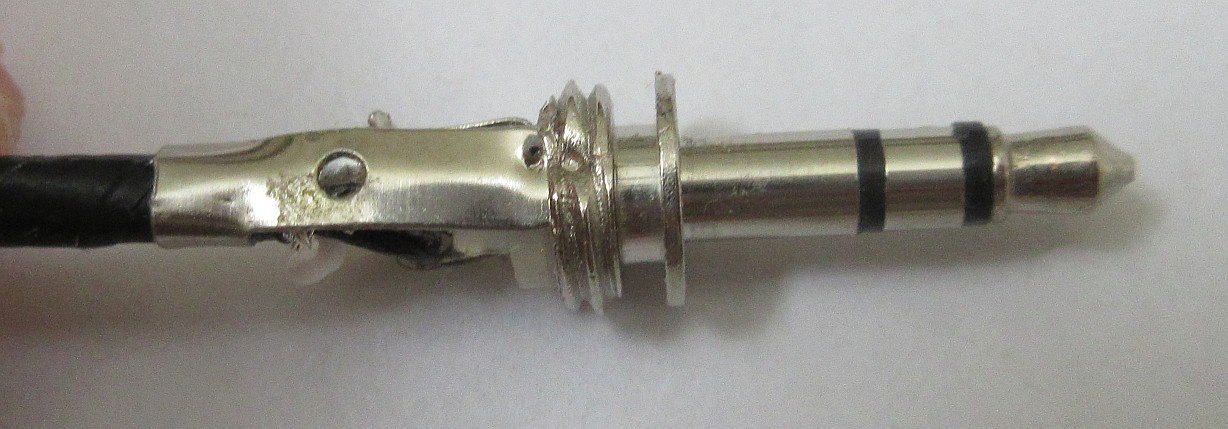

It seems that some of the cheaper Chinese parts are up to snuff when it comes to metal and plastic. This is the usual cheap connector that came off aliexpress.

I went into a few issues with the connector. These connectors are made with multiple smaller parts and the riveted together. The problem is that the white piece of plastic spacer can deform under heat from soldering. As a result, the ground ring can spin around and make poor connection. Older more reliable connectors use phoenic and can survive the soldering.

To make the matter worse, the plating on the connection has some serious solderability issue unless you use an aggressive resin and/or file off the plating.

I use my trusty center punch to punch a hole on the side. The Chinesium is soft enough that the punch pieces through the outer layer and pinch into the ground contact. This stops it from spinning around and make a reliable air tight connection.

For the coaxial power plug, I sometime have to use the center punch on the rivet too as they loosen up easily after soldering.

The next common problem is the recycled plastic housing cracks for exposure under UV or something. For that, I made a DIY one out of PVC jacket from old cables with a bit of superglue.

That thick one is probably from the old SCSI 1 Centronic era.

Here is the housing from those indestructible jackets. The connector side is simply screwed into the jacket.

I made a shim out of cardboard on a couple of the connectors because the "Ring" wasn't making proper connection to my PC motherboard audio connector. It worked for my other 3.5mm connectors, so it could be an edge case of mechanical tolerances.

K.C. Lee

K.C. Lee

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.