Some partly finished sub-projects are in progress. As a major workshop re-arrangement is planned (big milling machine incoming :) and it will take some time, this post sums up the current status.

For the frame parts, a negative frame/assembly support was build. The single struts end in an plate with two screw holes to mount towards the frame:

A form was build to recreate the frame struts:

Reinforcement was added to the outer part (not shown here). Frame parts still to be build...

The rear corners are one of the main parts that attract rust on all of these vans:

There is a company that sells re-build corners. They are good quality and fit, but two corners would cost half of what I paid for the van, and I want to push my metalworking skills, so...

The traditional way to create sheet metal car panels is by stamping. As I got no big hydraulic press there must be another way...

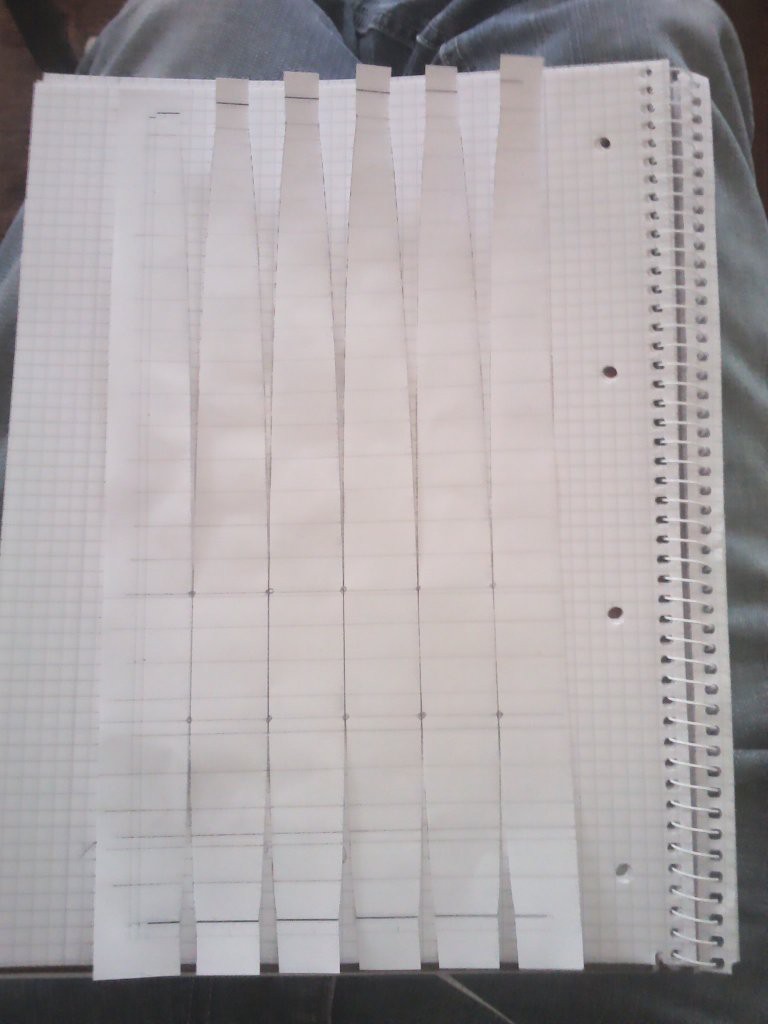

After obtaining the corner dimensions and some math voodoo, we got a slottet piece of paper...

