW8400-ND/768491

Plier: Xuron 9100 https://xuron.com/index.php/main/consumer_products/3/77

Diagonal cutter: Xuron 485 https://xuron.com/index.php/main/consumer_products/5/38

Do you use some sort of fixtures or jigs to make your sculptures?

Do you use some sort of fixtures or jigs to make your sculptures?

Recently I have started to use 20awg wire which I straighten using a hand drill

Recently I have started to use 20awg wire which I straighten using a hand drill

https://www.instagram.com/p/BuSGI2uHrX-/

Made a quick video on how to straighten a brass wire into a rod. The end result is slightly under-twisted, but you'll get the idea. This is still a new technique to me, so I'll post my experiences as I learn more/get better at it. Update: For those of you wondering about the ruler, I got it from this gentleman https://www.sv1afn.com/pcbruler.html

2,147 Likes, 37 Comments - Mohit Bhoite | मोहित भोईटे (@mohitbhoite) on Instagram: "Made a quick video on how to straighten a brass wire into a rod. The end result is slightly under-..."

I get a lot done in terms of fixtures with just machinists sqaure

I get a lot done in terms of fixtures with just machinists sqaure

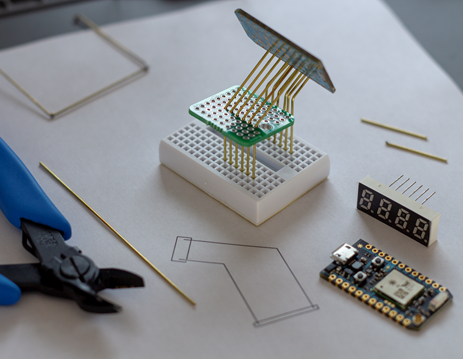

sometime 3d printed jig go a long when - especially when creating LED matrices

![]() do you have the LED jigs on thingiverse?

do you have the LED jigs on thingiverse?

Neat - looks like the drill work-hardens the wire a bit too.

Neat - looks like the drill work-hardens the wire a bit too.

I do! https://www.thingiverse.com/thing:3147406

I do! https://www.thingiverse.com/thing:3147406

![]() Have you tried incorporating brass tubing with the solid wire?

Have you tried incorporating brass tubing with the solid wire?

wow, I'd never heard of that drill straightening trick

wow, I'd never heard of that drill straightening trick

Tubing would be really cool. Especially with mitered bends

Tubing would be really cool. Especially with mitered bends

Brass tubing is great too, but difficult to bend. I gave successfully use it to created slightly stronger robot chassis- or when I need to pass wires

Brass tubing is great too, but difficult to bend. I gave successfully use it to created slightly stronger robot chassis- or when I need to pass wires

wow, cool, also didn't know that straightening trick

wow, cool, also didn't know that straightening trick

@Dan Maloney mitered/brazed tubing has been on my list but haven't had time to do any sculptures

@Dan Maloney mitered/brazed tubing has been on my list but haven't had time to do any sculptures

Great drill trick. But I'm curious what your soldering process is, just ample care? I can do OK 3/5 times, but 2/5 is just a big ugly glob of solder. Any tips there?

Great drill trick. But I'm curious what your soldering process is, just ample care? I can do OK 3/5 times, but 2/5 is just a big ugly glob of solder. Any tips there?

applying a generous amount of flux at the joint works like magic! I also clean the joint with fine steel wool to get a better finish

applying a generous amount of flux at the joint works like magic! I also clean the joint with fine steel wool to get a better finish

here is an example of the square being used

here is an example of the square being used

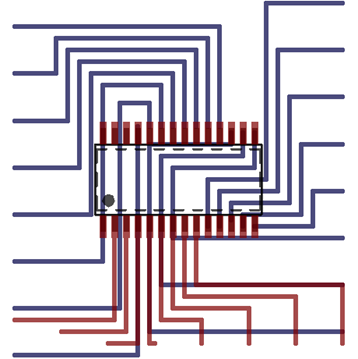

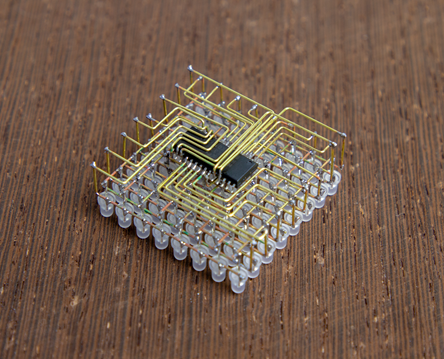

sometimes just using proto-pcbs also helps

sometimes just using proto-pcbs also helps

you can also use the PCB layout as a template

you can also use the PCB layout as a template

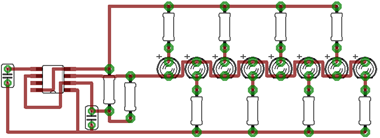

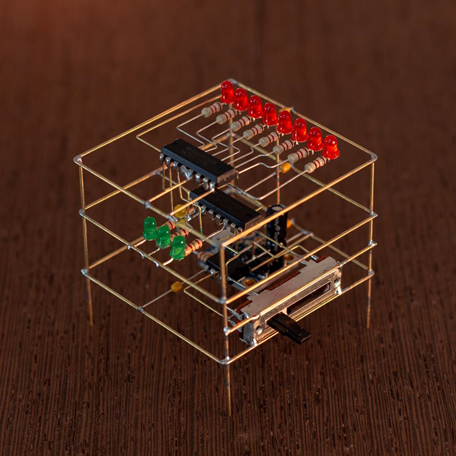

to this:

to this:

or this:

or this:

Question on cuts: do the irregular ends left by side-cut or flush-cut snips cause any problems when soldering? Seems like a clean cut with a scissor-type cutter might make a better match-up that would be easier to solder.

