Is the minimum layer height you can achieve dependent on the resin used (i assume different resins may be more sensitive to the UV light?) along with the stepper motor?

Is the minimum layer height you can achieve dependent on the resin used (i assume different resins may be more sensitive to the UV light?) along with the stepper motor?

Absolutely!

Absolutely!

That's a great question, with a LOT of variables

That's a great question, with a LOT of variables

I use car analogies a lot, so hopefully this makes sense!

I use car analogies a lot, so hopefully this makes sense!

![]() What entry level machine would recommend?

What entry level machine would recommend?

But it's sort of like asking "What's the fastest you can go?"

But it's sort of like asking "What's the fastest you can go?"

One of my biggest hurdles and one that is not taken into consideration enough is how toxic resin is for not only humans but the environment @Andrew Sink But with proper precautions and making sure everything is cured, it can work out well and safely

One of my biggest hurdles and one that is not taken into consideration enough is how toxic resin is for not only humans but the environment @Andrew Sink But with proper precautions and making sure everything is cured, it can work out well and safely

It depends on the car, how many people are in it, what road you're driving on, etc!

It depends on the car, how many people are in it, what road you're driving on, etc!

I think my obstacle to adopting MSLA is the mess, but we've already seen that can be managed. I guess the odor might be next -- I have a small shop, can't really ventilate it well.

I think my obstacle to adopting MSLA is the mess, but we've already seen that can be managed. I guess the odor might be next -- I have a small shop, can't really ventilate it well.

But basically, with layer heights, a widely accepted standard is 50 microns (.05mm)

But basically, with layer heights, a widely accepted standard is 50 microns (.05mm)

An interesting fact is you can print a thicker layer using a translucent resin, as the UV light is able to penetrate deeper through the resin itself!

An interesting fact is you can print a thicker layer using a translucent resin, as the UV light is able to penetrate deeper through the resin itself!

Using a thick opaque resin, this would be more of a challenge!

Using a thick opaque resin, this would be more of a challenge!

![]() The Lambert-Beer law.

The Lambert-Beer law.

@SimonAllen, I'm VERY partial to the Elegoo Mars 2 Pro

@SimonAllen, I'm VERY partial to the Elegoo Mars 2 Pro

It's inexpensive, and it provides reliable results

It's inexpensive, and it provides reliable results

same^^

same^^

@Dan Maloney I haven't found the odor to be too bad. In fact, I print in my office, which is a room in my apartment.

@Dan Maloney I haven't found the odor to be too bad. In fact, I print in my office, which is a room in my apartment.

It's also heavy enough to not worry about tipping over, and it's a popular-enough model that there is a large user base online to bounce ideas off of!

It's also heavy enough to not worry about tipping over, and it's a popular-enough model that there is a large user base online to bounce ideas off of!

Since SLA printers have a smaller build volume than Filament printers, is there a way to fuse smaller SLA prints together into a larger piece?

Since SLA printers have a smaller build volume than Filament printers, is there a way to fuse smaller SLA prints together into a larger piece?

@controlmypad, GREAT question!

@controlmypad, GREAT question!

I have the Mars Pro and it's great with the seperate air purifier.

I have the Mars Pro and it's great with the seperate air purifier.

There are MANY options for fusing parts, the easiest is by creating models as an assembly (think dovetail joint) to assemble after printing

There are MANY options for fusing parts, the easiest is by creating models as an assembly (think dovetail joint) to assemble after printing

![]() @Dan Maloney a god carbon filter and HEPA filter goes a long ways.

@Dan Maloney a god carbon filter and HEPA filter goes a long ways.

![]() Assemble together with mating surfaces wetted with the printing resin, before the final curing.

Assemble together with mating surfaces wetted with the printing resin, before the final curing.

The material used for 3D printing is not as important or critical to learning this, as the basic 3D design and compiler (to convert to instructions. Cost and time management, knowing the market or need, having a good application that helps people or groups. On Mars and the moon, they will use molten materials, electrochemical and plasma separation, and the tools will start with "3D". The chemistry, physics of materials will be critical to making things that last. Keep in mind the needs of the rest of the century for reliable tools and methods for other worlds.

The material used for 3D printing is not as important or critical to learning this, as the basic 3D design and compiler (to convert to instructions. Cost and time management, knowing the market or need, having a good application that helps people or groups. On Mars and the moon, they will use molten materials, electrochemical and plasma separation, and the tools will start with "3D". The chemistry, physics of materials will be critical to making things that last. Keep in mind the needs of the rest of the century for reliable tools and methods for other worlds.

