In the world of electronic components, the choice between Land Grid Array (LGA) and Ball Grid Array (BGA) packaging plays a crucial role in determining the performance and reliability of integrated circuits. This article aims to provide a comprehensive comparison of LGA and BGA, outlining their characteristics, advantages, and considerations. By understanding the differences between LGA and BGA, you can make an informed decision on which packaging option is best suited for your specific application needs.

LGA: Land Grid Array

LGA is a surface-mount packaging technology where the package has an array of metal pads on the substrate. The integrated circuit (IC) is mounted on top of the pads, and the connection is made through soldering or conductive adhesive. LGA packages do not have solder balls but rely on the metal pads for electrical and mechanical connections.

Advantages of LGA:

- Improved thermal performance due to the direct contact between the IC and the PCB, allowing for efficient heat dissipation.

- Easy inspection and rework as there are no hidden solder joints.

- Less prone to solder joint failure and cracking compared to BGA.

BGA: Ball Grid Array

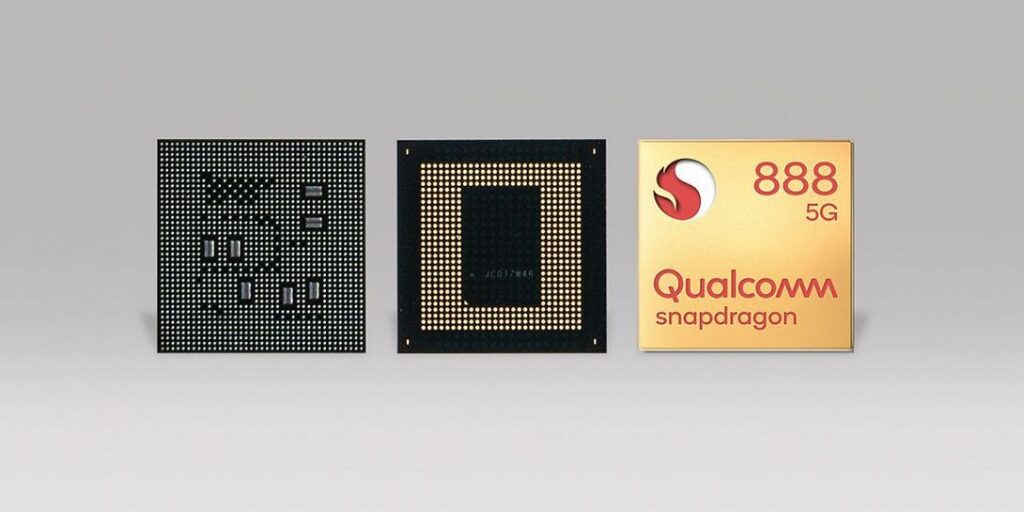

BGA is a packaging technology where the IC is mounted on a substrate, and the electrical connections are made using an array of solder balls on the bottom of the package. The solder balls act as both electrical and mechanical connections to the PCB.

Advantages of BGA:

- Higher pin density allows for more connections in a smaller area, making BGA suitable for complex and high-performance integrated circuits.

- Better electrical performance and signal integrity due to shorter electrical paths and reduced inductance.

- Improved resistance to mechanical and thermal stresses, making BGA packages more robust in demanding environments.

Considerations for Choosing Between LGA and BGA

When deciding between LGA and BGA, several factors should be considered:

- Packaging Size: If size constraints are critical, BGA is typically the preferred choice due to its higher pin density and smaller footprint.

- Thermal Considerations: If thermal management is a priority, LGA's direct contact with the PCB enables better heat dissipation.

- Manufacturing Process: BGA packages require more complex manufacturing processes, such as precise ball alignment and reflow soldering, which can impact production costs.

- Accessibility and Rework: LGA packages offer easier inspection and rework capabilities compared to BGA, as the connections are visible and accessible.

- Application Requirements: Consider the specific requirements of your application, such as electrical performance, reliability, and environmental conditions.

Conclusion

The choice between LGA and BGA packaging depends on various factors, including size constraints, thermal considerations, manufacturing processes, and application requirements. Both LGA and BGA offer unique advantages, and understanding their differences is crucial in making an informed decision. By carefully evaluating your specific needs and considering the pros and cons of each option, you can select the right packaging technology to optimize the performance, reliability, and manufacturability of your integrated circuits.

Related Article:

Sam

Sam

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.