I have a few pages of written/drawn notes I'd like to document and discuss here. Before doing that, some higher level project direction thoughts. These paragraphs are a bit disparate, but I promise I'll tie 'em together at the end.

First, this project was never conceived around solving a world problem. Millions are hungry, fresh water is scarce, wealth inequality is rampant, climate change is accelerating, and cities are polluted. A ton of other Hackaday Prize 2018 (and previous) entries are doing a fantastic job coming up with novel ideas to address society's biggest needs; just spend a few weeks on the new projects list and you'll see a few bubble up. No, the Phonetroller was always about getting a solid gaming experience onto a mobile platform -- that's about it. But it would be nice to, at the very least, not make things worse.

Second, it's really hard to get game controller ergonomics right. I putzed around with a few button types and handle configurations and never had anything close to the experience with a mass-market controller. They all have their quirks, whether it's the square corners of the NES controller or the encoder joystick (and generally insane layout) on the N64, but nearly all performed their primary task well: they became an extension of the user, to the point that directing on-screen character movements became instinctive and control fidelity stopped limiting player ability. None of the (few) designs I've built come close to that standard.

Third, customization really can deliver an improvement in user experience, and not just due to the inherent satisfaction gained by building something oneself. Anyone who has used a generic phone docking station knows the frustration and potential for damage caused by poor fit; in the case of a handheld controller, fit is that much more critical as the controls must withstand the stresses of constant handling and movement. My experience with my Phonetroller prototype(s) has shown me what a really solid phone-accessory interface can feel like. It's great, and that only happens if you build the accessory to fit your phone (in its case!).