You can also add a bit of UV-curable resin and cure it with a UV light to permanently bond two parts

You can also add a bit of UV-curable resin and cure it with a UV light to permanently bond two parts

Great question, @controlmypad!

Great question, @controlmypad!

I agree with @Nicolas Tremblay, the built-in air filter on the Mars 2 Pro is another great feature!

I agree with @Nicolas Tremblay, the built-in air filter on the Mars 2 Pro is another great feature!

![]() When we do the gluing-together-with-resin step before the final curing, we have a lot of unreacted acrylate groups left on the surface and we can achieve higher bonding strength.

When we do the gluing-together-with-resin step before the final curing, we have a lot of unreacted acrylate groups left on the surface and we can achieve higher bonding strength.

I made a UV laser holder for tacking parts together.

I made a UV laser holder for tacking parts together.

http://www.24hourengineer.com/2021/04/2021-04-05-m-uvlasermodule-completed.html

I used a tower fan put on its side, and open my window just enough to lay it sideways!

I used a tower fan put on its side, and open my window just enough to lay it sideways!

This blows air outside, while another window allows air inside the room

This blows air outside, while another window allows air inside the room

![]() hello, is there any real cleaning liquid alternative to IPA? :)

hello, is there any real cleaning liquid alternative to IPA? :)

It's basically a VERY low-tech air exchange system!

It's basically a VERY low-tech air exchange system!

@borelli.g92, that's another great question!

@borelli.g92, that's another great question!

Thank you, it sounds like it could fuse nearly seamlessly and also work for clear prints?

Thank you, it sounds like it could fuse nearly seamlessly and also work for clear prints?

Negative pressure ventilation works well. Stick a fan in the window blowing out.

Negative pressure ventilation works well. Stick a fan in the window blowing out.

I haven't used it, but I've seen Simple Green used to clean parts

I haven't used it, but I've seen Simple Green used to clean parts

It's a solvent that should break down the resin, but it's something I haven't personally tried

It's a solvent that should break down the resin, but it's something I haven't personally tried

![]() I disabled the chamber fan, and just leave it form saturated vapors. Limits the total amount of evaporated material, if the vapor pressure at the printing temperature is sufficiently low, which is easily the case with the big-molecule reactive diluents. (The oligomers don't contribute to the vapor pressure, nor the photoinitiators.)

I disabled the chamber fan, and just leave it form saturated vapors. Limits the total amount of evaporated material, if the vapor pressure at the printing temperature is sufficiently low, which is easily the case with the big-molecule reactive diluents. (The oligomers don't contribute to the vapor pressure, nor the photoinitiators.)

IPA is definitely not something you want to be careless with, but it works great for cleaning parts!

IPA is definitely not something you want to be careless with, but it works great for cleaning parts!

@David Geller, great point!

@David Geller, great point!

@controlmypad, yes, you can use the resin to fuse parts together! However, if there is any resin that is uncured, it will be visible through the clear surface

@controlmypad, yes, you can use the resin to fuse parts together! However, if there is any resin that is uncured, it will be visible through the clear surface

![]() @Andrew Sink yes. that's right. A friend of mine who is a chemist suggested me to find the right dilution of acetone. That should work as well. Any feedback on that? :)

@Andrew Sink yes. that's right. A friend of mine who is a chemist suggested me to find the right dilution of acetone. That should work as well. Any feedback on that? :)

Making *fully* clear parts that are made from multiple pieces is difficult, and at a certain point, it becomes more attractive to move to a casting process

Making *fully* clear parts that are made from multiple pieces is difficult, and at a certain point, it becomes more attractive to move to a casting process

@borelli.g92, I don't know that I would use Acetone

@borelli.g92, I don't know that I would use Acetone

![]() Note on side. The curing reaction is fairly exothermic. I spilled a little bit of the resin on myself, wanted to peel the drop off instead of smearing it with a tissue, and lit it with UV LED. OUCH. Got a nice drop-shaped blister (and scar).

Note on side. The curing reaction is fairly exothermic. I spilled a little bit of the resin on myself, wanted to peel the drop off instead of smearing it with a tissue, and lit it with UV LED. OUCH. Got a nice drop-shaped blister (and scar).

@Thomas Shaddack is correct, you don't want to spill the resin on yourself!

@Thomas Shaddack is correct, you don't want to spill the resin on yourself!

NOPE!

NOPE!

