...me neither!

Where have I been? Up to no good, apparently.

So, I have this weir idea to use acrylic (PMMA) as masking, because it is convenient and readily avaliable, however, to do photolitography with it, you need an electron beam...sooo, where do you get one?

Unlike some countries, in mine, there are no electron microscopes readily avaliable for cheap prices, so I had to look for an alternative source of a focused e-beam.

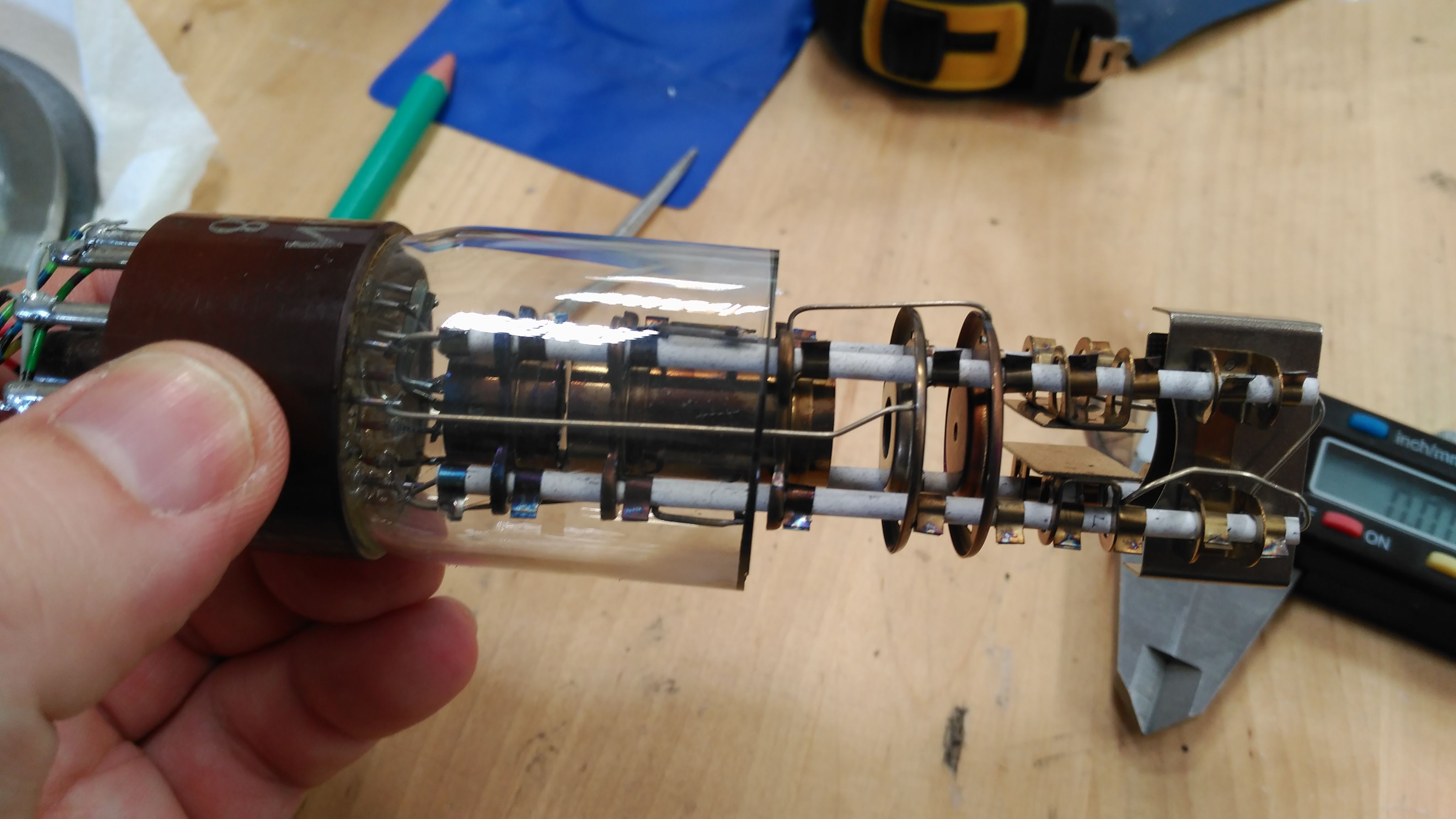

Yup, that's an oscilloscope CRT pointing inwards to the vacuum chamber.