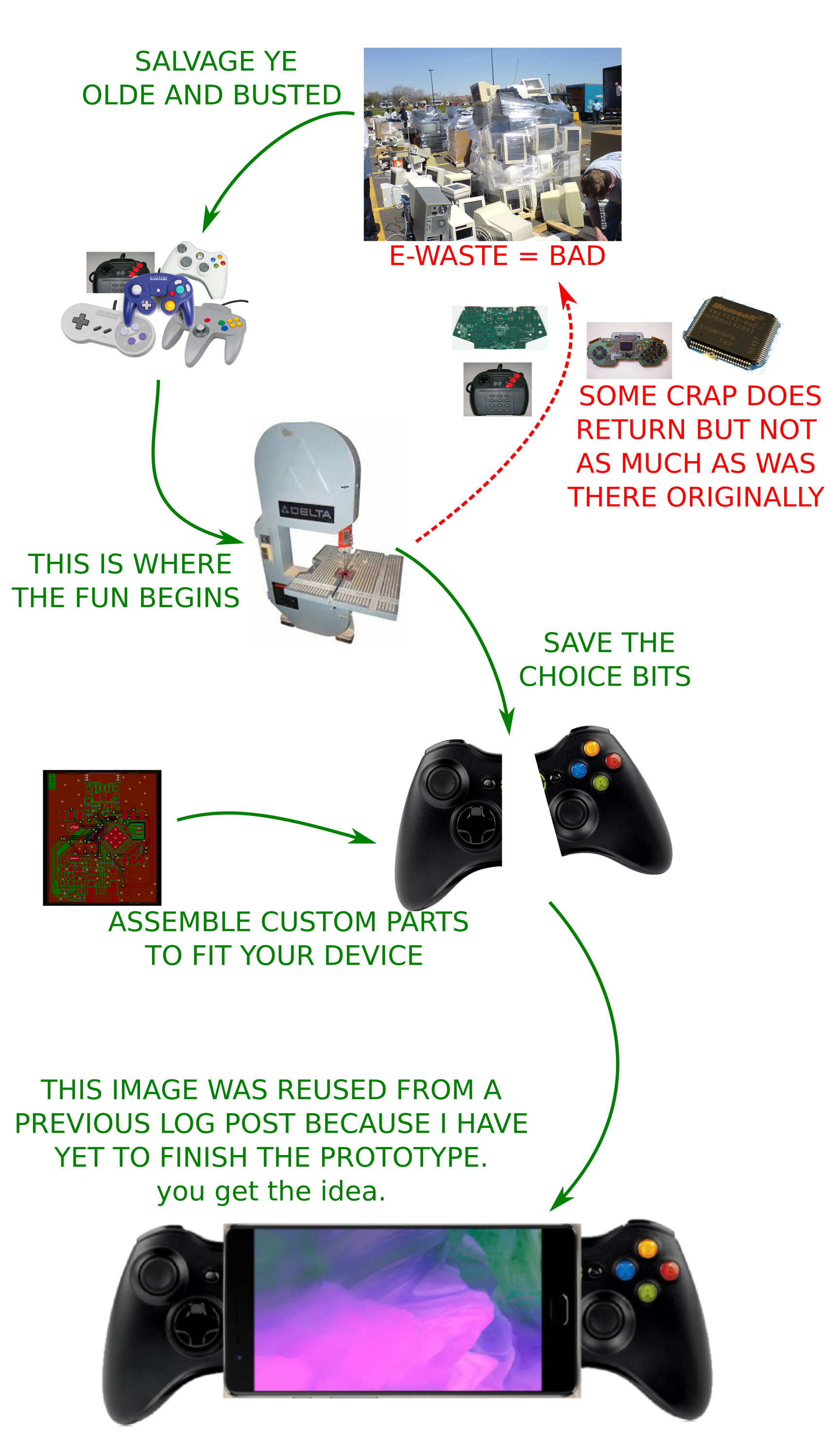

This all comes together in a shitty flow chart:

In a nutshell: reduce e-waste by upcycling parts of discarded gadgets (controllers, in this case) into modern devices. Going after mass-market platforms (XBOX360 controllers to start, but maybe DualShocks, etc someday?) means it will hopefully be worthwhile to develop custom parts and instructions for retrofitting a specific device.

I extended the concept pretty far in my mind, particularly after I decided that wholesale replacement of the controller PCB is the way to go (more on that in another post). A few ideas:

- 3D print a companion fixture for each controller chassis so it can be held securely and precisely, then release toolpaths for milling the features required to adapt to a phone (although it's important that this can be done manually as well).

- Modularize the phone connection parts to the point that the controller can be re-adapted to a new phone once the current one is no longer used (hopefully recycled!).

I doubt that game controllers constitute anything approaching a detectable percentage of all e-waste (let alone all trash); this project is less about reducing numbers as it is about encouraging people to think about reusing stuff instead of throwing it away. And the way the project does that is by, as highlighted earlier, providing a superior experience compared to existing products on the market.

