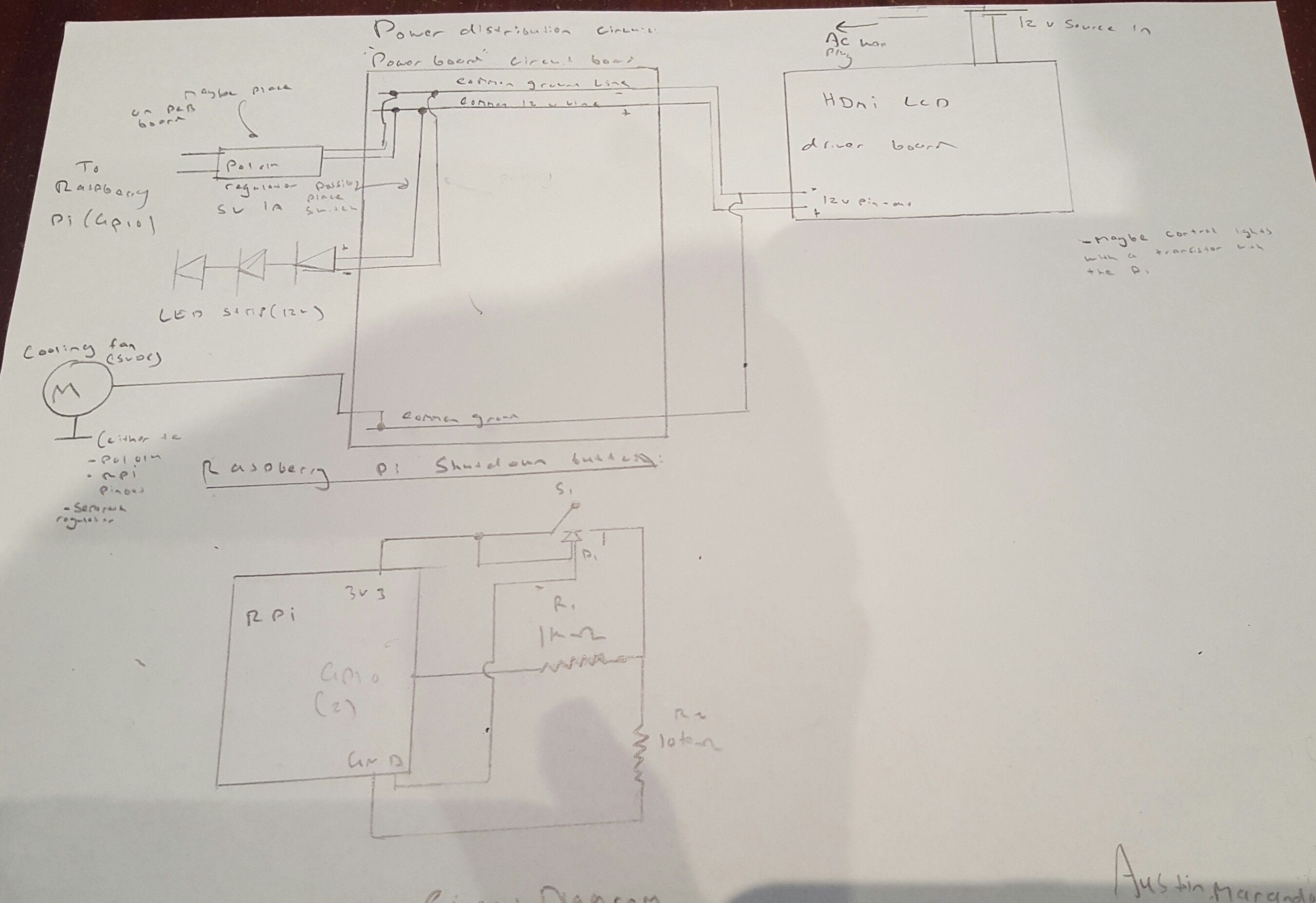

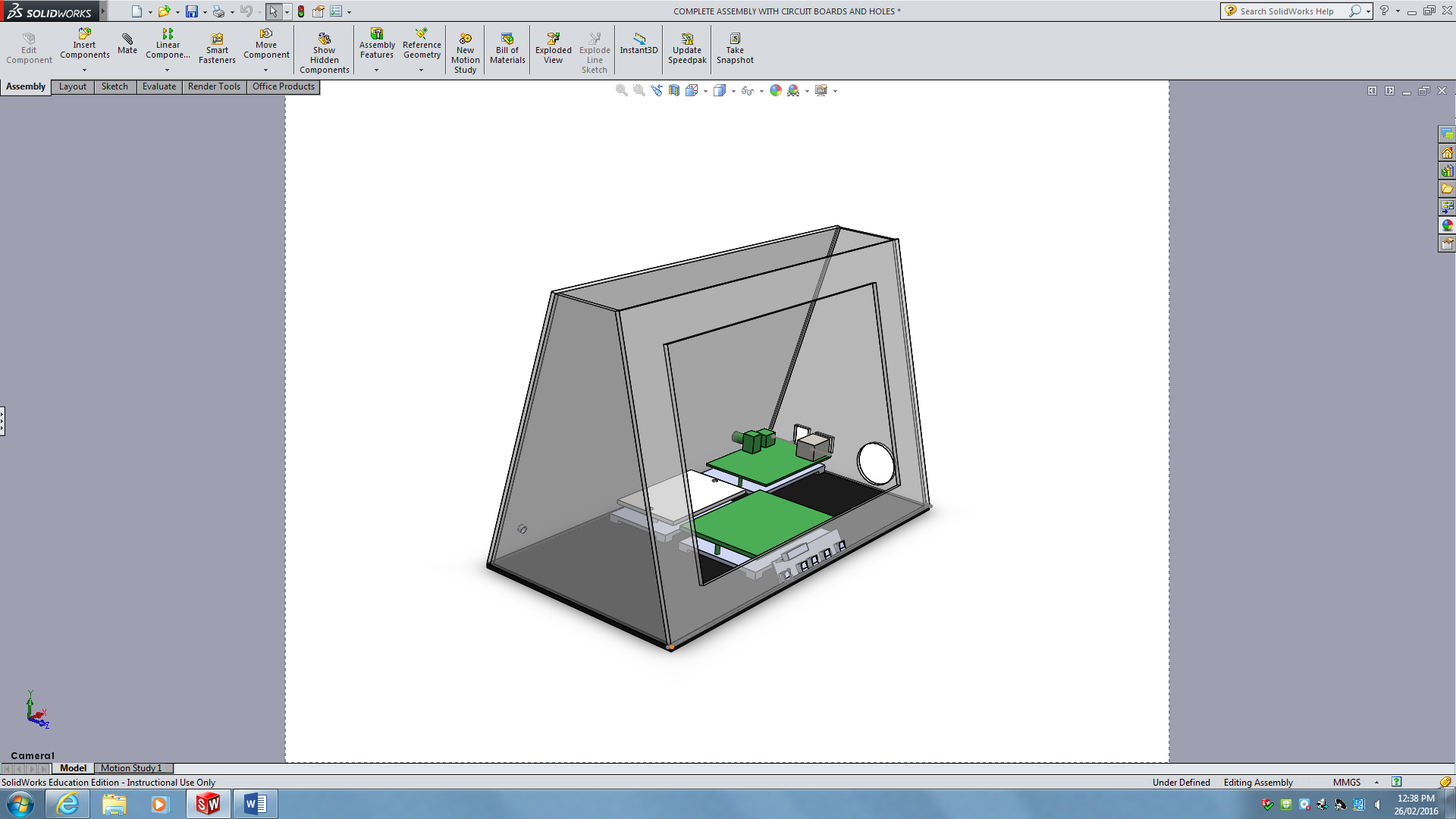

MAIN OBJECTIVE:

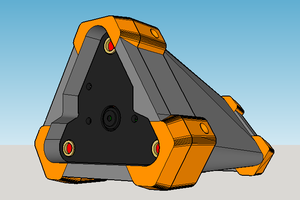

To create an open-source programmable and easy to use photo display unit, allowing for an easy transition from digital image to display.

