Description of the vibration monitoring circuit for mechanic diagnostics which will be included in the system proposed for this project.

The whole story began back in 2012 at my PhD theses. I developed a hardware neural network system by modifying some existing products and schematics to monitor the vibration inside a 4-stroke single piston Honda GX200 engine. The most interesting part is that engine - it was modified to work with hydrogen injection in the intake manifold. Yes, you read correctly: hydrogen, not gasoline fuel. But - like any engine, from time to time you need to check its lubricating oil level and add a small quantity to keep the lubrication parameter optimal. Searching, testing, reading datasheets, finally the electronics were ready and the micro controller was programmed, numbers were flowing through the serial cable, diagnostics system finally started to work OK after around 3 months. Extremely happy after the initial tests, I compiled a scientific article to submit it for publishing to some International Scientific Indexed (ISI) academic journal.

Publishing of scientific articles with valid results in high standard academic journals is required for completing PhD and become a PhD Engineer. ISI journals accept only articles with high scientific value, they are extremely strict, no mistakes accepted, the research must be valid, the paper is verified by professional reviewers with strong academic background, there's a long time interval until you get an acceptance answer (positive or negative) and usually the publishing fee is sky high. But it increases the academic value of a PhD theses because the accepted-for-publish scientific research (part of theses) is acknowledged internationally.

And the nightmare began: every academic journal I submitted this article to, everyone, absolutely EVERYONE demanded that all references to the hydrogen to VANISH. I started to strip the text for hydrogen references. Not enough. Not even a single WORD was accepted! They did not look at spelling mistakes, they did not consider the arrangement in page, picture sizes or text fonts. And do you know who else did that? Even academic scientific magazines that show their concern regarding to environment pollution. Some respectable academic publication even found a reason with no significance regarding main subject - vibration monitoring: "Did you run at least one computer simulation to monitor the performances of that engine using hydrogen fuel, compare with the same engine using traditional fuel and output the numbers in some tables or charts?" My short answer: "Can you help me with an idea about who might give me such a software and license for a price lower than your publication acceptance fee?" Silence.

So an experiment was performed that may help reducing pollution and the most important persons refuse to pull up their academic heads from their scientific butts and at least place a call to ask "what's happening there, what is that hydrogen dude up to? " No. No way. Just vibrations, nothing else. Clean fuel references must go away. Not from Eastern Europe. People from that area invented the jet engine, the math behind the science of rockets, the alternative current, electrical transformer, science of cybernetics, cervical pap smear test, one of the most amazing unlimited power source, ejectable airplane seat, cholera vaccine, the insulin, the first man-carrying airplane, the language of Dracula is the second language spoken in Microsoft Corporation, so there is no way another small victory from that place will ever be allowed.

Short description of the idea:

Hydrogen is a dry fuel. It's not like gasoline or diesel. If it burns inside a moving pressurized mechanism, it causes more friction than normal. So it's natural that the lubrication oil will have some trouble doing the job it's supposed to do. Let's see how we can monitor the oil level in the engine. Ultrasonic level sensor? Meh! Oil is spread all over inside the engine block, there's no way you can get any valid information while the engine is spinning. Capacitive sensor? Same problem. Some sensor to smell the exhaust? Maybe an expansive 50k$ Chromatography device which will tell you any explosion-based engine burns a small amount of oil. Temperature monitoring? That's a slow process, it starts to raise AFTER the fault happened. Superman vision? No scientific base for that. Vibration monitoring? That might work, that's the only way the engine can "report" fast enough there's something wrong. So let's try Vibration Monitoring.

Scientists are already doing vibration analysis by recording some data from sensors and passing it through specialized programs containing software-defined artificial neural networks. But nobody had the balls (yet) for hardware ANN approach combined with a 3-axis accelerometer. And Hydrogen intake instead of benzene-based hydrocarbons? This will rock the world, this will push the current limits of pollution reduction.

In the mean time I managed to understand that hydrogen intake causes more problems. You have a lot of energy losses through heat and frictions. And if you have more than one cylinder you need single-point injection for each. A common intake for all cylinders will cause the engine to explode unless the intake and outtake fuel valves are modified. Valves are able to seal air-fuel mixtures but hydrogen molecules are much much smaller and can be easily released from a pressured cylinder. Place a spark inside one and the flame will pass out through the valves to the common intake (or exhaust) until it reaches the cylinder which performs the mixture intake. Next step - two pistons inside engine which are supposed to do the same job but at different timings will blow away at the same time and if you are unlucky - this will break the crankshaft and blow some nice big holes in the engine block. You wonder why my car looks like a rusty trash dumpster? Guess why: I discovered this hydrogen issue on my own: I disconnected the gasoline hose and only the hydrogen was left. Guess what happened when the remaining gasoline in the carburetor was finished. Remember Stan and Oliver, those two great comics? Imagine them dirty of oil after an engine explosion, then imagine all the horrified pets barking and mewing all over neighborhood. The car had to stay abandoned for a few years until I slowly managed to put the engine back in working condition.

