Today I planned to mount an SQ12 camera on an old RC boat to make for some interesting footage. I pulled out the old boat, put in the batteries for both the boat itself and the controller, turned it on . . .

. . . and you guessed it nothing! I had an almost identical extra boat and controller (the only difference was the frequency it operated on.) I put in batteries, got nothing. I checked to make sure the batteries were good and they were.

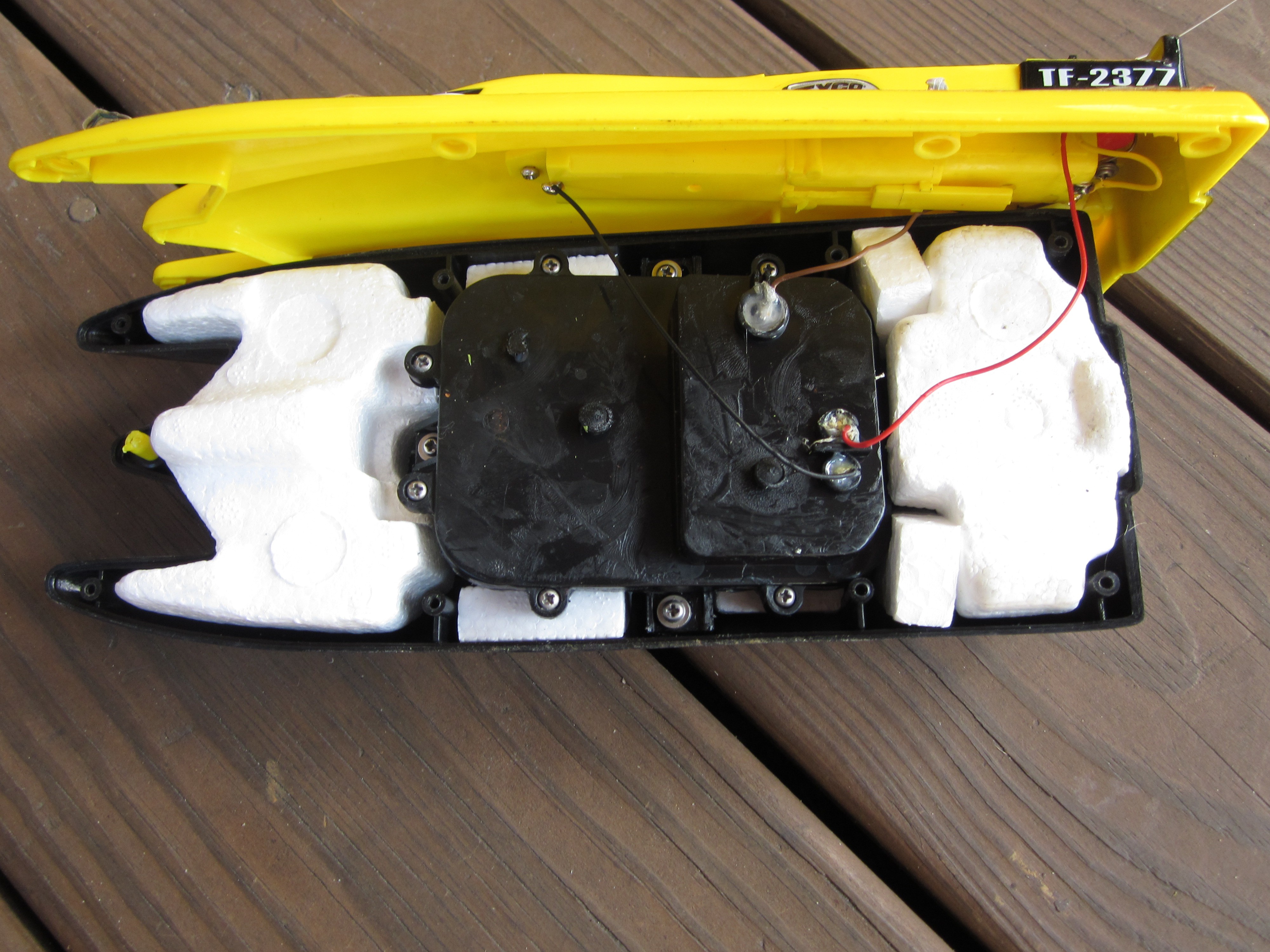

I this point I feared the worse case scenario, the PCBs on both boats were ruined by the water. Seeing that I was unable to turn them on, I decided to take them apart! Sadly I had to damage the stickers to get to the screws to take the top off, but there was no other way. I did have one screw well snap on me due to the fact the screws were torqued down so hard. Inside I found a a few styrofoam pieces and an internal box that likely housed the PCB and motors.

