Mark Hughes and Greg Ziraldo will host the Hack Chat on Wednesday, November 10 at noon Pacific.

Time zones got you down? Try our handy time zone converter.

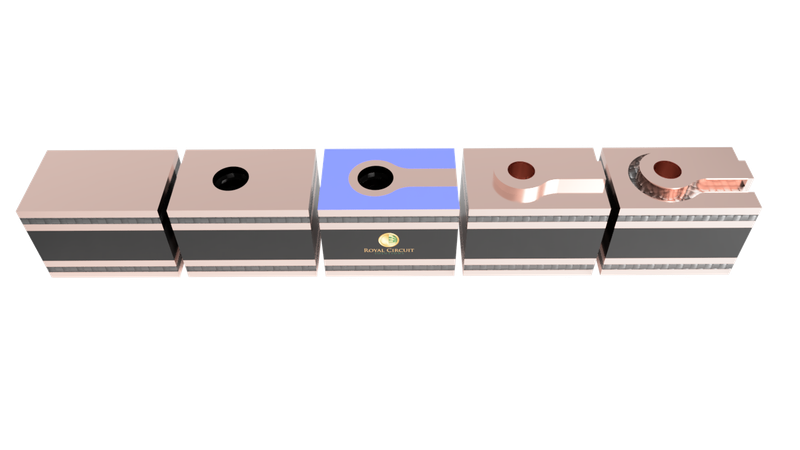

For as useful as printed circuit boards are, they do seem a little flimsy at times. With nothing but a thin layer -- or six -- of metal on the board, and ultra-fine traces that have to fit between a dense forest of pads and vias, the current carrying capacity of the copper on most PCBs is somewhat limited. That's OK in most cases, especially where logic-level and small-signal currents are concerned. But what happens when you really need to turn up the juice on a PCB?

Enter the world of heavy-copper PCBs, where the copper is sometimes as thick as the board substrate itself. Traces that are as physically chunky as these come with all sorts of challenges, from thermal and electrical considerations to potential manufacturing problems. To help us sort through all these issues, Mark and Greg will stop by the Hack Chat. They both work at quick-turn PCB assembly company Advanced Assembly, Mark as Research Director and Greg as Senior Director of Operations. They know the ins and outs of heavy-copper PCB designs, and they'll share the wealth with us.

Why not just use thinner copper and wider traces?