The hydrogen approach works better with Fuel Cells - see the success of Riversimple LLC company - less energy losses, no spark plugs, lubrication oil, belts, heat, smoke, cylinders, pistons, crank shafts. The age of covering distances by burning things started when humans lived in caves and it's finishing soon. Hydrogen energy is converted straight into electricity. But hydrogen intake in fuel engines is still a great step at least to reduce the toxic smoke floating above the big big cities. Anyone interested in that? In my local area - most of the people were and still are extremely interested. But here in this part of the world - nobody, because it does not come from a multi-billionaire business man but from some crazy dude nobody heard before, driving some ancient rusty chicken coop on four wheels made 14 years before the end of the last century.

I decided to monitor mechanical faults of the (former) mobile rusty trash dump using hardware artificial neural networks. At first - wheels status only. I will leave the engine block for later, because that requires a garage and a lot of time to dismantle the engine, replace good parts (bearings, shafts) with damage parts, assemble the engine again and keep it running to get that precious desired training data.

I might have some pictures from the great days when I modified the car to work with hydrogen injected into the intake air manifold. I will post them if I receive any request. The results were unexpectedly good - when the gasoline burns in oxygen, the exhaust contains carbon monoxide. When it burns in hydrogen, the exhaust contains mainly water (steam), carbon dioxide and some hydrocarbons (most of them from the lubrication oil). Some tests with a Varian Chromatograph can confirm. When I took the car to perform the two-years technical inspection as required by the Law, imagine the faces of the engineers when they could not understand why the exhaust pollution level of an old car (manufactured in 1986 with technology from 1960s) was lower than most of the EURO-3 automobiles that came in that testing facility in that day. That's because they measure carbon monoxide levels. Of course I had to disconnect the hydrogen intake to get the test results suitable for this kind of old non-euro cars.

Since the article was rejected so many times, I will place it here for whoever wishes to improve their knowledge. Scientific references included. I hope nobody here will dismiss this project log due to the word HYDROGEN.

EARLY REDUCTION OF POLLUTION IN IGNITION-BASED ENGINES USING INTELLIGENT LUBRICATION FAULT DIAGNOSIS AND HARDWARE NEURAL NETWORK

[skaarj]

Petroleum and Gas University of Ploiesti, 39th Bucuresti blvd, 100680, Romania

Abstract

A common source of pollution, caused by ignition engines, represents an improper lubrication, which determines improper fuel burn, mechanical failures and serious engine damages. Although standard lubrication oil level measuring procedures are present in the latest technologies, this paper describes an original method for early detection of faults in the engine block by means of intelligent processing of engine core vibrations through artificial neural network approach. Certain tests were performed by deliberately draining amounts of oil from the lubrication system and processing the corresponding vibration data. Some experimental results obtained so far are also discussed in the paper.

Key words: hardware artificial neural network, intelligent transducer, micro controller, vibrations

1. Introduction

Vibrations in common ignition engines core are intensely used for identifying mechanical subsystem malfunctions, as they characterize the proper functionality of ignition-based engines – which influence the external environment pollution (Charltona, 1998). Artificial intelligence techniques are widely used in diagnosis of failures in the engine cores. Early Fourier function applied to the recorded frequency specter, provided by a vibration sensor (Vulli et al., 2009), can identify the occurrence of specific events inside the engine block. The latest research in this field shows that vibration analyses is also widely used in perfecting engine design (Leontopoulos et al., 1998). Yadav and Kalra (2009) propose time-frequency mathematical models of vibrations and pattern recognition, with data obtained from failing mechanical components deliberately integrated inside the engines. Further processing is performed by filtering the noise and extracting certain areas from the spectrogram, where the interested frequencies are present. Other method for identify and diagnose of failures consists of proximity vibrations sensors applied in special cases such as turbo jet engines (Cohen, 2006), characterized by high temperature parameters which exceed the working conditions of a commercial ignition engine. This particular approach avoids direct contact to the engine block by using vibration transducers based on capacitive (piezoelectric) sensors. The disadvantage of this approach is an extremely high price due to the high precision required in hardware manufacturing. Another method considered (Siemens AG, 2005) is to acquire the vibration signals using MEMS (micro electro-mechanical system) sensors in direct contact with the engine block. According to Vogla et al. (2009), MEMS accelerators, widely spread among all PDA devices, contain radio modules for transmitting the recorded parameters and, through their wireless advantage, can be successfully placed on moving mechanical parts and contribute to early phase detection of failures. Scholl et al. (1997) propose the vibration analysis through MEMS accelerometers for calibrating the ignition timing using Fourier function applied to the recorded spectrograms.

Above considerations focus on general aspects in identifying mechanical malfunctions and engine controls using vibrations acquired from the engine core. An accurate knowledge of the mechanical process is provided by the fast processing speed of artificial neural networks, fed with a suitable set of engine operating parameters.