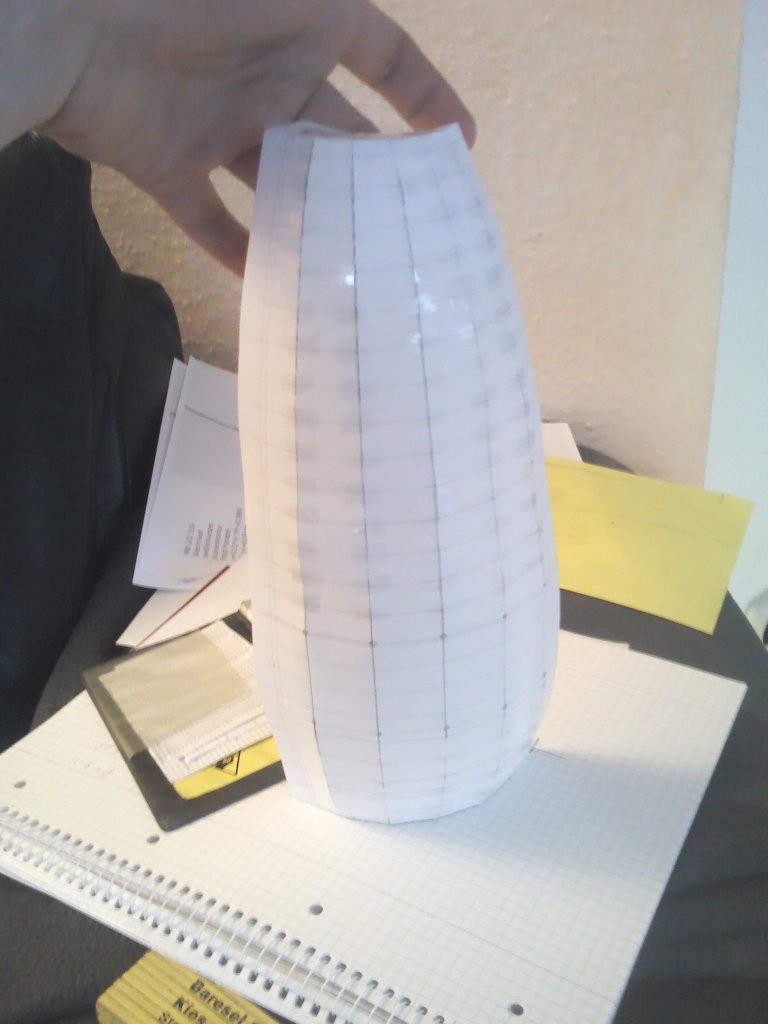

...that assembles into something threedimensional after application of some tape:

...and build a gigantic paper-mache/oregami-van. Not.

