...which doesn't mean that this project comes to an end, too. I have created a promotion video for the final judging:

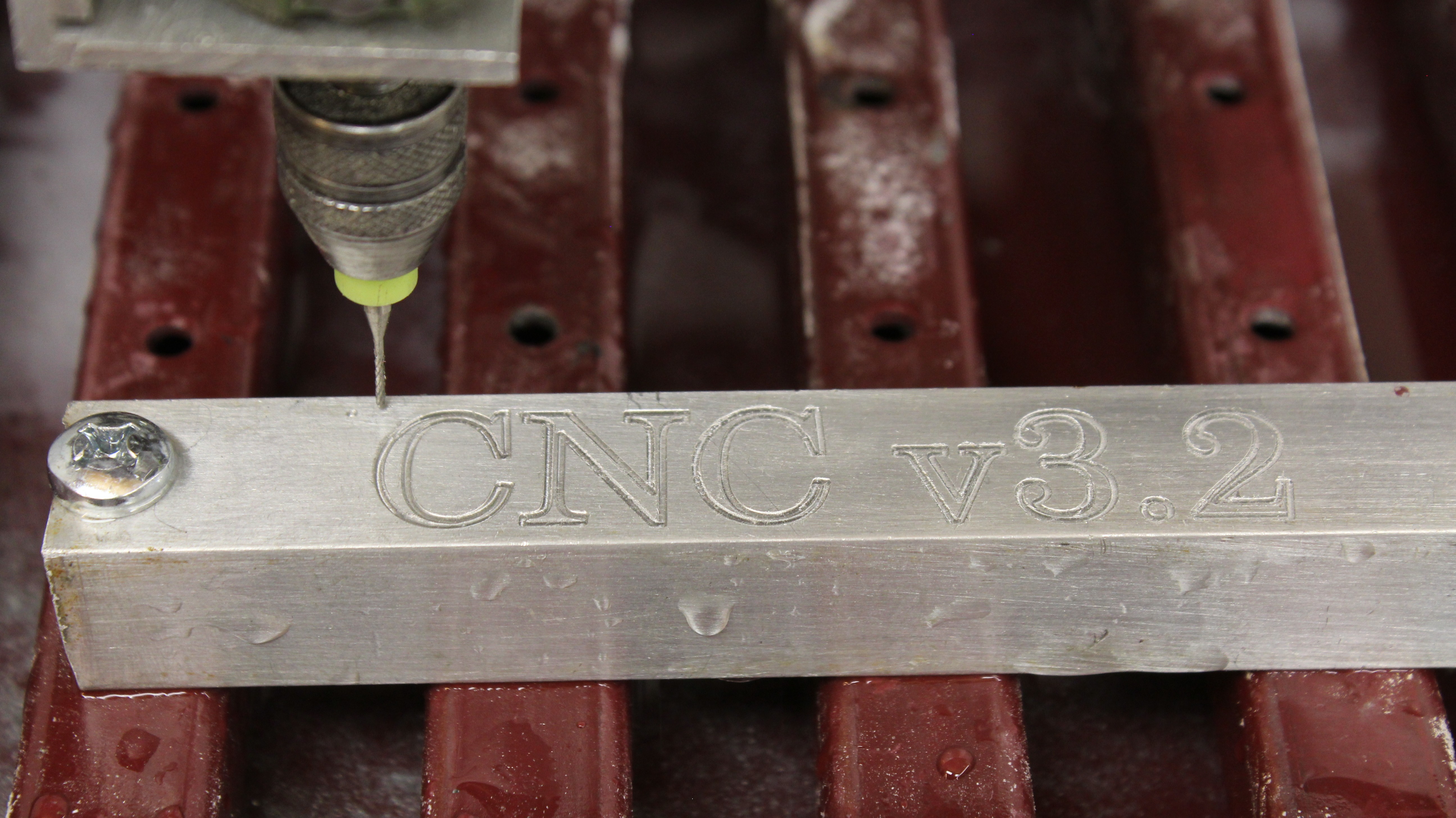

The major improvement since the first test run is the adjustable table with a bowl underneath that enables to create a circular flow of coolant in the near future. I have engraved another piece of aluminium using more water to remove the chipping, giving a smoother result. A pump and a skirt around the router will be installed soon, to make it even better. Have a look at the full resolution picture:

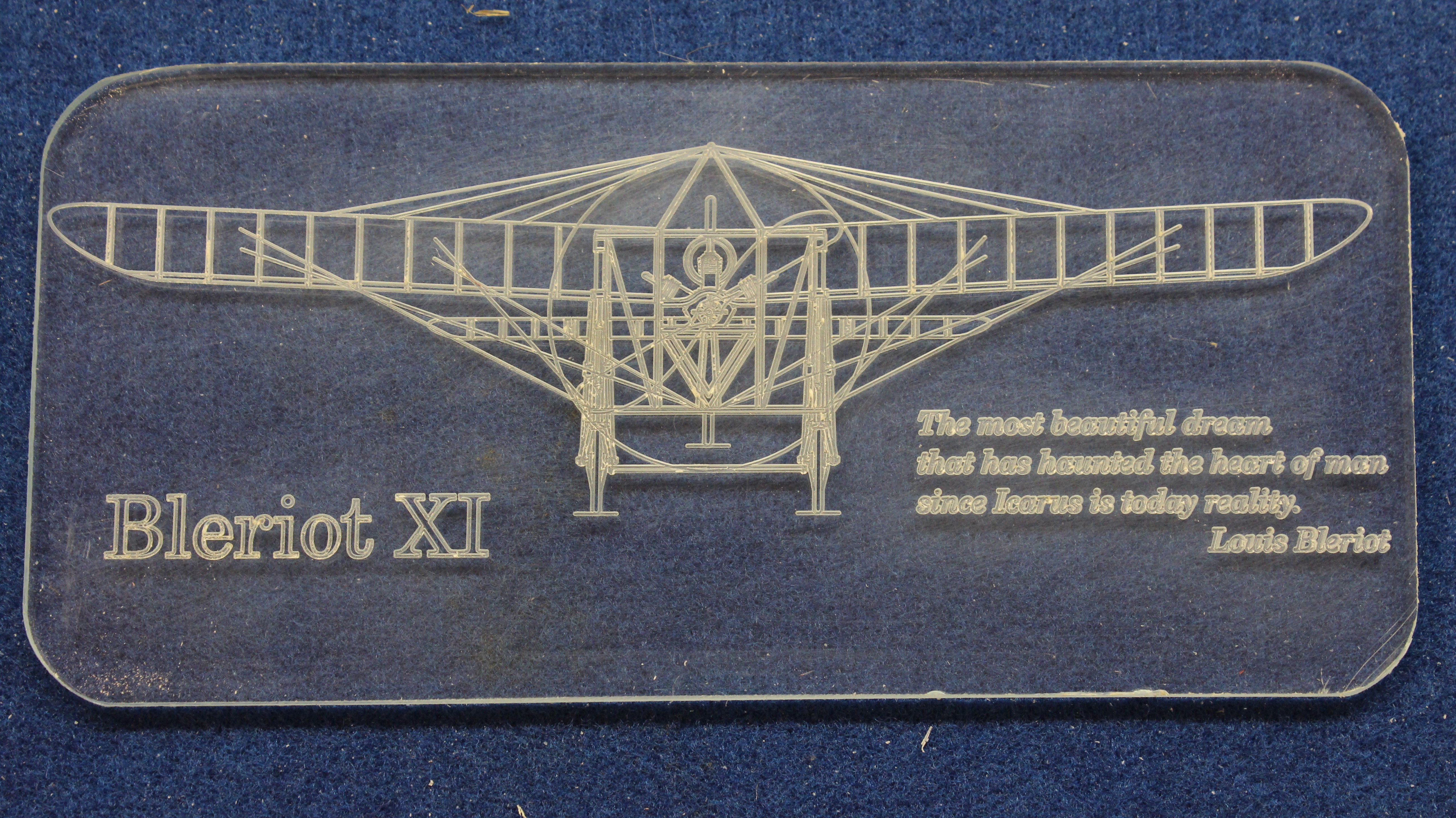

I have also engraved and cut a piece of acrylic plastic. The machine is still very slow since I did not make any changes to the motors or the quick and dirty software. The characters have a height of only 3mm and the text is clearly readable, isn't it?