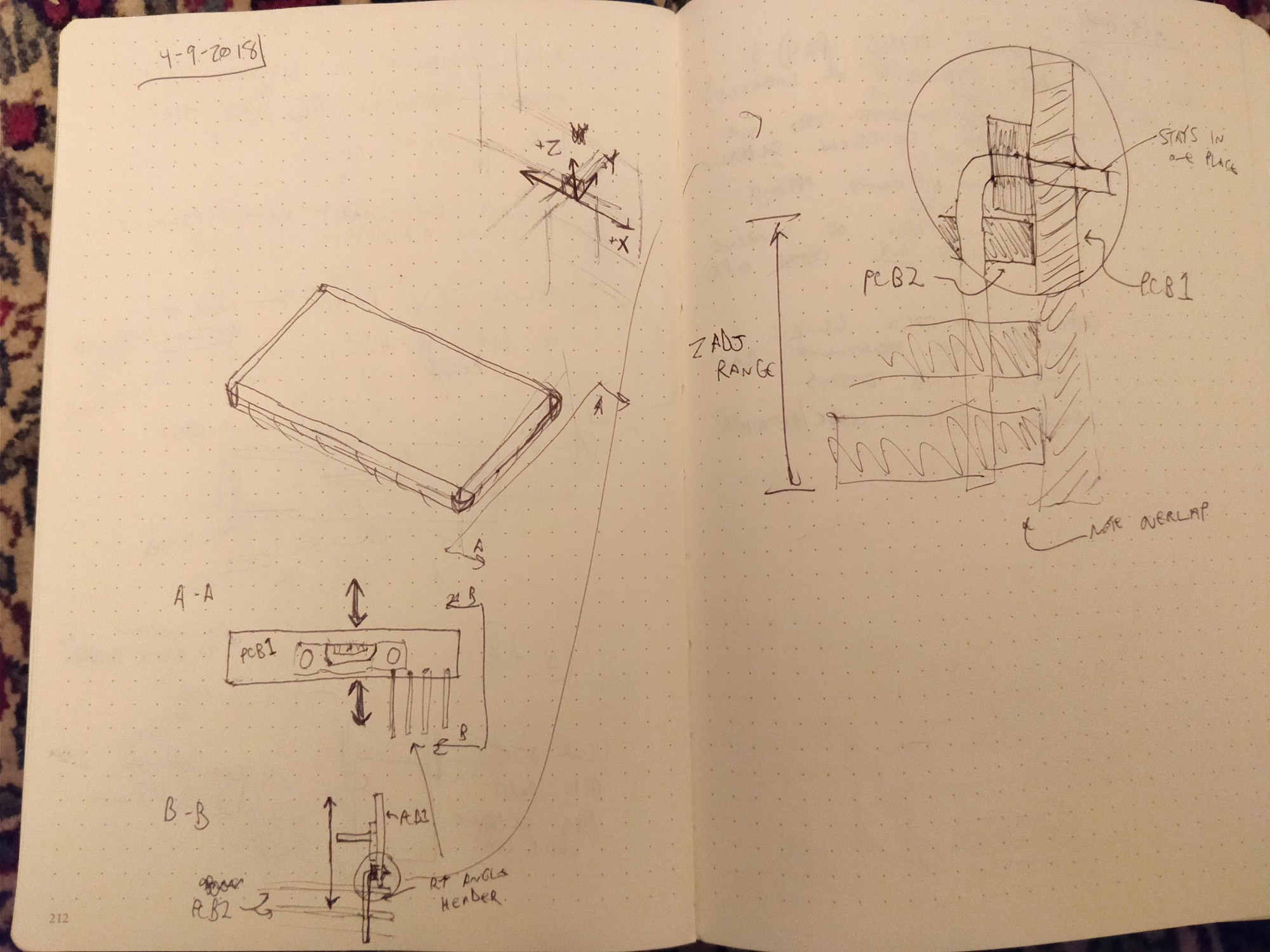

Anyhoo, I'll try to distill all the blabbing above into the Project Details section at some point, hopefully before the first Prize deadline on 4/23. In the meantime, here are the aforementioned notes I jotted down earlier this week along with annotations. You'll note that .. ahem .. parts of the project were going in a different direction then. Changes can happen at any time so it's best to write it all down! Boom!

