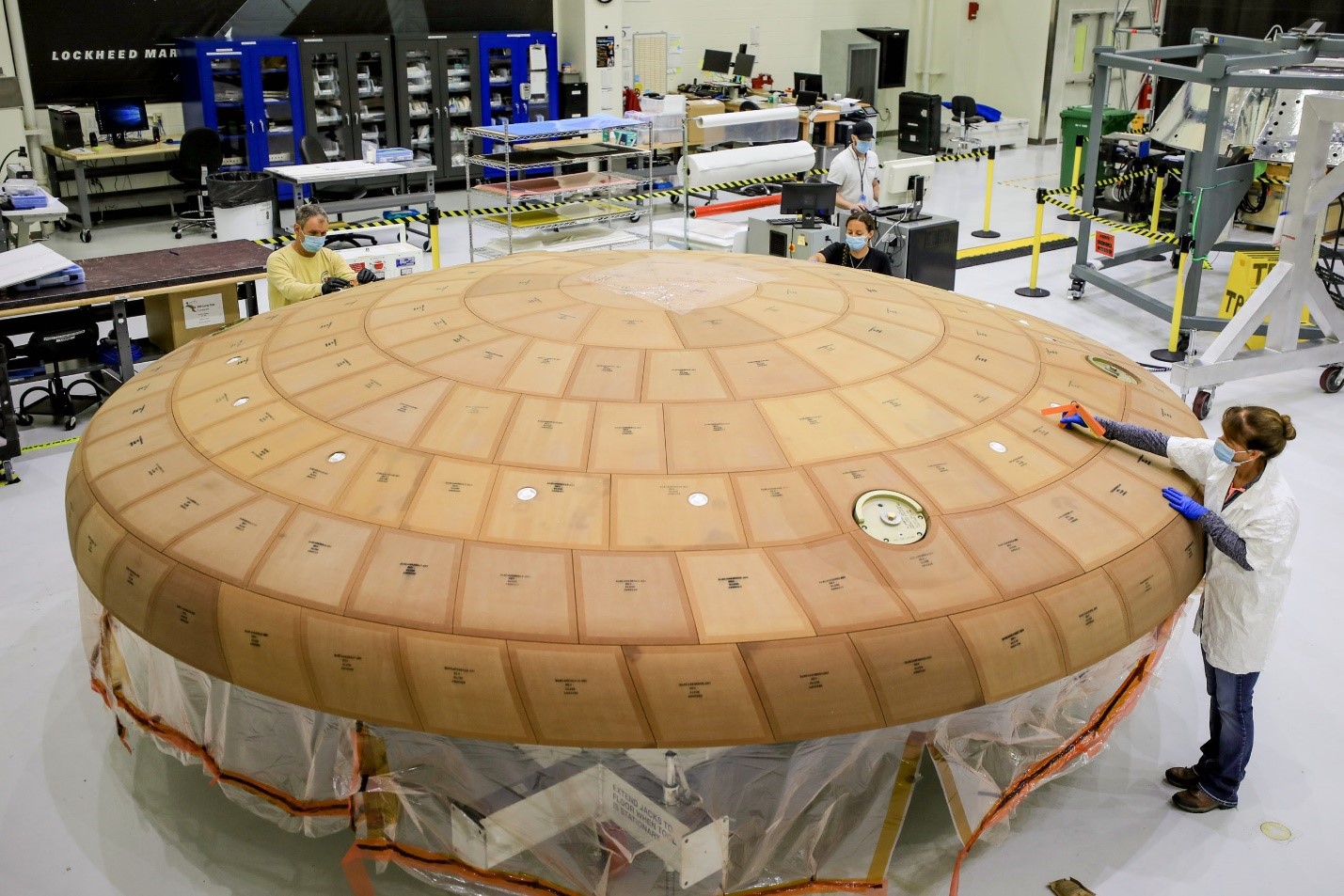

The 16.5 foot diameter Artemis heat shield (Image from NASA/Glenn Benson)