For control I made a CNC to analog board:

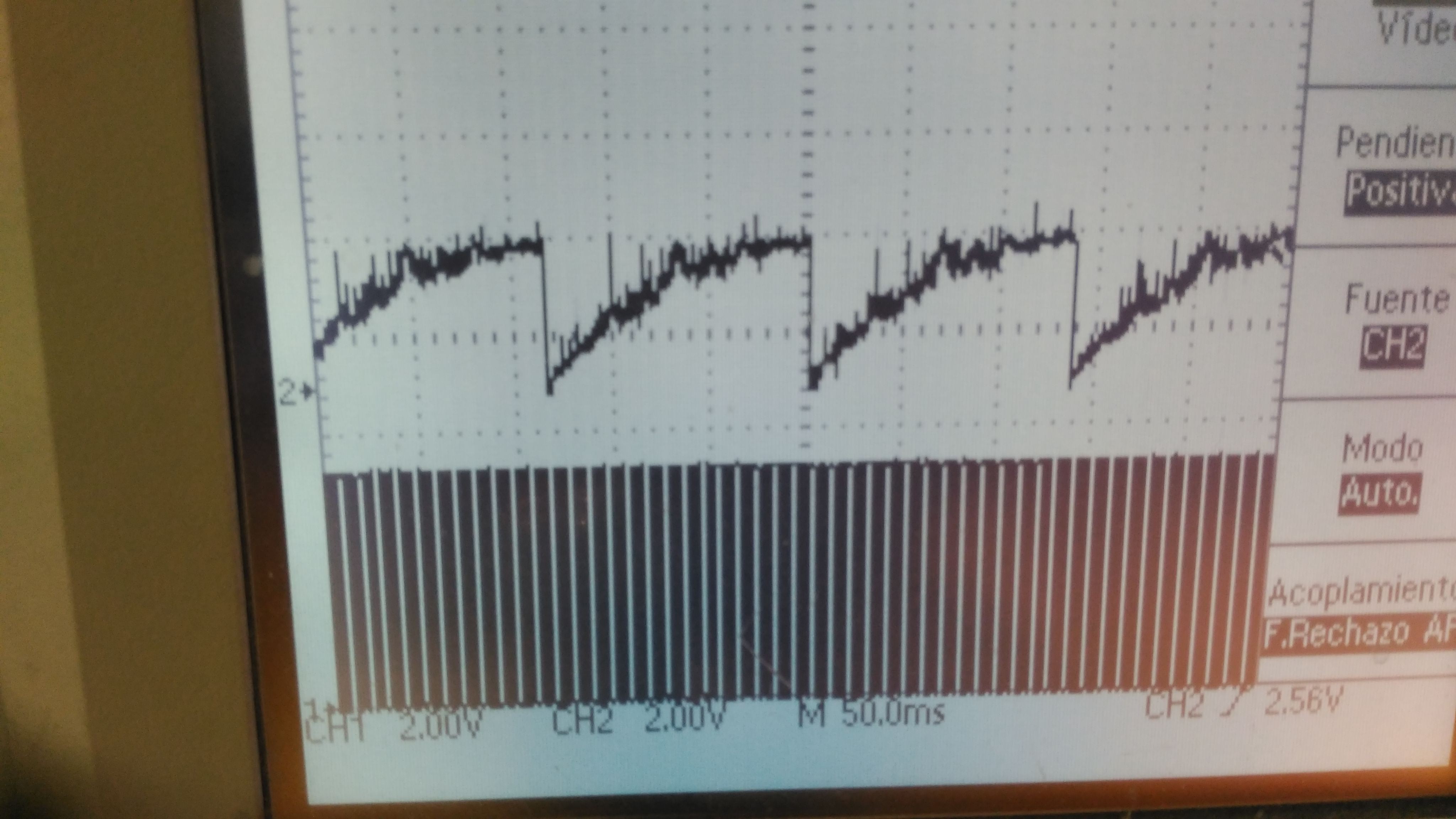

Using 3 up/down 4 bit counters to get the step and direction lines from my laser cutter software and using a DAC to have an analog value that the oscilloscope electronics could use. However, I had problems with the integrated DAC, wich was noisy as hell during switching:

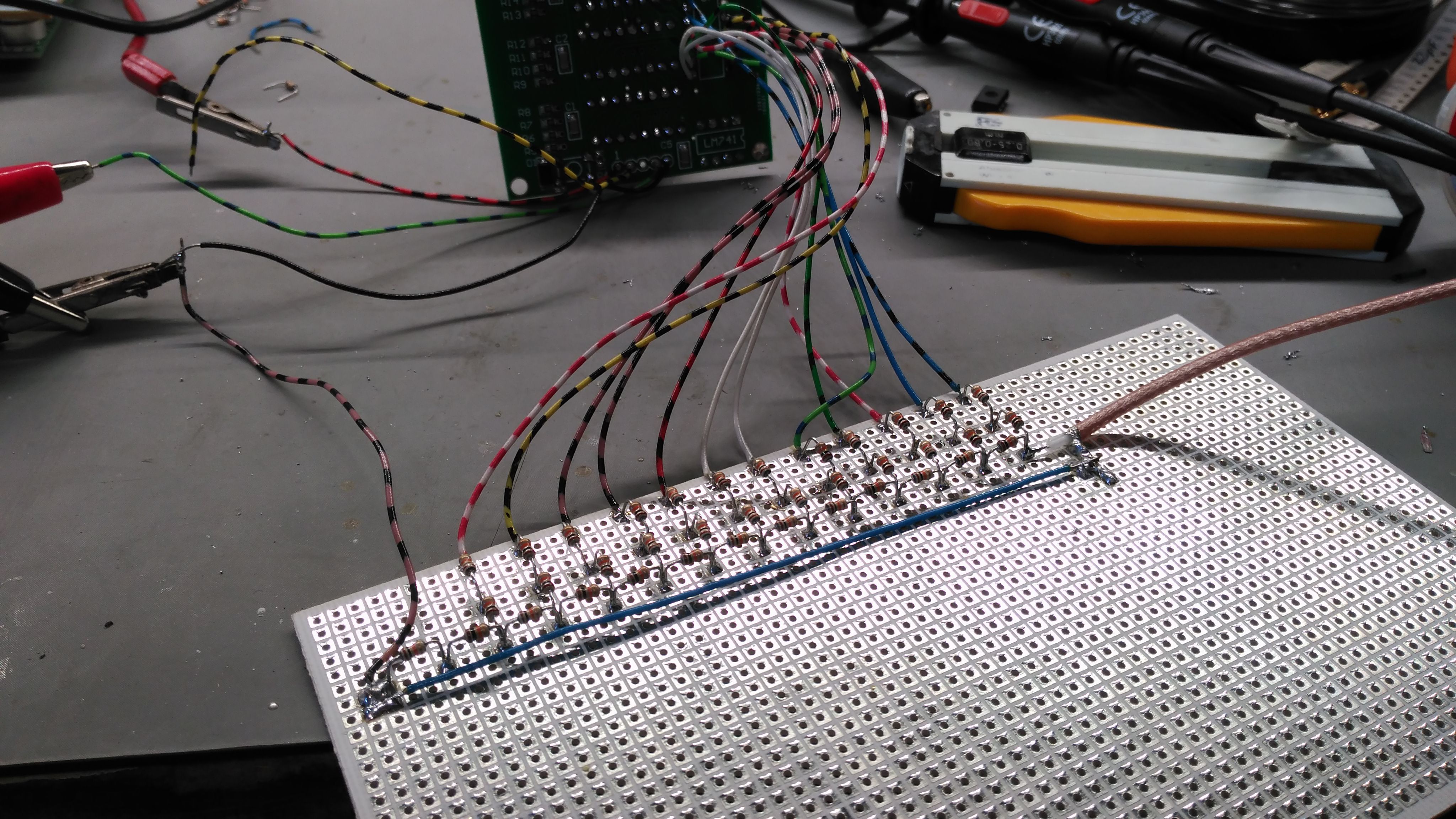

And had to resort to making my own R-2R ladder.

It was done with 5% resistors, just for the heck of it, and it is pointless as is, but I had a bag of them, so, no regrets.

