Definitions

Here are the definitions of the words currently used when it comes to batteries...

| Concept | Definition |

| Cell | One elementary part of a battery. (Lithium Ion 18650 elements in my case) |

| Lihtium Ion 18650 cell | A cylindrical cell having a diameter of 18 mm and a length of 65 mm. Weighs approximately 45 gramms. These cells a very common. LG, Samsung, SOny, Panasonic and others produce several billions of these cells each year. A Tesla Model S car contains 7 104 of these cells. |

| Module | A group of cells wired in parallel to increase the current capacity and decrease the internal resistance. |

| Internal resistance | A parasitic characteristic of a battery that creates losses, heating and degradation of the battery. The internal resistance cannot be null, but should be kept as low as possible. |

| String | A group of Modules wired in series to increase the voltage and therefore decrease the joule losses at high currents. In a battery design, one always tries to increase the voltage as much as possible. 10 % of increase of the voltage will decrease the joule losses of 20 % at the same current. In a Tesla Model S, the strings are made of about 100 modules in series, giving a total of 400 Volts. |

| Joule losses | Occur each time a current flows through a cable or a battery. These losses increase with the square of the current. If you can achieve to divide the current in a system by two, the joule losses will be divided by four. In general to decrease the current, you must increase the voltage accordingly to keep the same power rating. |

| Stack | The whole battery made of one of several strings wired in parallel. |

| Power | The current flowing through the stack times the voltage of the stack (in watts) |

| Energy | The power going in or out of the stack times the time (in Joules or Watt-hours). |

| 1 Joule | Energy of 1 Watt of power produced during 1 second |

| 1000 Joule | Energy produced by a sports rower at each stroke |

| 1 kWh | Energy of a 1 kW (= 1000 Watts) of power produced during 1 hour. One kWh is equivalent to 3 600 000 Joules |

| 10 kWh | Average Energy consumed by my house during one day ( = 3 600 kWh per year) |

| 100 Wh | You need approximately 100 Wh to make one liter of water boil |

| 200 Wh | You need approximately 200 Wh to drive one kilometer with an electric car |

| Phase A | First step of my Powerbucket project where the total capacity will be 10 kWh |

| Phase B | Second step of my Powerbucket project where the total capacity will be 110 kWh |

| BMS | Battery Management System. Takes care of the battery by measuring the individual module voltage and temperature. Furthermore, the BMS insures also proper balancing of the cells, avoiding dangerous overcharging. The BMS also maintains counters of the energy going in and out of the battery stack |

| Specific energy | The amount of energy stored in one Kg of battery. The specific energy of a good lead acid battery is 40 Wh/Kg. The specific energy of a good 18650 Lithium Ion element is 250 Wh/Kg, 6 times more. |

Powerbucket Specifications

This table contains the main characteristics of the Powerbucket

| Item | Value | Why ? |

| Number of cells in parallel in one module | 5 * 14 = 70 | Fits well in my wooden bucket |

| Number of modules in a string | 15 | Fits well in my bucket AND is OK for my inverter |

| Nominal Powerbucket stack voltage | 15 * 3.6 = 54 Volts | Well In the input voltage range of my inverter (38 to 66 V DC) |

| Minimum Powerbucket stack voltage | 15 * 3.0 = 45 Volts | Well above the minimum input voltage of my inverter (38 V DC) |

| Maximum Powerbucket stack voltage | 15 * 4.2 = 63 Volts | Well below the maximum input voltage of my inverter (66 V DC) |

| Number of cells in phase A | 15 * 70 = 1050 cells | Number of modules in series times the number of cells per module |

| Nominal voltage of one cell | 3.6 V | This is the average voltage of one cell during discharge. |

| Capacity of one cell | 2900 mAh | I will use PANASONIC NCR18650PF cells having 2900 mAh capacity |

| Energy in one cell | 3.6 * 2.9 = 10.44 Wh | Nominal voltage in volts X nominal capacity in Ampere hour = nominal energy stored in Watt hour |