I saw a picture of someone who spilled the resin on their leg before walking outside; once the sun cured the resin it led to a particularly nasty burn

I saw a picture of someone who spilled the resin on their leg before walking outside; once the sun cured the resin it led to a particularly nasty burn

eek, didn't realise it was that dangerous. are the fumes bad too then?

eek, didn't realise it was that dangerous. are the fumes bad too then?

@anfractuosity: the short answer is: "It depends"

@anfractuosity: the short answer is: "It depends"

Some people are very sensitive to the smell of UV-curable resin, and some aren't

Some people are very sensitive to the smell of UV-curable resin, and some aren't

ahh

ahh

If you've ever been to a nail salon, a UV printer smells almost exactly the same

If you've ever been to a nail salon, a UV printer smells almost exactly the same

In fact, the same principles used to create a resin 3D printed part are used to make UV-curable acrylic nails!

In fact, the same principles used to create a resin 3D printed part are used to make UV-curable acrylic nails!

They even use the same wavelength UV LEDs that we do!

They even use the same wavelength UV LEDs that we do!

![]() It's relatively harmless, the oligomers are big molecules that won't get through skin, the reactive diluents are the biggest concern (they can be nasty irritants and some people can get allergic to them, but there are some that are fairly good - I chose the one for my mix that didn't make my skin feel itchy after exposure, it has one of the lowest irritation indexes).

It's relatively harmless, the oligomers are big molecules that won't get through skin, the reactive diluents are the biggest concern (they can be nasty irritants and some people can get allergic to them, but there are some that are fairly good - I chose the one for my mix that didn't make my skin feel itchy after exposure, it has one of the lowest irritation indexes).

Thanks. I have been working since 2 am and have to get back to it. Best to everyone.

Thanks. I have been working since 2 am and have to get back to it. Best to everyone.

These are all really great questions!

These are all really great questions!

Bye @RichardCollins, thanks for stopping in!

Bye @RichardCollins, thanks for stopping in!

Ok, so, let's talk about washing / curing!

Ok, so, let's talk about washing / curing!

![]()

![]() for postcuring, one nasty thing to deal with is the oxygen inhibition. The presence of oxygen interferes with the radical polymerization. Major issue with printing inks.

for postcuring, one nasty thing to deal with is the oxygen inhibition. The presence of oxygen interferes with the radical polymerization. Major issue with printing inks.

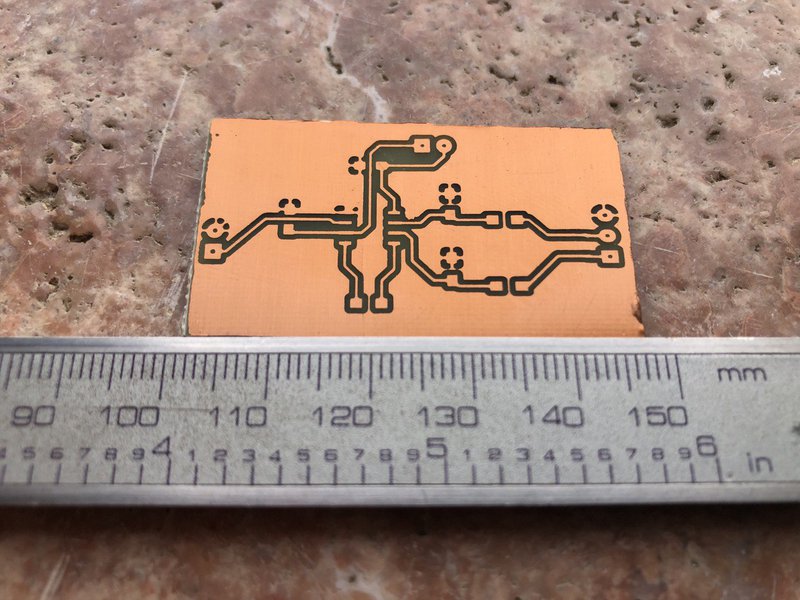

![]() Another nice usage of UV-based 3d printers is to make PCBs.

Another nice usage of UV-based 3d printers is to make PCBs.

Have you ever tried?

Here's an example of a resin 3D printer, next to a Wash / Cure station!

Here's an example of a resin 3D printer, next to a Wash / Cure station!

This station has two functions: 1) wash the part, 2) cure the part!

This station has two functions: 1) wash the part, 2) cure the part!

Looks like the washing step generates a far amount of waste. What's the best practice for disposing of that?

Looks like the washing step generates a far amount of waste. What's the best practice for disposing of that?