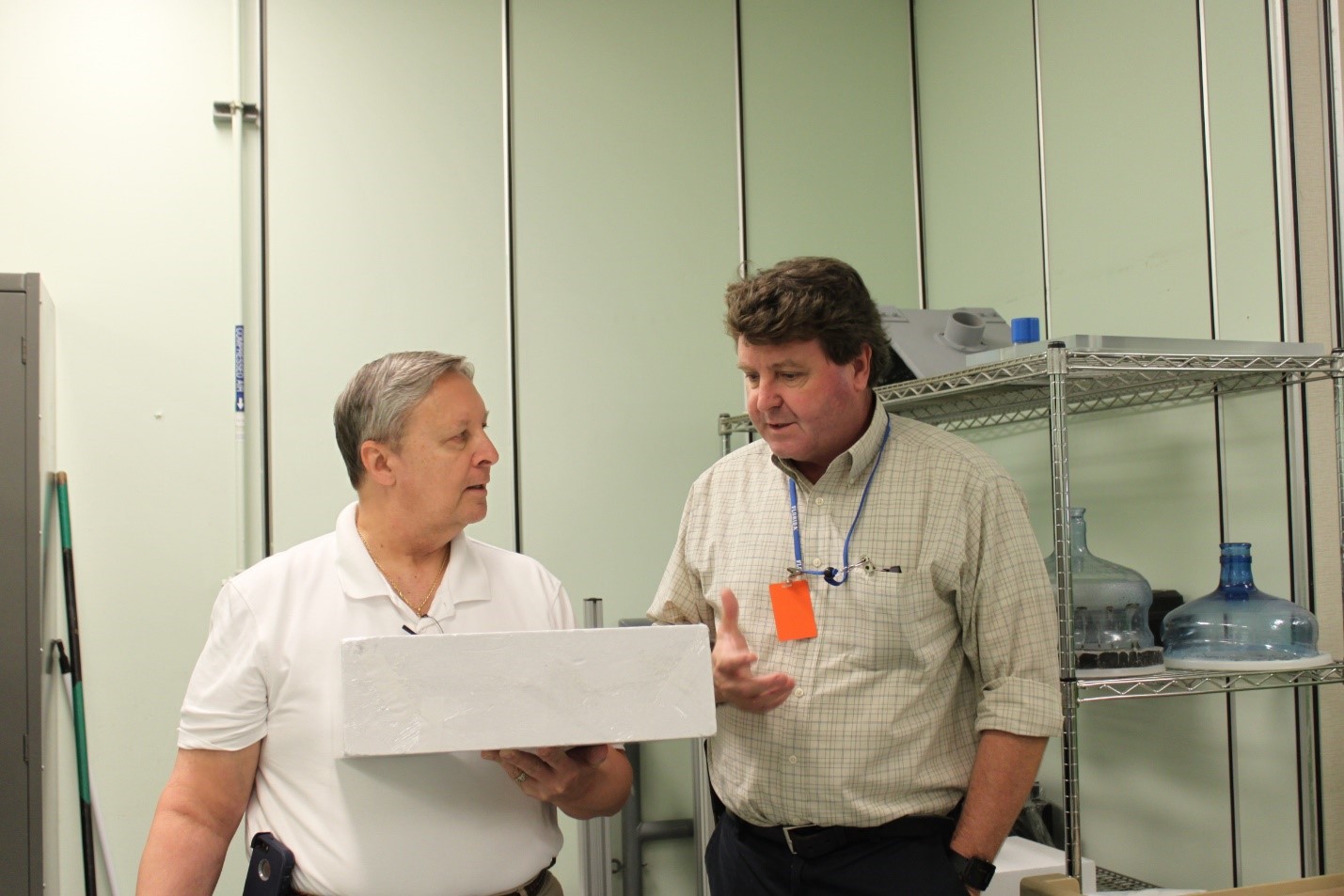

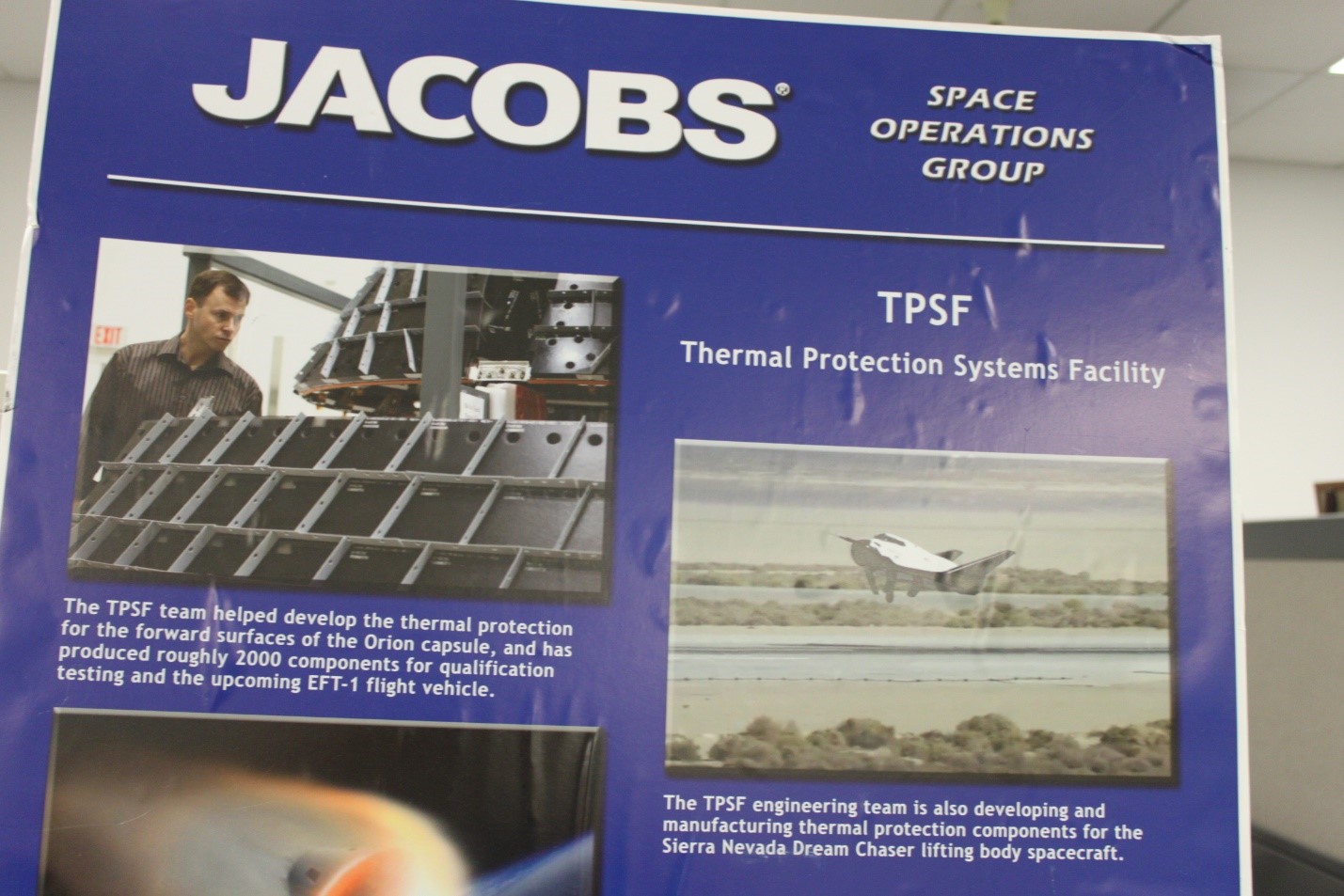

I had visited NASA’s Kennedy Space Center (KSC) in Florida where I had the pleasure of touring the Thermal Protection System Facility (TPSF) Annex run by Jacobs Space Operation Group. Martin Wilson gave me a guided tour. Wilson has a wealth of experience working with a variety of materials that were used on NASA’s Space Shuttle fleet which last flew in 2011.

Wilson, working in this field since the early 90s, has also developed thermal protection for the Orion spacecraft as well as the Artemis program. Advanced heat resistant materials are needed to protect the space vehicles upon re-entry back into the Earth’s atmosphere.

A lightweight surprise

The Space shuttle heat protection tiles weighed approximately 9 pounds per cubic foot. In his lab, Wilson picked up an Orion heat shield tile and said “catch” while he tossed it to me. I braced myself to catch a heavy tile, but when I caught it, the tile was as light as a piece of Styrofoam! Wilson was able to creatively manufacture these new tiles which would add far less weight than previous designs.

