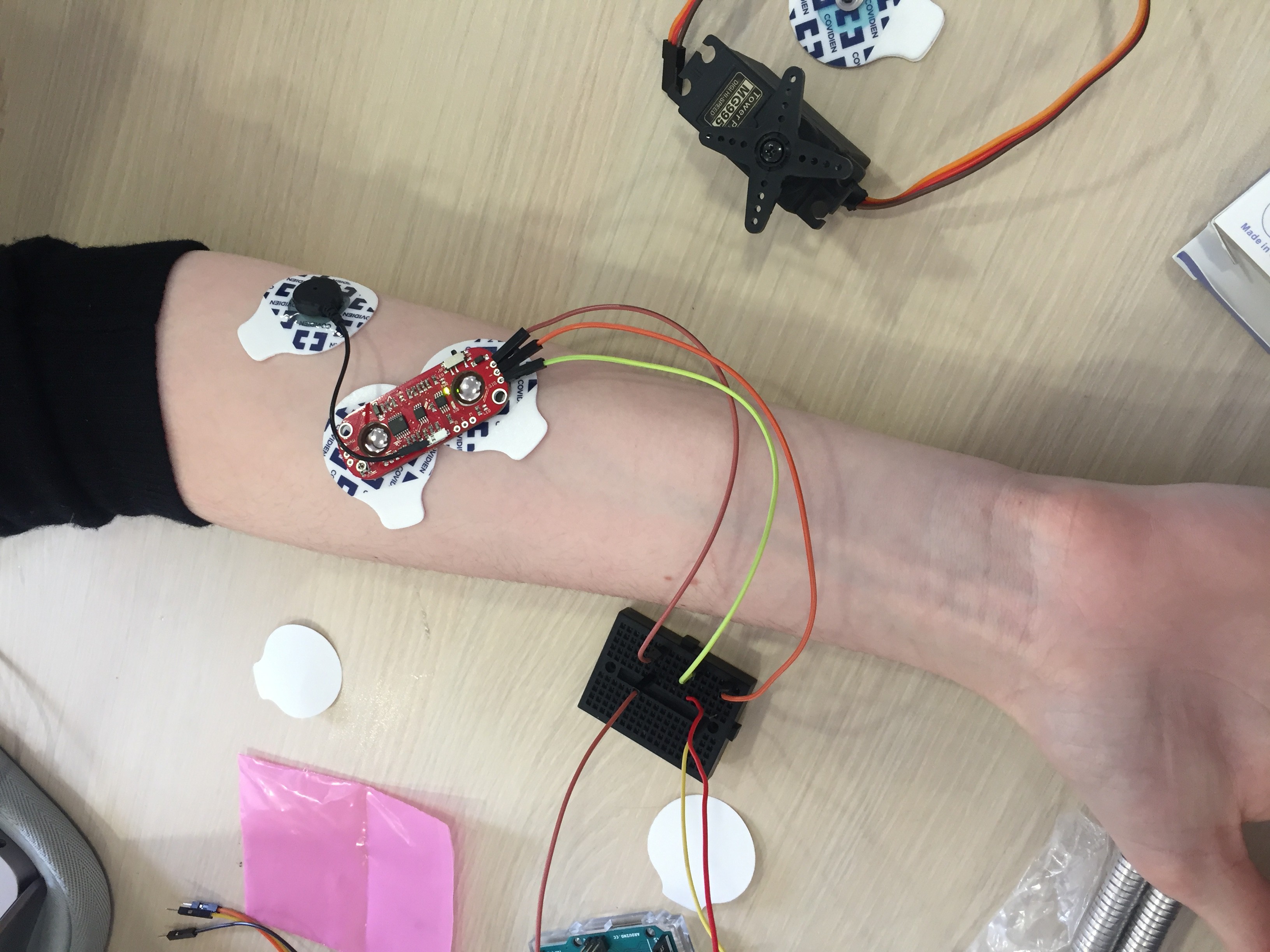

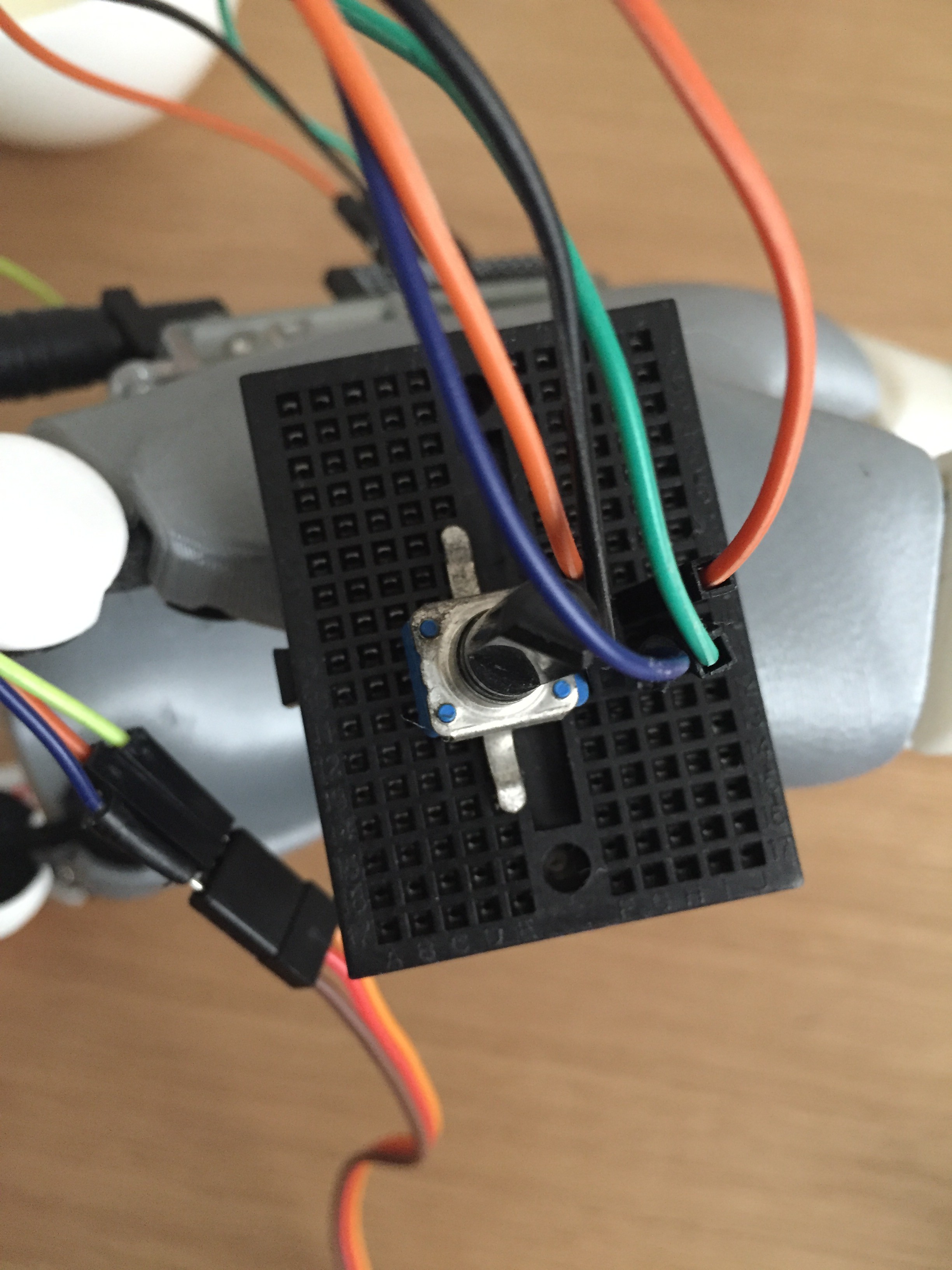

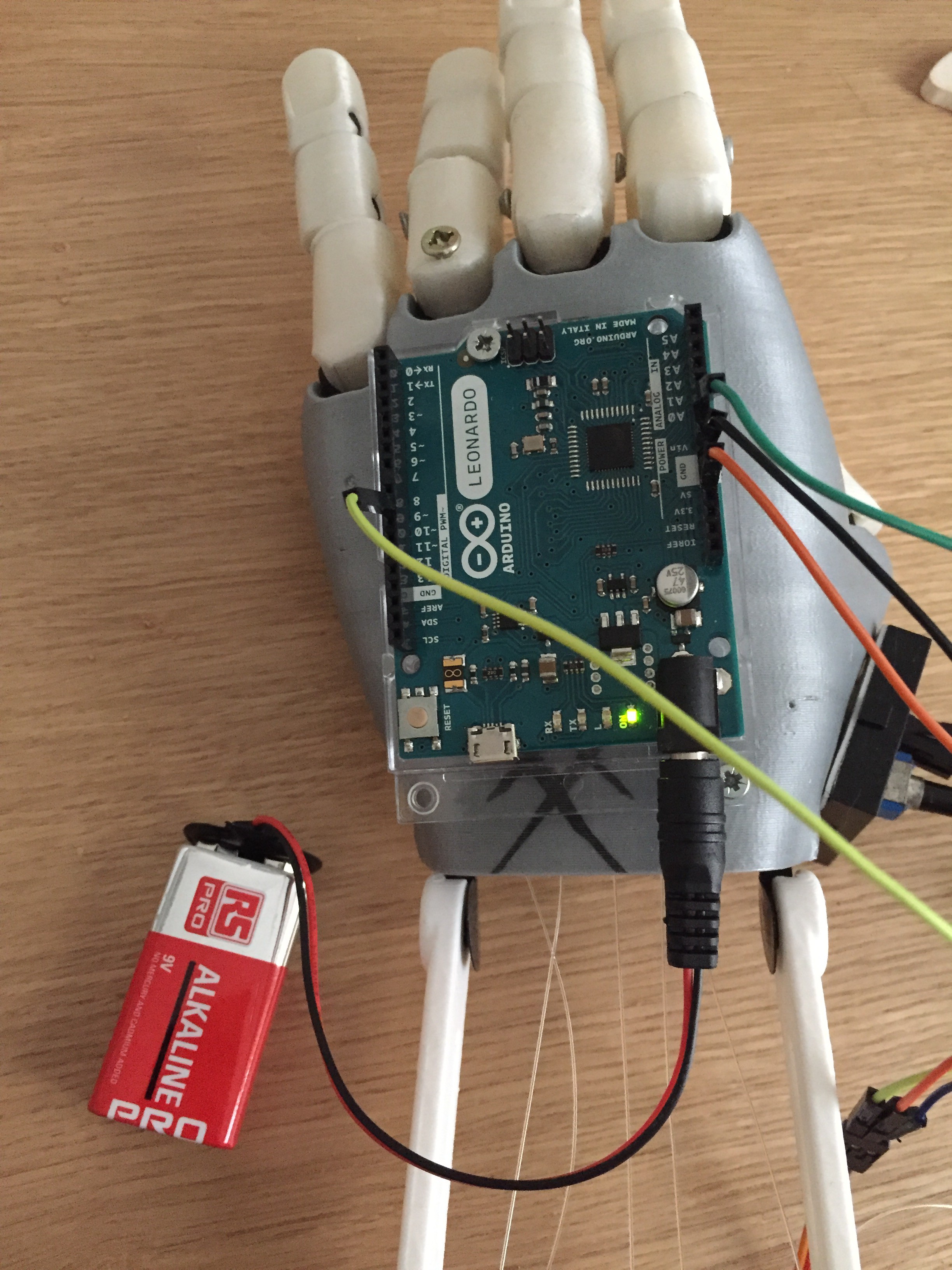

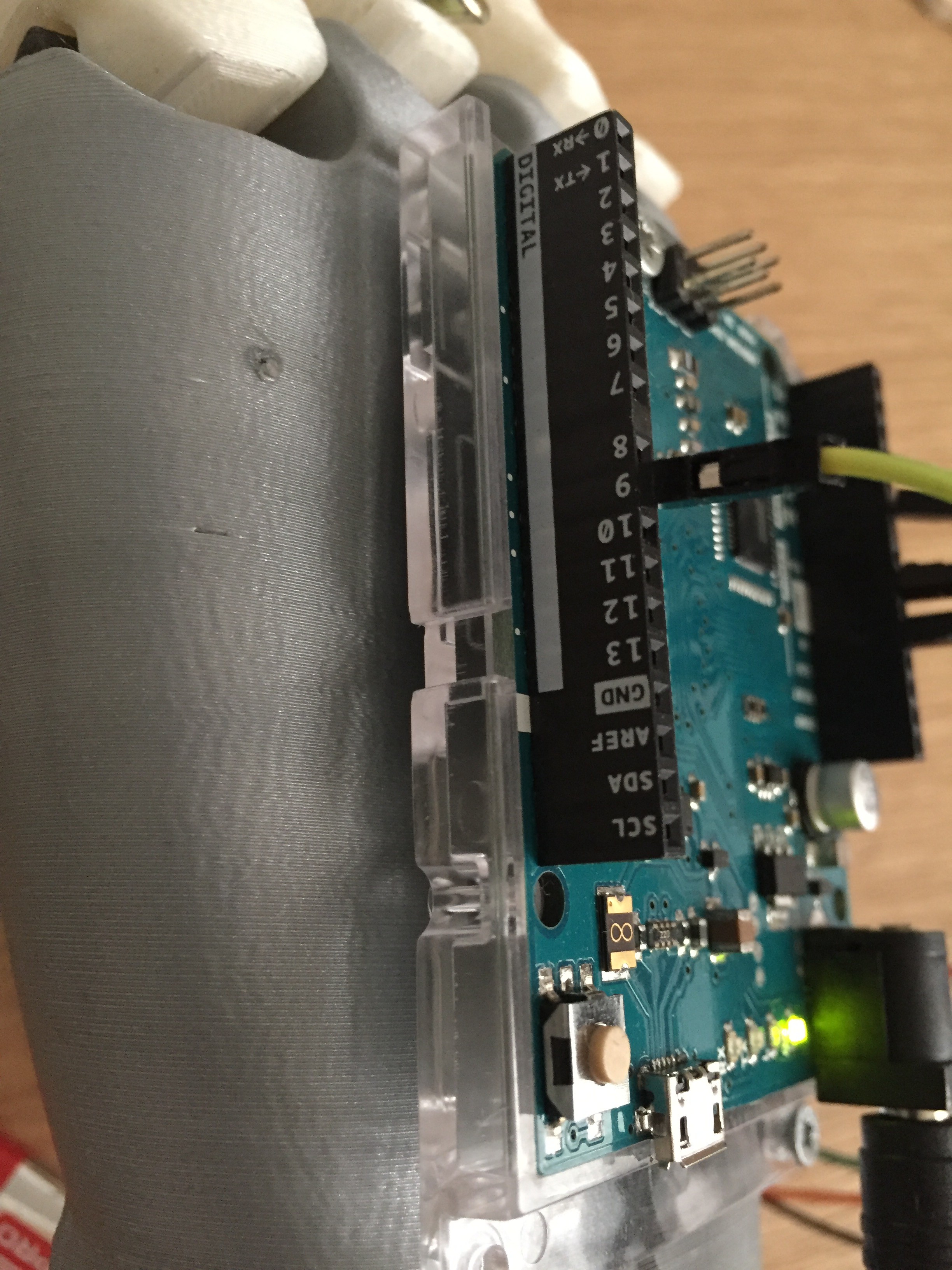

