I'm the owner of a Sunhokey prusa i3 2015 model, and i forgot to talk about it so here is a review of my model.

Build volume is 200mm x 200mm x180mm (approximate) arround 15KG and 12v rated.

I bought it in kit to assemble for 300$ (including taxes) from Shenzhen Sunhokey Electronics Co.

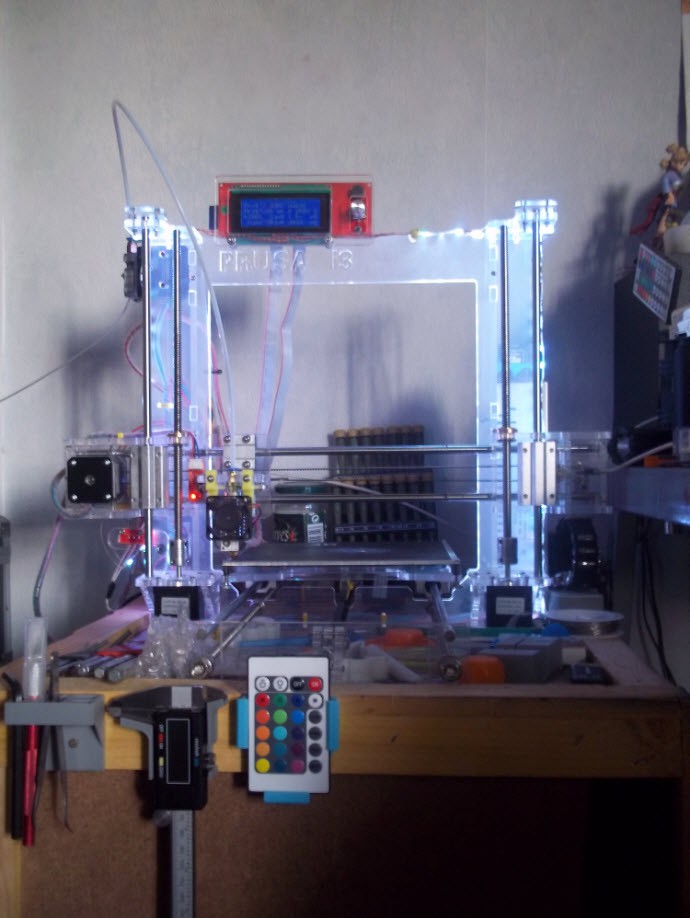

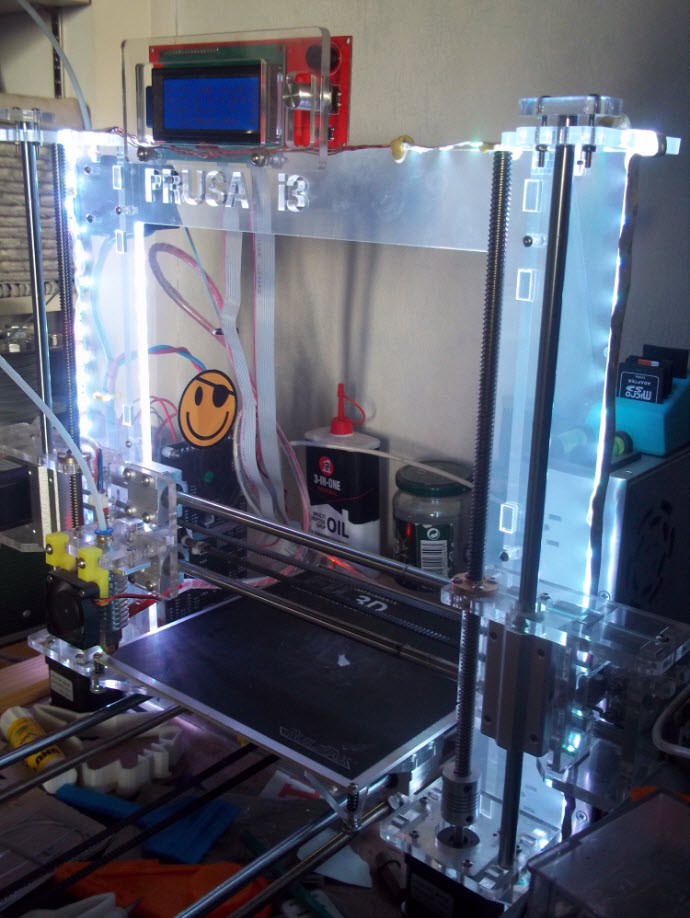

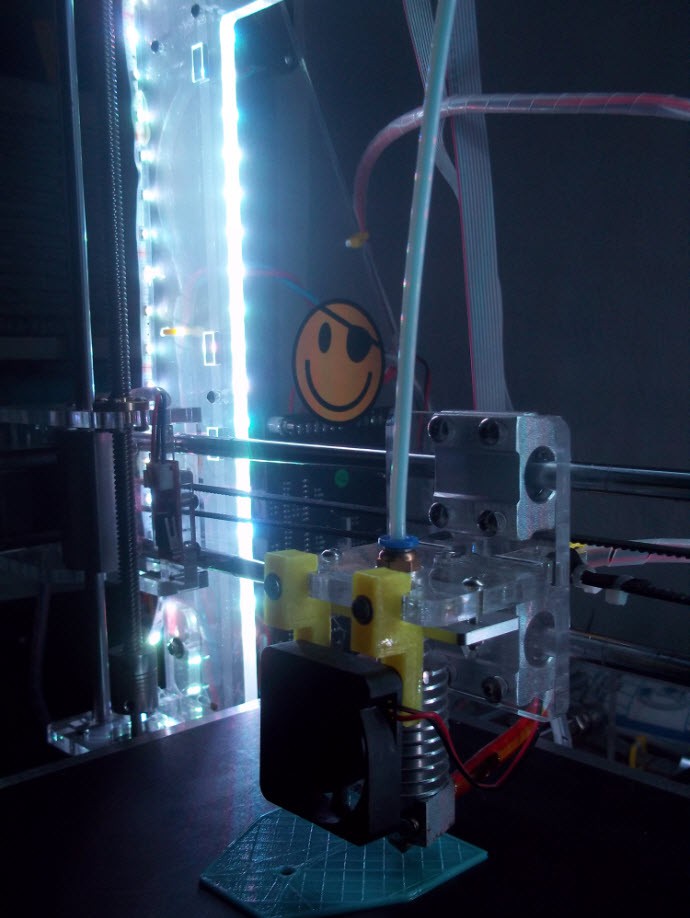

Here is the global view of the printer:

The Hotbed is a MK2b, with a BuildTak plastic sheet on print bed.

