Motivation:

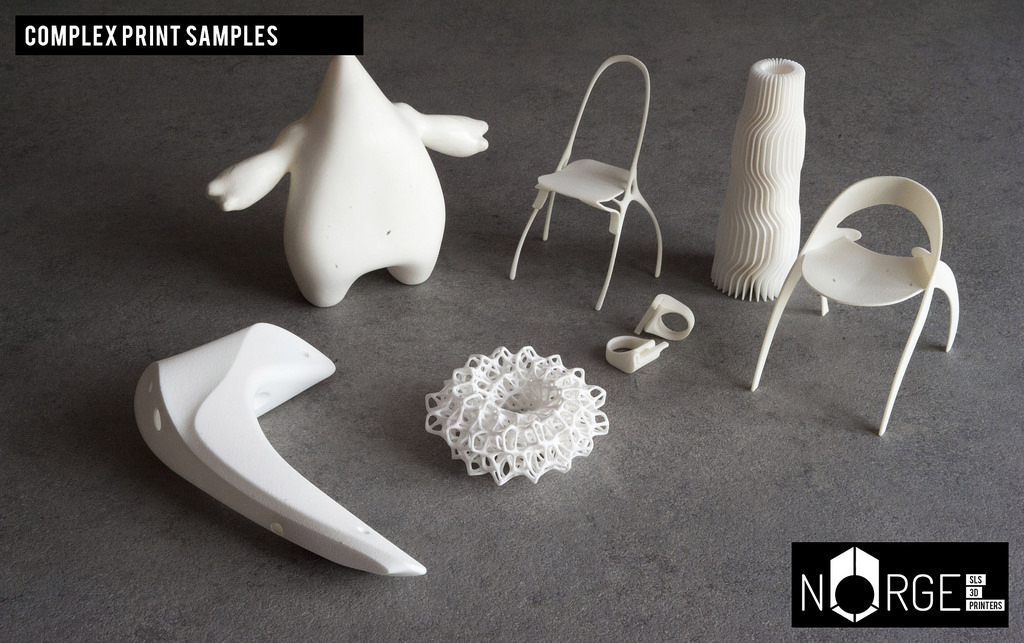

They say with 3D printing, the complexity is free. That is not true for FDM printing technology. It is, with SLS tech:

Basic Idea:

To create a SLS 3d printer that is as cheap or close in cost to a Reprap 3D printer to build. The prohibitively expensive parts of this system are the laser and the scanner system:

The common method used in SLS systems:

Lasers:

The laser need not be very powerful. 10 watt lasers are use in Nylon SLS systems such as the Norge Ice1: https://3dprintingindustry.com/news/first-low-cost-sls-3d-printers-hit-scene-31351/

This can be done by heating the build chamber/box to 10 degrees below its Tg (glass transition) temperature and using the laser to increase the temperature over Tg to it's melting point. The surface

- For laser, a 5 watt laser can be used to melt the nylon. Heating the build volume with heated plates from all sides and above via a heat lamp the nylon could be brought close to its melting point. Then, the laser can be used to raise it over this point, causing it to melt. This also would help combat warping of the parts, which in FDM printing nylon is notorious for.

- The Scanner system: For this typically a galvanometer is used. They are expensive. The laser could be moved using a common xy mechanism (such as corexy) or by scanning the beam across the build platform by means of a galvanometer. A low cost galvanometer system could be implemented as below:

Most likely, it will be much better to buy an off the shelf unit like this one: http://www.ebay.com/itm/261517002270 (KPPS stands for kilo points per second)

5 watt laser for 400usd, small compact unit, could be quiet nicely mounted on an xy gantry system without the need for mirrors: http://www.ebay.com/itm/Engraving-laser-head-445nm-5W-43mm-PSU-CNC-laser-diode-/231671786425

40 watt co2 laser for 240usd: http://www.ebay.com/itm/40-Watt-CO2-Laser-Tube-/380994929411

Combined with the above galvo's in the ebay link this could certainly be very potent.

"At £7.500 GBP + VAT (about $13,000 USD + tax),

the Ice1 uses a 10W solid state laser to sinter items up to 20 x 20 x

25cm in size at a speed of 8 to 25mm/hour, with the same layer

thicknesses as its older sibling." Source: https://3dprintingindustry.com/news/first-low-cost-sls-3d-printers-hit-scene-31351/

Good reading as well: https://3dprint.com/62887/polyforge-3d-printer/

FAQ on SLS printing on the reprap wiki: http://www.reprap.org/wiki/DIY_Selective_Laser_Sintering_FAQ

Great resource for SLS research and R&D according to Ccecil on #reprap, IRC: (I've gone ahead and bought this book from book depository) https://www.amazon.com/Focus-Methods-Printing-Emerald-Gems/dp/1785608657#reader_1785608657

Any criticism, comments or suggestions are welcomed!

In the end I would LOVE to see a community built SLS machine,

whether thats me undertaking dev work or in collaboration with others, I want to see this happen.

TTN

TTN

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.