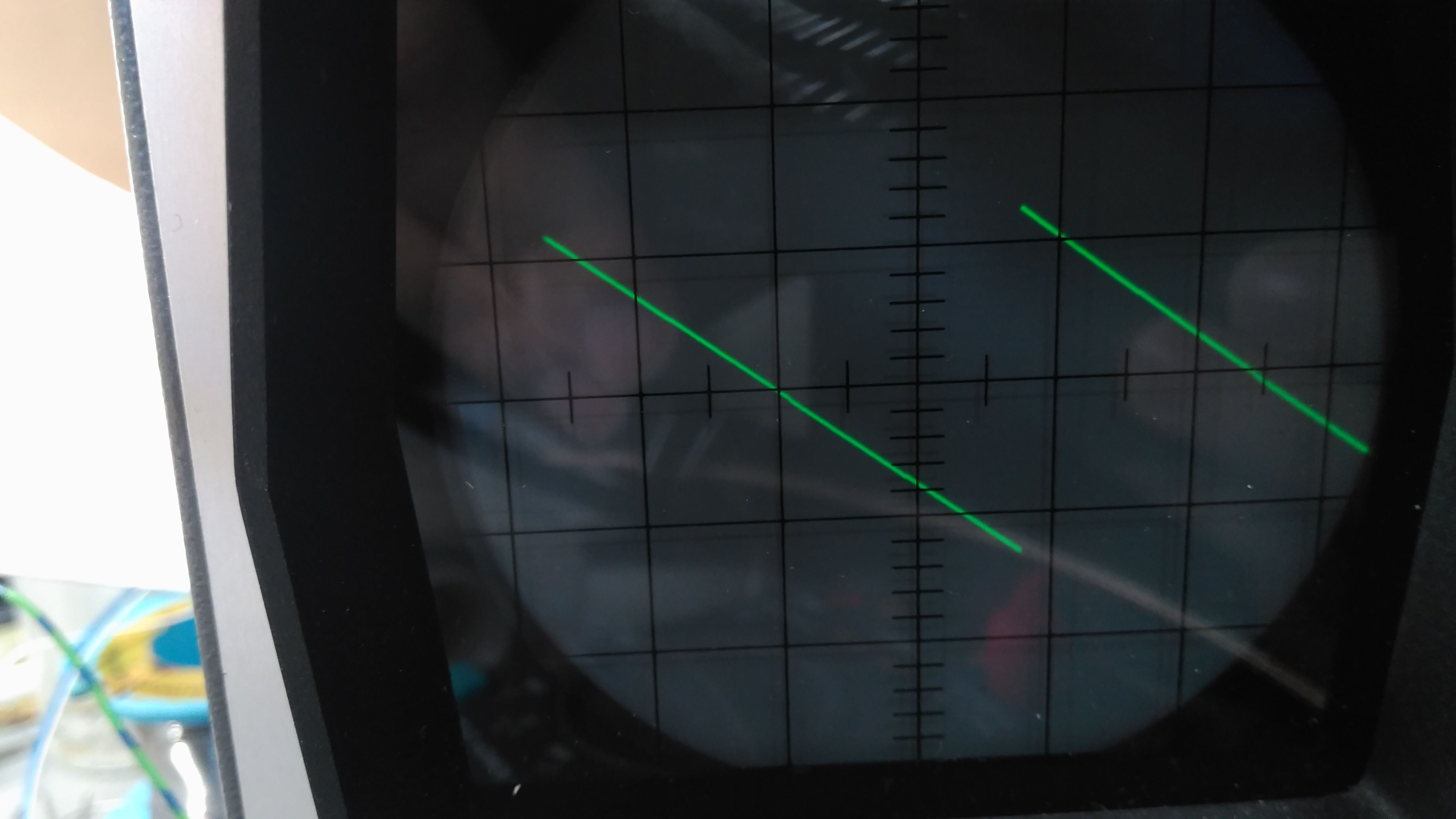

It was done with 5% resistors, just for the heck of it, and it is pointless as is, but I had a bag of them, so, no regrets.Anyhow, the performance, side by side, was much better:

I implemented two of them (hacked the blanking too) and had some fun:

(long exposure shot):