| Total energy in the Powerbucket stack in phase A | 10.44 * 1050 = 10962 Wh | |

| Number of cells in phase B | 11 * 1050 = 11550 | Full bucket capacity |

| Total energy in the Powerbucket stack in phase B | 10.44 * 11550 = 120 582 Wh | More than 120 KWh |

| Weight of one Module | 4.5 Kgs | Total weight of the 70 cells, nickel strips, copper bars, plastic holders and solder |

| Specific energy of one module | (10.44 * 70) / 4.5 = 162 Wh/Kg |

About safety

Lithium batteries become dangerous when overcharged or short circuited. In order to mitigate the consequences of a single cell failure, I have decided to equip each indivual cell of a "Tesla Style Fuse". This fuse is made of a short piece of 0.5 mm diameter tinned copper wire welded on the negative pole of the cell. If the current flowing through this fuse exeeds 15 A, il melts, isolating the faulty cell.

A side project: Microwave Oven Transformer Spot Welder

The best way to solder the cells is to use a spot welder. I have designed and built my own because I wanted a maintainable, long lasting and improvable tool. Furthermore it is dirt cheap to build.

The Battery Management System

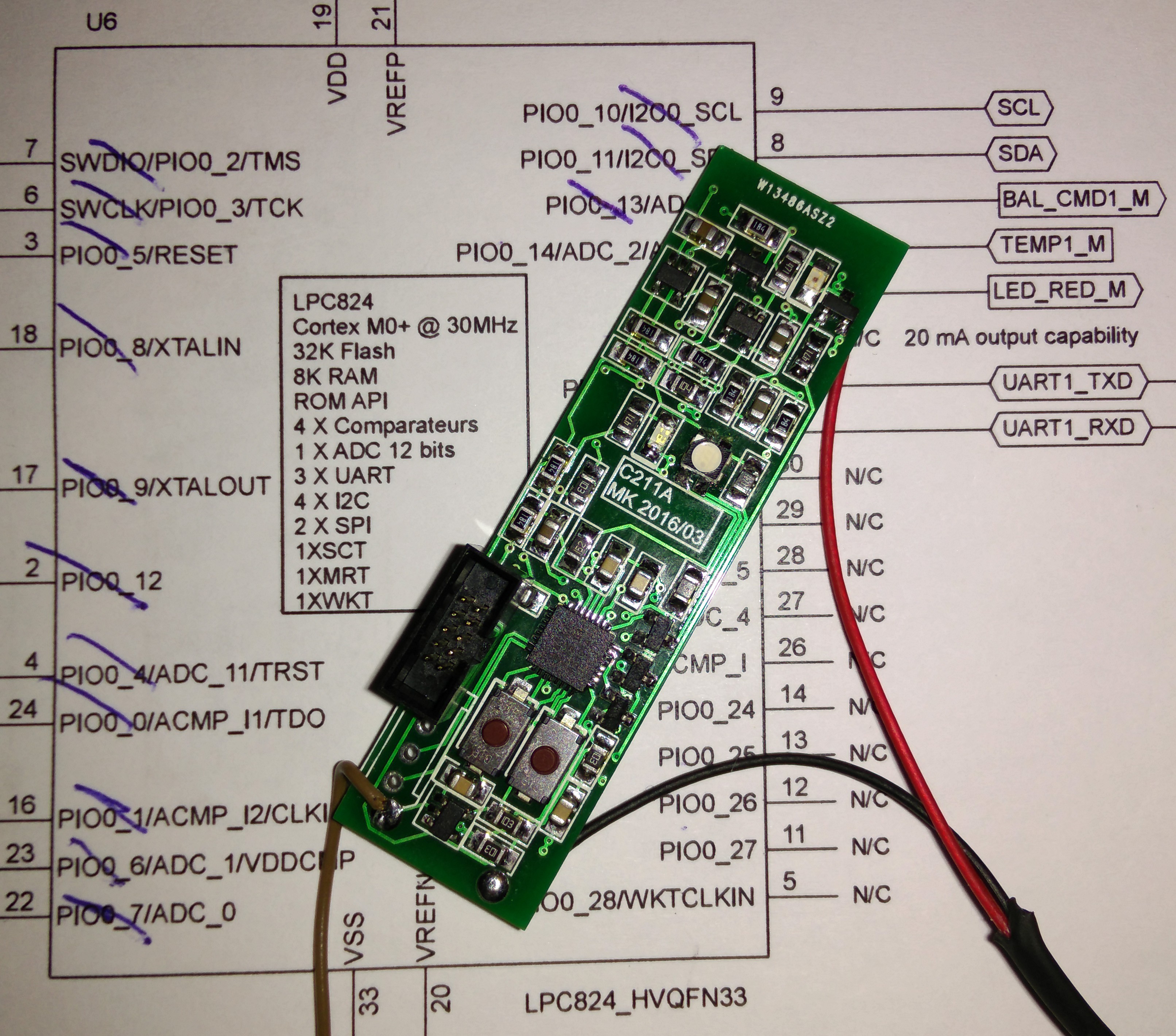

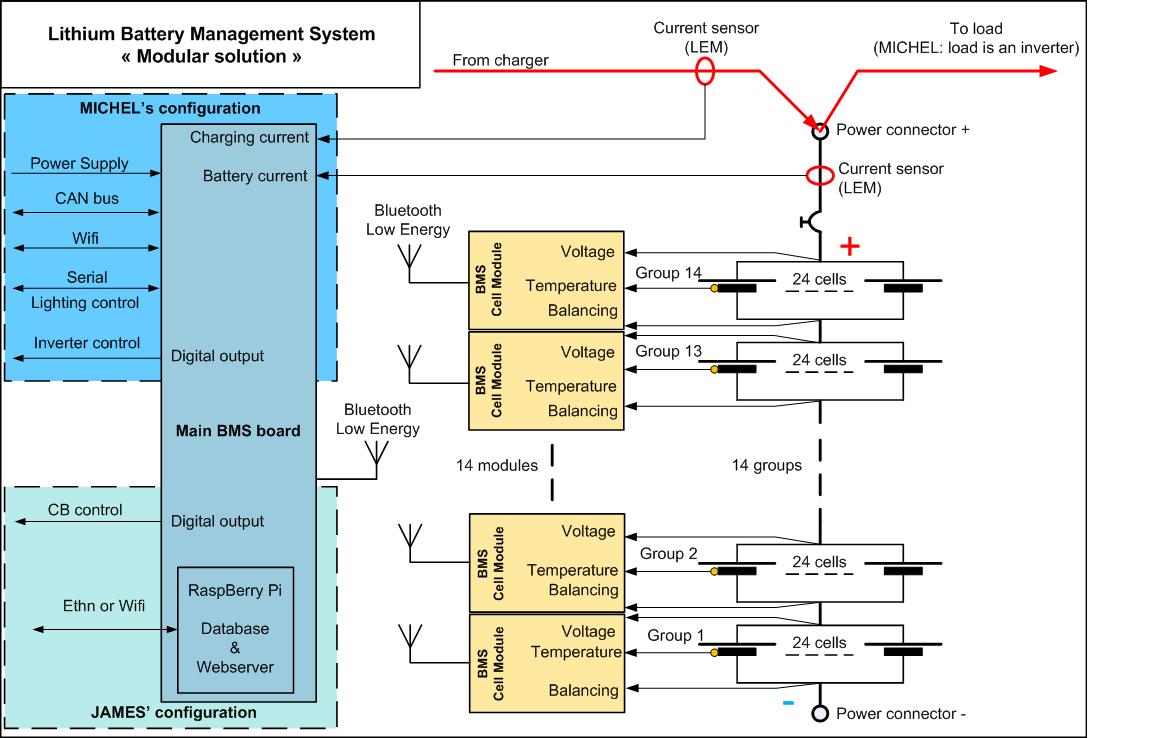

I have decided to design my own BMS based on a modular approach. It will consist of 15 Module boards communicating with a main board through Bluetooth Low Energy. Thanks to the BT communication I will get rid of all the insulation problems.