Processing plywood also works fine. I will have to play around with different router bits to get less rough edges. There are bits with a counterclockwise cutting spiral resulting in smoother edges on top, so that the engraved penguin will look better:

After sanding the edges it looks great:

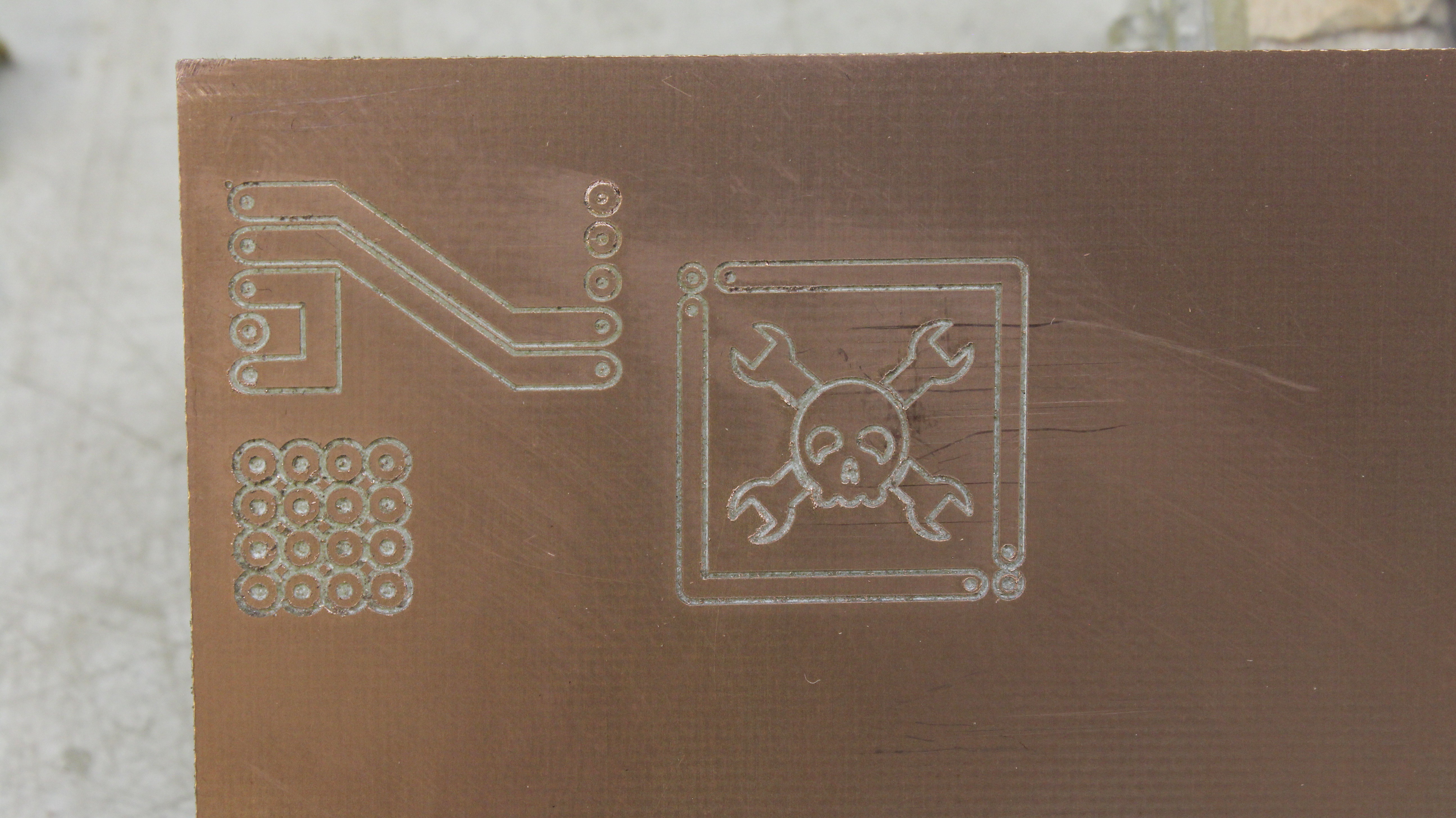

Engraving a copper plated board is better now, but still not perfect. The sheet bends and vibrates on the table. I will add a special mount for making circuit boards. The software still allows to process only *.svg files, thus in principle this is no circuit layout. Once again the 16 dots on the bottom left are arranged on a 2.5mm grid as used in prototyping boards. Trying different V bits is also on my list of things to do. The aluminium tube connected to a vacuum cleaner removes the chipping which results in smoother edges:

Norbert Heinz

Norbert Heinz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.