Here are some demonstrations that we've been working on. Using the motor in these different applications has helped us evaluate our own design and make improvements where necessary:

Closed Loop 3D Printer:

Demonstration of a rep rap Prusa with closed loop position control.

A Mechaduino servo motor can be used as a drop in replacement for each stepper motor and stepper driver. The Mechaduino has interrupt based step/direction command handling.

Closed loop control means that external disturbances or rapid accelerations will not cause a loss in steps.

Closed loop motors run more efficiently since they only apply the required torque to track a position command. Stepper motors must apply their maximum torque all the time. This means that the closed loop motor will run much cooler and can apply much higher peak torques.

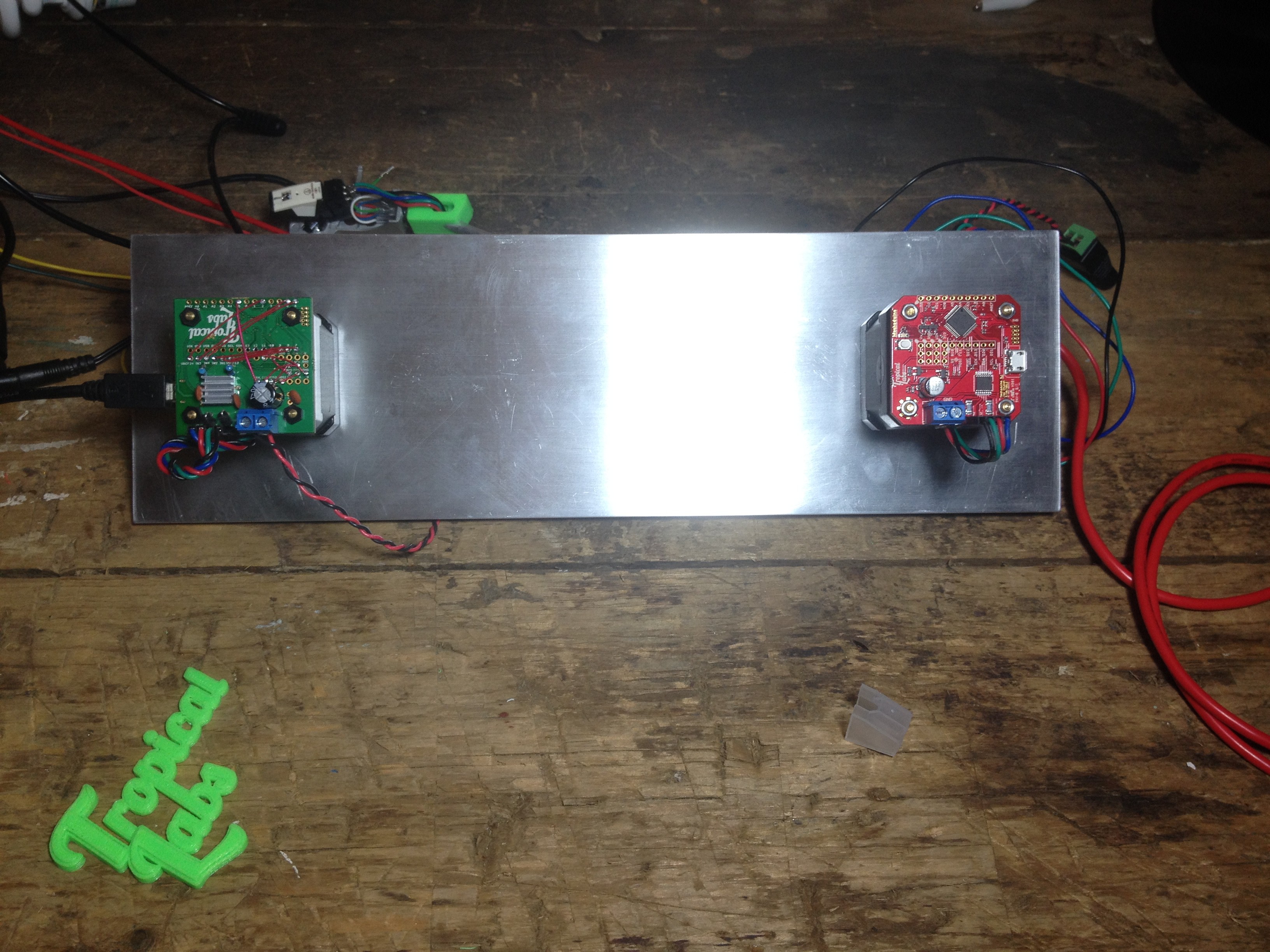

Electronic Gearing/Haptics:

Implemented with analog setpoints and two motors:

M1 position -- to -- M2 setpoint

M2 position -- to -- M1 setpoint

It works! Could use some filtering to remove noise, but not bad for first attempt! Could also be implemented over serial or I2C.

