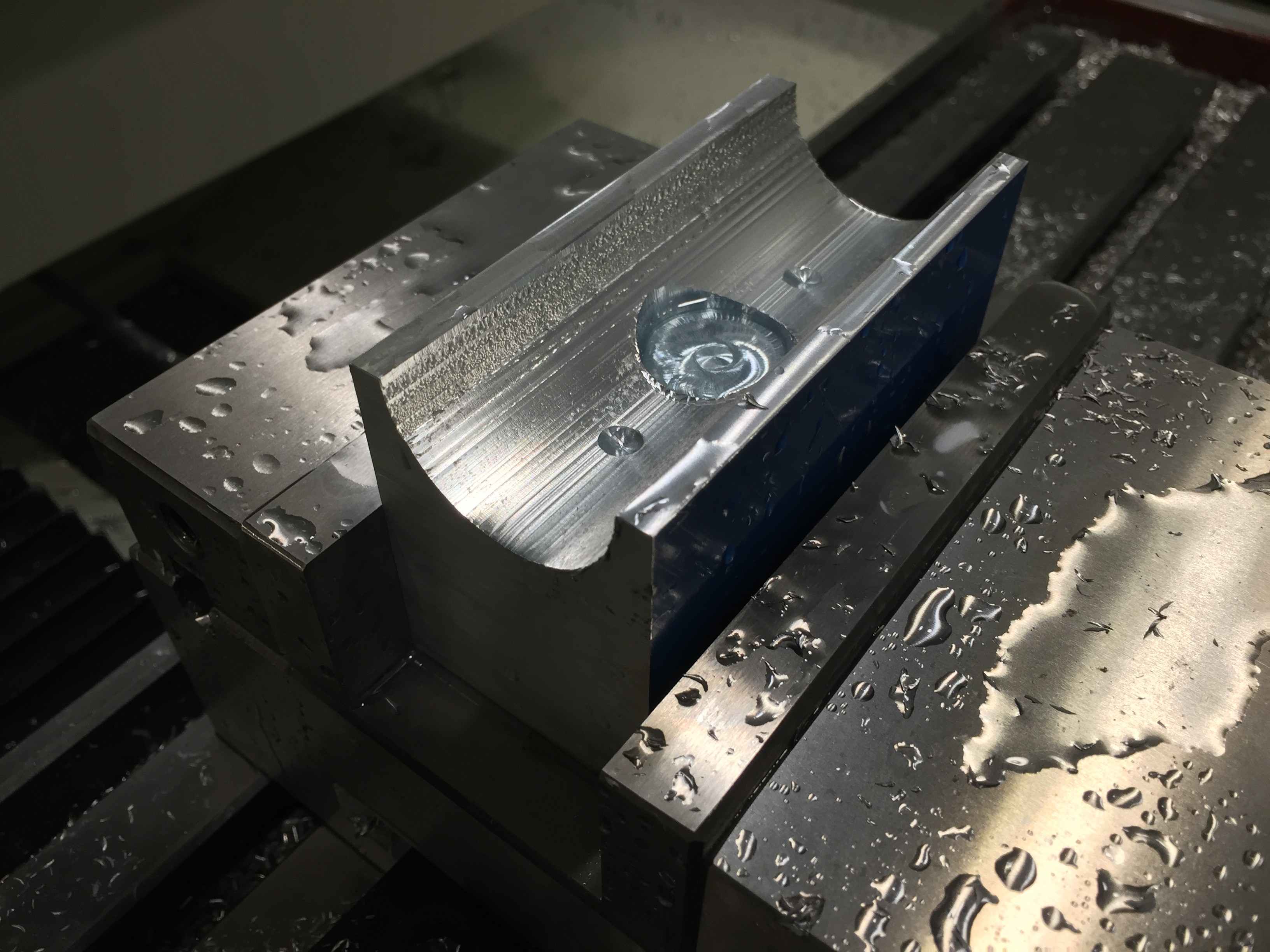

Last week we roughed out the bearing block, but there were still a few operations left to perform to get the piece finished up and operational. We started by clearing out the inner channel using a parallel pass operation with a ball end mill to take down the roughness of the finish.