This paper presents the current research developed at Petroleum and Gas University of Ploiesti, Romania (Buruiana, 2012) in developing a hydrogen-based ignition engine, with the aim of clean emission gases. Research experience of the author and literature results in this area (Adnan and Ibrahim, 2008, Al-Rousan, 2010) make it possible to point out the presence of significant connection between the growing need for clean emissions, and the proper conditions in the combustion process. According to Rao (1996), mechanical lubrication systems, which are directly responsible for temperature dissipation, have a direct influence in thermal deformation, so far being successfully predicted by neural networks. Such deformations inevitably lead to failure in the structure of the combustion chamber, with negative impact in the exhaust gases. As previously demonstrated (Adiletta, 2006), it is possible to recognize different changes in lubrication characteristics in oil dampers by artificial neural network means, considering that anomalous, unpredictable vibrations themselves represent a malfunction in the absence of any particular fault – because of changes occurred in a set of operating parameters. Neural network approach in monitoring the wear of lubricating oil is proposed by Sinha et al. (2000). Thompson and Atkinson (1999) propose a method of modelling the emission gases inside engine ignition chamber by neural network approach, later developed by Adiletta (2006) in an original neural network-based method of modelling complete virtual diesel engines with emission prediction capability.

Avoiding lubrication-based malfunctions by hardware artificial neural network vibration analysis was considered in this paper. Our experimental system consists of a Honda GX200, 6.5 horsepower, 4-stroke engine, a vibration sensor and an experimental transducer based on a commercially-existing hardware artificial neural network. The training data, which was stored in the transducer memory, represents a set of vibrations acquired from the engine core in different lubricating conditions, by deliberate disposal of oil quantities during engine operation. Spectrograms describing three states of the process were extracted from the transducer internal memory. As further described, the experimental system is capable to recognize certain lubrication operating conditions.

2. Experimental set-up

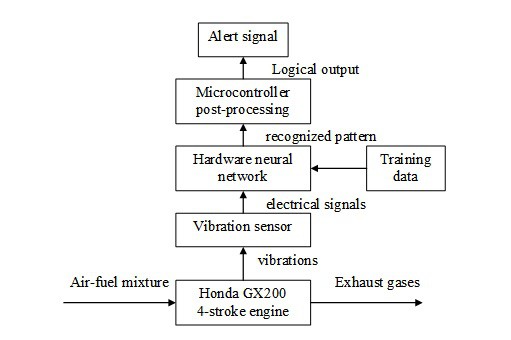

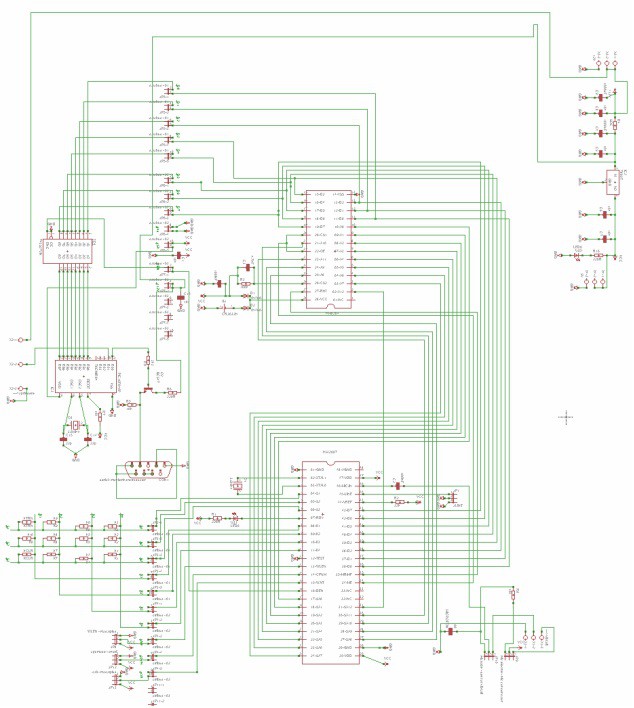

After a careful analyses of the latest technologies presented in the scientific literature, the MEMS approach was used in this experiment. The ADXL322 is manufactured by Analog Devices Inc. and provides analog signals for all three degrees of movement which correspond to the x, y and z axes. Fig. 1 describes the block schematic of the proposed system.

The vibrations acquired from the engine core are processed through the neural network by means of the pre-recorded training data. A resulting pattern identification code is provided to a micro controller, which signals a low oil level warning or alert.

Fig. 1. Block schematic

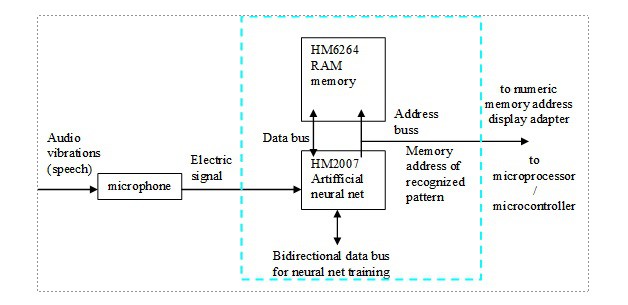

The hardware neural network chosen for this experiment is described in detail by Bachiochi (1994) and Wodarck (2009) as an intelligent system for speech recognition based on the multi-layer neuronal net principle, using the HM2007 hardware neuronal network microchip. Both systems are equipped with a microphone to acquire the vibrations in the audible spectrum. The block schematic of this speech-recognition system is presented in Fig. 2 (Bachiochi, 1994).