Applications include synchronous motion applications, but also extend to haptic force-feedback: torque applied to one shaft is felt on the other. A pair could be used to link motion of a joystick to a robotic arm, allowing the operator to "feel" when obstacles are hit. Could be used for bi-directional tele-operation of equipment. Imagine transmitting force and motions through the tactile equivalent of skype!

Robotic Arm:

A quick demo of a work-in-progress robot arm that uses a Mechaduino closed loop servo motor. Arm will eventually have 5 DOF.

Toilet Paper Dispenser:

This is primarily a demo of the Mechaduino servo motor. This novel bathroom appliance is a good way to show off the mult-mode capabilities (specifically force sensing, position control, and profile tracking) of the motor.

This application is totally self contained. Everything including the led indicators is controlled directly from the Mechaduino. It took only about 15 minutes to write the code for this custom Mechaduino application.

In addition to being a Mechaduino demo, we've realized that this little device could actually be a useful assistive technology since it only requires one hand to operate.

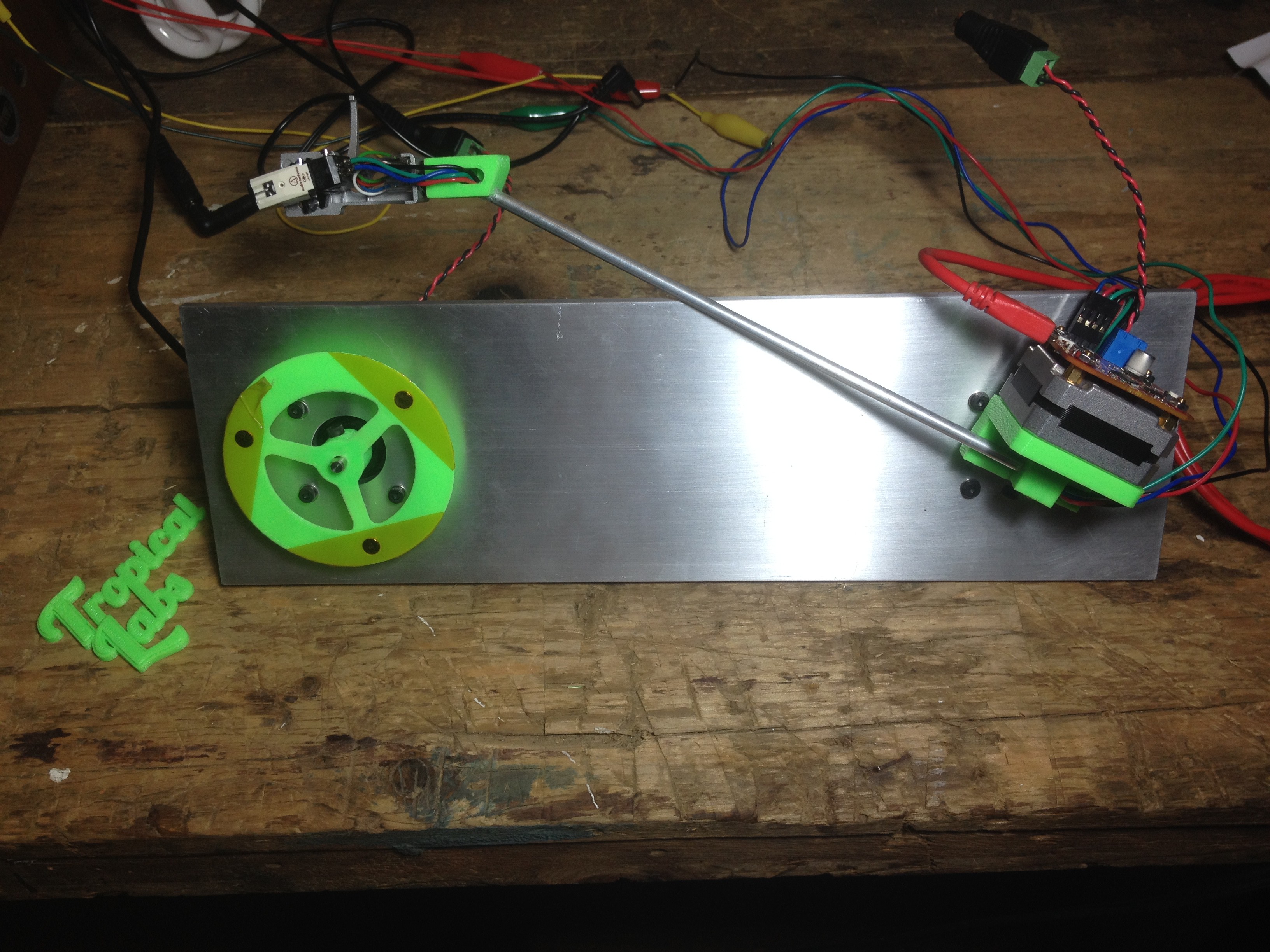

Record Player:

This is a bit of a teaser... the record player is still a work in progress, but we're very excited about it.