Figure 1 Thermal protection expert Martin Wilson is shown here on the right and Steve Taranovich is on the left of this photo holding a surprisingly lightweight Thermal demo tile that will be shaped to fit on the sides and top of the conical Orion spacecraft. (Image from Loretta Taranovich)

The Space Shuttle heat shielding

During re-entry, the Space Shuttle endured temperatures as high as 3,000 degrees F (1,650 degrees C) into Earth’s atmosphere.

The Space Shuttle tiles varied in thickness from 1 inch (2.54 centimeters [cm]) to 5 inches (12.7 cm) depending on the heating to which they would be subjected. The silica tile material is referred to as LI-900. It insulates heat so well that tiles can be held bare-handed on one side even while the opposite side is still red hot. LI-900 has a density of 9 pounds per cubic foot (144.2 kilograms per cubic meter [kg/m³]). They are made from pure silica glass fibers, but 94 percent of the volume of each tile is pure air, making each tile fairly light and strong!

Approximately 24,300 tiles were installed on each Space Shuttle, and each tile was designed to survive 100 trips to space and back.

Orion’s heat shield takes the brunt of the heat upon re-entry

In a new process, several large blocks of an ablative material called Avcoat, which is licensed from Boston-based Textron Systems, were produced at the Michoud Assembly Facility in New Orleans by Lockheed Martin. These blocks were shipped to Kennedy Space Center, where Lockheed Martin technicians machined them into more than 186 unique blocks and bonded them to the heat shield's surface.

The ablative material known as “Avcoat” were machined into 186 unique smaller blocks, and then applied by technicians onto the 16.5-foot-diameter (5-meter) heat shield’s underlying titanium skeleton and carbon-fiber skin.

Figure 2 Orion's new heat shield, for the Artemis-2 mission, is the largest of its kind developed for missions that will carry astronauts. The heat shield base structure has a titanium truss covered with a composite substrate skin composed of layers of carbon fiber material. (Image from NASA)

To fill tiny gaps between these blocks, the seams needed to be filled with a mixture, which over time, would become solid. Technicians then applied a coat of white epoxy paint to the heat shield's surface and also applied aluminized tape after the painted surface dried. The tape provides surface resistivity and will absorb solar heat and infrared emissions.

NASA chose an ablative heat shield which will slowly burn off since it is able to handle higher temperatures than the Space Shuttle tiles which were re-usable.

Unlike the Space Shuttle and other low-Earth-orbiting vehicles, which begin their entry into the atmosphere at close to 17,500 mph (28,200 km/h), the lunar-return velocities anticipated for Orion are expected to reach 24,500 mph (39,500 km/h), roughly equivalent to covering 36,000 feet every second.

Since Orion will be returning from the Moon and ultimately Mars (The Space Shuttle only orbited Earth and docked with the International Space Station) it will experience temperatures as high as 5,000 degrees F during re-entry into Earth’s atmosphere. The Space Shuttle only experienced 2,300 degrees F upon re-entry.

Orion’s heat shield can only be used once because the heat shield burns off.