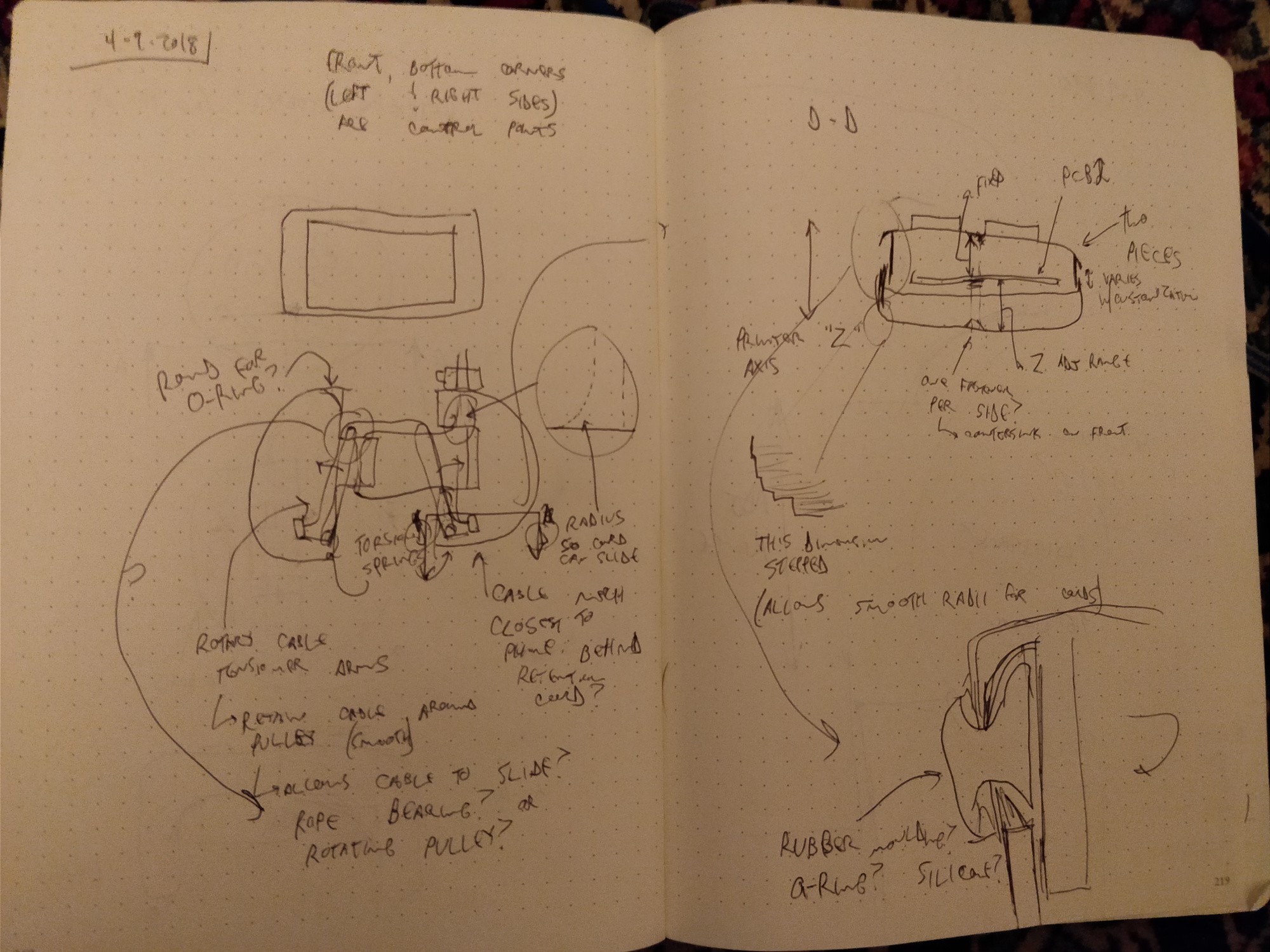

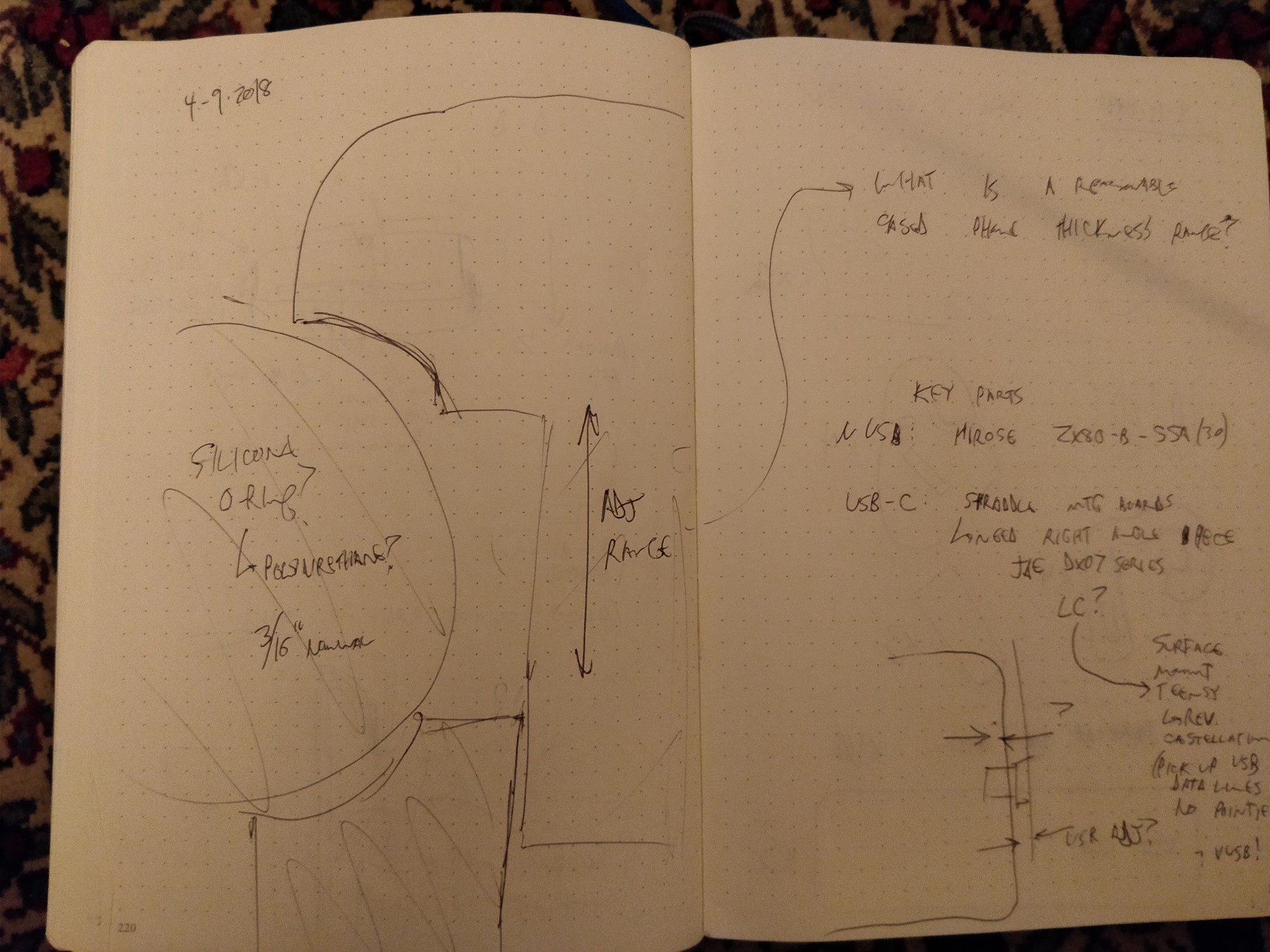

Above, I started thinking about how to allow users to adjust the uUSB or USB-C port location to fit their device. My hope is to produce a standard set of PCBs that are adaptable to a reasonable range of Android phones. However, the current assembly method I use -- plugging stuff into my phone and then fillet-soldering sheets of FR4 together -- isn't very device-friendly and is pretty easy to mess up. On the right page detail of section B-B, I show using a right-angle header to allow limited adjustment range while keeping the physical part of the soldering assembly simple. In this example, PCB1 has the short legs of the header soldered prior to assembly, and PCB2 can be adjusted vertically to ensure a snug fit. I think it still makes sense to have some long solder fillets to strengthen everything up, but using headers to do the initial tacking seems solid. Plus they can be used for electrical signals.