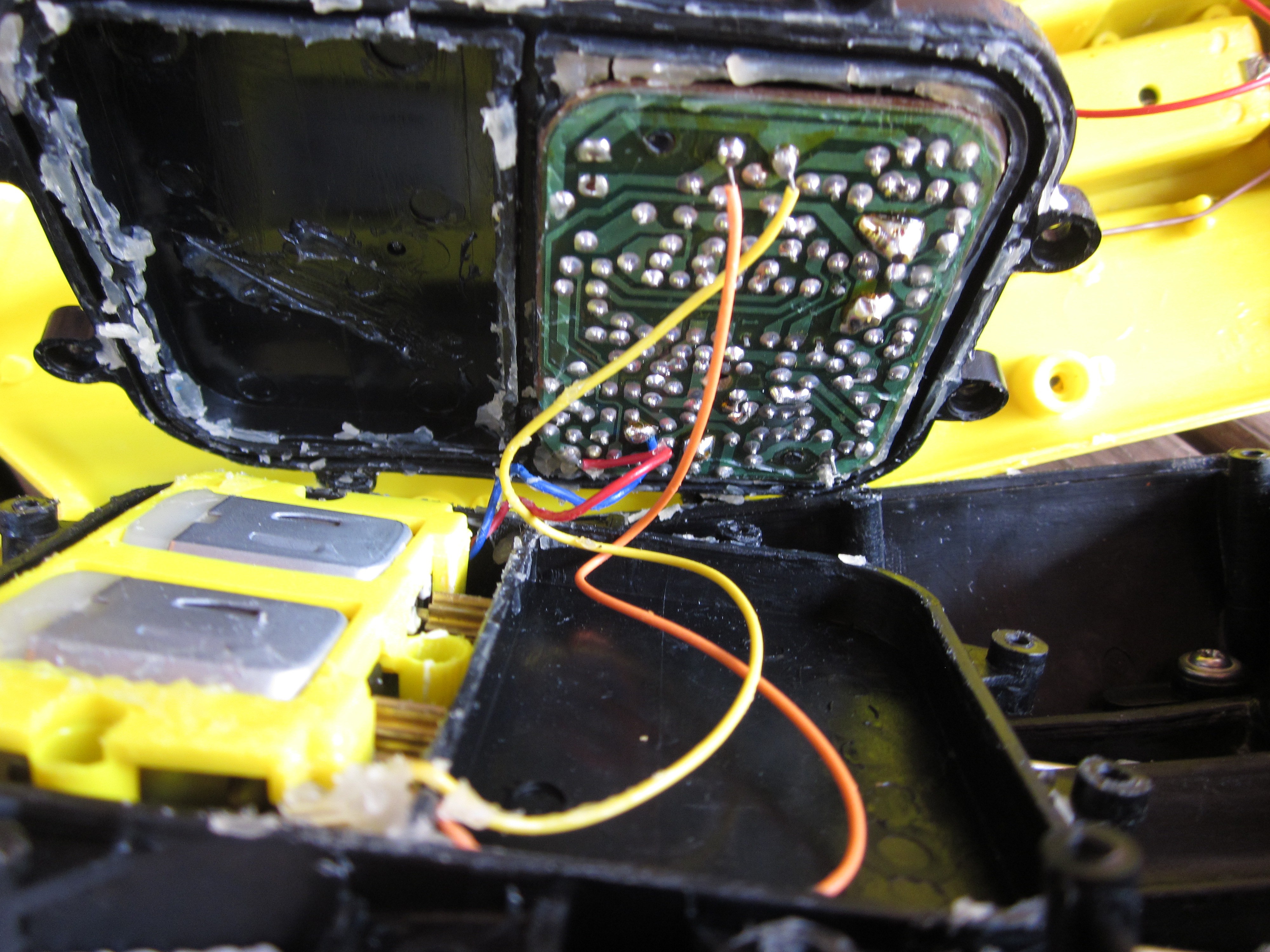

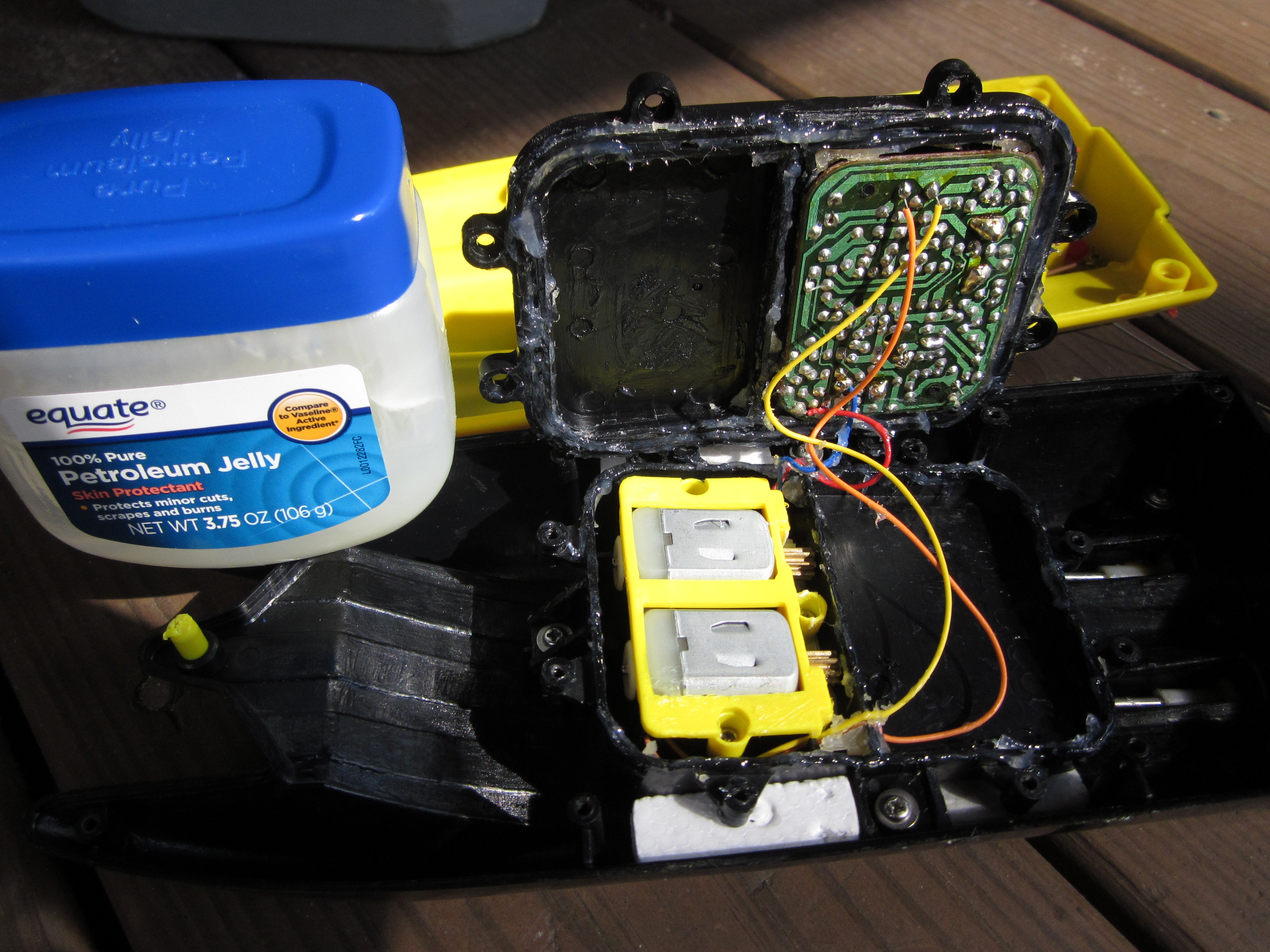

I pressed on and opened the inner box. Sure enough, it contained the PCB and motors. I couldn't find any obvious signs of damage to the PCB. Interesting to note is that some sort of grease was used to actually mitigate any water ingress, didn't expect to see any effort given as it was a cheapo product. It would have been better if it used a greased o-ring but can you expect. The grease was a bit cracked in areas, so I would need to fix that later before I closed everything back up.