Specific Objectives

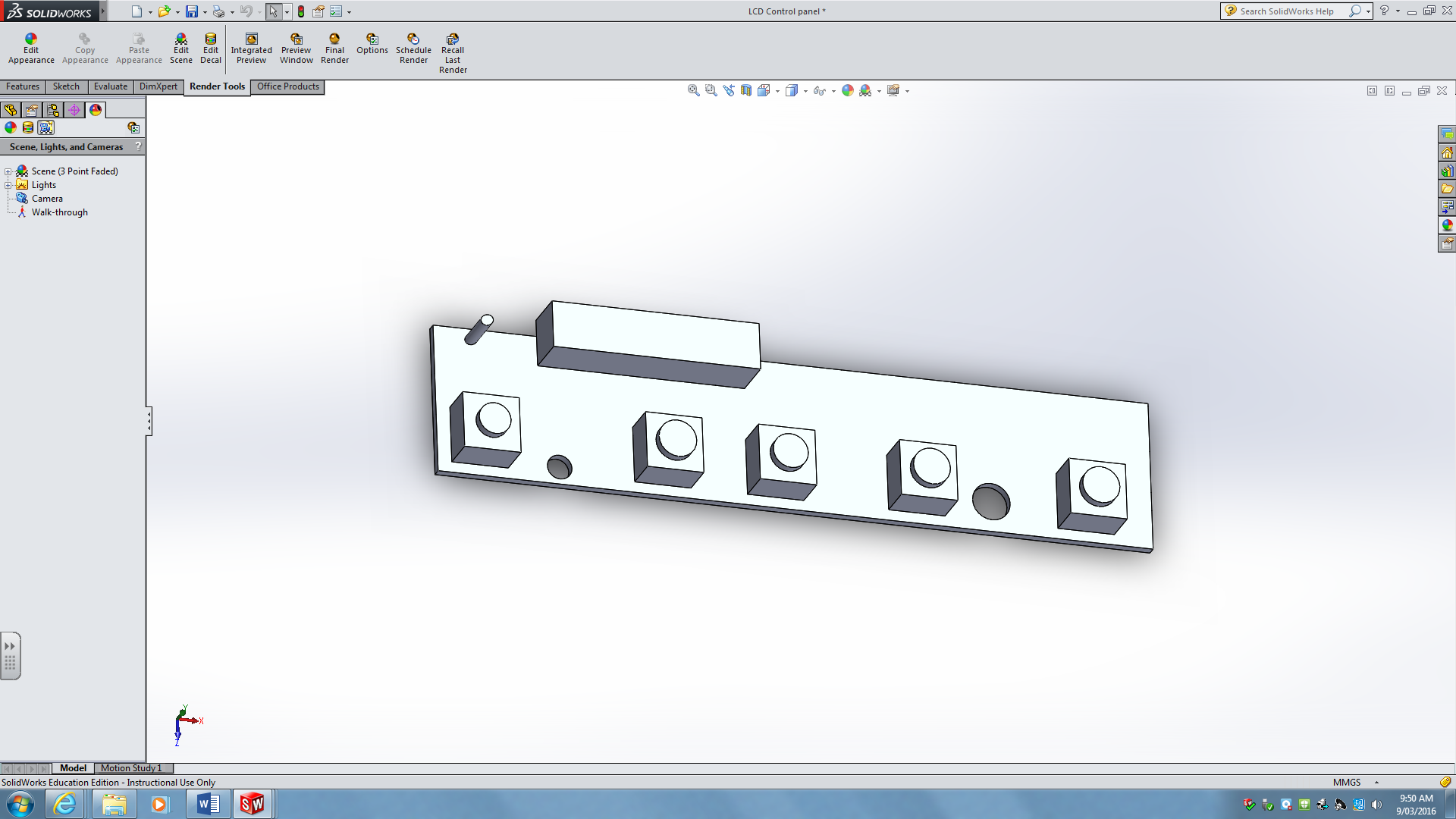

- The unit must Automatically mount the user's USB

- A Safe shutdown switch

- Must be open-source and allow the user to change anyfeature that he/she desires

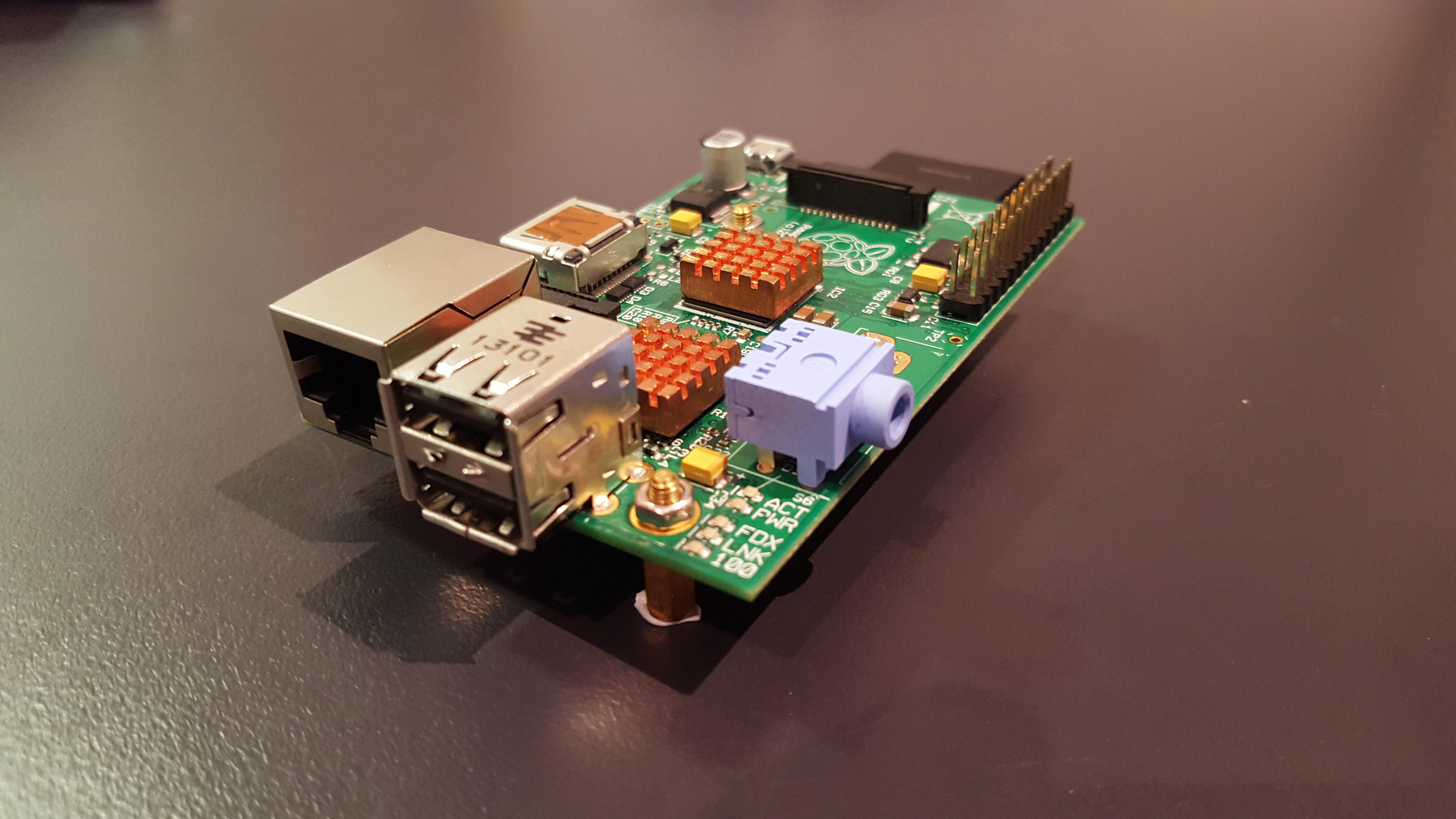

- Must be safe to operate, and have adequate cooling systems as to allow for an extended period of operation