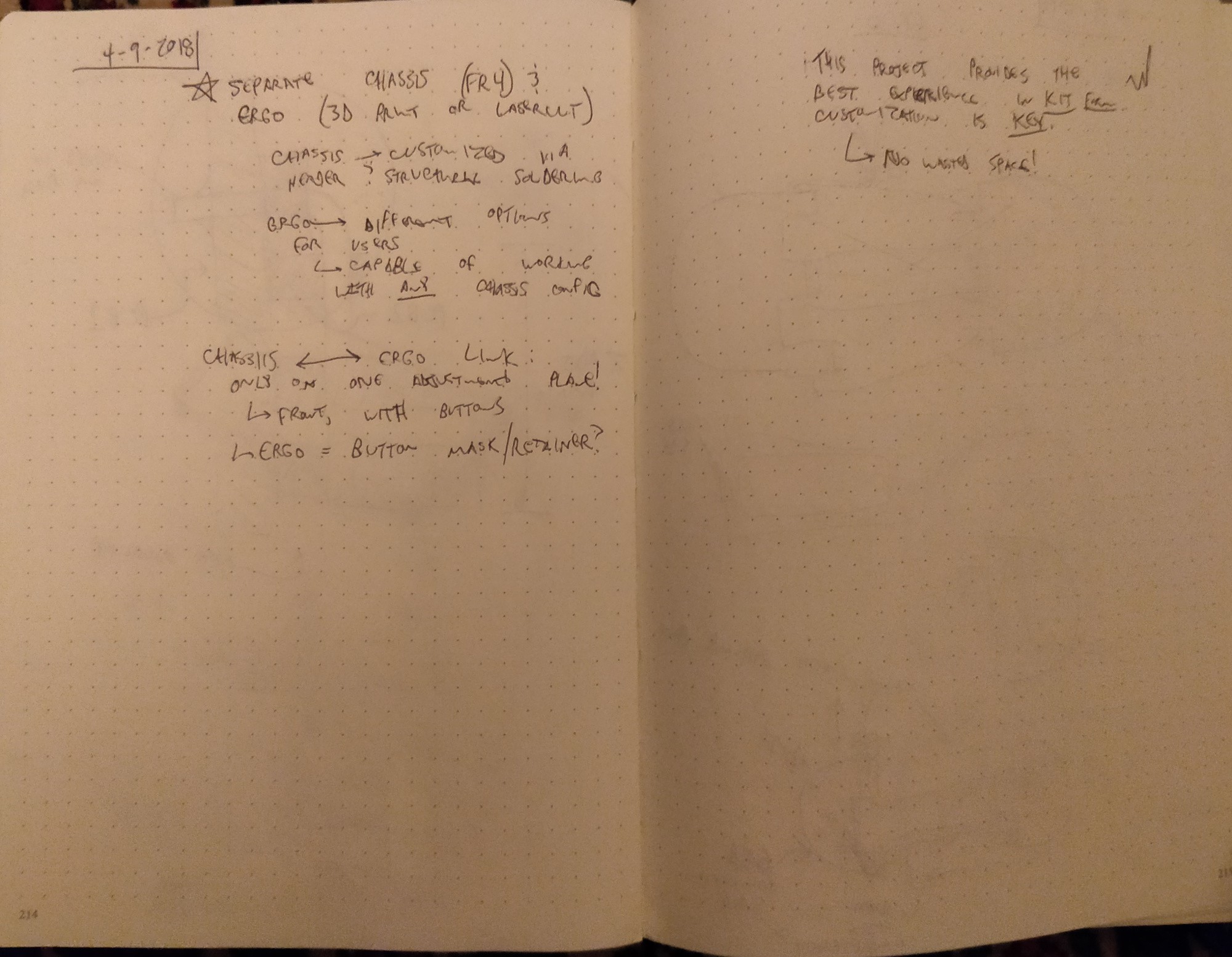

Above, the starred bit at the top is the key part -- separate the physical chassis, which supports the phone and electronics and is made of FR4, from the bits that the user contacts. Seems obvious looking at any consumer electronics product out there but it's a move away from Phonetroller (I). Then I started down a rabbit hole of a 3D printed 'ergonomics package' -- this was before I seriously considered repurposing existing controllers.