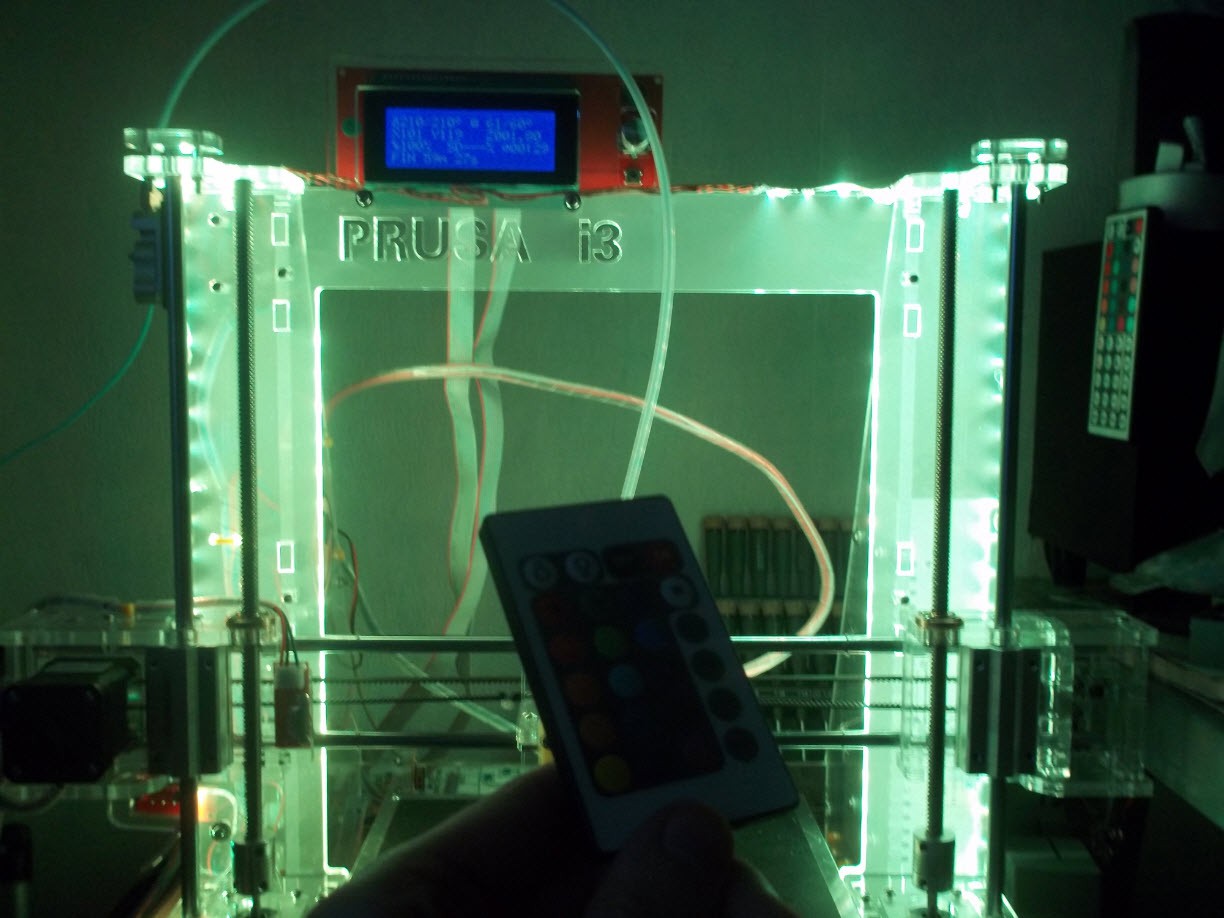

Customized with a Hackers sticker and a RGB 5050 SMD LED strip.

IR Remote controler for LED.

