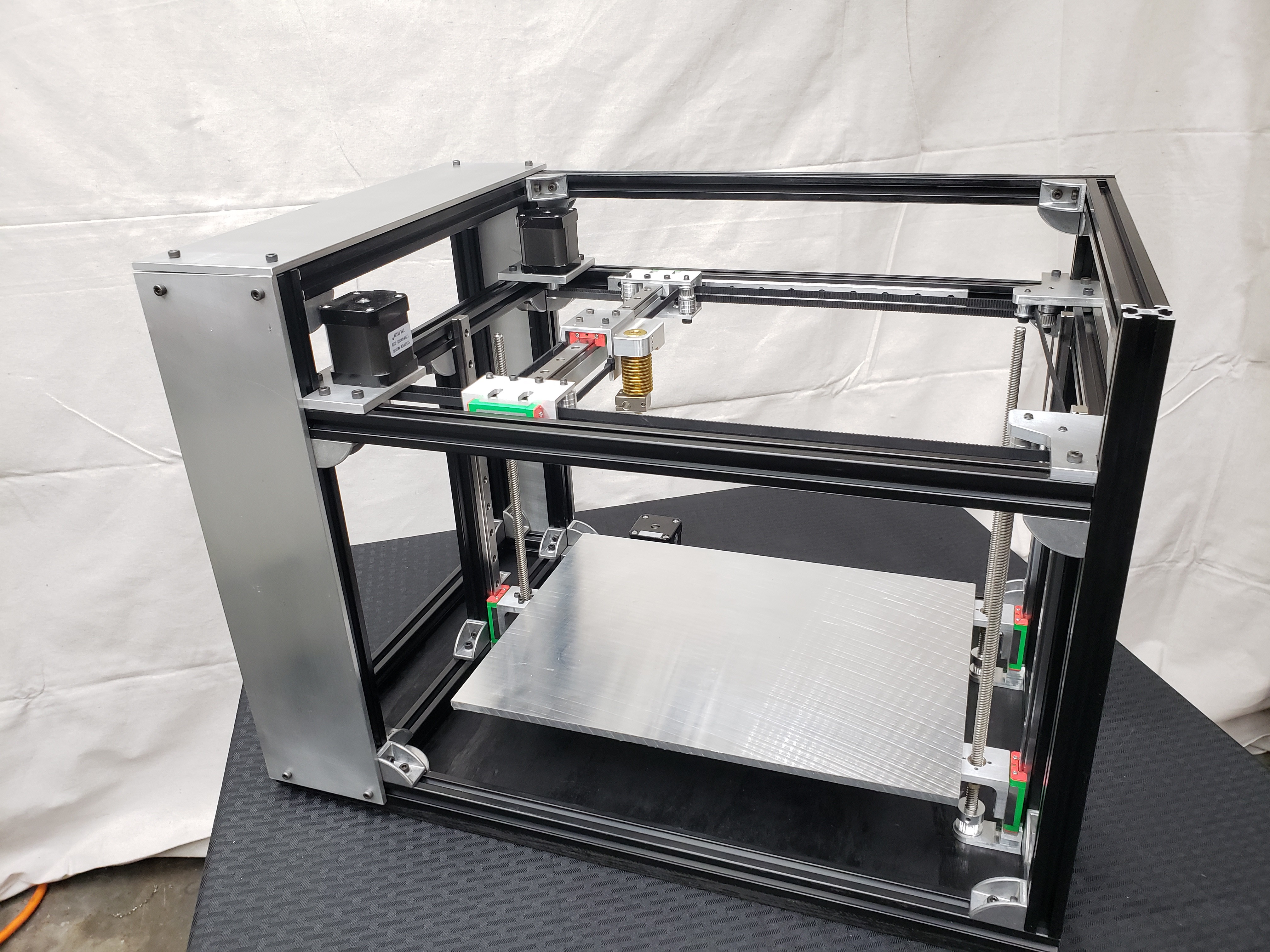

- The whole idea is to build a corexy printer that has:

- Modular

- Scalable

- Linear Rails

- BOM utilizes standard and available printer parts people already have so they can convert their printer into a SolidCore

- Easily add an enclosure

- All metal components or printable

We’ll probably make some changes such as reorienting the the y-axis linear rail into a vertical position similar to the RailCore, redesigning the carriages and motor/belt mounting plates where the z-axis motors are placed on the bottom of the machine. When I first designed the plates I thought it would look cool with the motors on top but after I machined everything I realized that moving the bed up and down could cause deflection in the main plates. I’m also considering making the carriage components and rail support one piece similar to the latest update on E3D’s Tool Changing printer. We’re working on a small budget lol which “recycling” parts from previous builds. For example the bed is made from 3/8 inch thick aluminum that we robbed from an old printer. We’ll change that to 1/4 inch thick once we get more money. The left motor plates are going to be re-machined to give room for a tool changer setup. The overall footprint of the machine relative to print volume is somewhat excessive. In order to have a solid enclosure design I had to move the motors inside the frame boundary. This sacrificed the overall printer size to print volume ratio.

DIY Designs

After searching the internet and studying every machine design that I could possibly find i begin to take note of the pros and cons of each motion system or platform. Some had great communities that further developed the machine. Some of the printers I researched were:

HyperCube Evolution or HEVO

C-bot / D-Bot

Jubilee

Hevort

Railcore

E3D Toolchanger

BlackBox

Mike Fisher’s QuadRod

Maarten van Lier’s corexy build

Triple Independent Motors Z Axis

We’re planning to use 3 z-axis stepper motors on the SolidCore printer. Each lead screw will be constrained by a MGN12 linear rail. Originally we were working on a design that used one single z-axis motor and a belt routing the three lead screws together in sync. But after having trouble sourcing the belt that was the perfect length I decided to just go with three stepper motors similar to the HeVort printer or Jubilee tool changing corexy.

I'll update the files when finished but there’s still a lot of work to be done.

Shane Hooper

Shane Hooper

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.