Modular solution

The Cell module is organized as follows:

I have populated and tested the first board - Everything works fine. So far so good...

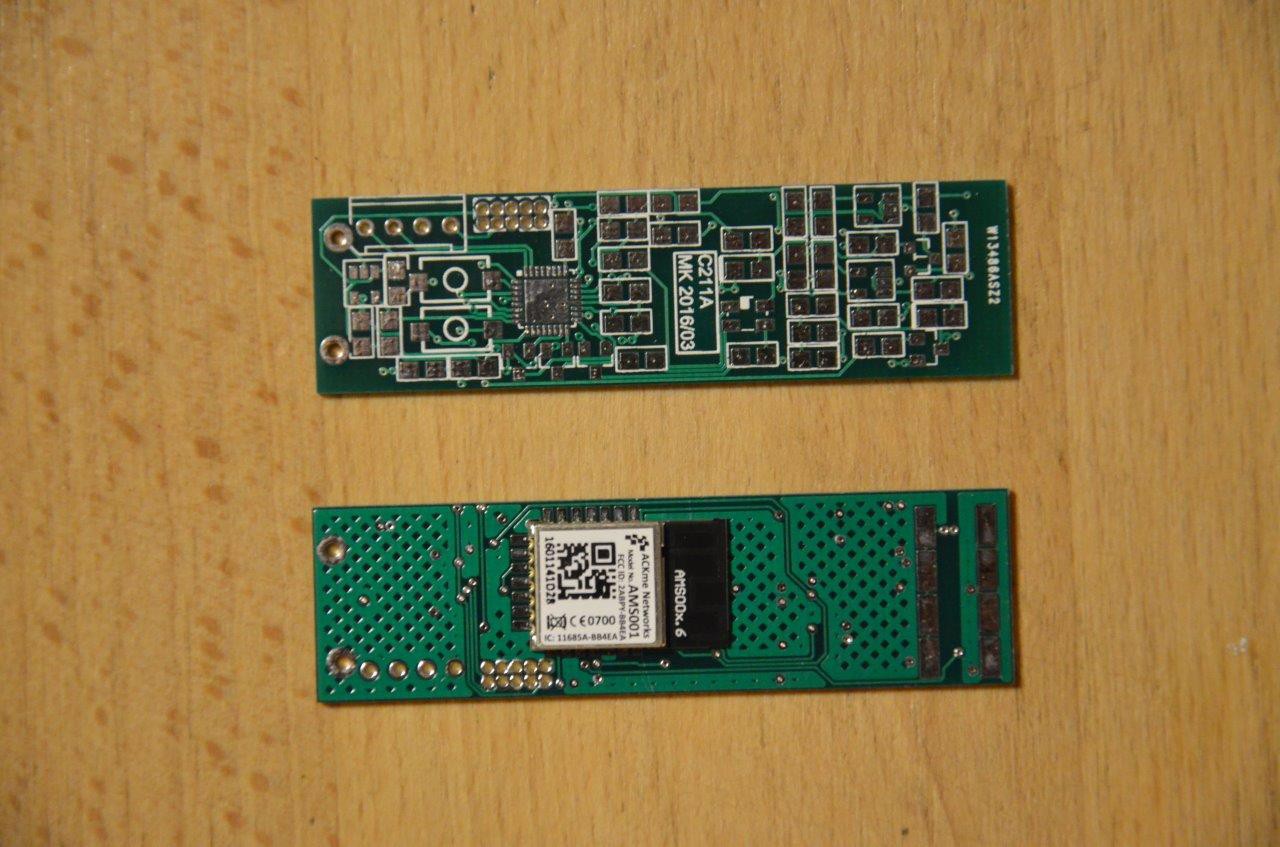

Bare PCBs of the module boards:

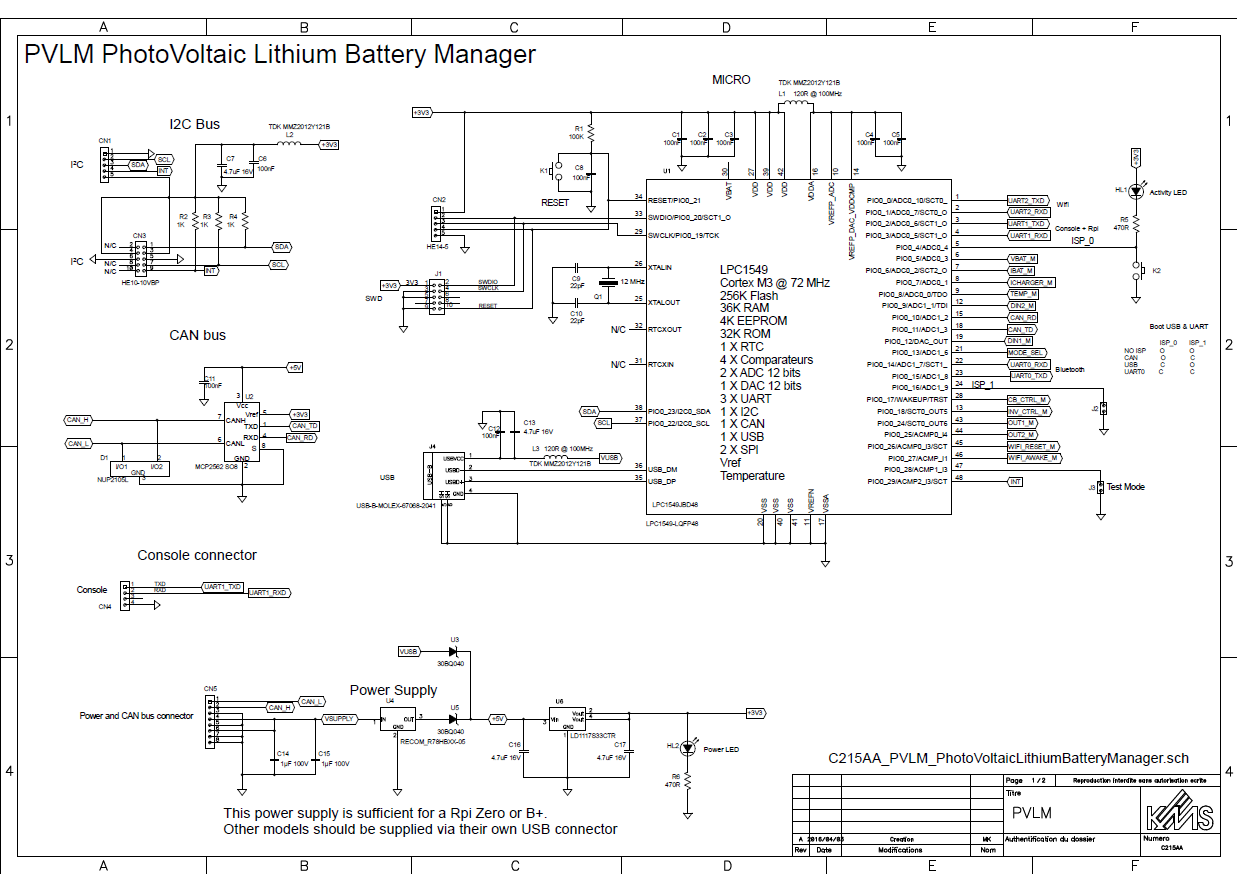

The Main module implements an NXP LPC1549 Cortex M3 processor running at 72 MHz. This chip is really the perfect choice for this application.

I have chosen the LQFP 48 package. Nearly all the pins are used.

More about this awsome device here.

