This log will cover 3D printing tips. If you have suggestions from your own experience please leave them below!

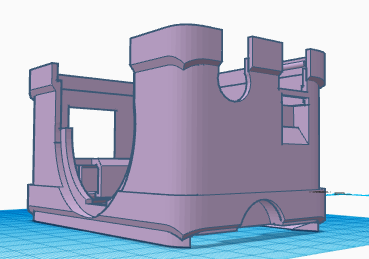

FED3 was designed to be printed with minimal support material, as our printers don't have supports. You'll notice that many of the parts "slope up", which allows them to be built without any supports.

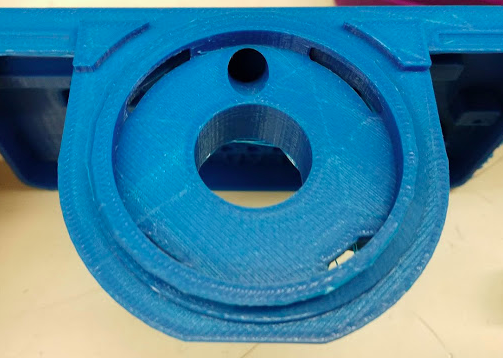

FED3 is a mechanical device, and the quality of the print will affect its reliability. One of the biggest issues we've experienced with FED3 are pellet jams, which can be caused by imperfections in the print. We print FED3 parts at a slow speed of 40mm/s and a layer height of 100microns. This takes about 24 hours of total print time to produce one FED3. The front plate takes about 10 hours but these settings make very smooth surfaces for dispensing pellets.

We print much faster while we are prototyping. Here are some examples of different print settings and potential issues that occurred below:

200 micron layer height, 40mm/s (~4 hours to print front plate). Print is OK but has some rough areas:

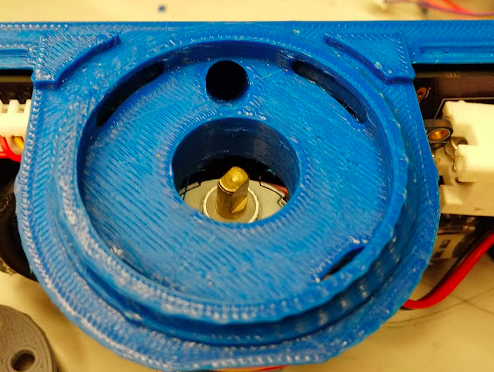

200 micron layer height, 100mm/s (~2.5 hours to print). Many problems!

Lex Kravitz

Lex Kravitz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.