Orion’s thermal protection system (TPS) tiles

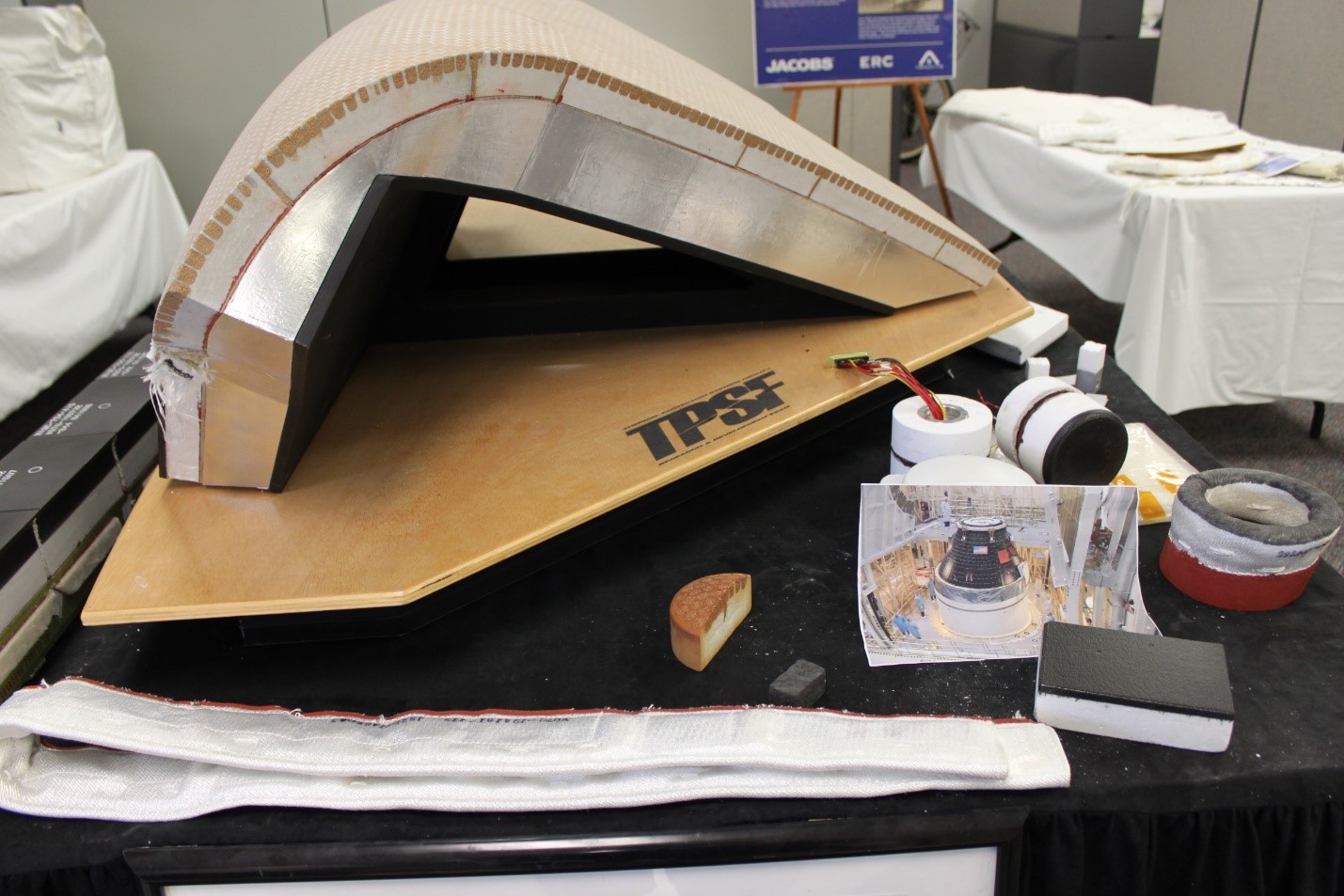

Figure 3 It takes many shapes to create a spacecraft heat shield (Image courtesy of NASA)

Orion’s TPS tiles are bonded to panels on the spacecraft’s back shell and forward bay cover. The silica tiles are an advanced version of those used on the space shuttle and will protect Orion’s crew from the searing heat of re-entry that can reach 5,000 degrees Fahrenheit during return from deep-space missions.

Figure 4 Technicians are shown here getting ready to bond TPS tiles on the Orion crew module,. Most of these tiles are a standard size except for those around widows, antennae, and thrusters. (Image from NASA)

Jacobs Thermal Protection System Facility (TPSF)

Figure 5 Jacobs TPSF (Image from Loretta Taranovich)

The Artemis-1 heat shield, was built in 2014. Artemis-1 was formerly Exploration Mission (EM)-1.

Moving forward on the Artemis-2 heat shield, NASA engineers will conduct non-destructive evaluations to search for “voids” in the bond-lines, as well as measuring the steps and gaps between the blocks. Any such blocks will be filled with adhesive material and reassessed. Also, the entire heat shield—which weighs some 5,000 pounds (2,270 kg)—will undergo thermal testing, ahead of being sealed, painted and taped so it will be able to endure on-orbit thermal conditions. This complete heat shield will be installed onto the Artemis-2 Crew Module.

“Space… the final frontier.”

Steve Taranovich

Steve Taranovich

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.