Fig. 2. Hardware neural network speech recognition system

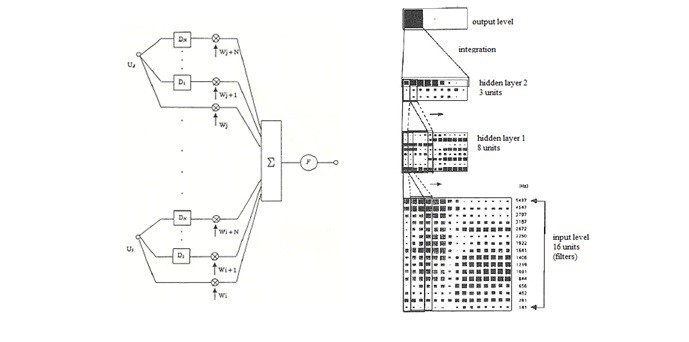

Wodarck (2009) proposes a method to determine the hardware neural nets architectures by using sets of training data generated in Matlab environment. The neural net architecture of HM2007 microchip was found to be TDNN (Time-Delay Neural Network), with the generic structure shown in Fig. 3. The variations in the air pressure corresponding to speech are acquired by the microphone. The signal passes N delay blocks and is split into N+1 distinct segments, which are integrated into a Fourier time-frequency set (spectrogram). The resulting N+1 vectors describing the N+1 signal segments are integrated in the previous mentioned spectrogram, which represent the trained data, and are stored into an additional SRAM memory.

Fig. 3. Generic TDNN architecture Fig. 4. Generic 4 level TDNN neural network

Dn represents the nth delay block; Wn – the corresponding share; F represents the Fourier function applied to the spectrogram, later stored in the external memory. Figure 4 presents an example of a TDNN network with two hidden levels.

According to Wodarck (2009), this particular neural network contains 64 neurons in the input layer corresponding to 64 filters on each 25Hz array of the 400...2000Hz frequency spectrum. The input signal passes through 27 delay blocks with a delay time of 68.6 ms repeating the same 64 neurons after each delay. These 64 neurons connect with an unknown number of neurons inside an unknown number of hidden layers. These parameters could not be determined (Wodarck, 2009) and are not available to the public in the HM2007 datasheet. The hidden layer is connected to the output layer which consists of 8 neurons using the hard limit transfer functions – having the logical value of „0” or „1” – and correspond to the D0...D7 outputs transmitting the binary coded memory addresses for storage or extraction of the trained data inside the additional SRAM.

The training is performed by manual (Wodarck, 2009) or x86-based microprocessor (Bachiochi, 1994) input of commands to the training bus.

The training method used in this experiment is the manual input of the memory location on the training bus, followed by acquirement of vibration from the working ignition engine (3000 RPM, no load connected). A total number of 40 different patterns were recorded, while amounts of oil were deliberately removed from the lubrication system until no further oil extraction was possible. The resulted data is stored in the HM6264 SRAM memory. Through the address bus, the hardware neural net signals the physical memory address of the recognized pattern, which is displayed by the mean of a two digit display (Wodarck, 2009), or acquired by a microprocessor system (Bachiochi, 1994).

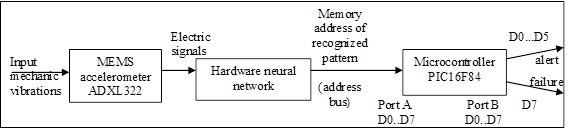

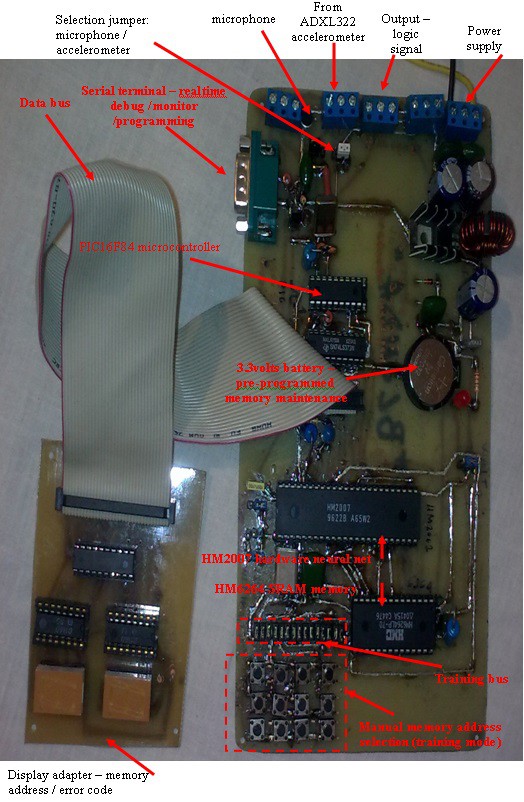

In order to identify the specific conditions of a low oil level in the lubrication system, the MEMS ADXL322 accelerometer was used as a signal source input for the hardware neural network described in Fig. 1, and the output was connected to a general use Microchip PIC16F84 micro controller, as shown in Fig. 5.

