I can see a light in the tunnel and it's not the sun at the tunnels end. Sounds more like a big engine that's going to suck me from wherever I can hide straight into disaster.

The name on that big engine is Clog.

There are two basic types of Ink Jet printers, thermal and piezo electric. In general, although I don't know that it is universally true, thermal printers are disposable, whereas piezo heads are builtin to the printer. For now this project uses disposable thermal heads for which the various ink manufactures tend to depricate in favor of piezo heads. They won't come out and say "Don't use a thermal print head", it's more like, "we suggest you use piezo heads".

My experience is, Ink Jet printers clog. The bottom line is I'd rather make my own piezo head and clean it as necessary, rather than keeping a stock of print heads handy.

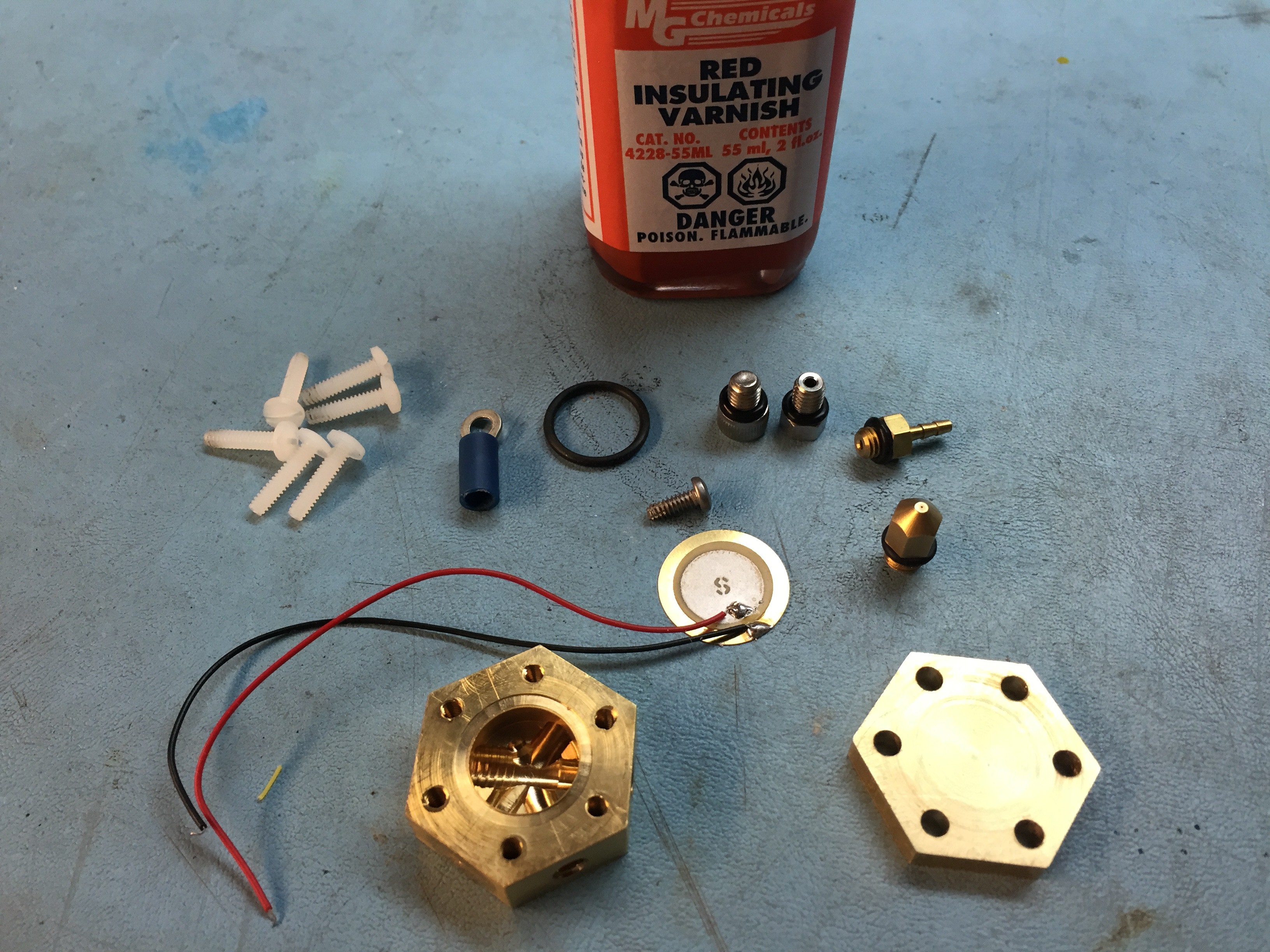

Here's the effort so far.