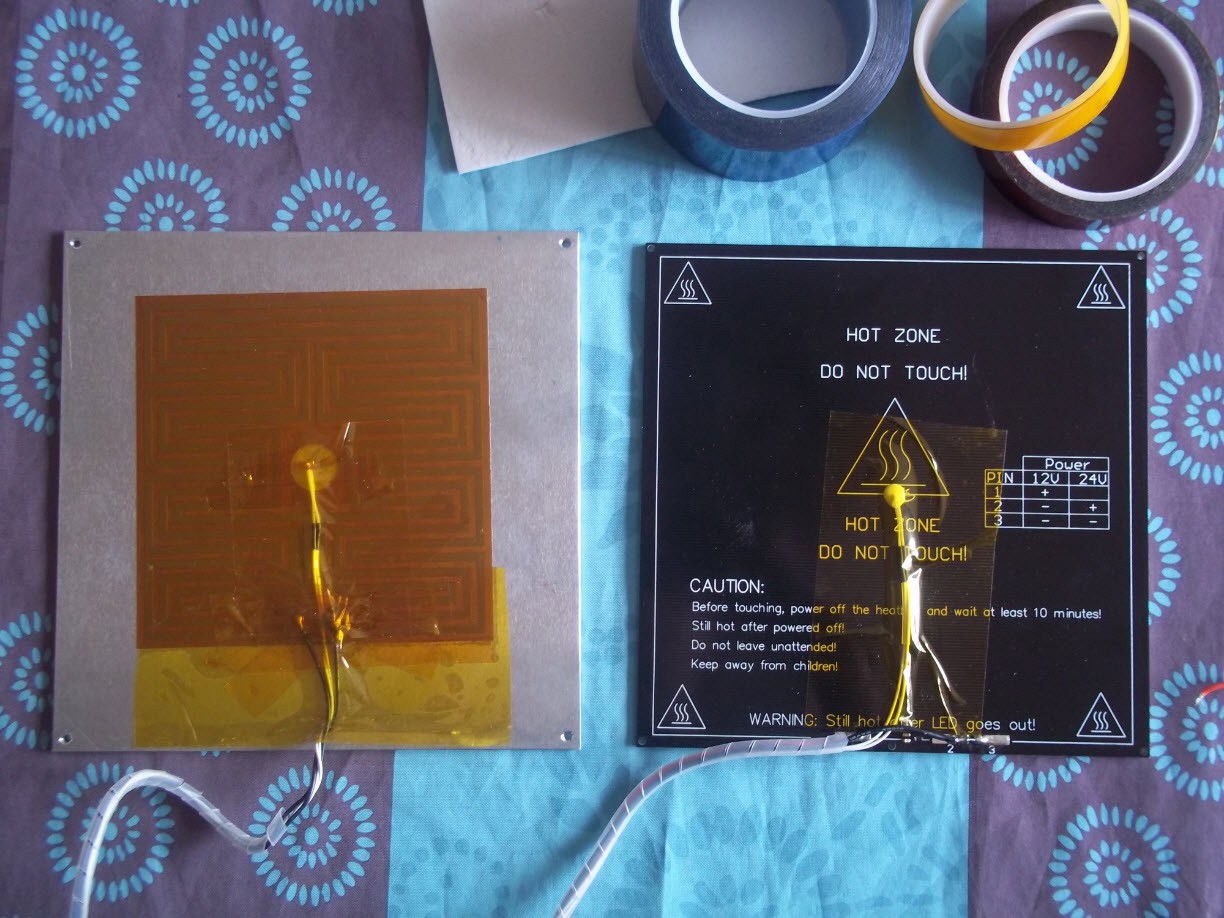

Comparison between the original Sunhokey hotbed and my MK2b hotbed (on the left):

The power wire of the resistor on my original Sunhokey hotbed have burn and damaged the plate.

MK2b is a very good alternative, and heat come munch more rapidly, i would recommend replacing the original hotbed.

My MK2b is using this time silicone insulated wires and a thermistor 3950, everything is attached with high temperature tape (Kapton).

Then i'm covering the back of the plate with styrofoam-like for heat transfer.

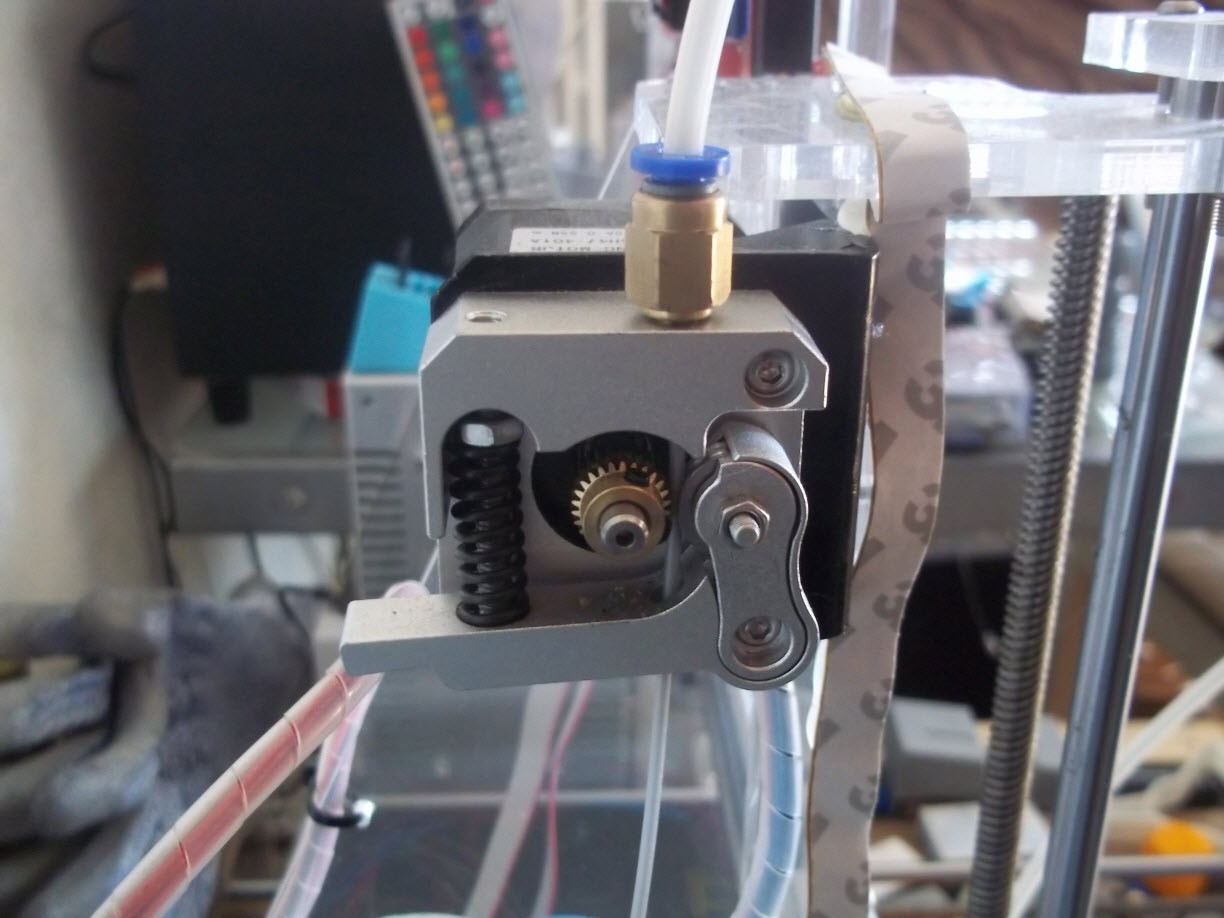

Bowden extruder:

Extruder with 40x40 cooling fan:

The Hotend is a ALU J-head, with a 0.4mm nozzle and a push fit pneumatic for the PTFE Tubing.

