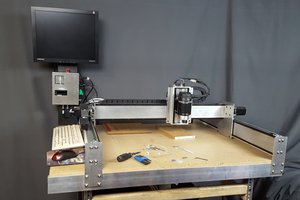

BlinkMold is a device that lets an user produce high accuracy platinum cure silicone molds with the minimum of machine skills or setup. Oh, and also double sided PCBs.

Please refer to the guerilla guide to cnc machining for ideas: http://lcamtuf.coredump.cx/gcnc/

dammitcoetzee

dammitcoetzee

Supplyframe DesignLab

Supplyframe DesignLab

Daniel Grace

Daniel Grace

Douglas Miller

Douglas Miller

Caleb Peters

Caleb Peters