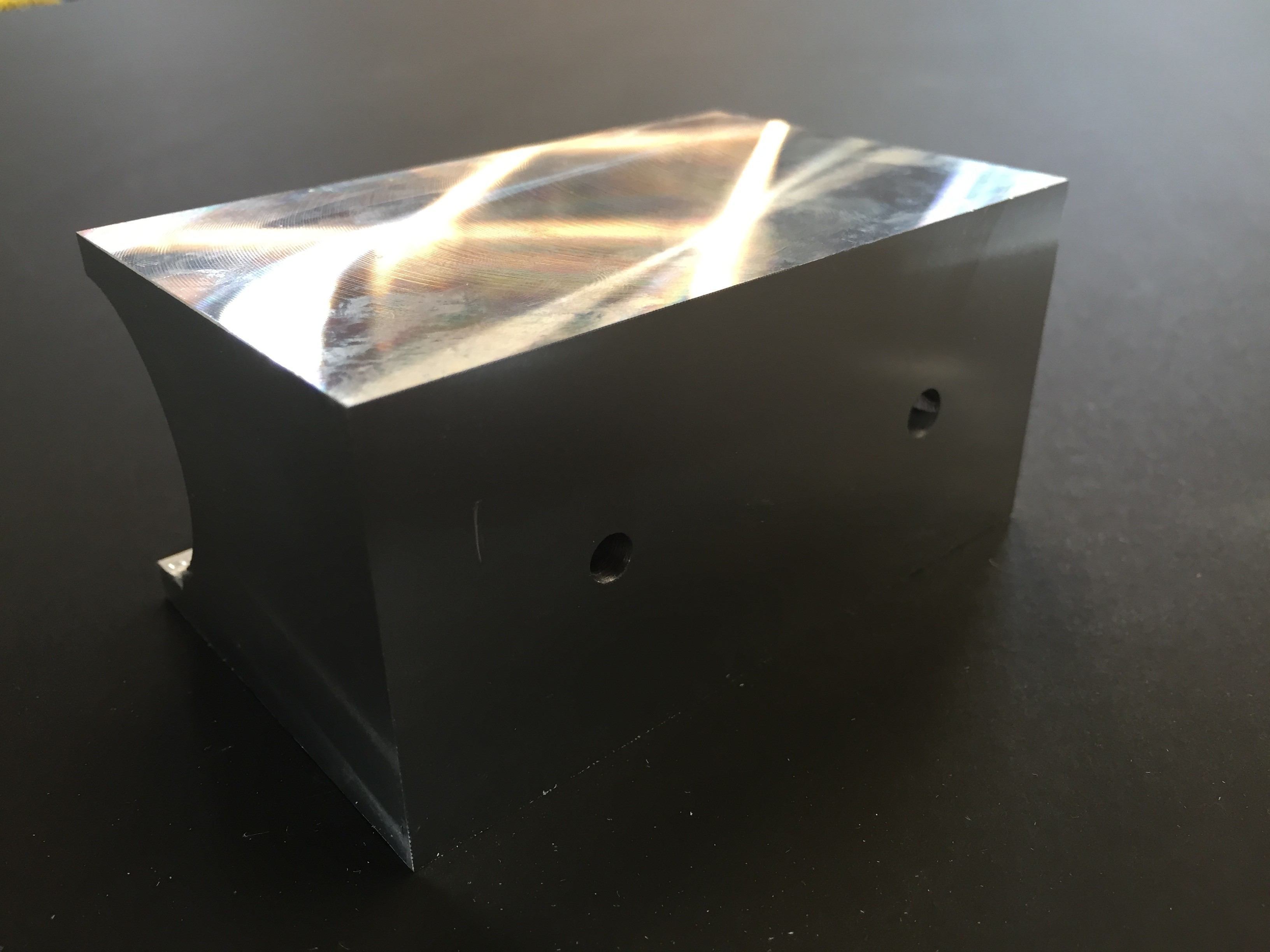

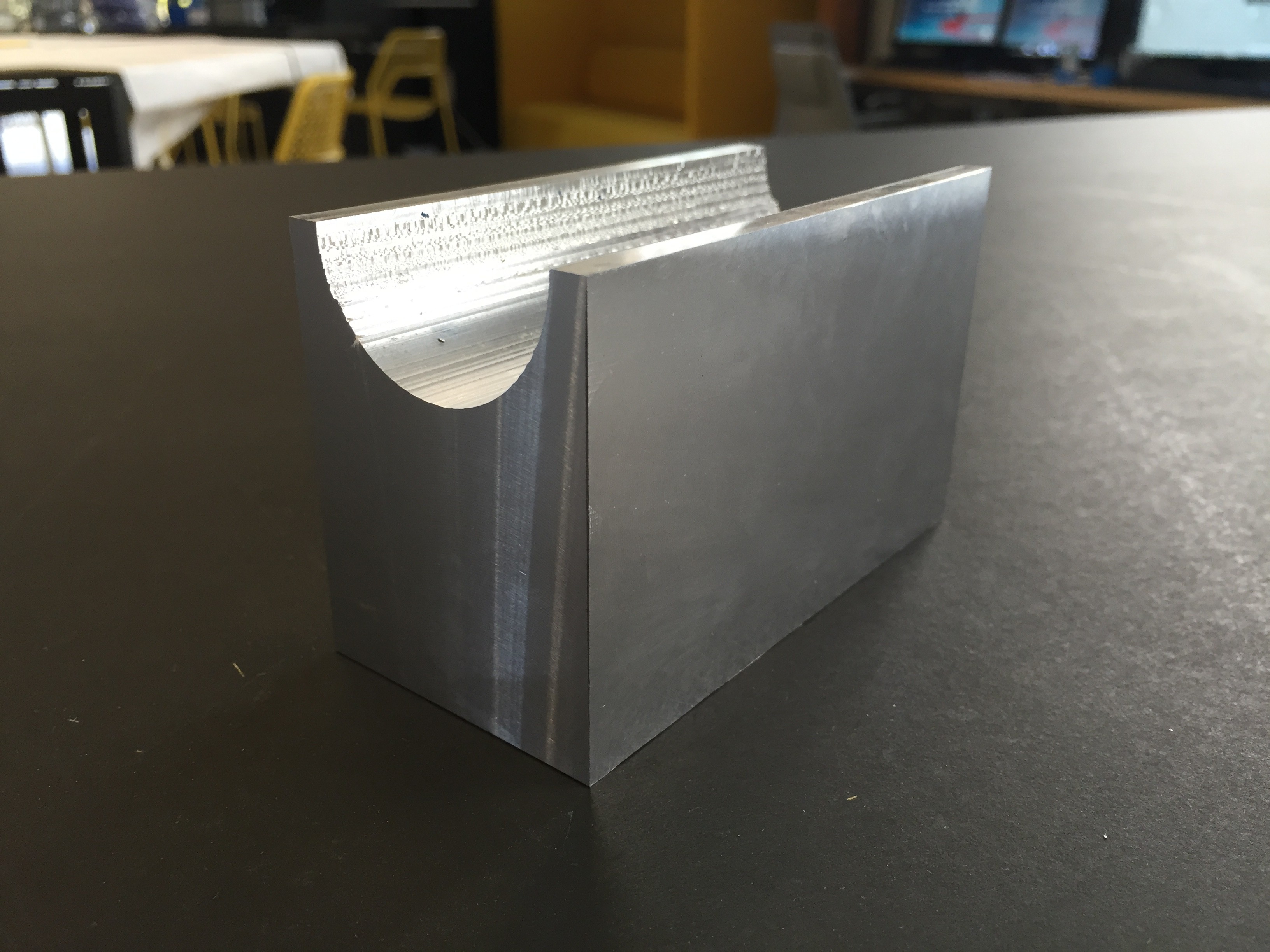

After that we used the fly-cutter to put a nicer finish on all the other faces of the block. We used a drill operation to add the mounting holes. It came out looking mighty fine.

All that's left it to bore out the center hole for the axle, but overall we've now got a good flow on machining these blocks. It should go fairly quickly from here on out.