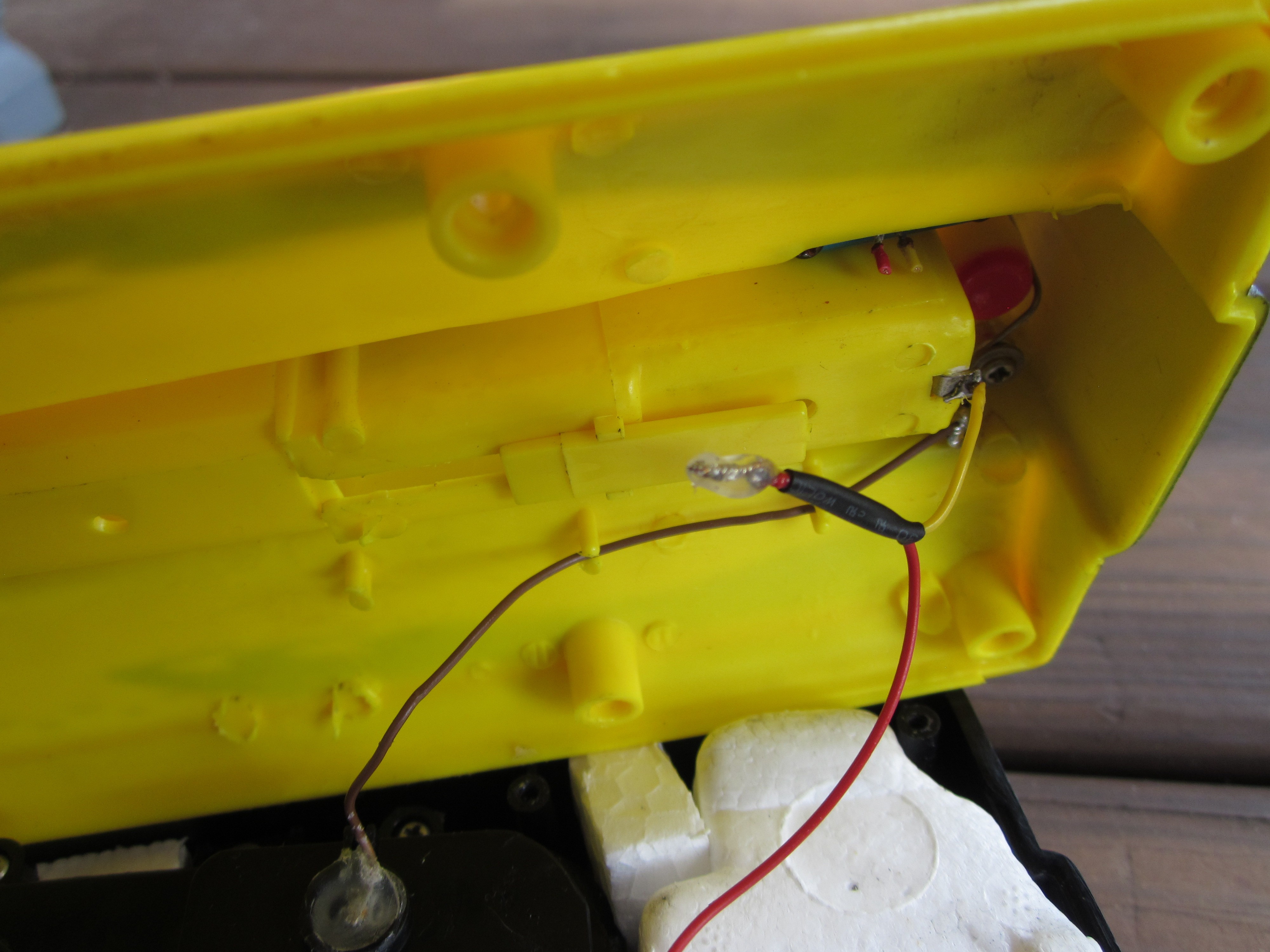

Seeing as everything looked fine in the PCB and motor box, I started thinking. Could it really something stupid simple as the power switch not working? I decided to short out the power switch leads. It came to life! I didn't open the other one and see if its power switch also failed (will likely do that in the future) but it's likely what happened to it as well.

Upon reflection, the failure isn't too surprising. The boat sits very low in the water and of course the points where the propeller shafts enter the boat means that water gets in the boat very easily, hence the sealed PCB and motor box and the styrofoam pieces. The instructions mention every so often pulling the boat out of the water and holding it vertically with the bow pointed up to let the water drain out. Just slightly above where the drain is located is the power switch, hence an easy point of failure.

My fix was to simply bypass the switch and solder the leads together. I tried some contact cleaner on the switch, but that failed to work.

Now came the resealing of the inner PCB and motor box. The old cracked grease wasn't going to do. I thought of what I could use that I had on hand and came up with petroleum jelly. There are likely better options out there but as it's non-conductive and it was what I had on hand, it's what I used. I used q tips to apply it (after removing the much of the old grease that could be easily removed.)

After that I closed everything up. and made sure it still worked. I then forgot about the styrofoam pieces and had to open it back up to put them back in.

Anyways here's some footage I took. As light as the camera is, it weighed down the boat too much and had to put it at an odd angle to reduce the chances of the boat tipping over.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.