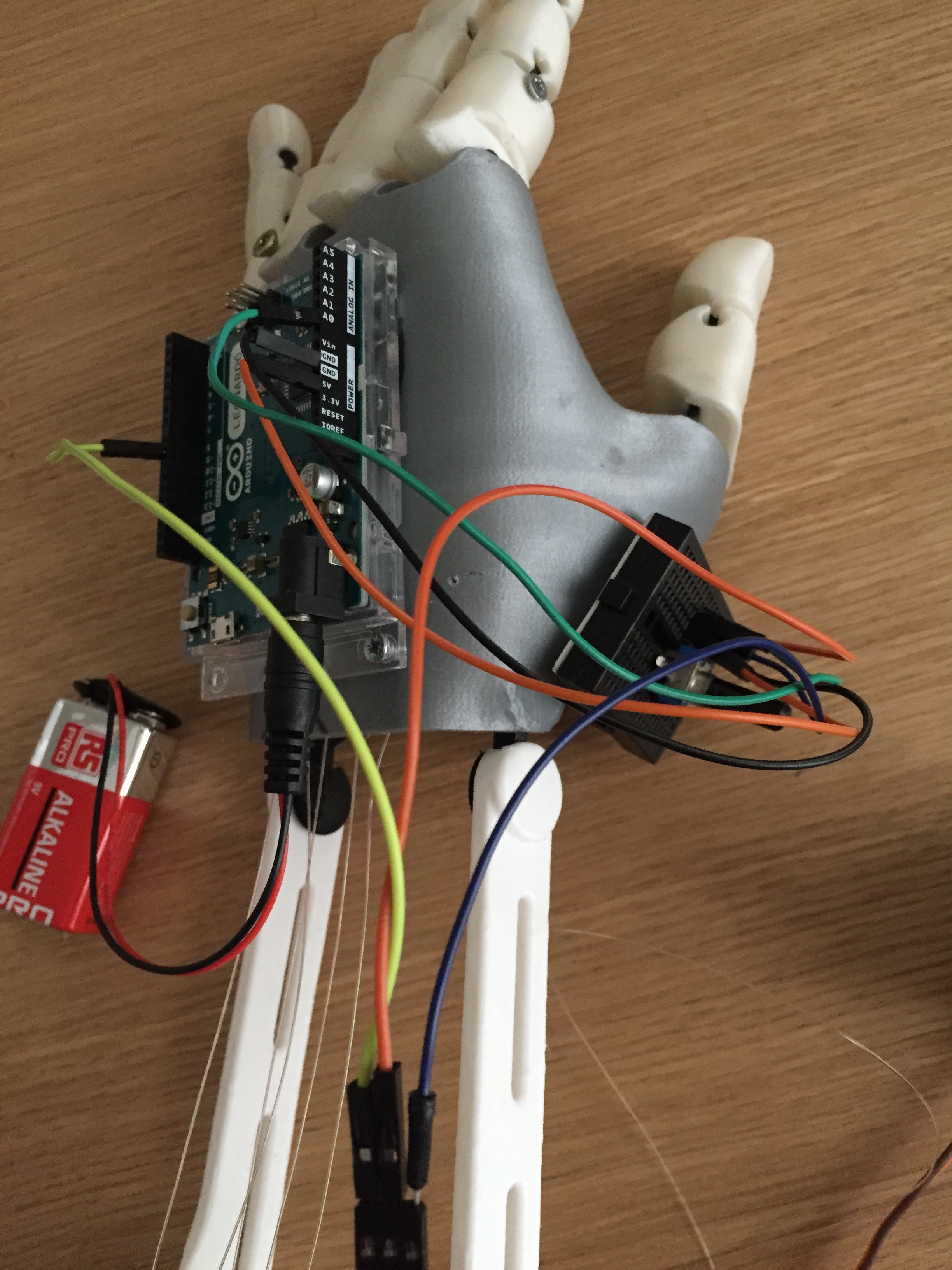

What we wanted to create was a prosthetic hand that anyone could customize and that would give you the ability to control your grasp on things. To do so, we came up with the idea of associating a muscle sensor with a servo motor and strings. The muscle sensor would interact with the motor so that everytime you contracted a muscle it would make the motor turn so that it tightened the strings.

WEI ahead

Making the world a better place one prosthetic hand at a time

Dan

Dan

Electroniclovers123

Electroniclovers123

Swaleh Owais

Swaleh Owais

Giovanni Leal

Giovanni Leal