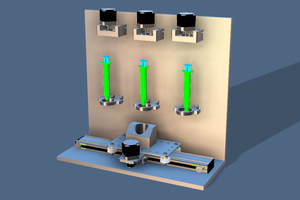

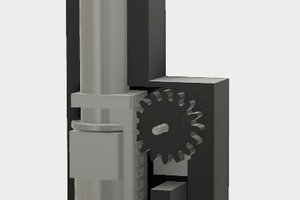

We kicked off this project last summer with www.cone-o-matic.com. This summer we will be pushing it further. The next steps are to complete a calibrated cuff and hinge to match the socket. We will tie into the Fusion 360 API's to clean and prepare the files for 3D printing. Lastly, we will scale the current iteration of Skip Meese's Gripper Hand and build the U/I to tie them all together.

Arm Yourself!

Arm yourself is an application that creates parametrically generated prosthetic arms that can be 3D printed to meet an international need.

Daniel R. Dugan

Daniel R. Dugan

Joan Horvath

Joan Horvath

Giovanni Leal

Giovanni Leal

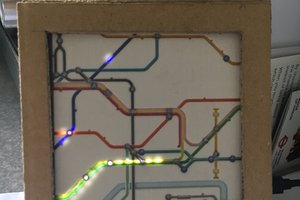

I'm sure it is the case for most 3D printer owners that their printers are idle the vast majority of the time. How can this printer time be used for projects like this? Are there generic parts that could be printed and supplied? Are they typically PLA or ABS?