Teflon tube is for 1.75mm filament.

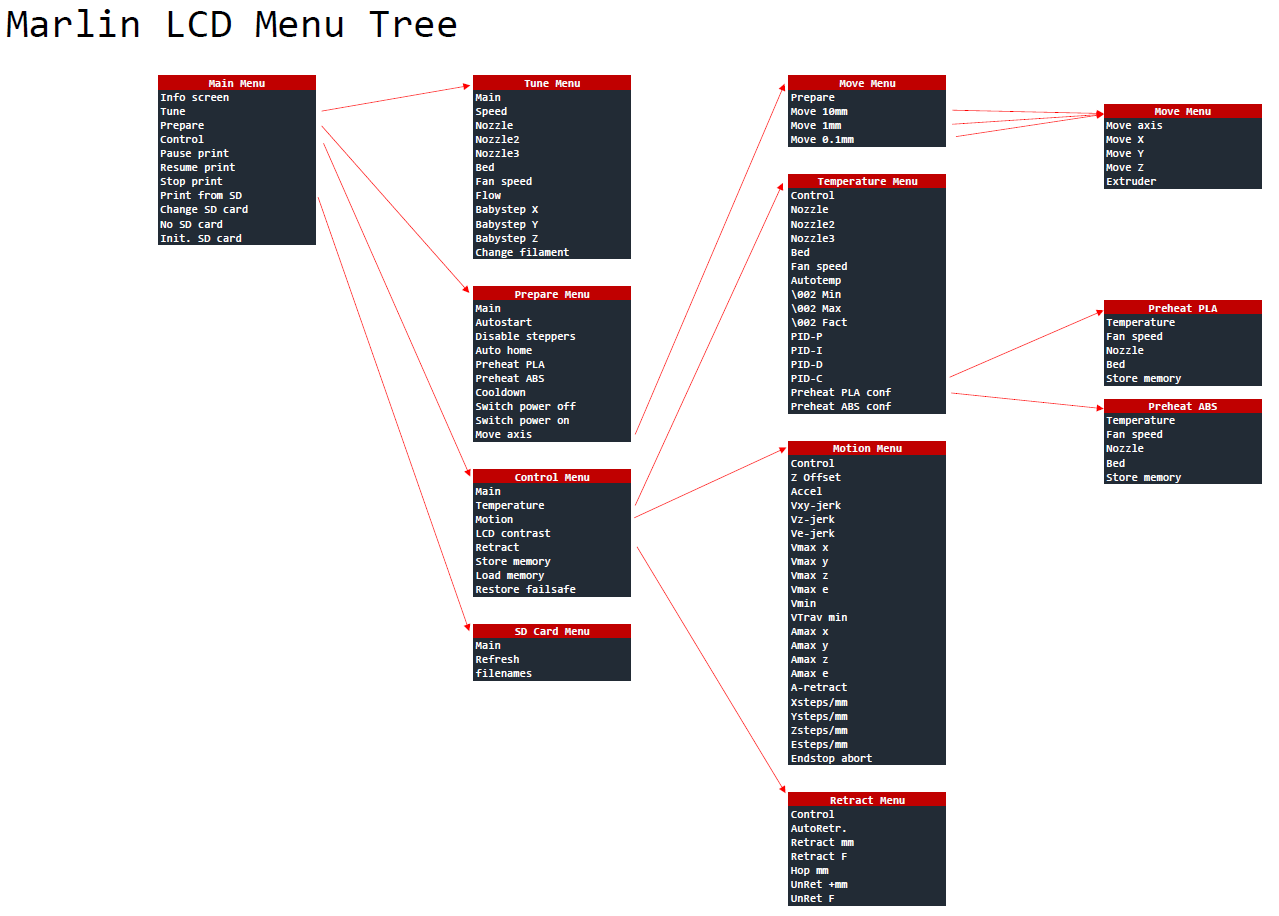

LCD screen control, support SD card print, using Marlin firmware:

You can get Marlin for Sunhokey 2015 here: https://github.com/rene-aguirre/Marlin

You can know your fimrware version by sending the gcode instruction: M503 to your printer.

LCD menu tree:

Motion menu relative to my printer:

Accel: 950

Vxy-jerk: 20

Vz-jerk: +000.40

Ve-jerk: 5

Vmax x: 100

Vmax y: 100

Vmax z: 5

Vmax e: 50

Vmin: 0

Vtrav min: 0

Amax x: 5000

Amax y: 5000

Amax z: 90

Amax e: 10000

A-retract: 950

Xsteps/mm: +080.50

Ysteps/mm: +080.50

Zsteps/mm: +0405.6

Esteps/mm: +0080.5

Temperature menu:

Min: 210

Max: 250

Fact: 000.10

PID-P: +022.20

PID-I: +001.08

PID-D: +114.00

PID-C: 1

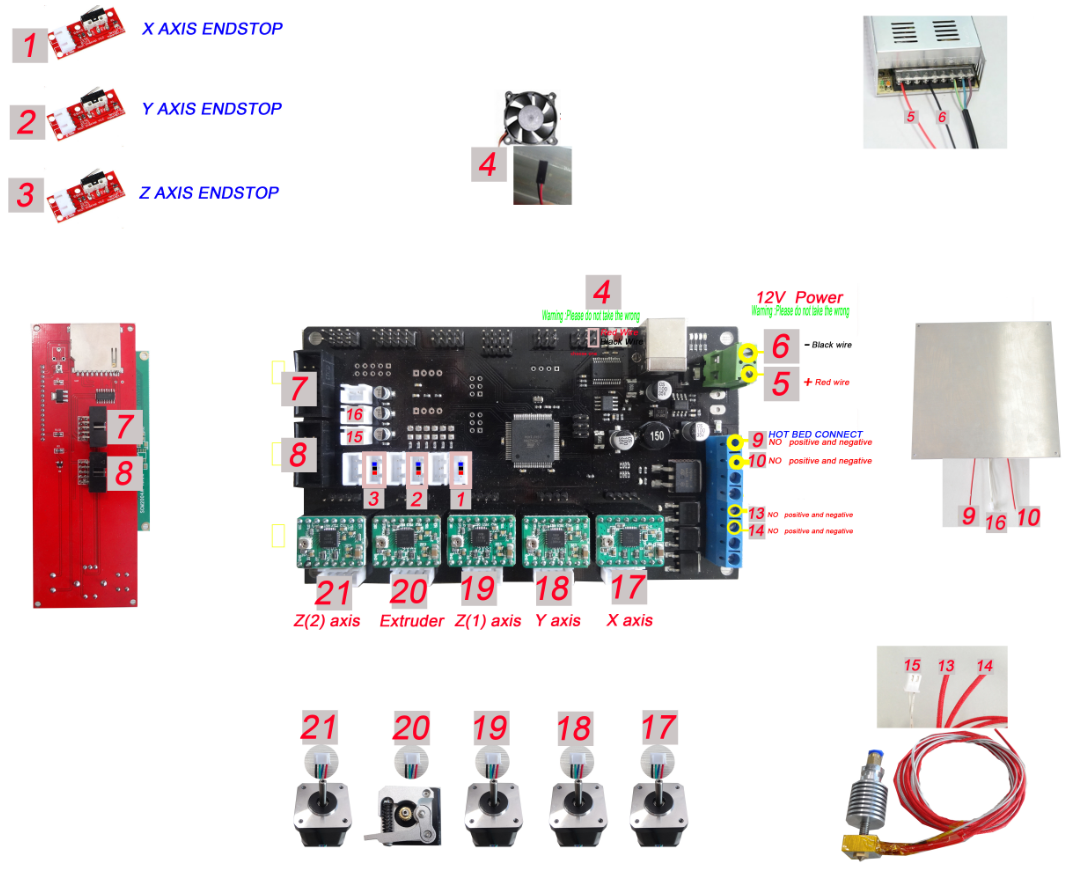

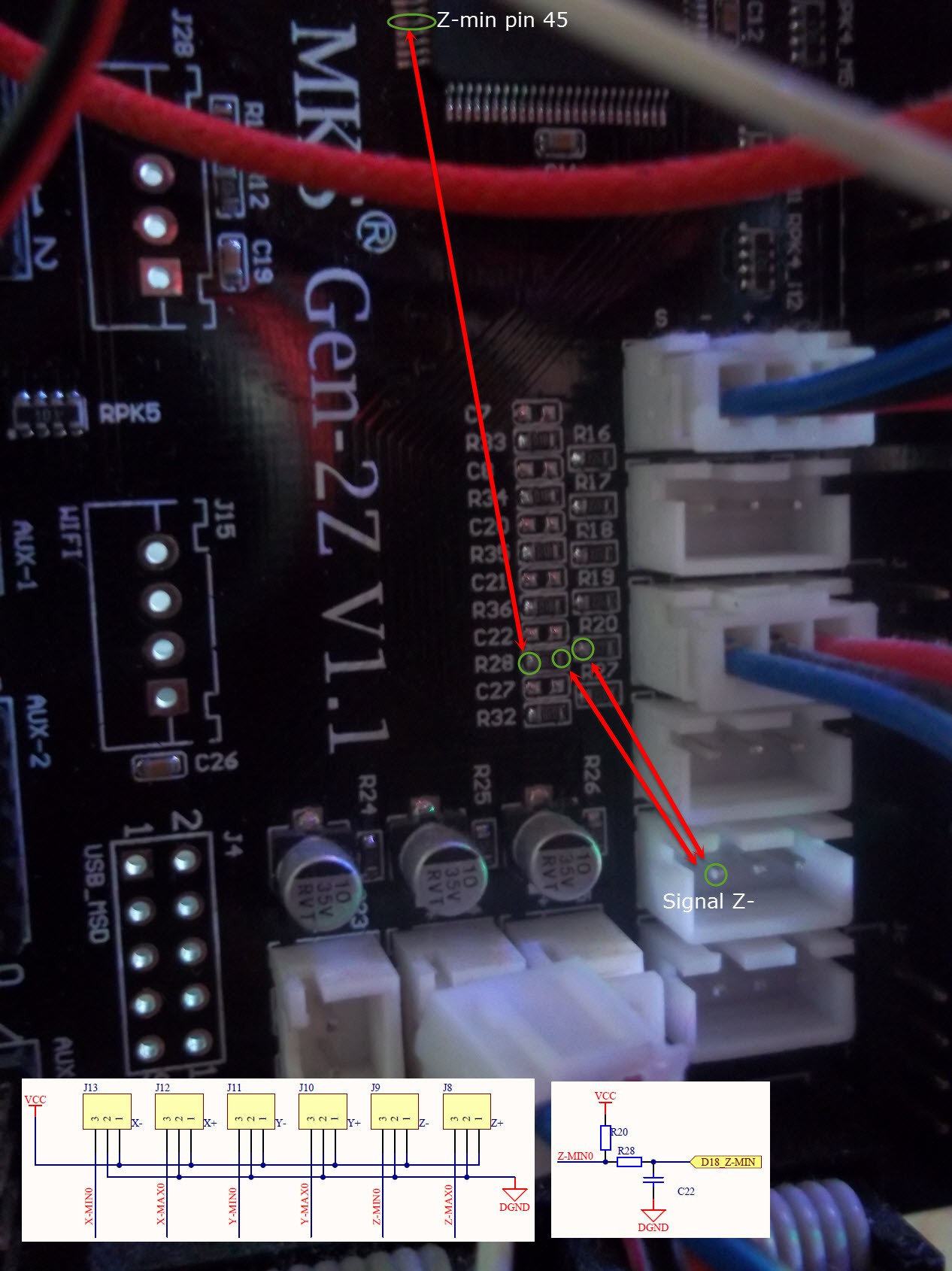

MKS motherboard:

You can get the schematic here: https://github.com/makerbase-mks/MKS-GEN (mks_gen_sch.pdf)

Hardware connect:

A Sunhokey 3D Printer owner on thinginverse reported that the motherboard was catching fire, i never experienced this problem.