Austin Marandos

Austin Marandos

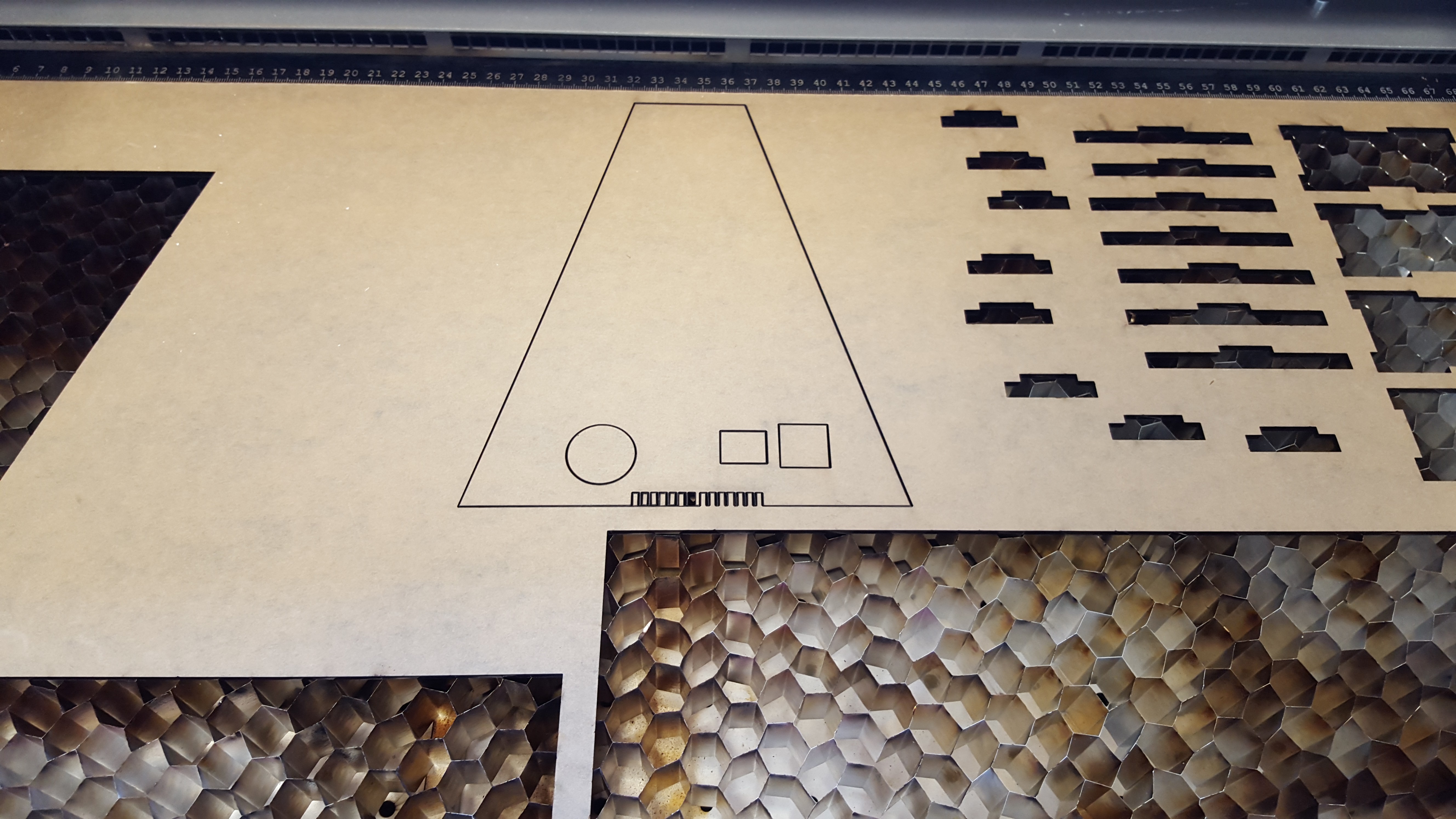

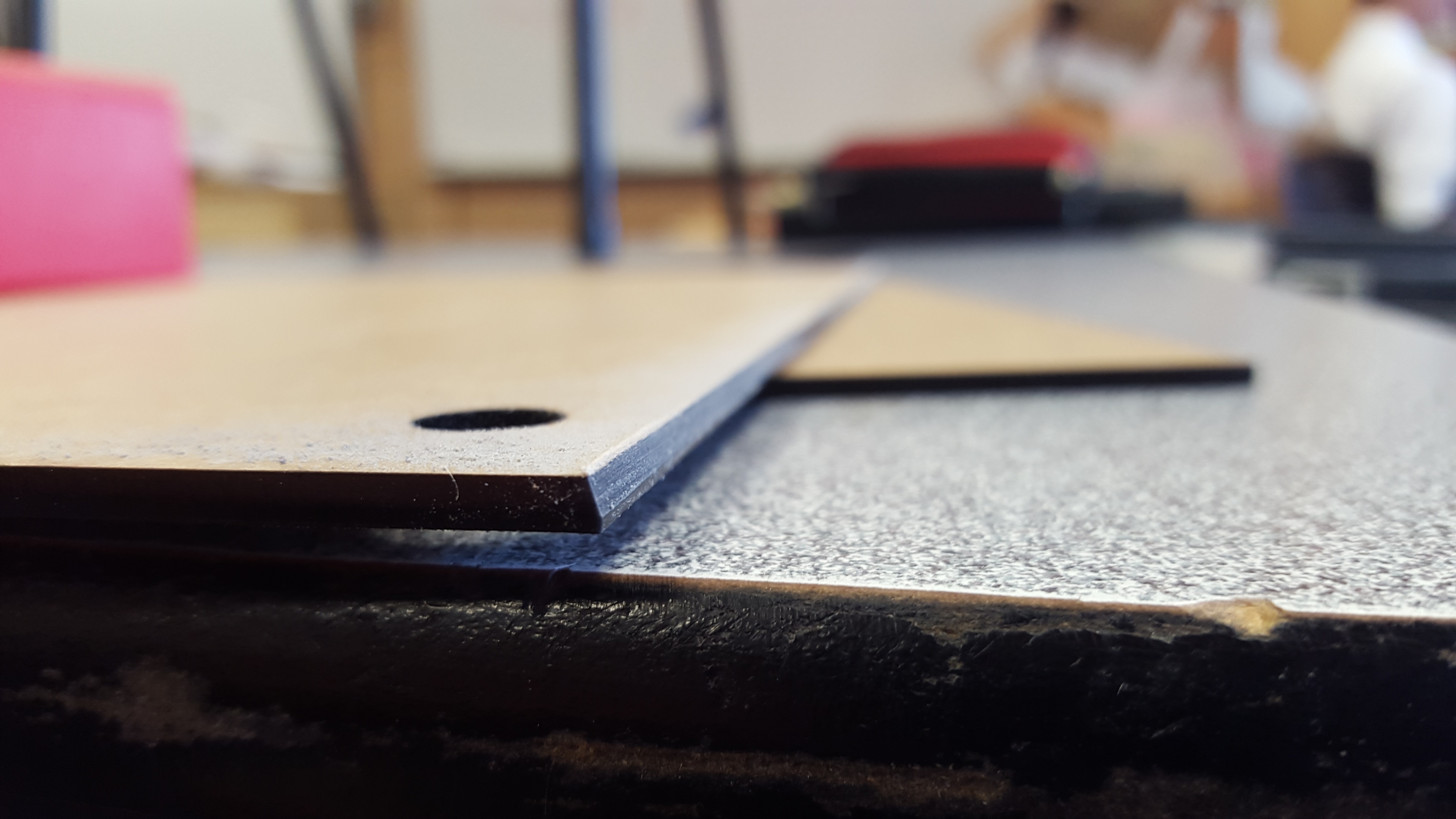

