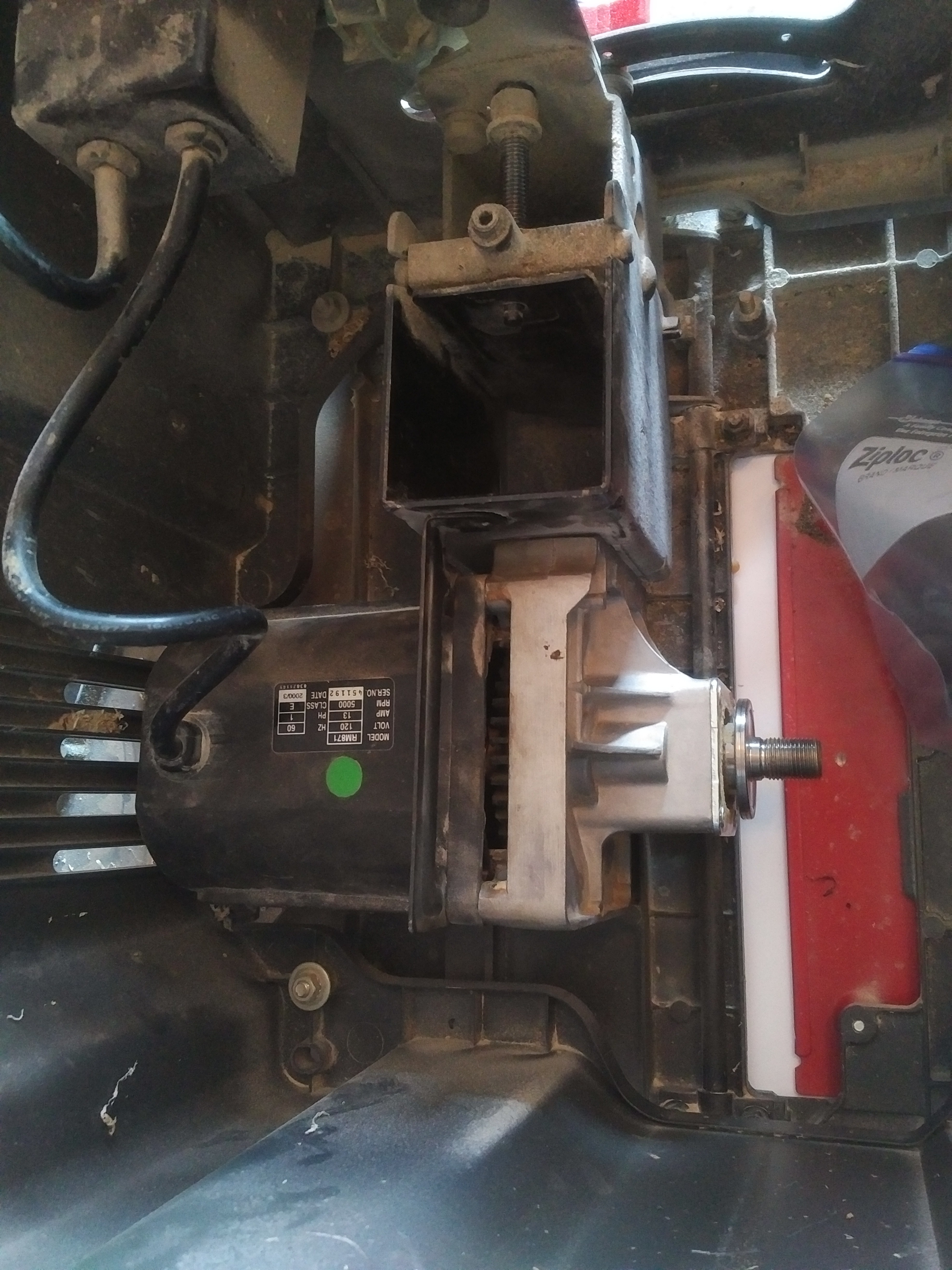

After seeing this repair listed I thought I'd post mine. My 1990's Sears table saw started slowing down and stopped one day. Pulling the motor apart revealed a black bearing which would only spin if I used pliers on it. being pressed on the shaft I had to destroy it to get it removed. I pried the dust covers off each side then extracting all the balls left the inner portion. I could not get it to pry off so I used the technique of grinding most of the way through and then hammering a chisel in the slot to crack the remains as in the image below.

Normally you grind a line parallel with the shaft all the way through but the side nearest the armature of the motor there wasn't enough clearance so I had to just grind away what I could on that end. The trick is to cut most of the way through but not all the way so as to not cut into the shaft. Then a thick chisel and a couple hits with the hammer to spread the cut wider to crack below the cut and then it will pull off easily. I measured and ordered a replacement from amazon, here you can see both.

Normally you grind a line parallel with the shaft all the way through but the side nearest the armature of the motor there wasn't enough clearance so I had to just grind away what I could on that end. The trick is to cut most of the way through but not all the way so as to not cut into the shaft. Then a thick chisel and a couple hits with the hammer to spread the cut wider to crack below the cut and then it will pull off easily. I measured and ordered a replacement from amazon, here you can see both.

The new bearing pressed on easily and I mounted the motor back in the saw and was back to making sawdust again.

The new bearing pressed on easily and I mounted the motor back in the saw and was back to making sawdust again.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.