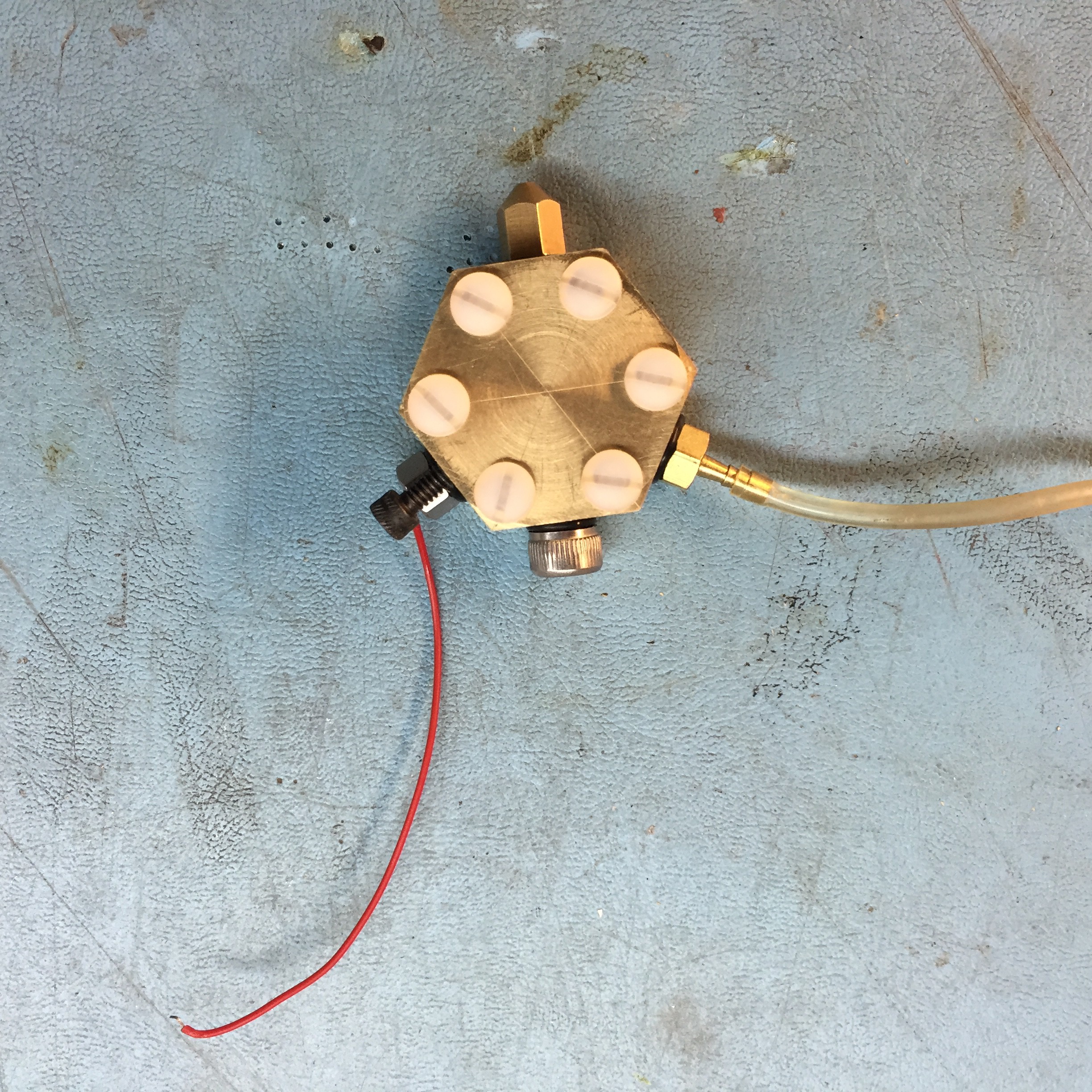

The black O-ring fits into the grove surrounding the cavity. The black wire on the bimorph is removed with the piezo surface facing the interior. After every is assembled it looks lie this.

So far it's a spectacular failure!

It has SO many problems! The volume of the cavity need to be reduced by a factor of 10,000, the jet diameter needs to be reduced from 0.3 mm to 30 micrometers, and I'll need to use a real pulser.

That ol train keeps getting closer. Better get on it. On the up side, this isn't rocket science. It's just the application of first principals.

On the positive side, the physical dimensions of the device are good, form and fit seem OK, the fluid line is about the right size.

Chuck Glasser

Chuck Glasser

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Thanks, I'm checking it out now.

Are you sure? yes | no

So if you haven't already, you should look up some of the conference talks that Jeff Gough did a few years ago about 3D printing/trying to do etch resist with wax in inkjet printer heads.

Other than being super interesting, he goes into a lot of detail about different printer techs, and his process for trying to customize them. Might give you some more tools in your toolchest.

Should be able to find them on YouTube.

Are you sure? yes | no