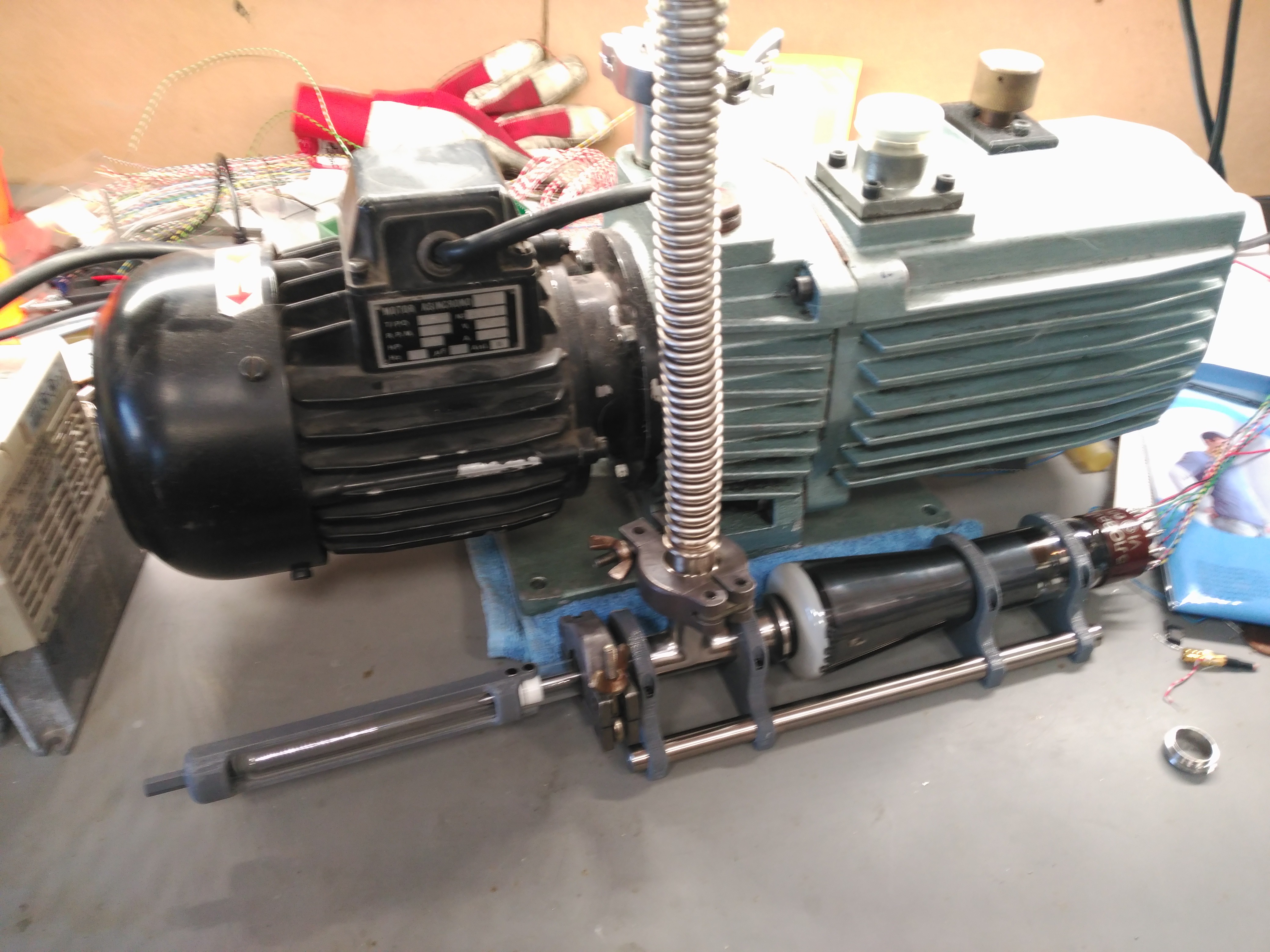

Originally I had planned to drill the front of the tube with this vacuum setup, and use it as is.

However, after five hours of trying to drill it dry I had only gone just half the glass, and decided it was worthless.

So I broke the vacuum with a small diamond drill and then cut the tube. It took a few trials to get a clean cut, so I ended with a short stub:

As you saw in the first photo, I glued it to a machined plate and sat it in the vacuum chamber.

In the end, I decided to try to start the tube with only the mechanical vacuum pump. I had a small hope that it would be inefficient, but work to some extent, however, 30/50 microns is still too high of a vacuum to properly run a CRT tube, and plasma discharge started right away.

Since I was pretty sure this was going to happen, I did record it in slow motion, to capture more details, fail starts @ 0:25

Also I already had bought parts to build an oil diffusion pump:

Unfortunately, I overestimated how low my TIG welder could go, and at it's lowest setting, pierced the thin 0,25mm stainless sheet. Rendering all pieces unusable.

Having to spend more money on this, and having just met someone who could help, I decided to try to obtain a turbomolecular pump.

Nixie

Nixie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.