Now for Endstops, you can know their statut (triggered or not) by sending to your printer the gcode: M119

If you are going to use an inductive sensor and a MKS Gen board, keep in mind that the board have pullup resistors (meaning you need to desolder) so check your board schematic first ! Here is a pic i took, showing where the resistors are located, R28 goes to microcontroller and R20 is pullup.

Here is a pic i took, showing where the resistors are located, R28 goes to microcontroller and R20 is pullup.

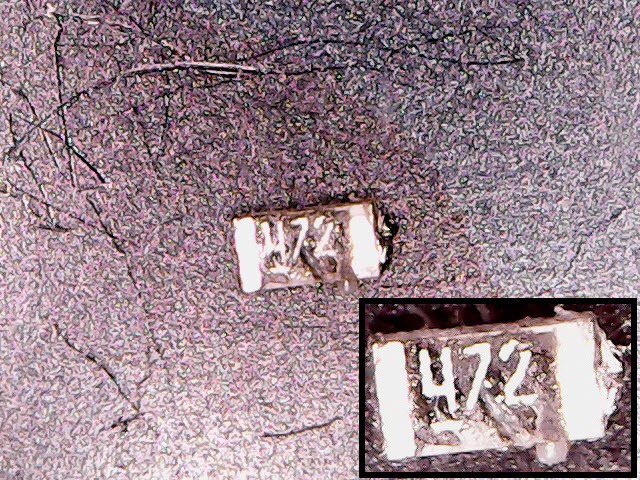

Resistors are using 0603, yes this is small, if you use hot air beware of connectors.

Picture from microscope of R20:

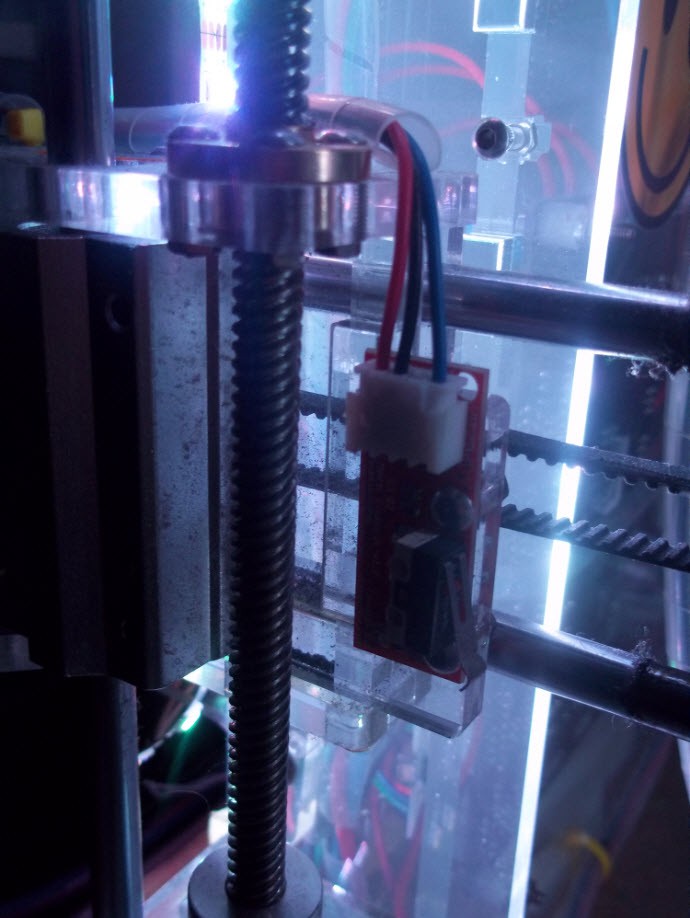

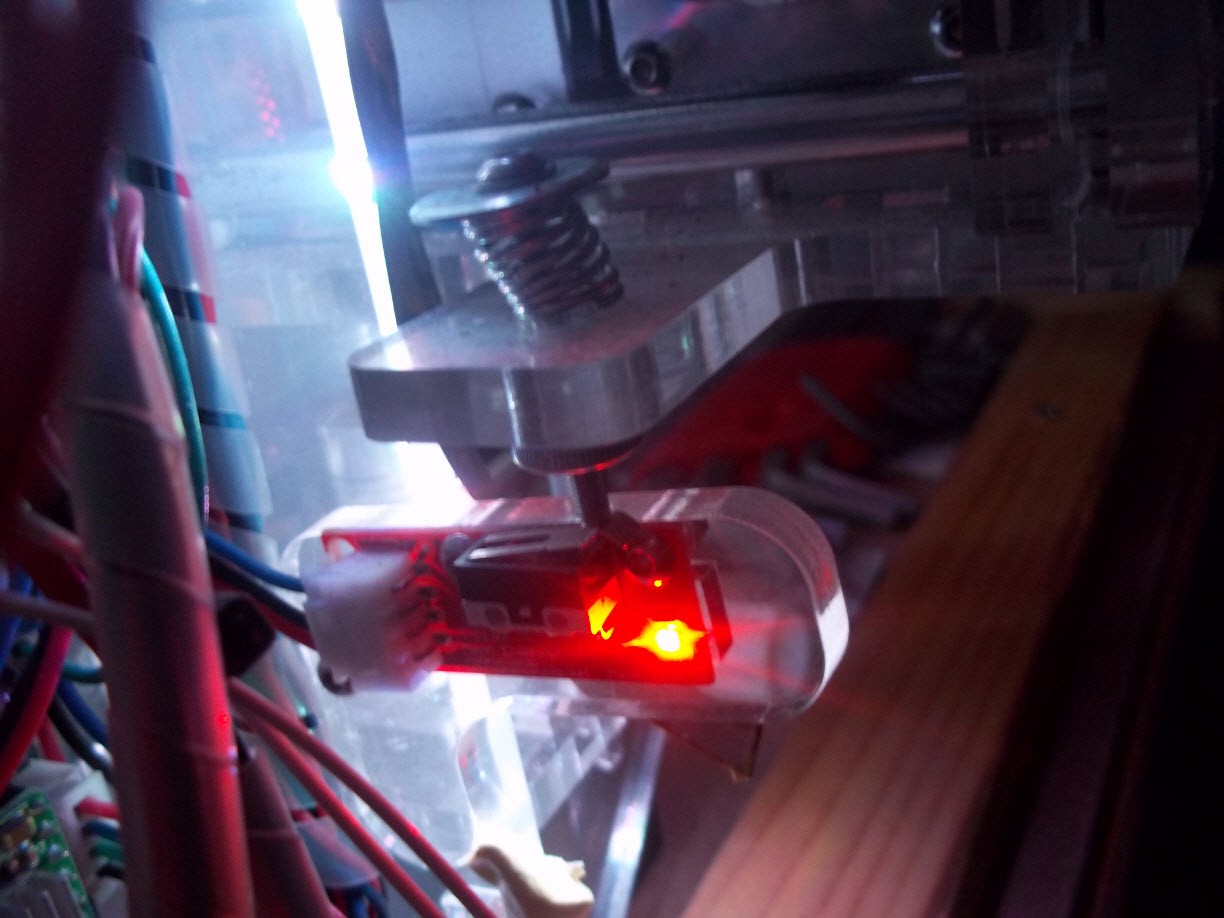

I would recommend using NPN DC6-36V LJ12A3-4-Z/BX 12 MM as proximity sensor, this version have built-in NPN transistor, and so all needed is to edit Marlin and add the 10k and 15k resistors on the sensor.

X axis endstop:

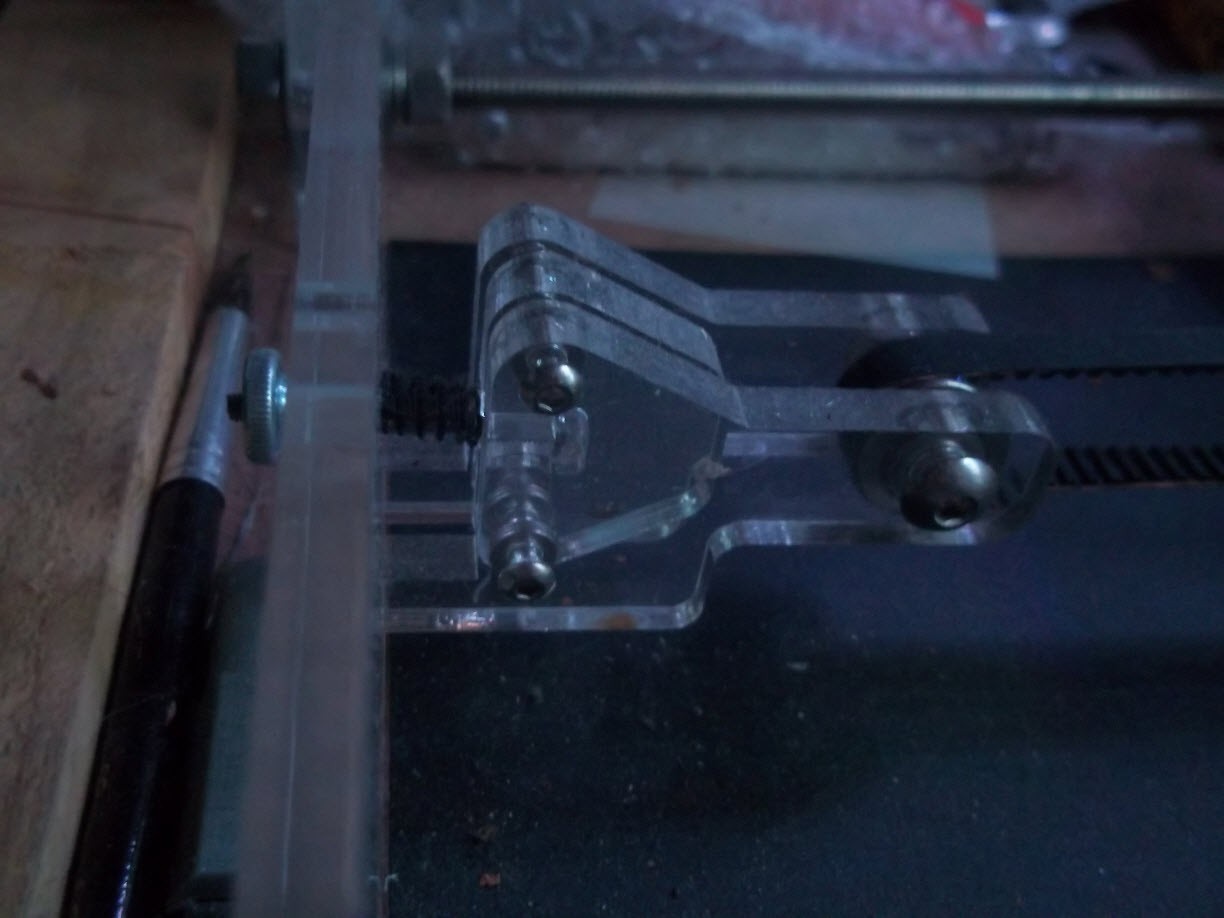

Adjustable X axis endstop:

Adjustable Y axis belt tensioner:

Making maintenance operations very easy.

Maintenance tools:

CRC 41220 Multi-purpose grease (100 ml) for the trapezoidal screw (Z axis)

And to lubricate the rest: WD-40 3 in one Drip Oil (200ml) any VG 100 oil can be fine i suppose.