Fig. 5. Block schematic of intelligent vibration transducer

The hardware neural network acquires the electric signals and outputs a specific code to the data bus (connected to the Port A pins of the micro controller):

- the memory address of the recognized pattern, if recognized among the pre-programmed data in the SRAM memory;

- an error code, according to HM2007 hardware neural network datasheet.

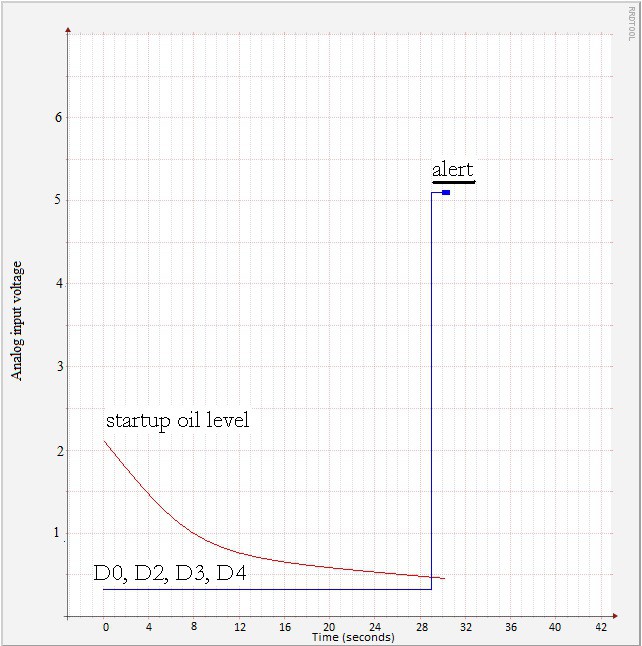

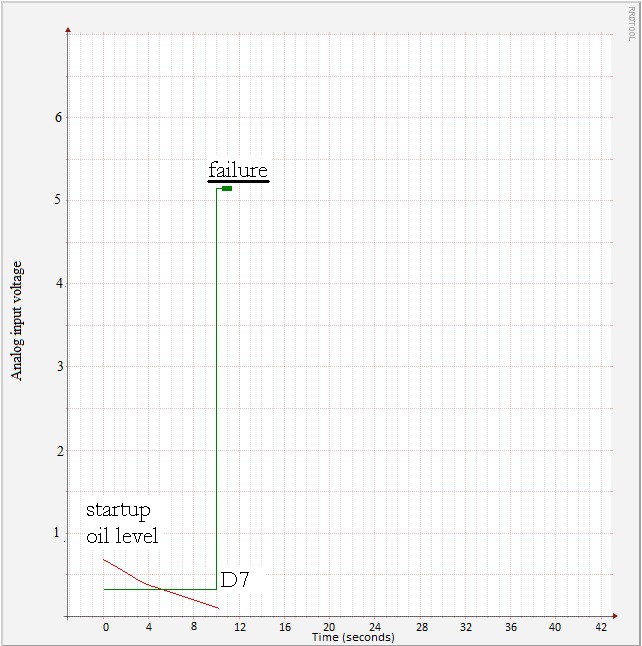

The fundamental step is performed at micro controller level, which consists in the elaboration of a binary digital output signal representing one of the 39 situations among the pre-recorded patterns. In this case, only six bits (D0..D5) of the Port B 8 bits register will be used. If the hardware neural network signals the lubrication failure condition (the last pre-recorded pattern is recognized), the internal micro controller program will fire the MSB (most significant bit) pin of the output register (D7).

Fig. 6 shows the electric schematic of the intelligent transducer, developed in Cad Soft Eagle Design (http://www.cadsoftusa.com). The hardware neural network intelligent transducer is shown in Fig. 7.

Fig. 6. Schematic of the hardware neural network based intelligent transducer

Fig. 7. Experimental set-up – intelligent hardware neural network vibration transducer