After printing, the part is washed in IPA to rinse any excess resin off. Printing models hollow is a great way to reduce material usage as well as minimize the wear and tear on the part!

After printing, the part is washed in IPA to rinse any excess resin off. Printing models hollow is a great way to reduce material usage as well as minimize the wear and tear on the part!

*fair amount

*fair amount

Great question @Dan Maloney!

Great question @Dan Maloney!

It actually generates *FAR* less than you may think

It actually generates *FAR* less than you may think

![]() You can use IPA multiple times

You can use IPA multiple times

The IPA is heavily reusable

The IPA is heavily reusable

So, for instance

So, for instance

I filled this wash station with 3 liters of IPA, several months ago

I filled this wash station with 3 liters of IPA, several months ago

![]() What is your experience with dunk tanks, vs agitated tanks (with magnet string), vs ultrasonic cleaning?

What is your experience with dunk tanks, vs agitated tanks (with magnet string), vs ultrasonic cleaning?

and it is still potent enough to remove the material from parts!

and it is still potent enough to remove the material from parts!

![]() @Andrew Sink - That's the same cure station I have. It's been the difference between me using my mars elegoo, and not. The cleanup was just not fun. I've had the same experience with my IPA, and have not replaced it yet.

@Andrew Sink - That's the same cure station I have. It's been the difference between me using my mars elegoo, and not. The cleanup was just not fun. I've had the same experience with my IPA, and have not replaced it yet.

It does this by inducing cavitation (making little bubbles) and actively rinsing the parts!

It does this by inducing cavitation (making little bubbles) and actively rinsing the parts!

![]() My favorite is ultrasound. Improvised setup with eyeglasses cleaner with water, and in it a beaker with alcohol.

My favorite is ultrasound. Improvised setup with eyeglasses cleaner with water, and in it a beaker with alcohol.

This way, instead of just soaking, the uncured resin is actively removed!

This way, instead of just soaking, the uncured resin is actively removed!

Once the part has been washed off, it can then be cured after the support has been removed!

Once the part has been washed off, it can then be cured after the support has been removed!

The UV lights in the chamber will fully polymerize the part, turning it into a completed model!

The UV lights in the chamber will fully polymerize the part, turning it into a completed model!

From there, you can paint, sand, post-process to your hearts desire!

From there, you can paint, sand, post-process to your hearts desire!

An interesting note, once the part has been fully cured, it will be significantly stiffer (and more brittle) than it's previous semi-cured state

An interesting note, once the part has been fully cured, it will be significantly stiffer (and more brittle) than it's previous semi-cured state

If you take a part pre-curing and tap it on a desk, you will hear a "thunk"

If you take a part pre-curing and tap it on a desk, you will hear a "thunk"

a post-cured part will make a "click"

a post-cured part will make a "click"

Are there any dimensional changes after curing? Shrinkage perhaps?

Are there any dimensional changes after curing? Shrinkage perhaps?

![]() Indeed. So some operations (thread-cutting, removing of supports...) can be better done on only briefly surface-cured part.

Indeed. So some operations (thread-cutting, removing of supports...) can be better done on only briefly surface-cured part.

Any rules for determining how long to cure?

Any rules for determining how long to cure?

Great question, @Dan Maloney !

Great question, @Dan Maloney !

Dimensional change is a really hard subject to tackle, as the number of variables (including the geometry and features of the object) can influence the final part size

Dimensional change is a really hard subject to tackle, as the number of variables (including the geometry and features of the object) can influence the final part size

I rarely have parts that don't mate up, so I've never spent a lot of time chasing down the tolerance post-cure

I rarely have parts that don't mate up, so I've never spent a lot of time chasing down the tolerance post-cure

@Involute, Not really, but it's worth noting that curing does generate heat in the part

@Involute, Not really, but it's worth noting that curing does generate heat in the part

So for practical purposes, not an issue.

So for practical purposes, not an issue.

So I'll typically cure for 1 minute

So I'll typically cure for 1 minute

then let it sit for several minutes

then let it sit for several minutes

then cure for one more minute

then cure for one more minute

And to be fair, FDM prints have some dimensional issues too, after they cool.

And to be fair, FDM prints have some dimensional issues too, after they cool.

That's true!

That's true!

So, practically, again, the answer is "It depends"

So, practically, again, the answer is "It depends"

It's such an unsatisfying answer!

It's such an unsatisfying answer!

Trust me, I know!

Trust me, I know!

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.