For cleaning the acrylic frame i'm using KFC alcohol-based hand wipes (work very well against dust !)

Steel cleaning rods for clogged nozzle:

And of course safety gloves, if you think this is optional.. wait to have a 3D printer ;)

You aren't a truly 3D printer enthusiast if you haven't burn yourself once or cut yourself while removing a print or doing maintenance stuff :)

Some even do battle wounds.

Now related to problem i encountered:

⚠ This printer don't work with Cura.

For an unknown reason cura turn off the fan, but anyway the manufacturer configuration is established with Repetier.

🔥 Original hotbed have burn

As i explained the hotbed is lame, and must be changed.

Apart that i don't really have negative critics about it, only improvement ideas.

If you want some:

- Add another cooling fan

- Changing the acrylic for a metal frame or at least the hotbed chariot by MDF or something who can resist more to temperature deformation (although i don't have deformation problem)

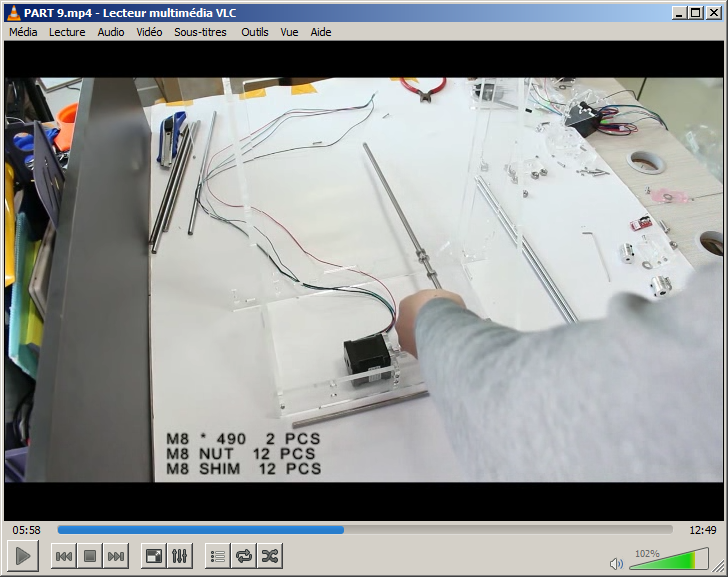

This printer is friendly, easy to assemble, (instructions on how to build come in a video DVD)

Easy to calibrate and do work of quality with PLA, printing with ABS is a bit challenging.

May only the challenge guide you :)

If you have any questions you can ask them here and i will reply, otherwise you can also ask the Sunhokey 3D printer owner community of Thinginverse.

To backup your firmware using avrdude:

avrdude -p m2560 -c wiring -P com5 -b 115200 -F -U flash:r:prusa_i3_backup.hex:i

avrdude -p m2560 -c wiring -P com5 -b 115200 -F -U eeprom:r:prusa_i3_backup.eep:i

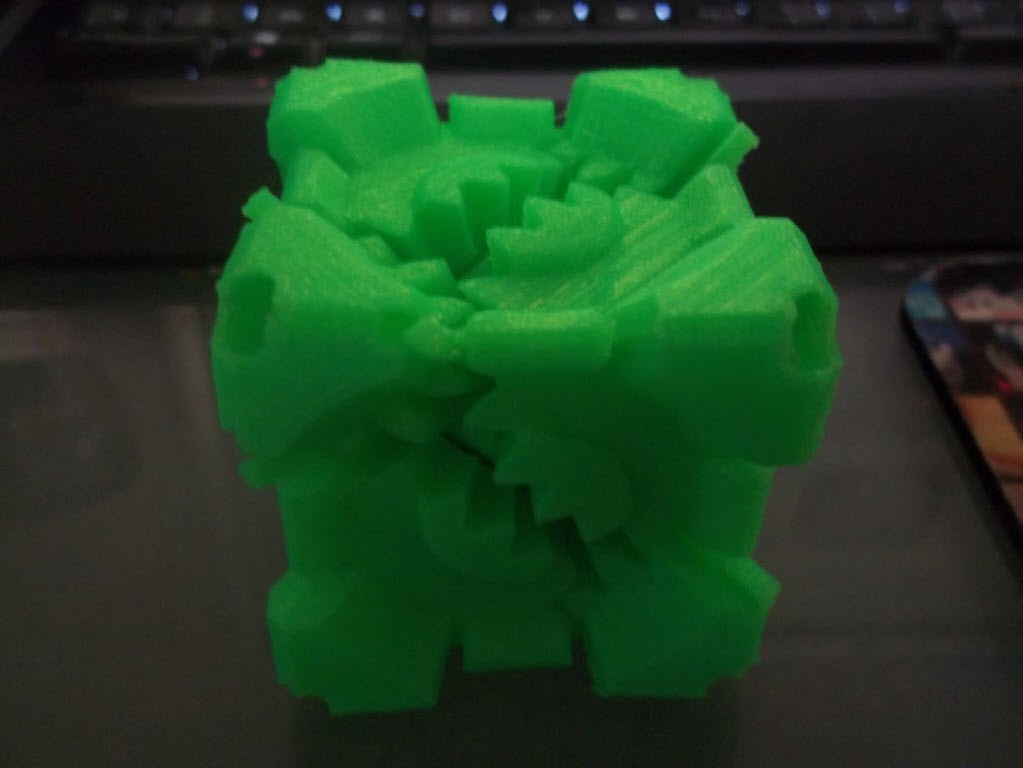

A 3D printed weighted storage cube gears with my printer:

Good luck with calibration !

Good luck with calibration !

You can find all my makes and designs on my Thinginverse profile here: http://www.thingiverse.com/Xylitol/about

My CuraEngine parameters can be found here: http://pastebin.com/gqw52Pqx

Oh, and guess who did this mess http://hackaday.com/2015/09/18/dear-tsa-this-is-why-you-shouldnt-post-pictures-of-your-keys-online/

Xylitol

Xylitol

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.