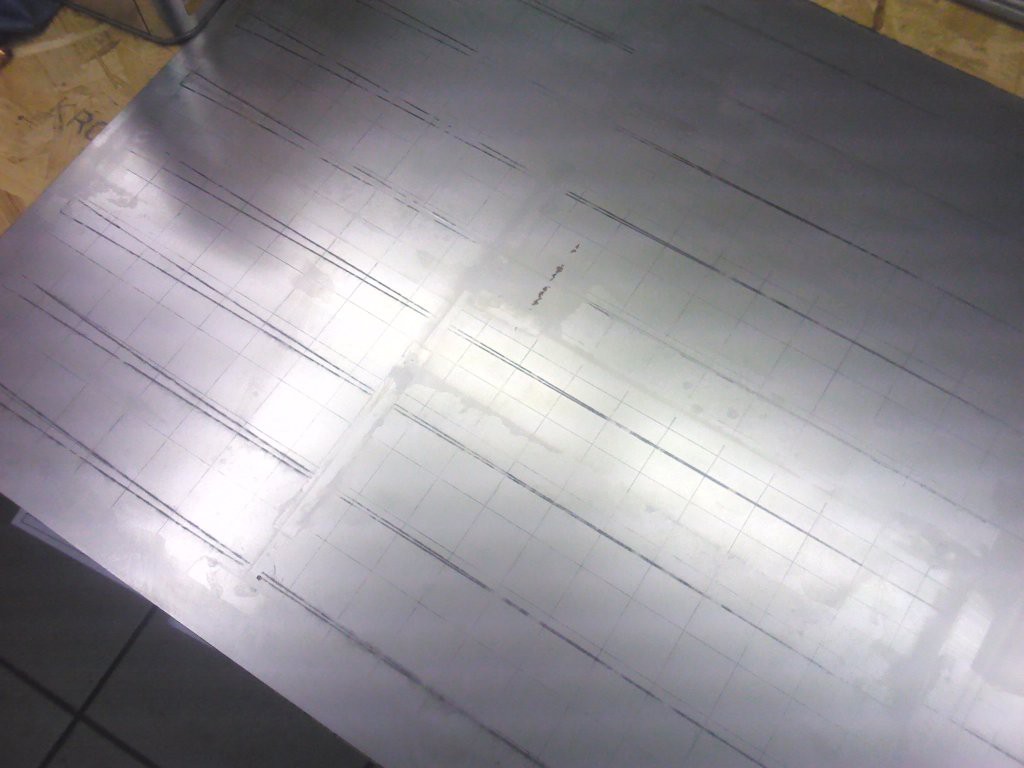

As I've got an A4 paper printer only, multiple pages with the right pattern were printed and taped together:

It is possible to transfer the lines to a sheet of metal by application of acetone. As an solvent, acetone dissolves the laser printer toner and lets it stick to the sheet of metal by some pressure (rubber roll):

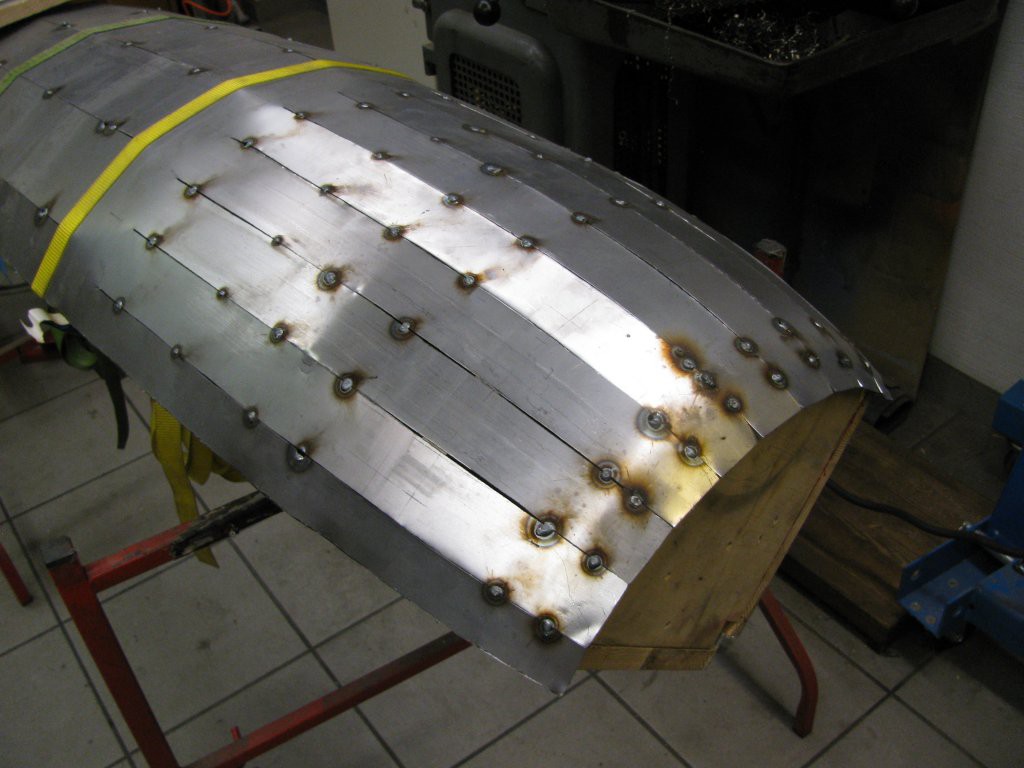

A wooden support structure helps to bring the sheet in form:

Cutting in progress:

Tension belts are used to bend the sheet of metal in place, MAG spot welding is used to fix the sheet in place:

The Argon gas bottle was empty after a first WIG test weld to adjust the current for best results, so I had to stop for the day and take a ride to the hardware store for a refill. Filling the gaps with TIG welds, grind and beat the surface flat, bend over the edges etc. is planned next.

Updates on corner-rebuild can be expected in the next weeks. As usual, I am low on spare time, the daytime job, friends and other real life stuff need attention, too...

rawe

rawe

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.