3. Results and Discussion

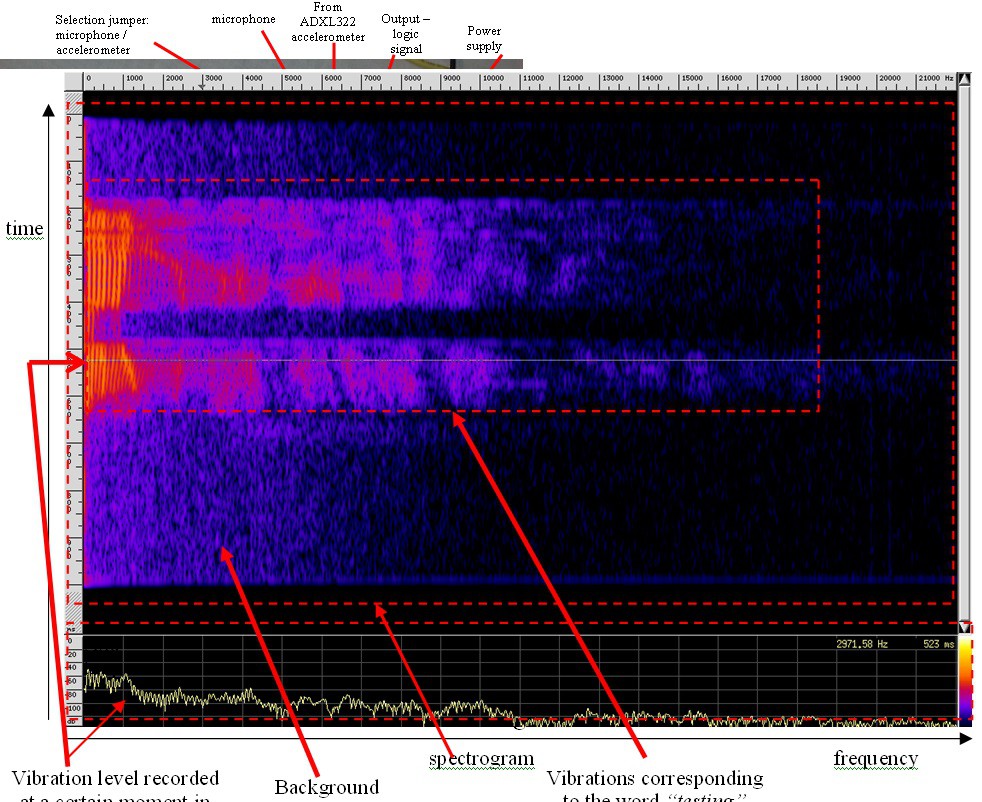

To test the capabilities of our experimental setup, the vocal mode was first chosen using the built-in microphone. A number of 40 different spoken words, each lasting 0.92 seconds, were recorded in the SRAM memory using the keyboard connected to the training bus. A number of 20 different words, each lasting 1.9 seconds, were later recorded. In both cases, a 280 ms pattern-recognition response time was measured. Figure 8 shows the spectrogram of the recorded word „testing”, as it was extracted from the SRAM memory and displayed using the „baudline signal analyzer” (http://www.baudline.com) utility software component of the Unix 8.2BSD operating system.

Fig. 8. Spectrogram of the spoken word „testing”

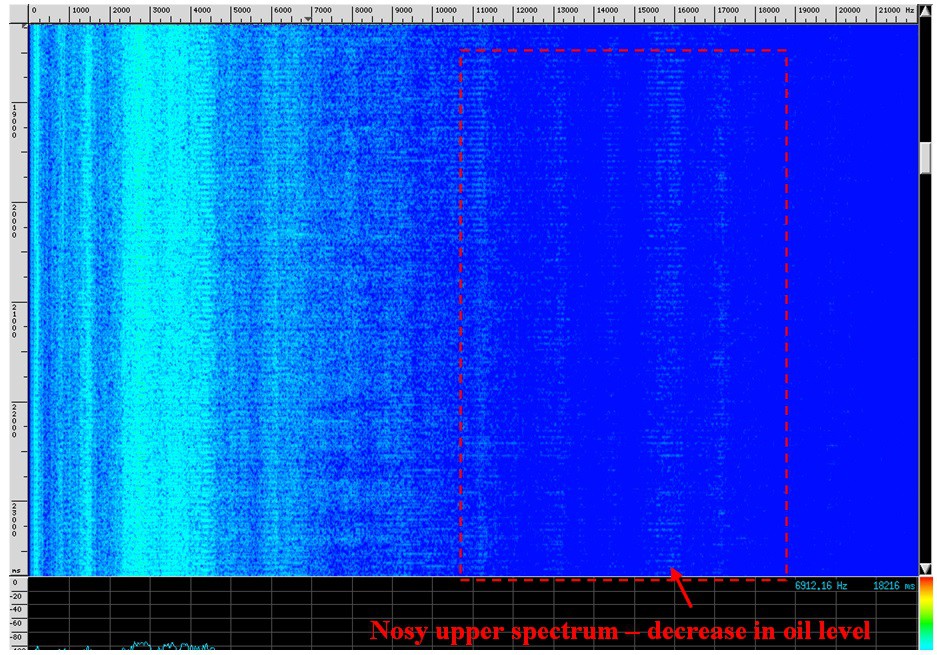

The next step consisted of training the network by using vibrations specific to different oil levels inside the lubrication system. A number of 40 different vibration samples were recorded while small quantities of oil were extracted successively from the engine block, and at the same time the corresponding vibrations signals were transferred in the SRAM memory, until no further oil extraction was possible. For a short period of time (while recording the last vibration sample), the engine worked outside the recommended manufacturer parameters. Figs. 9, 10 and 11 show three illustrative cases of lubricating conditions, extracted from the internal memory and displayed with the BSD Unix baudline signal analyzer utility software.

