PCB milling is a really useful thing to do on a CNC machine because you can build really nice, complicated electric circuits. And unlike chemical etching, which only makes the traces, a CNC machine drill holes for through hole components and cut and trim the copper clad board. Quite a few people asked about whether or not the Sienci Mill One was able to do PCB milling. So we gave it a shot.

Our first few tries were not great, since we had traces of varying sizes, even though they were all supposed to be the same. While milling large objects, a high degree of precision is not needed. But for milling PCBs with features that are fractions of a millimetre, high precision is critical.

Then we found the issue that was causing us to have sub-par boards. The nuts for the lead screws were coming loose from the gantry, and that extra bit of wiggle was causing the positioning of the machine to be off. So we tightened those screws and made sure that they wouldn’t come loose over time.

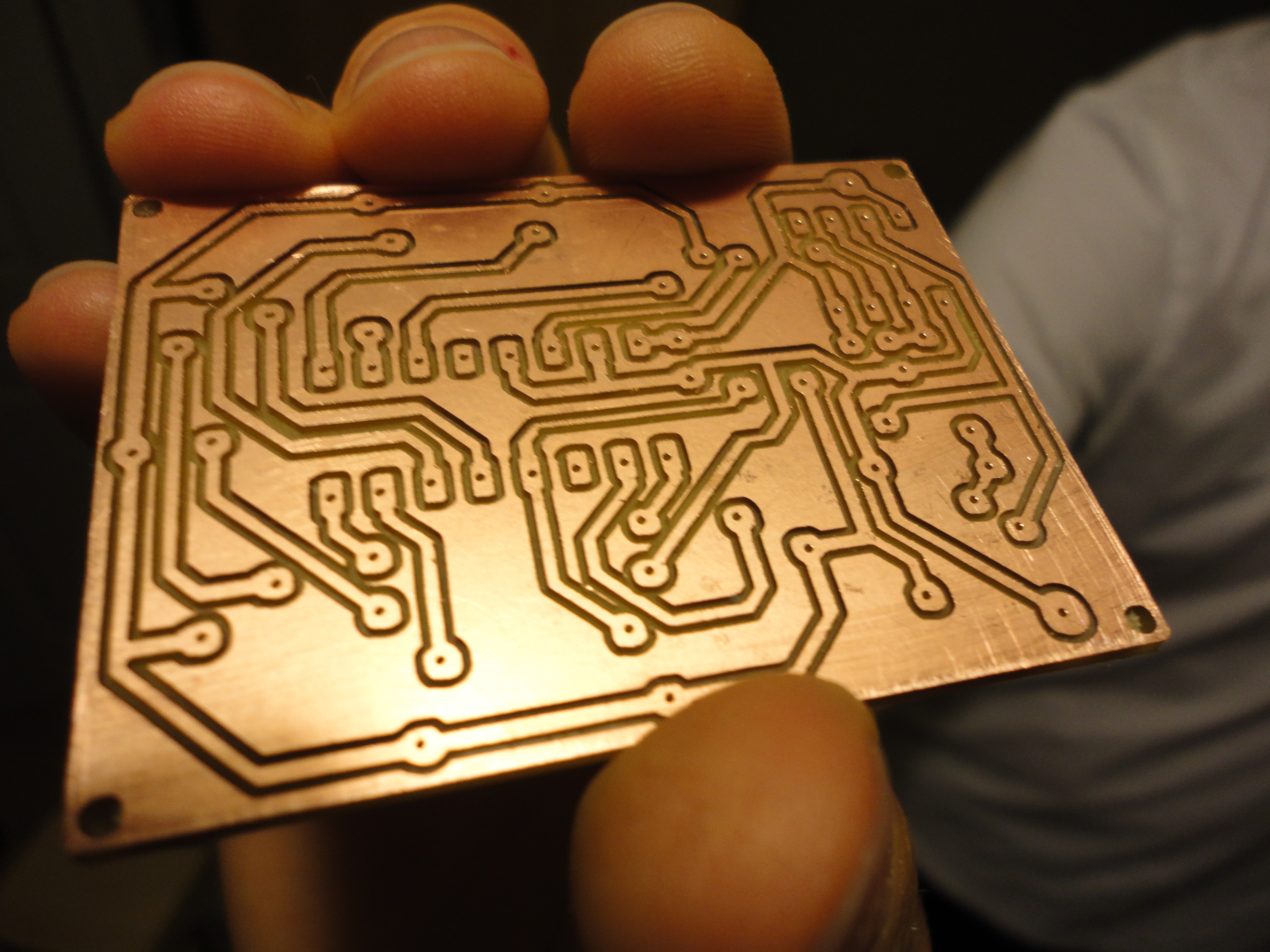

And that made a huge huge impact on the quality of our traces! Check it out:

Andy Lee

Andy Lee

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.