With some quite decent tooling and equipment coming from China these days, my curiosity was sparked as I saw a rather affordable kinematic mount. For those not familiar with such lab equipment, this is a holder for lenses, prisms, filters or anything you'd like to position and adjust with respect to a beam path. These are supposed to be rock solid, like down-to-the 100nm region solid, like "I'm worried about thermal expansion due to room temperature changes" solid.

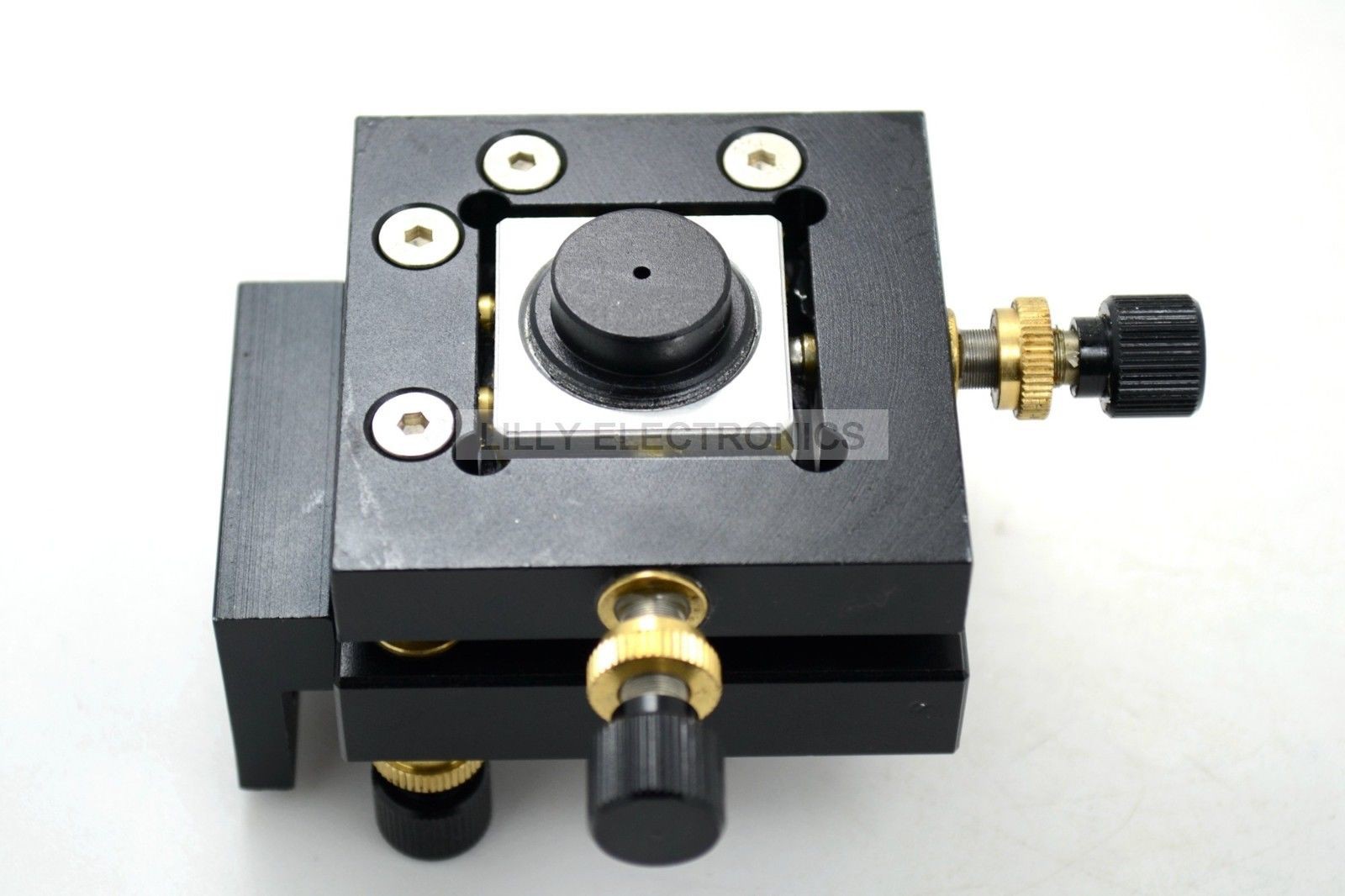

Here's the culprit as sold on ebay,

Now while I can fully accept that simplifications have to be made to reach a certain price point like $30 delivered, making a good product also implies not wrecking it by stupid design decisions or by having someone in the production chain who didn't know what they were doing.

First of all, the threaded holder that comes with the kinematic mount is not really held in there properly and you hear a nice crunchy sound when you tighten up the anodized pieces. I'd love to have seen a set screw with a POM or Nylon plug there. But that's not what we're here for.

See, the beef that I have with this mount is not so much the things that have not been done rather than the things that have been done wrong. For example, the fine adjustment screws are actually inserts that you can buy separately for other purposes. They're just designed into this mount as a separate component. They are also produced with different heights of the knurled fixing nut and guess what?

they are glued in place.

One actually came loose during shipping. I pushed it back in gently in the vise but it came out anyway. The same was true for the other 2 out of four (the last one is always stuck!).

The sad thing is that this will always happen because all elements are preloaded by both sets of tension springs and screws with a stack of spring washers. The latter is supposed to avoid twisting the front plate off the ball joint and possibly to give a haptic "stop" so you know when you're about to overtension the springs and the preload force gets quite high towards the end (also the screw is a tad too short or the bearing ball is too large). So high in fact that you're losing the fine touch needed for precision optics.

The collar on the threaded bushings is supposed to aid in the assembly process to stop the bushing at a proper depth. Obviously it could also have been utilized to set the bushing and avoid it being stripped back out by the preload. This is guaranteed to sabotage your optical alignment due to position drift. Almost feels like this was done on purpose ;-)

Alright, let's fix it then, shall we?

Just remove the bearing ball, undo the preload springs and.. oh wait.

the springs are such that you can screw in the countersunk screws easily but they tighten up against the threads in the left-hand direction. Should've seen that coming.

A way to avoid this is to either leave them in or to pull them up by 3mm, reach in with another screw driver and act upon the start of the spring. I left the other three in place and proceeded with removing the spring washer limit screws.

The rest of the assembly comes apart quite easily so I removed all adjustment screws, unscrewed them from their bushings and inserted the latter from the insides.

You'll have to remove the set screws to loosen the springs centering the optics holding block but then you're good to go. Here's the translation stage back together.

Look closely and you'll see that the fixing nuts have different heights. As it turns out one can actually reach into the pocket formed by the bore and the reinserted bushing, the other one cannot. Always a catch. This means that the longer one can tighten against the brass bushing while the shorter one tightens against the anodized surface.

Anyway, let's wrap this one up.

Some massaging and cursing later the whole assembly is back together. From how this feels I suggest to clean bore and bushing with alcohol, remove the cheap glue and add a small dab of loctite to keep the bushing from rotating.

So, bottom line? These 4-axis kinematic mounts can be quite ok if your project is on a budget but as with most of the other unfinished tooling you're used to seeing, you're paying the difference to a brand name product with your time and motivation. Hope this was helpful.

for reference also check out

https://www.newport.com/c/adjustment-screws

https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=8013

ps. they actually reacted to my review and fixed the orientation issue. Nice.

helge

helge

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.