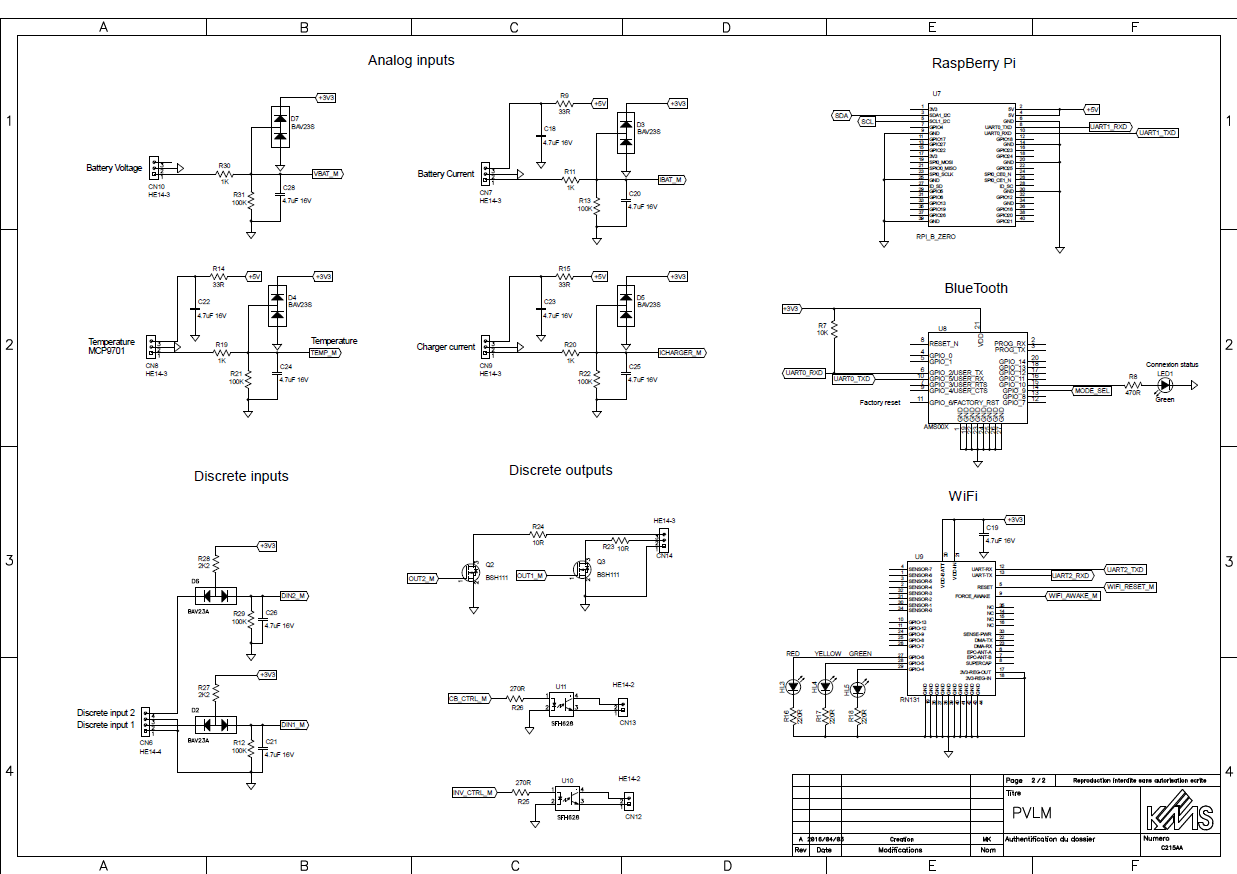

The board features:

- Wifi

- BT Low Energy

- USB full speed

- CAN bus

- I2C

- An embedded RaspBerry Pi (A model B or a Rpi Zero can be supplied by the board itself)

- A console connector

- 4 analog inputs with 12 bits of resolution

- 2 discrete inputs

- 4 discrete outputs

- The microcontroller can boot (= be flashed) from BlueTooth, CAN or USB.

- Power supply: ultra wide 9 to 72 VDC input range (X8)

Schematic of the BMS main module

First page - Microcontroller, Power Supply, I2C and CAN bus

Second page - I/Os, RaspBerry Pi interface and wireless communication

Michel Kuenemann

Michel Kuenemann