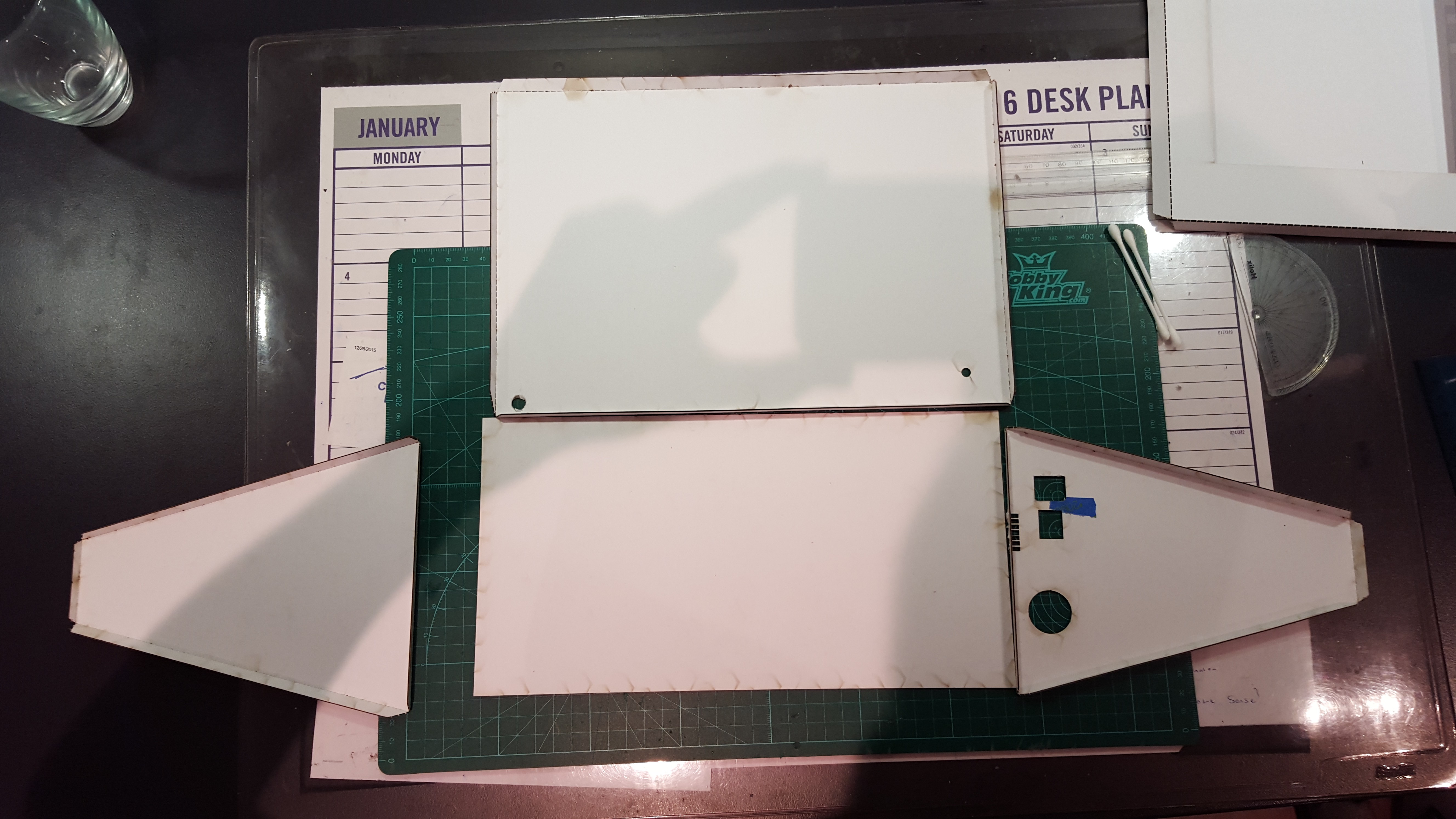

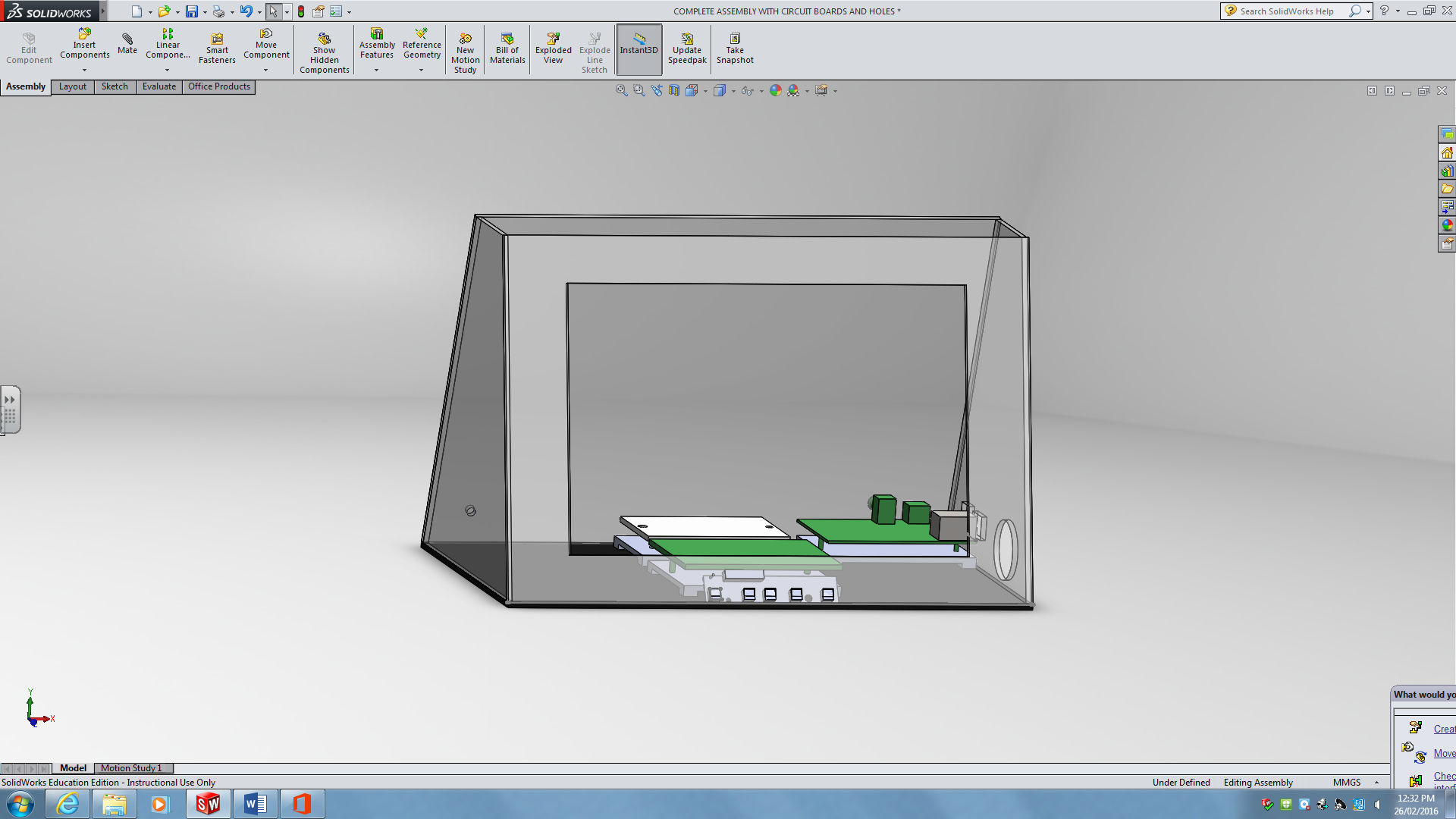

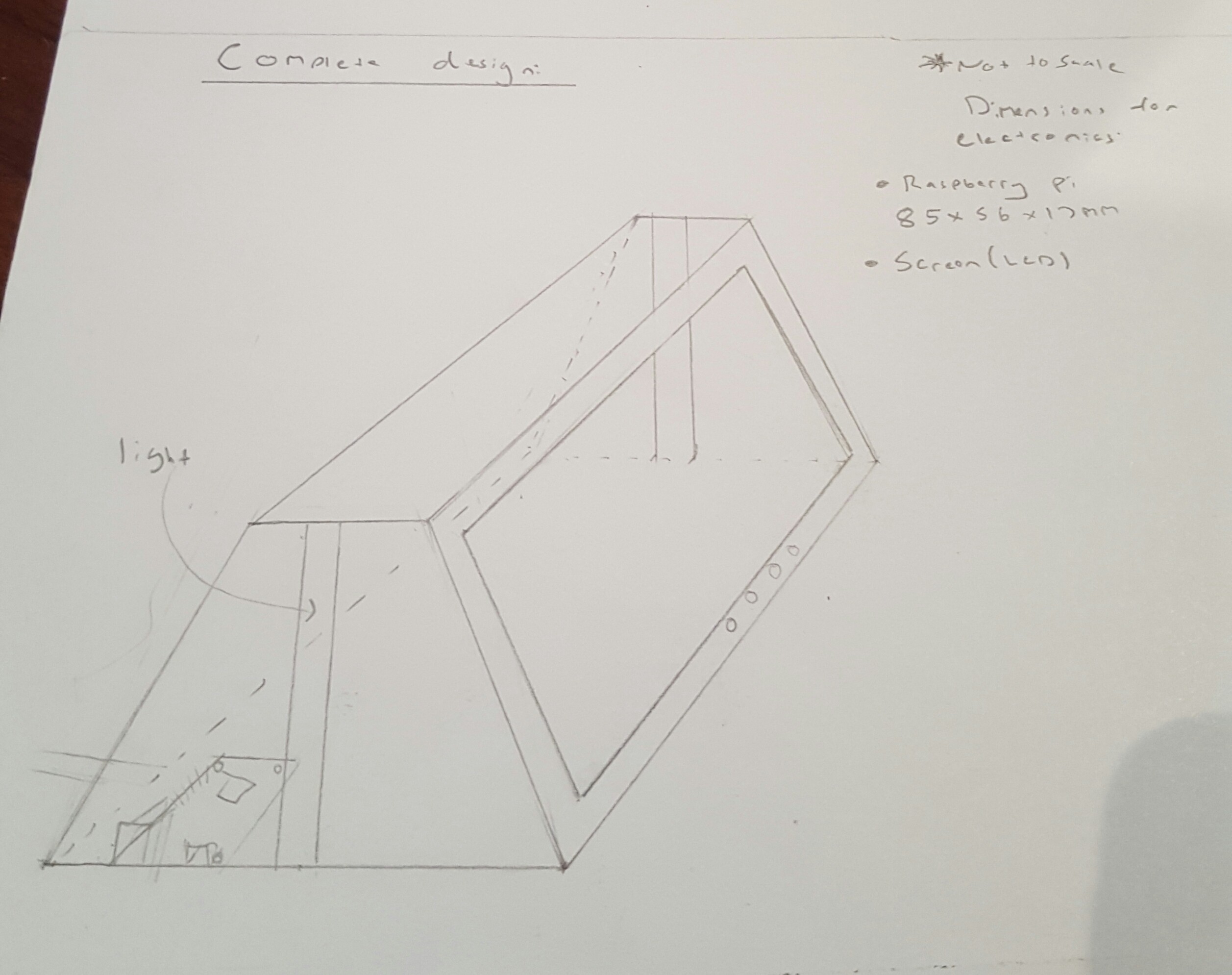