Fig. 9. Extracted spectrogram characterizing a low oil level

| |

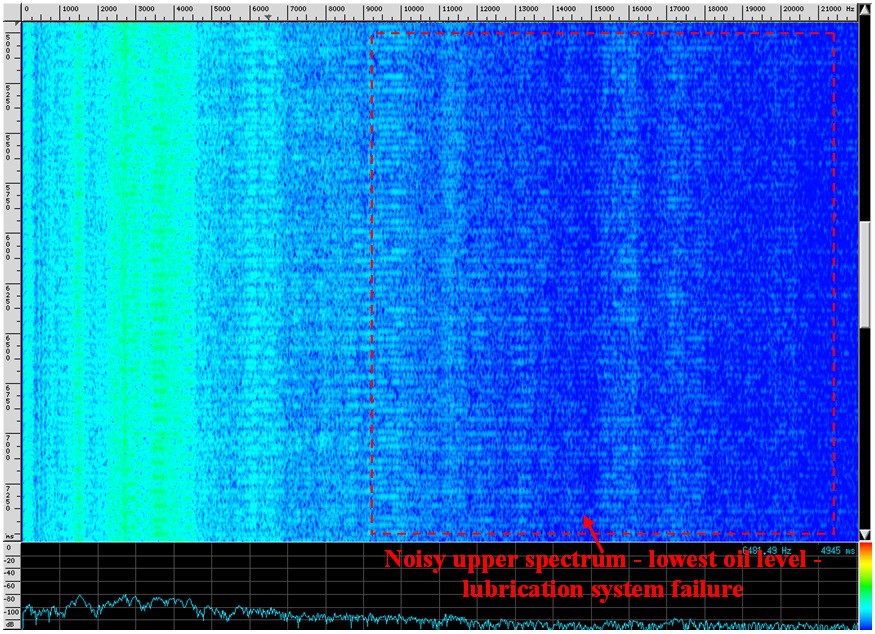

Fig. 10. Spectrogram showing the absence of oil in the lubrication system (noisy upper frequency spectrum) |

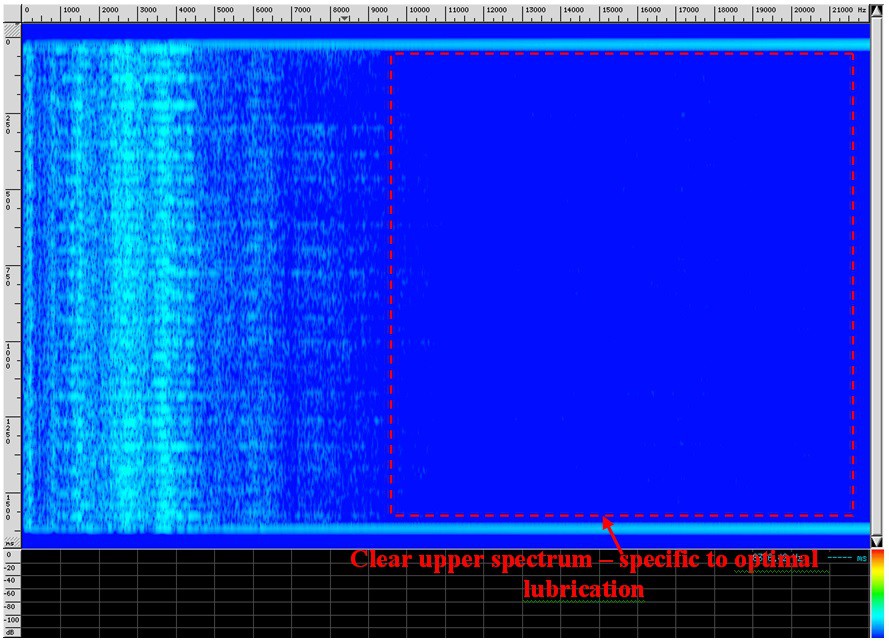

Fig. 11. Spectrogram showing a proper lubrication (clear upper frequency spectrum)

The next step in the experiment was testing the intelligent transducer on simulated conditions of lubrication system failures. The transducer was switched from training mode to pattern recognition mode. A number of three tests were performed. The first test consisted of vibration acquirement while the lubrication oil level was set according to manufacturer specifications. In the second test, the lubrication system was deliberately drained out to an extremely low level (as shown in Fig. 12), outside of the recommended manufacturer parameter, with the corresponding identified pattern shown in figure 9. The last test was performed after total extraction of lubricating oil (as shown in Fig. 13), in this case the transducer signaled a failure, with the identified pattern shown in Fig. 10. The failure signal was used to deactivate the engine ignition system as a procedure for emergency process shut down. The decrease oil level shown in both Fig. 12 and Fig. 13 is caused by internal engine mechanical components in movement.

Fig. 13. Lubrication system failure (portD.7 vs determined oil level)

4. Conclusions

During the training and testing experiments, the engine block suffered mechanical deformation damages due to operation with oil level below the manufacturer’s specifications, but we managed to acquire an important set of data which will help avoiding any lubrication system malfunctions on long term operation. The vibration analyses by means of artificial neural network can be used on field operating situations, where the engine operates unsupervised for long periods of time, avoiding any toxic gases caused by oil burning in the ignition chamber due to long term mechanical deformations. This method has application in environmental protection by equipping engines with such intelligent transducers. The hardware artificial neural network method was chosen because this system can be integrated as a separate module, independent of other monitoring systems. For other environmental protection applications, this method can be extended for any other mechanical applications by means of new sets of training data, such as deliberately integration of defective mechanical component in direct relation with the ignition chamber, such as worn elliptical-shaped cylinders or worn segments which lead to lubrication oil consumption and toxic exhaust gases. This situation example is treated by training the neural network with the specific vibration signals for preventing both such future malfunctions and the negative environmental impact.