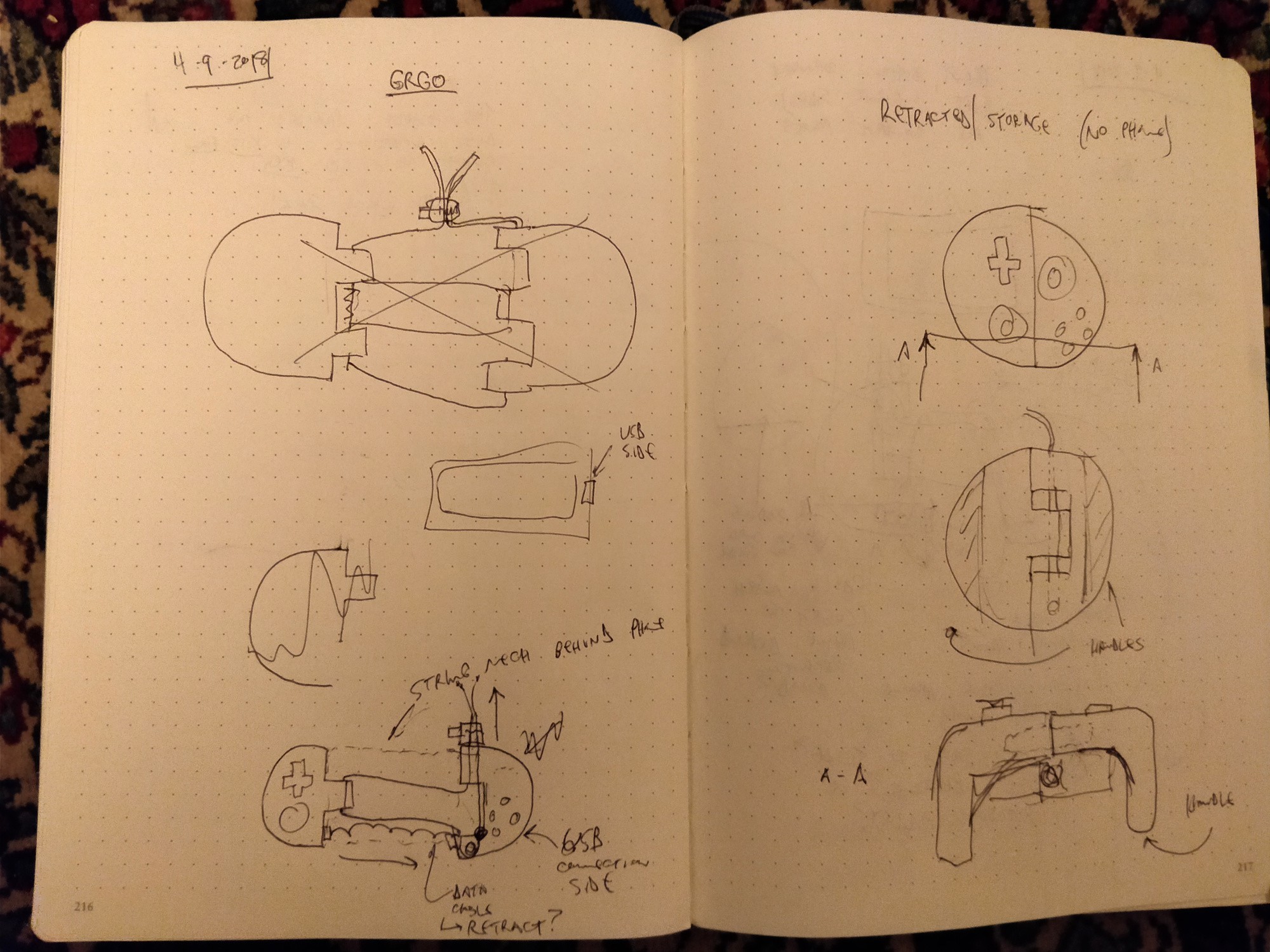

Above, thinking about a removable controller in terms of its store-ability. This concept mates together into a round puck secured using a drawstring; the same drawstring can be loosened and adjusted to secure the device on the phone. I imagined this as beefy paracord and one of those springy push-button cord retainers often found on coats and such. The bottom right image shows the design with downward-turned handles. Producing good ergonomics seems like it would require a lot of iterations with the 3D printer (understatement of the century, and apologies to all the industrial designers out there...)

A bit further down said rabbit hole. On the left, thinking about cable tensioning mechanisms; I'm still keen to avoid putting anything wireless (and power-hungry and fussy and expensive) into the design, so the two sides need to be linked somehow. The overly complicated concept there shows a pair of spring-loaded retractable arms with pulleys on the top that extend to keep the cord out of the way and .. yeah, springs are probably fine for now. On the right, thinking about how to design the 3D printed model -- maybe a clamshell approach with a gap to accommodate different device thicknesses...

... and a giant O-ring to fill the ensuing panel gap, because why not? Silicone? Polyurethane? In any case, the righthand page covers a few potentially important parts -- a micro USB dock connector, and a reasonably suitable USB-C plug (not a dock connector, as those don't seem to exist).

We're supposed to get a fuckload of snow this weekend so I'll hopefully get the prototype wrapped up. Excitement!

zakqwy

zakqwy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.