Question on cuts: do the irregular ends left by side-cut or flush-cut snips cause any problems when soldering? Seems like a clean cut with a scissor-type cutter might make a better match-up that would be easier to solder.

great question Dan, yeah, depending on the type of join you are looking at, you'd want a flat cut or a pinch cut. But even then, there is enough solder going around to fill the voids and gaps

great question Dan, yeah, depending on the type of join you are looking at, you'd want a flat cut or a pinch cut. But even then, there is enough solder going around to fill the voids and gaps

Is there any kind of project that you're especially excited to give this artful treatment?

Is there any kind of project that you're especially excited to give this artful treatment?

BTW the Xuron 485 has a clip retainer that stops from having your brass rods flying across the room - or into an eye

BTW the Xuron 485 has a clip retainer that stops from having your brass rods flying across the room - or into an eye

I suppose cutting a bit long and then cleaning up the cut with a file or sandpaper would work too

I suppose cutting a bit long and then cleaning up the cut with a file or sandpaper would work too

totally

totally

here is a great tutorial on soldering brass that is helpful

here is a great tutorial on soldering brass that is helpful

https://davidneat.wordpress.com/2015/05/03/a-quick-guide-to-soldering-brass/

![]() how do you clean the flux off the completed sculpture?

how do you clean the flux off the completed sculpture?

@Nicholas Upton I'm hoping to start building kinematic robotic sculptures soon

@Nicholas Upton I'm hoping to start building kinematic robotic sculptures soon

@hazelton with fine steel wool and alcohol wipes

@hazelton with fine steel wool and alcohol wipes

For hard to reach places, I use liquid flux remover

For hard to reach places, I use liquid flux remover

Mohit, your work is very inspiring - thanks for sharing your tips and tricks. For brass tube bending, have made use of the trick where you pack it full of sand (or similar) before bending to keep it from collapsing?

Mohit, your work is very inspiring - thanks for sharing your tips and tricks. For brass tube bending, have made use of the trick where you pack it full of sand (or similar) before bending to keep it from collapsing?

@Mohit Bhoite | मोहित भोईटे what brand is the pcb ruler you show in that instagram post? Love Particle btw, currently prototyping a client project with a Boron LTE.

@Mohit Bhoite | मोहित भोईटे what brand is the pcb ruler you show in that instagram post? Love Particle btw, currently prototyping a client project with a Boron LTE.

![]() you can also try filling brass tubing with soapy water and freeze before bending.

you can also try filling brass tubing with soapy water and freeze before bending.

Thank you @Andy Geppert ! I have not tried that. I wonder if it would also work for 1mm tubes

Thank you @Andy Geppert ! I have not tried that. I wonder if it would also work for 1mm tubes

this seems to require infinite amounts of patience.. is it like meditation for you?

this seems to require infinite amounts of patience.. is it like meditation for you?

@Matt Phillips I ruler from the video is made by Makis Katsouris

@Matt Phillips I ruler from the video is made by Makis Katsouris

https://www.sv1afn.com/pcbruler.html

@diego-quiroga it totally is like meditation, thats why i love it!

@diego-quiroga it totally is like meditation, thats why i love it!

![]() How do you resolve situation when you need to solder 3 wires in one place? How do you ensure that previously soldered 2 wires do not desolder while soldering the 3rd?

How do you resolve situation when you need to solder 3 wires in one place? How do you ensure that previously soldered 2 wires do not desolder while soldering the 3rd?

It how I like to unwind from a days work of designing PCBs, lol

It how I like to unwind from a days work of designing PCBs, lol

do you ever keep designs that didn't work out, just because they look cool?

do you ever keep designs that didn't work out, just because they look cool?

or do they all work out, in one way or another

or do they all work out, in one way or another

@hazelton - I gotta try that trick!

@hazelton - I gotta try that trick!

@mic.cisek its tricky but with practice you learn to apply the right amount of heat for the right amount of time. It also helps when all three rods are filxed/taped - but that isn't always the case

@mic.cisek its tricky but with practice you learn to apply the right amount of heat for the right amount of time. It also helps when all three rods are filxed/taped - but that isn't always the case

@mumi I try my best to make it work. I do have a lot of failed attempts that never see any camera time.

@mumi I try my best to make it work. I do have a lot of failed attempts that never see any camera time.

The brass from the failed projects also get reused for newer ones

The brass from the failed projects also get reused for newer ones

What do you think are the most aesthetically pleasing component packages? Which ones do you like using the best?

What do you think are the most aesthetically pleasing component packages? Which ones do you like using the best?

What do you use to ventilate your workspace? If anything

What do you use to ventilate your workspace? If anything

I also want to give a shout-out to @Jiří Praus who has been doing some fabulous work, and more importantly sharing his process!

I also want to give a shout-out to @Jiří Praus who has been doing some fabulous work, and more importantly sharing his process!

@Nicholas Upton I use a solder fume extractor

@Nicholas Upton I use a solder fume extractor

like this one: https://www.amazon.com/TENMA-21-7960-SOLDER-FUME-EXTRACTOR/dp/B001DPOU02

like this one: https://www.amazon.com/TENMA-21-7960-SOLDER-FUME-EXTRACTOR/dp/B001DPOU02

@Dan Maloney any packages with 0.1" pitch are fantastic. My favorites have been the seven segment displays

@Dan Maloney any packages with 0.1" pitch are fantastic. My favorites have been the seven segment displays

![]() I love your work, and I'm considering trying my hand at a classic experimental sound circuit this way. Have you integrated speakers or piezos in your designs? and are they all powered by but

I love your work, and I'm considering trying my hand at a classic experimental sound circuit this way. Have you integrated speakers or piezos in your designs? and are they all powered by but

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.