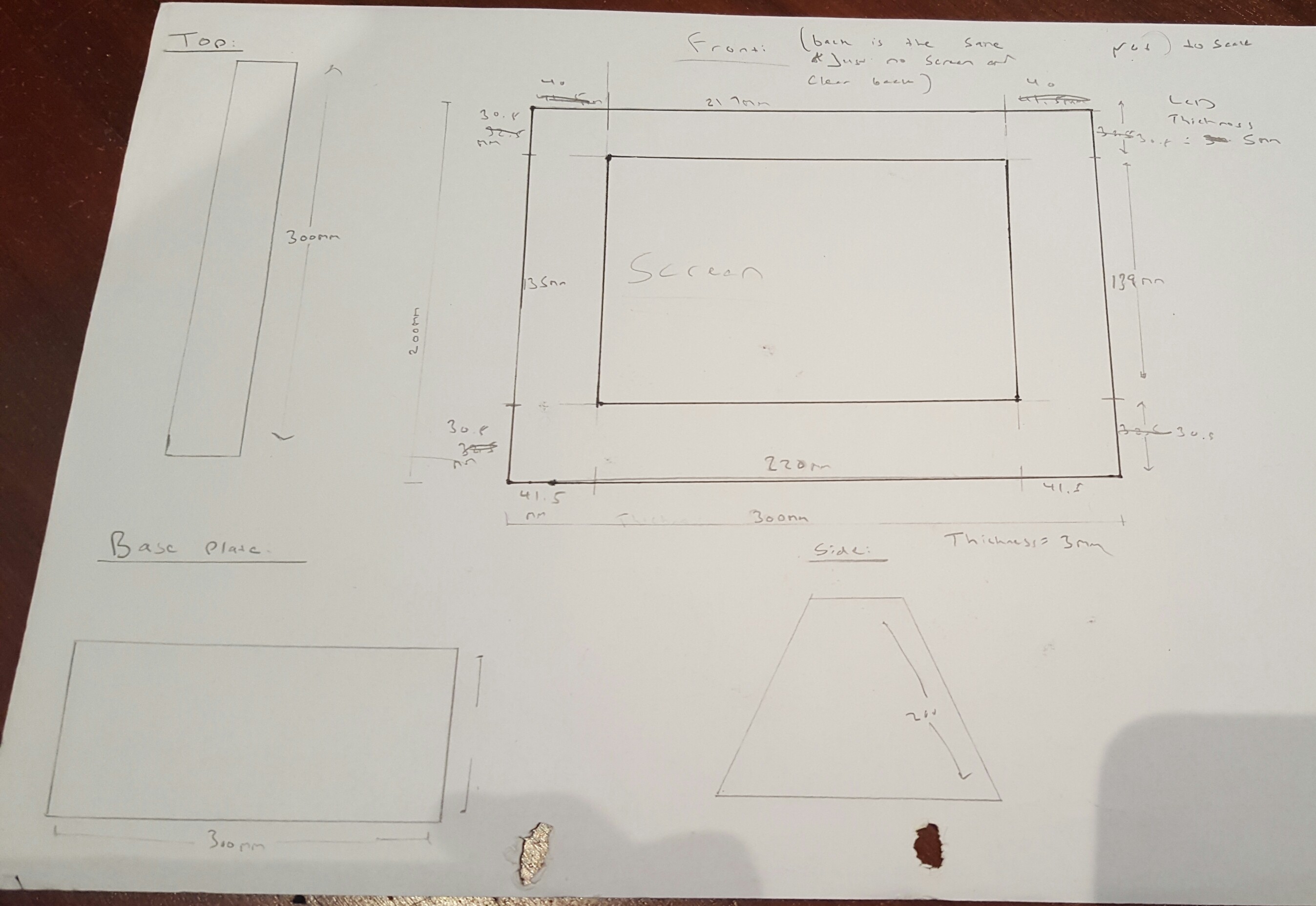

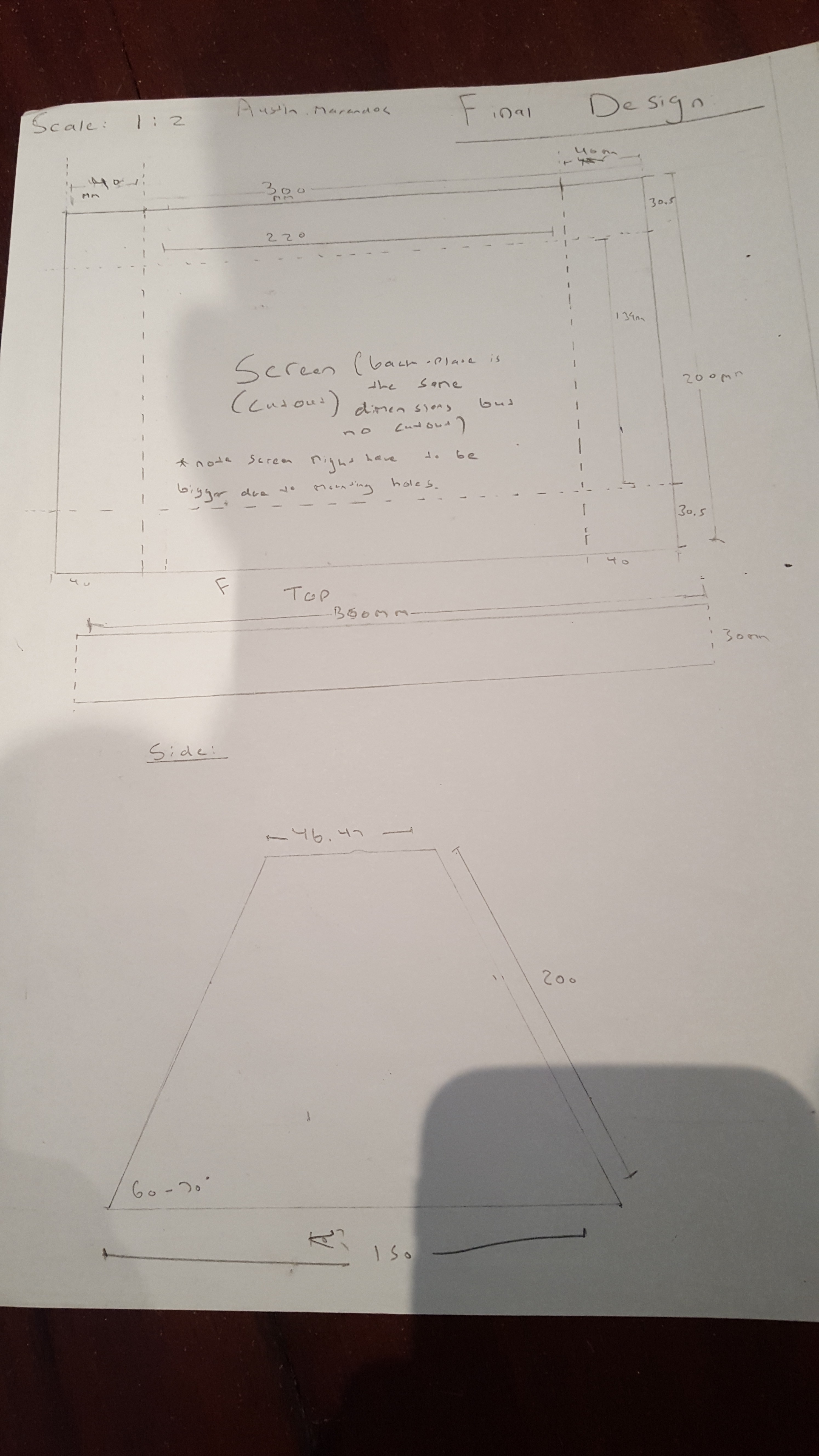

Construction of Perspex pieces:

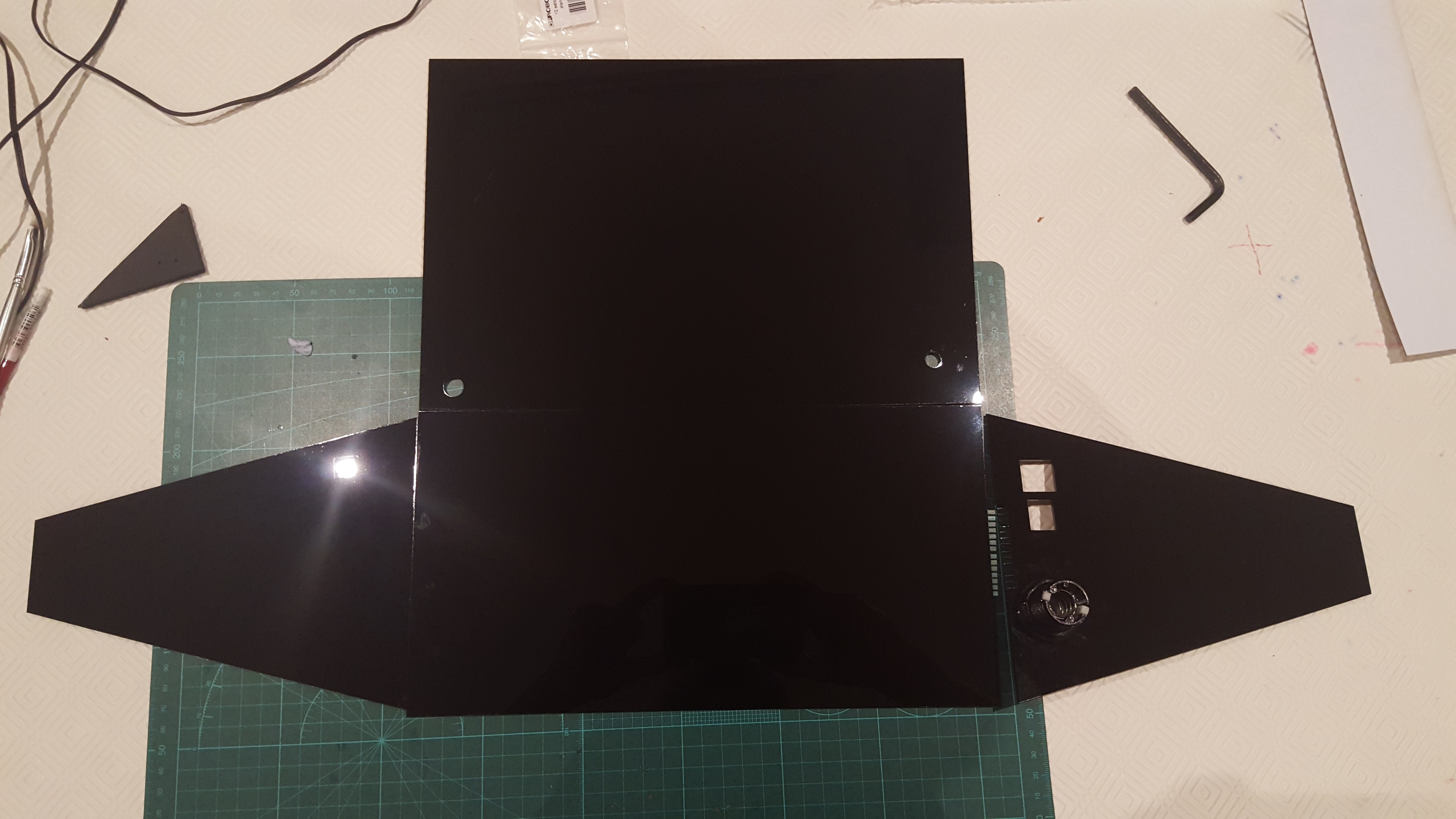

Construction of Perspex pieces: All pieces assembled (with protective cover on). Note: it has not been glued yet since not all the electronics had been installed