References

Books:

Siemens, AG (2005), A spectral vibration detection system based on tunable micromechanical resonators, Chemnitz University of Technology, Chemnitz, Germany, Sensors and Actuators A: Physical Volumes 123-124, pp. 63-72;

Wodarck, J.T. (2009), A hardware implementation of an artificial neural network, California State University, Northridge, U.S.A.;

Rao, B.K. (1996), Handbook of Condition Monitoring, Elsevier Advanced Technology, Oxford OX5 1GB, UK, ISBN 1 85617 234 1, pp. 185-189;

Journal papers:

Adnan, M., Ibrahim, D., (2008) Hydrogen as a renewable and sustainable solution in reducing global fossil fuel consumption, International J. of Hydrogen Energy 33, 4209-4222;

Adiletta, G. (2006), Monitoring of Lubricating Conditions with a Neural Network Pattern Recognition Technique, International Conference on Tribology AITC-AIT, Parma, Italy;

Al-Rousan, A. (2010), Reduction of fuel consumption in gasoline engines by introducing HHO gas into intake manifold, International J. of Hydrogen Energy 35 pp. 12930-12935;

Bachiochi, J. (1994), Ta(l)king control, The Computer Applications Journal 49, 1994;

Charltona, S.J. (1998), Handbook of Air Pollution From Internal Combustion Engines - Chapter 11 -Control Technologies for Compression-Ignition Engines, Advanced Diesel Engine Technology, Cummins Engine Company, Inc., Indiana, USA - Pollutant Formation and Control, pp. 358-419

Leontopoulos, C., Robb, D.A., Besant, C.B. (1998), Vibration analysis for the design of a high-speed generator for a turbo-electric hybrid vehicle, Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, pp. 212-271;

Scholl, D., Barash, T., Stephen, R., Stockhausen, W. (1997), Spectrogram Analysis of Accelerometer-based spark knock detection waveforms, Ford Motor Co., U.S.A., available online at DOI: 10.4271/972020

Sinha, A.N., Mukherjee, P.S., De, A., (2000), Assessment of useful life of lubricants using artificial neural network, Industrial Lubrication and Tribology, Vol. 52, Iss. 3, pp. 105-109;

Vogla, A., Wanga, D.T., Storasa, P., Bakkea, T., Takloa, M.V., Thomson, A. (2009), Design, process and characterisation of a high-performance vibration sensor for wireless condition monitoring, Sensors and Actuators A: Physical Volume 153, Issue 2, pp. 155-161;

Vulli, S., Dunne, J.F., Potenza, R., Richardson, D., King, P. (2009), Time-frequency analysis of single-point engine-block vibration measurements for multiple excitation-event identification, Journal of Sound and Vibration 321, pp. 1129-1143;

Symposia volumes:

Thompson, G.J., Atkinson, C.M., (1999), Neural Network Modeling of the Emissions and Performance of a Heavy-Duty Diesel Engine, Journal of Automobile Engineering Papers Controller, Proceedings Professional Engineering Publishing Limited, Suffolk IP32 6BW, United Kingdom; On Line at http://www.atkinsonllc.com/Assets/downloads/PAPERS/JpurnAutoEngr.pdf

Yadav, S.K., Kalra, P.K. (2009), Automatic Fault Diagnosis of Internal Combustion Engine Based on Spectrogram and Artifcial Neural Network, Proceedings of WSEAS International conference on Robotics, Control and Manufacturing Technology 10, ISBN: 978-960-474-175-5, pp.101-107;

Dissertations:

Buruiană, V. (2012), A Research in Intelligent, Microcontroller-based Monitoring and Alert Automatic Systems, PhD Thesis, Petroleum and Gas University of Ploieşti, Romania, pp. 161-193 (in press);

Cohen, E.D. (2006), Vibration Detection in Turbomachinery using non-contacting sensors - Master Degree Thesis, M.I.T., Boston, U.S.A.;

<END OF TRANSMISSION>

______________________________________

kernel panic: improbability coefficient below zero

[skaarj]

[skaarj]

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

This is outstanding work ! I'm really impressed !

This log must be read by the Hackaday.com editorial staff !

@Al Williams

@Mike Szczys

@Elliot Williams

Are you sure? yes | no

Thank you.

Is there any procedure for me to do? Should I write

them? I come from a community that shows their scientific appreciation

in.... different unusual ways, this is why I am asking.

More will come. Radiation detection system is almost finished, this time the scientific article is already published in a respectable magazine... Springer.

Are you sure? yes | no

Springer, the other mafia...

I'm glad you can write anything you want here, for free !

Are you sure? yes | no