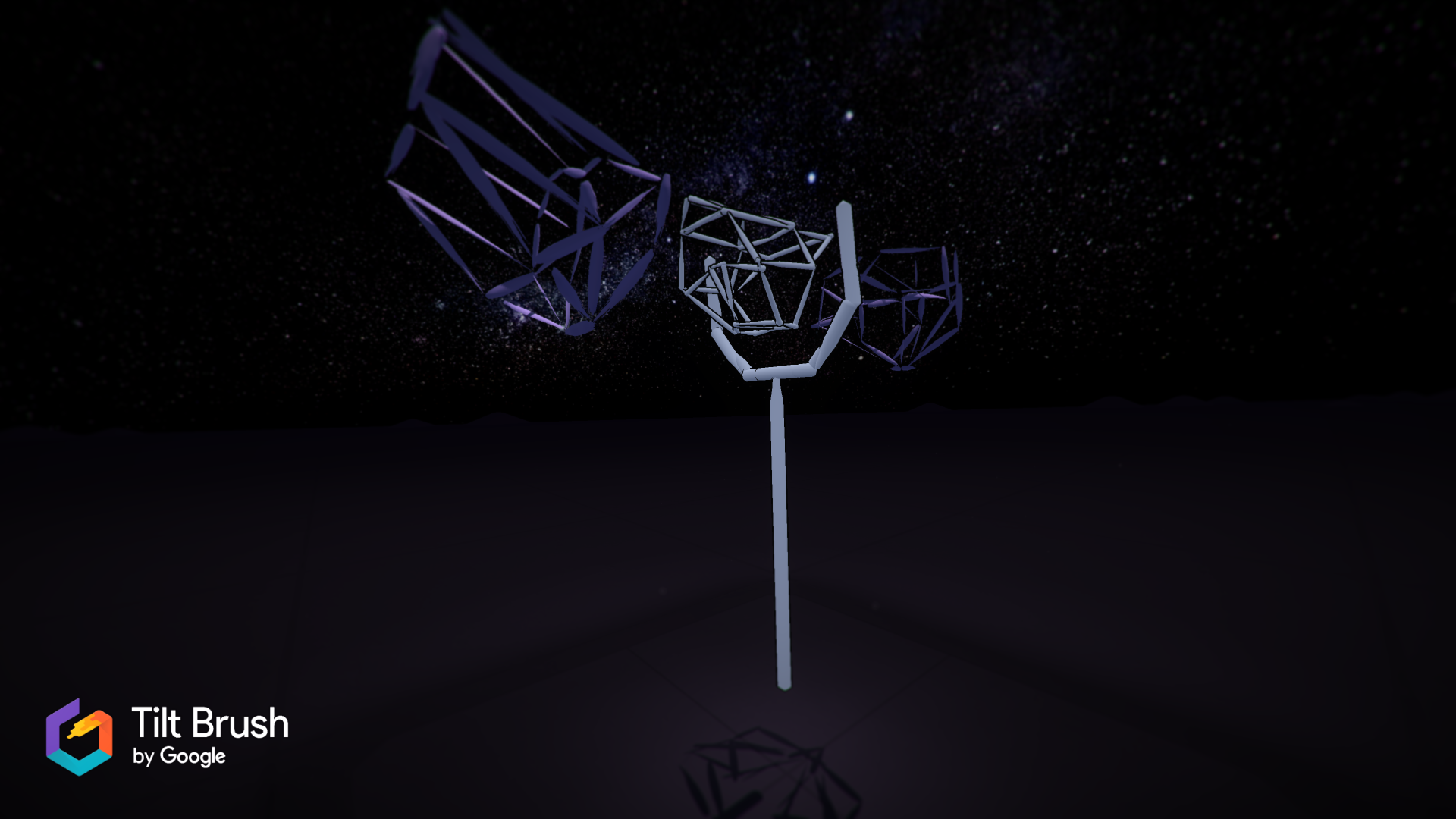

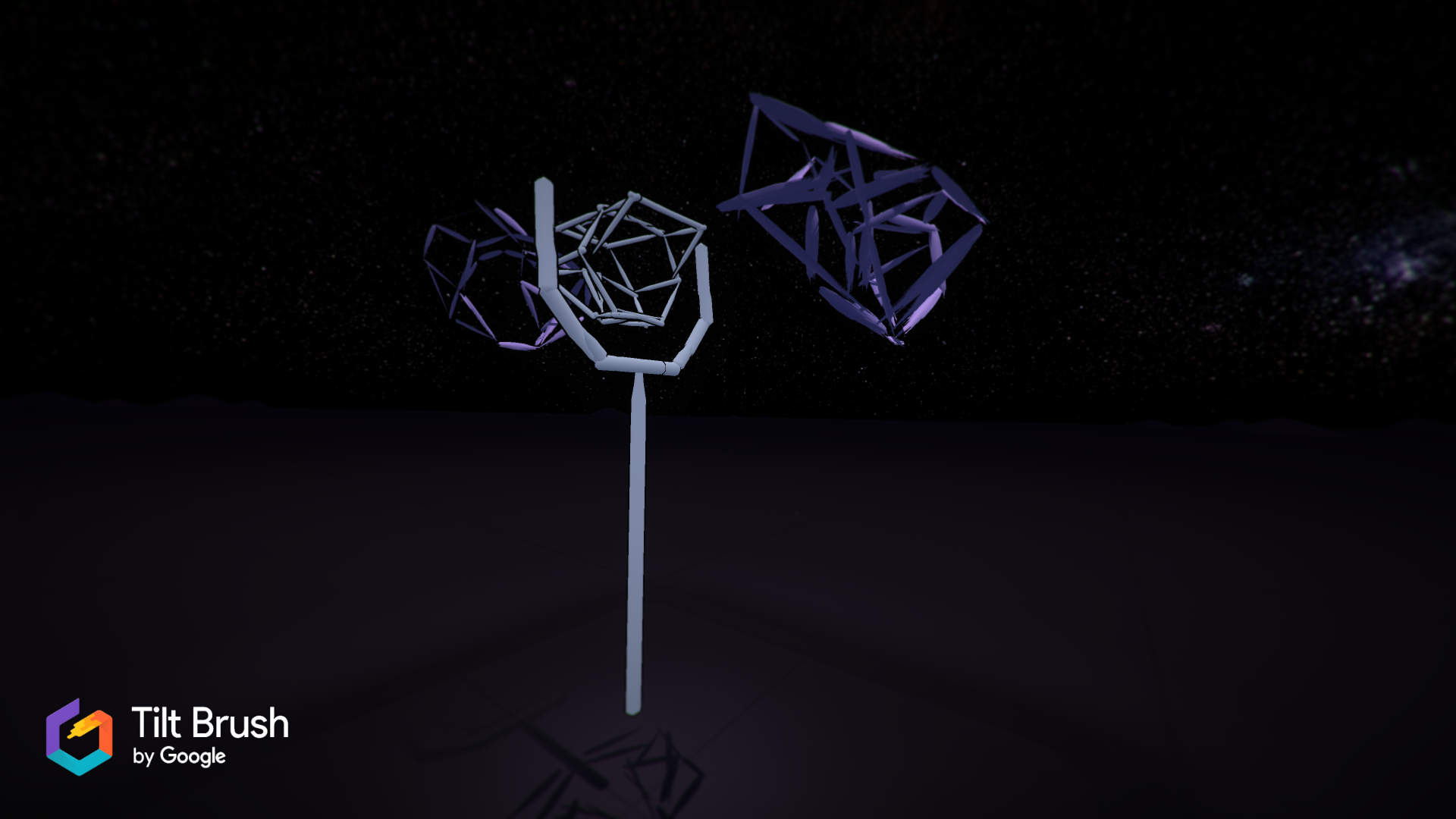

On the design front, I played around a bit with sketching out some new shell ideas using Tilt Brush. It's really helpful to get a sense of scale in VR.

Next step is to finalize the shell design and mill the positive mold out of MDF on the ShopBot. Once that's ready we'll be able to vacuum form the shells quickly and easily.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.