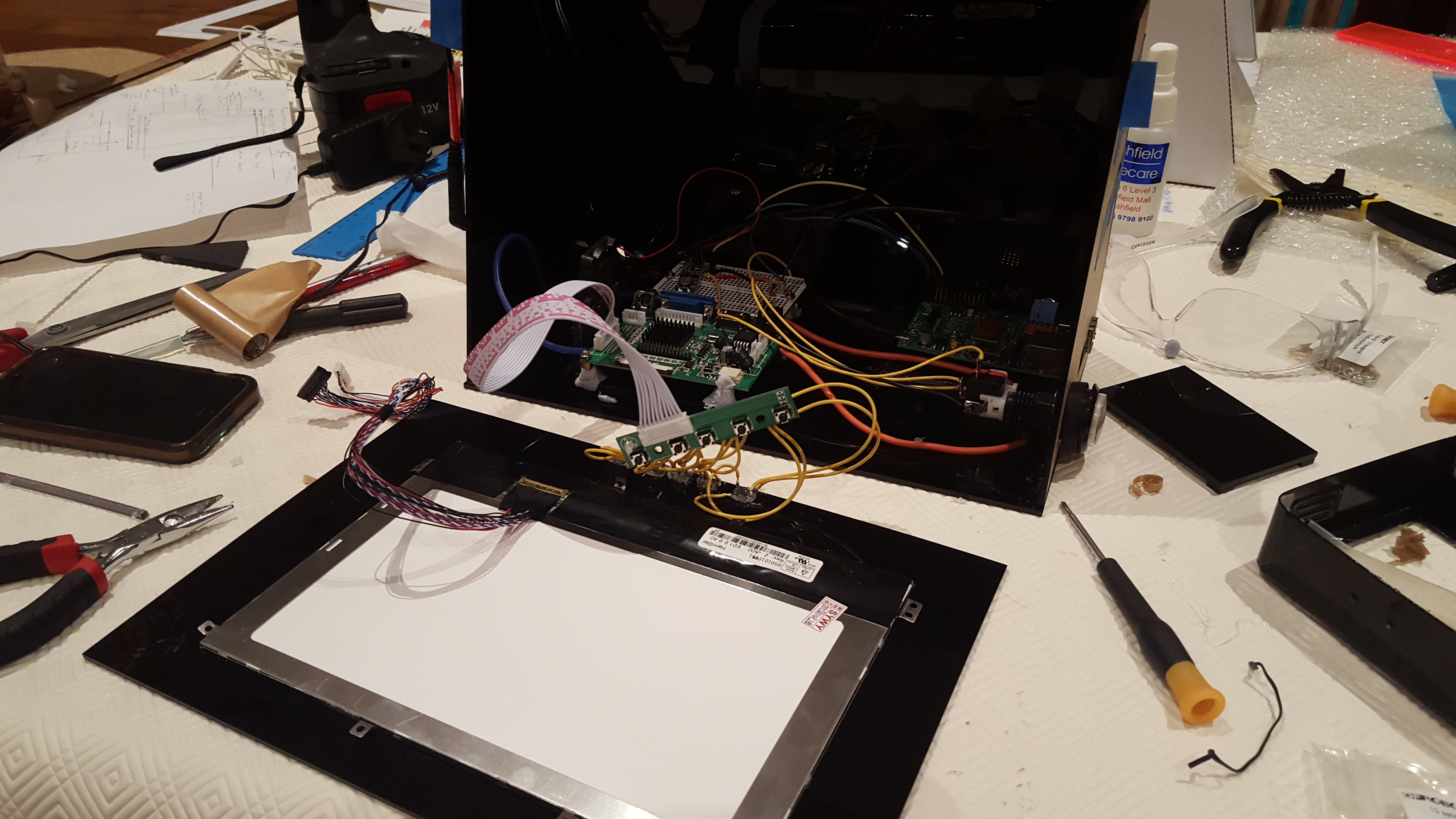

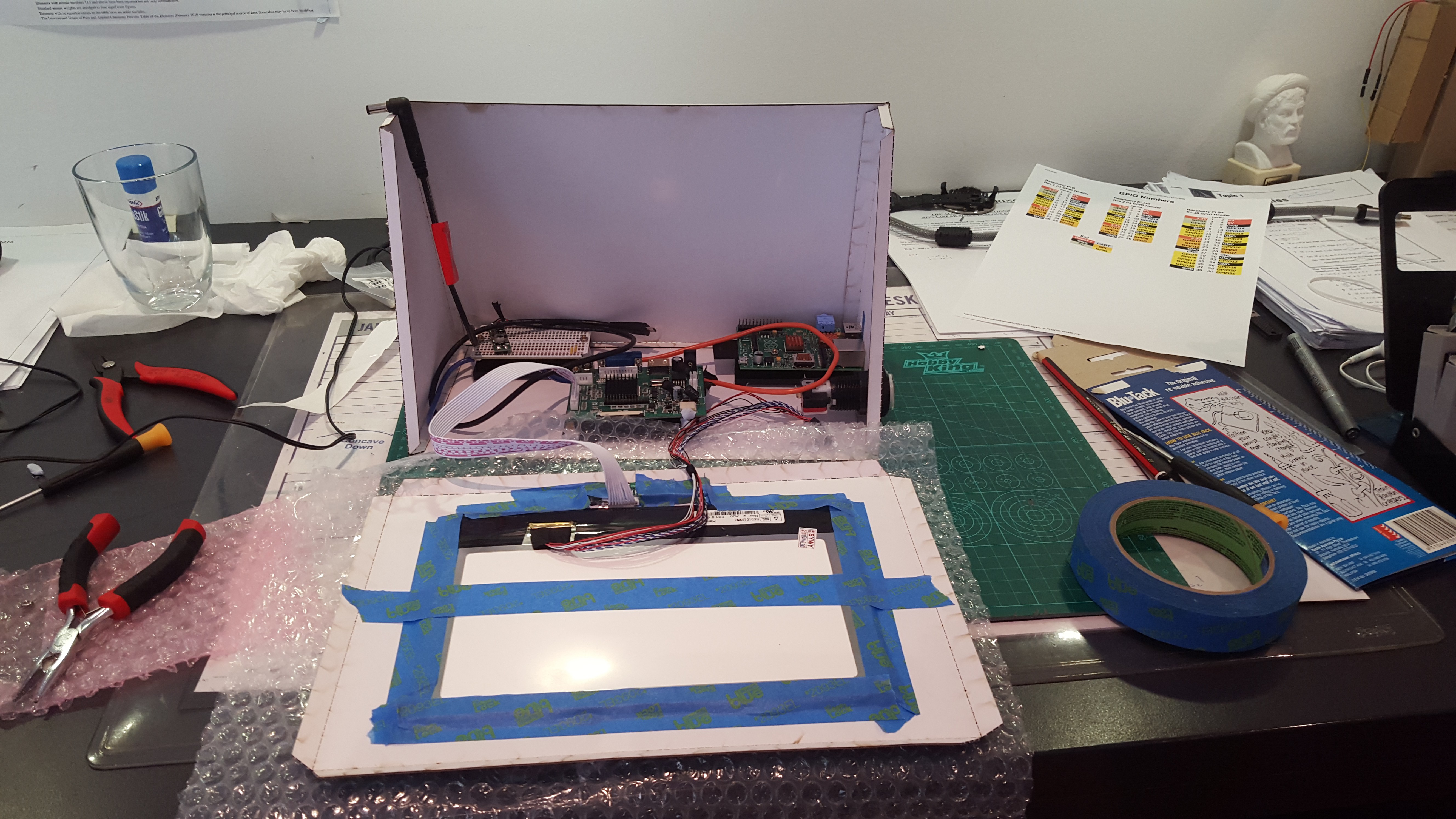

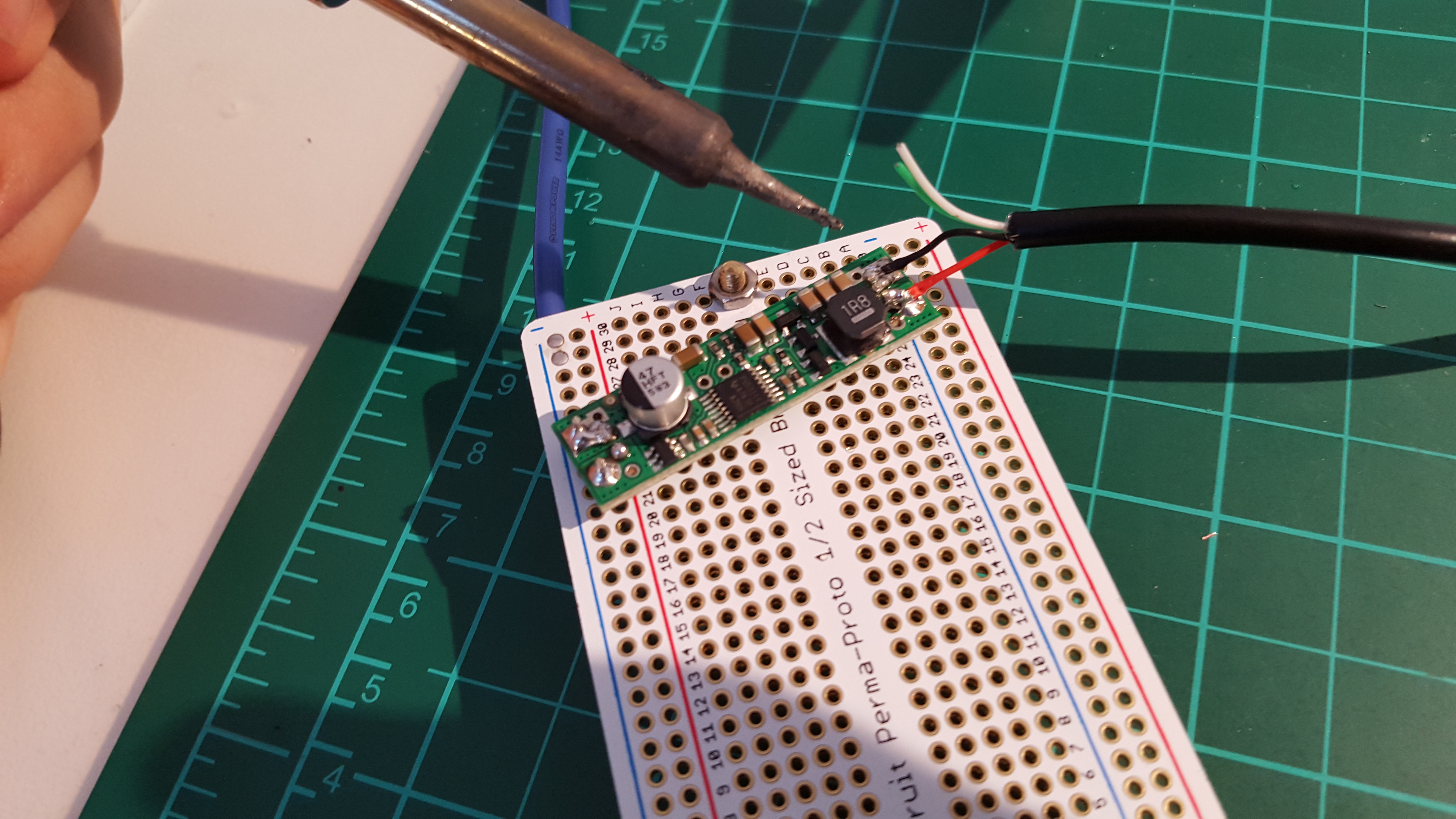

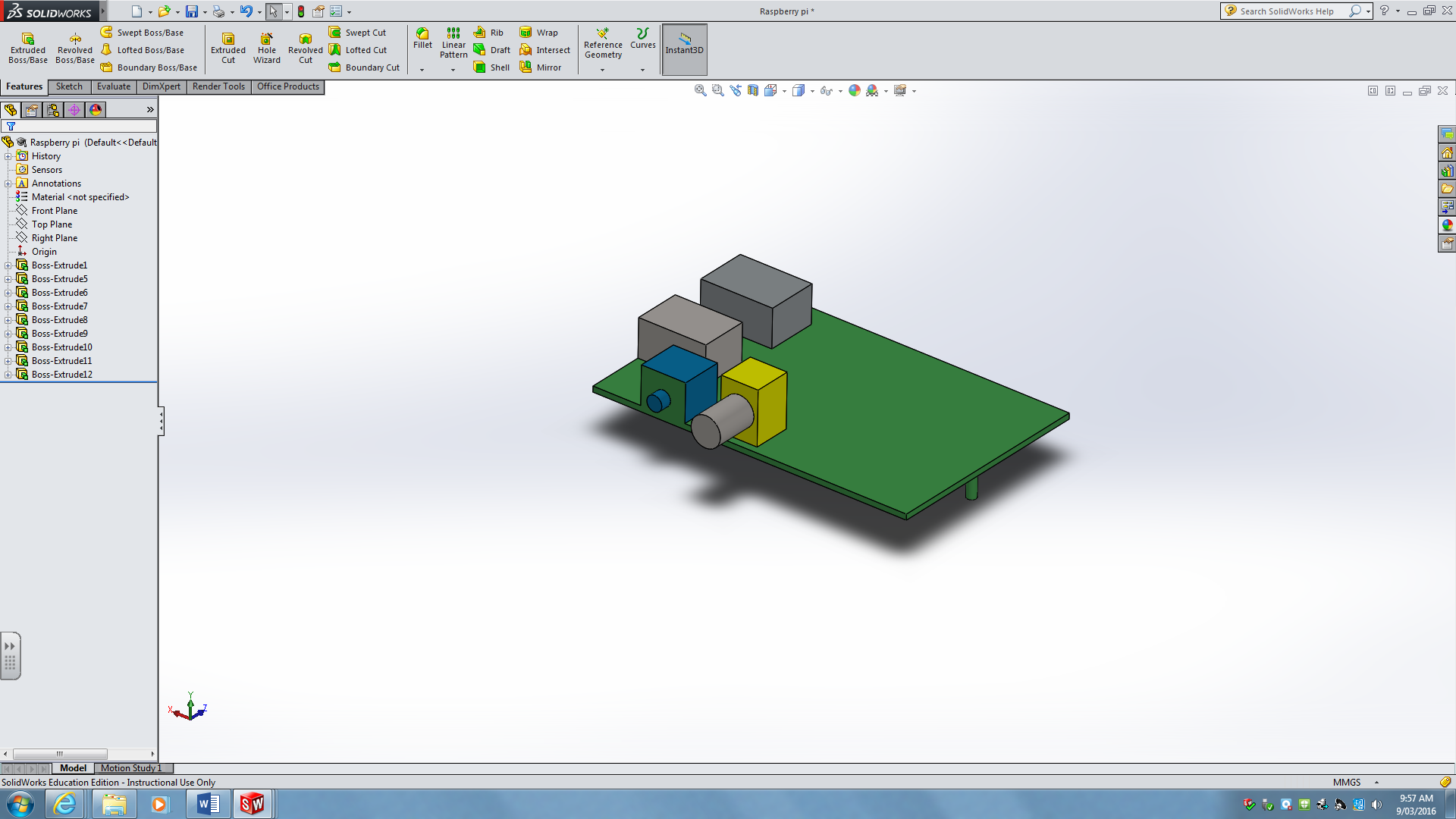

All pieces assembled (with protective cover on). Note: it has not been glued yet since not all the electronics had been installed Installation of LCD and Electronics:

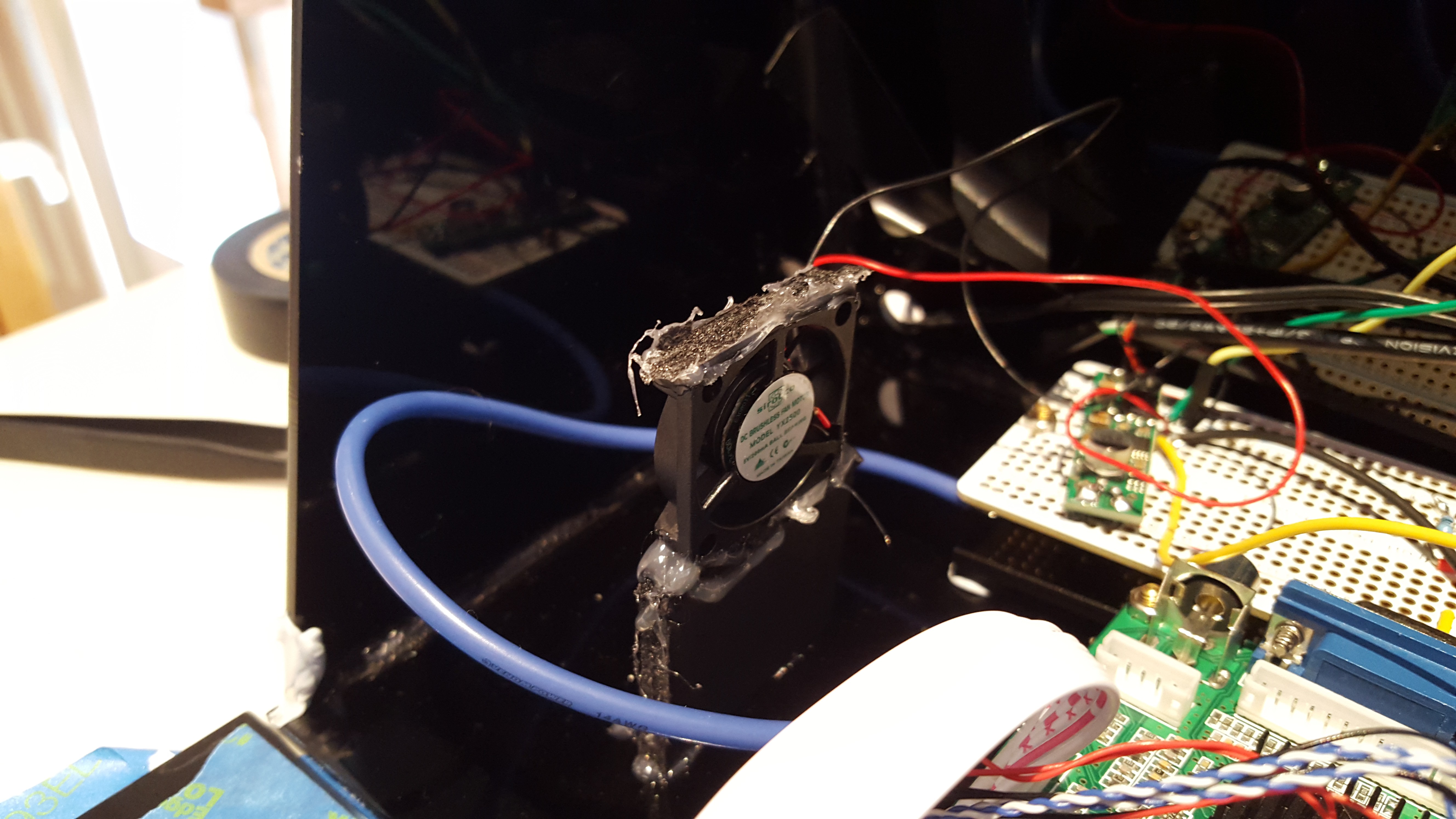

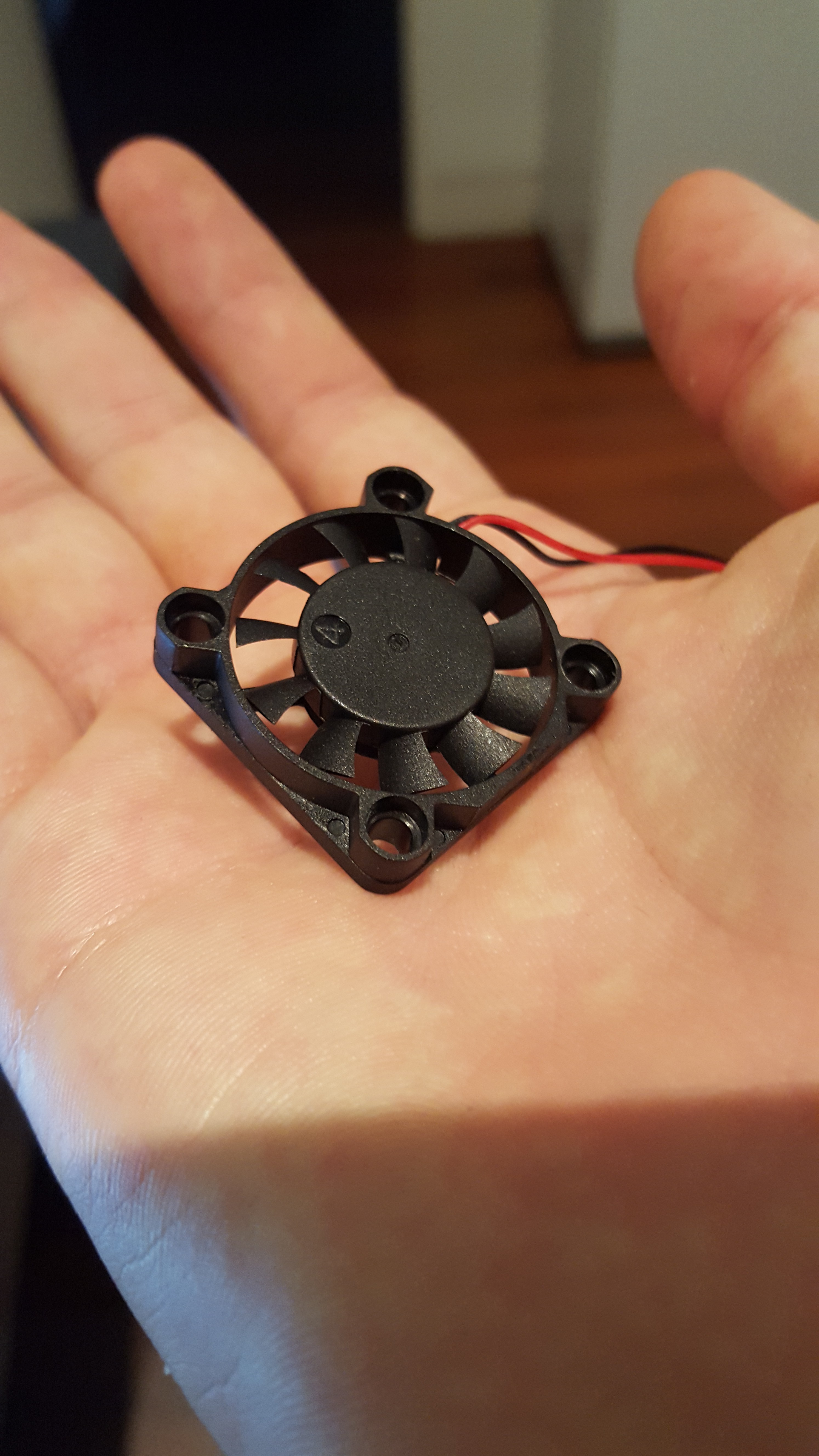

Installation of LCD and Electronics: Fan installation: (the fan was pointed directly at the LCD driver IC). There was also a vent on the opposing side.

Fan installation: (the fan was pointed directly at the LCD driver IC). There was also a vent on the opposing side.

The top panel had two magnets, this was essential as there was no other way of accessing the electronics.

The top panel had two magnets, this was essential as there was no other way of accessing the electronics. Matching interior magnet:

Matching interior magnet: "See through" top panel:

"See through" top panel: Final design:

Final design:

An finally the 5V micro cooling fan. This thing actually worked wonders, it increased my Pi's performance drastically even though it was located at-least 5cm away from the Pi's CPU

An finally the 5V micro cooling fan. This thing actually worked wonders, it increased my Pi's performance drastically even though it was located at-least 5cm away from the Pi's CPU

And more....

And more....

danielmcgraw

danielmcgraw

Cees Meijer

Cees Meijer

ken.do

ken.do

production

production