The world has began to move towards home-energy storage solutions that can partly offset your power bills and charge your electric vehicle. Solar panels have been paired with electric-storage solutions. Solar-panels , however, *rely on large-scale silicon production plants* and therefore consumers and the cost of power production is heavily reliant on these production lines and silicon markets.

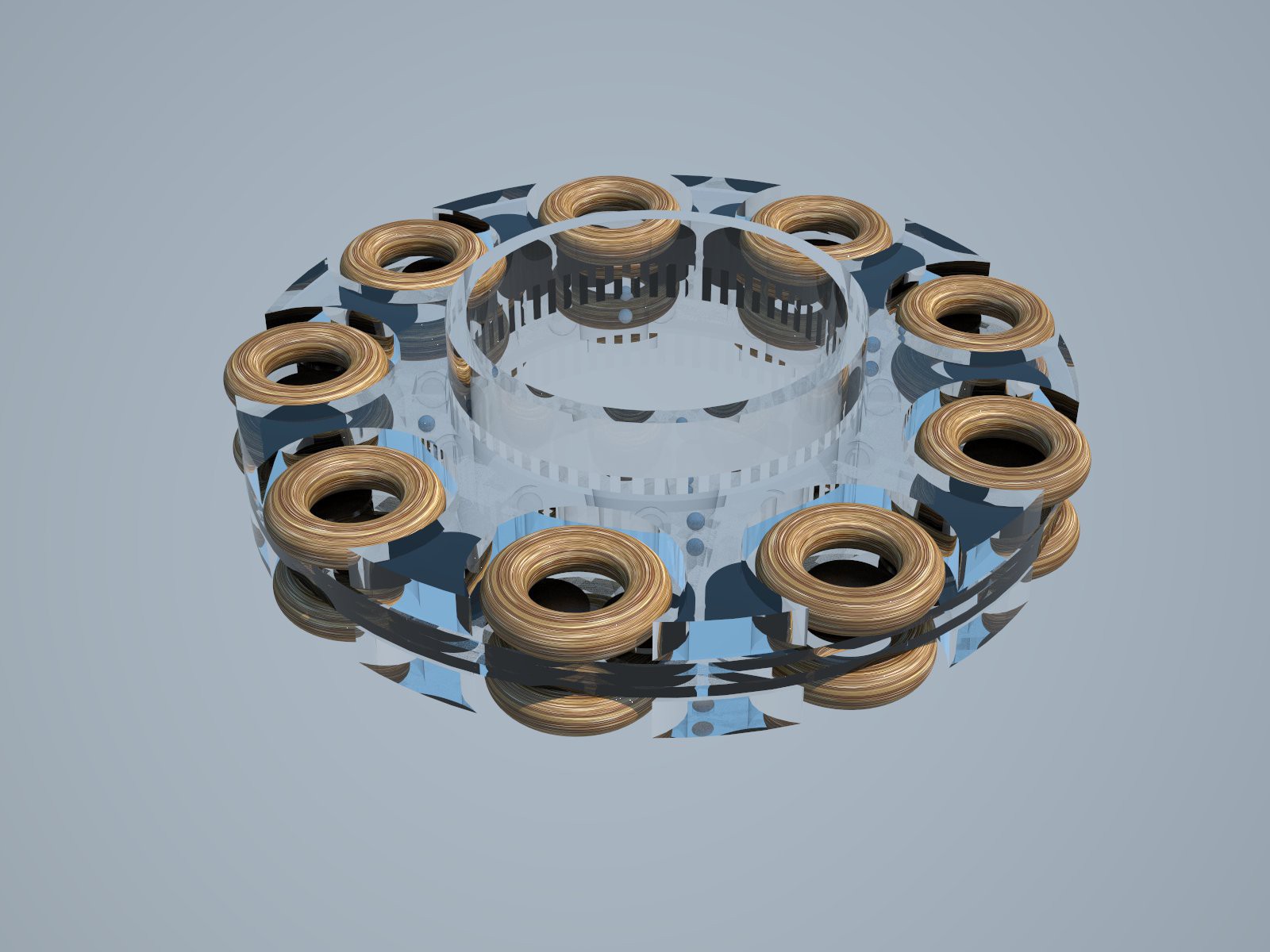

However small scale wind-power generation can be made home-grown, based on simple designs that can be easily assembled. By utilizing ubiquitous recyclable materials, such as ABS plastic, and machining automation which is now widely available, we have began to explore the idea of building a low-cost alternator.

This alternator should be tuned towards a wind-turbine application.

Our efforts align with those who want to empower the world from the bottom-up, join us on:

Plastic Alternator Project Page

Kostas Lagogiannis

Kostas Lagogiannis

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.