The idea is that instead of using a gimbal to allow the tone arm to move, we will have two Mechaduinos control the needle movement. This will open up the door to all kinds of interesting capabilities. Using gravity compensation, the record player could be hung on a wall and play the record vertically. Since we have full control of the needle movement, we've designed the tone arm to be able to flip backwards and around in order to play the back side of the record. Yes. This record player has auto reverse.

And, of course, the record itself is spun by a Mechaduino in closed loop velocity mode.

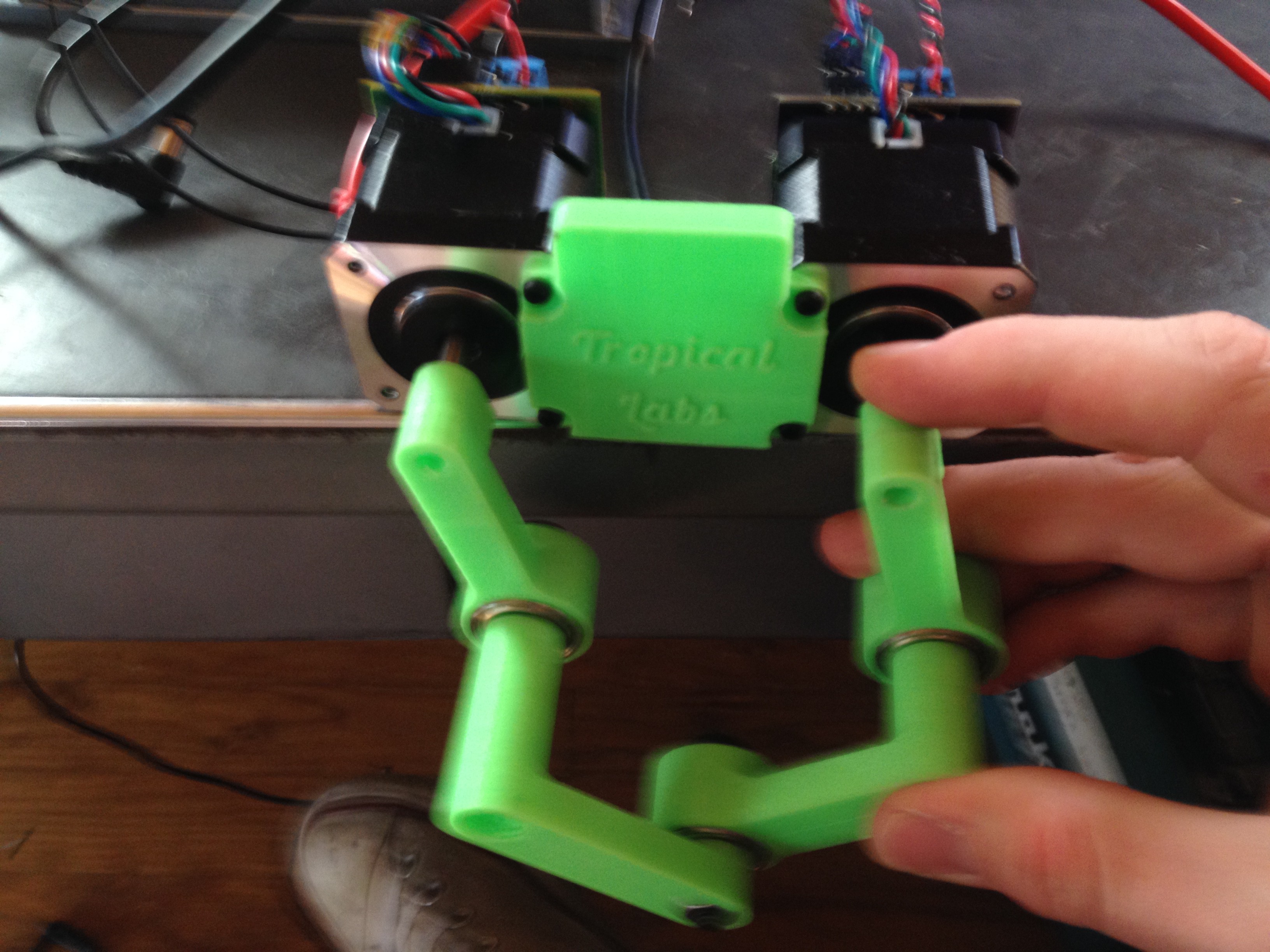

5-Bar Scara Robot:

Another teaser. Parallel robots often have complicated kinematics: You have to do a lot of math to go from motor positions to end-effector position and back. With this little 2 DOF positioner, we'd like to show off a "training" mode of the Mechaduino. Rather than performing motion planning and solving forward and inverse kinematics, a user will be able to move the arm through a desired trajectory, training it.

jcchurch

jcchurch

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.