Hello, once again I am here to talk about wheels, don't worry, next time will be something different, but for now, it is wheels.

First the video, because hell why not:

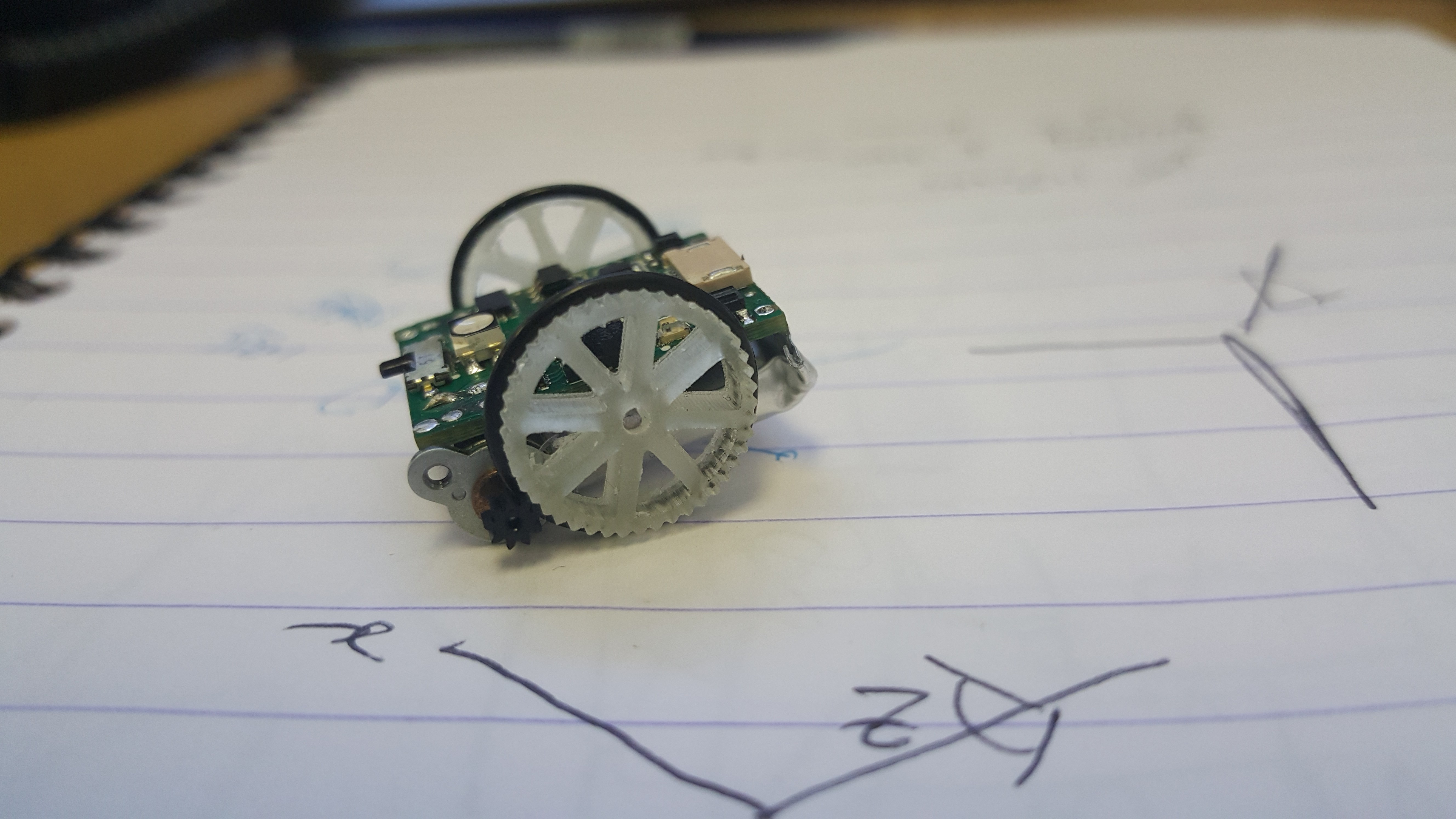

The wheels that I have settled on are made with a DLP driven, resin curing 3D printer. Whilst I would not recommend making a million like this, it is surprisingly expedient. On one bed I could fit something like 50 wheels, and have them completed in around 1 hour including clean up! For reference the printer I am using at the moment is the Roland ARM-10 that is in residence at the ICAH (Imperial College Advanced Hackspace) digital manufacturing lab.

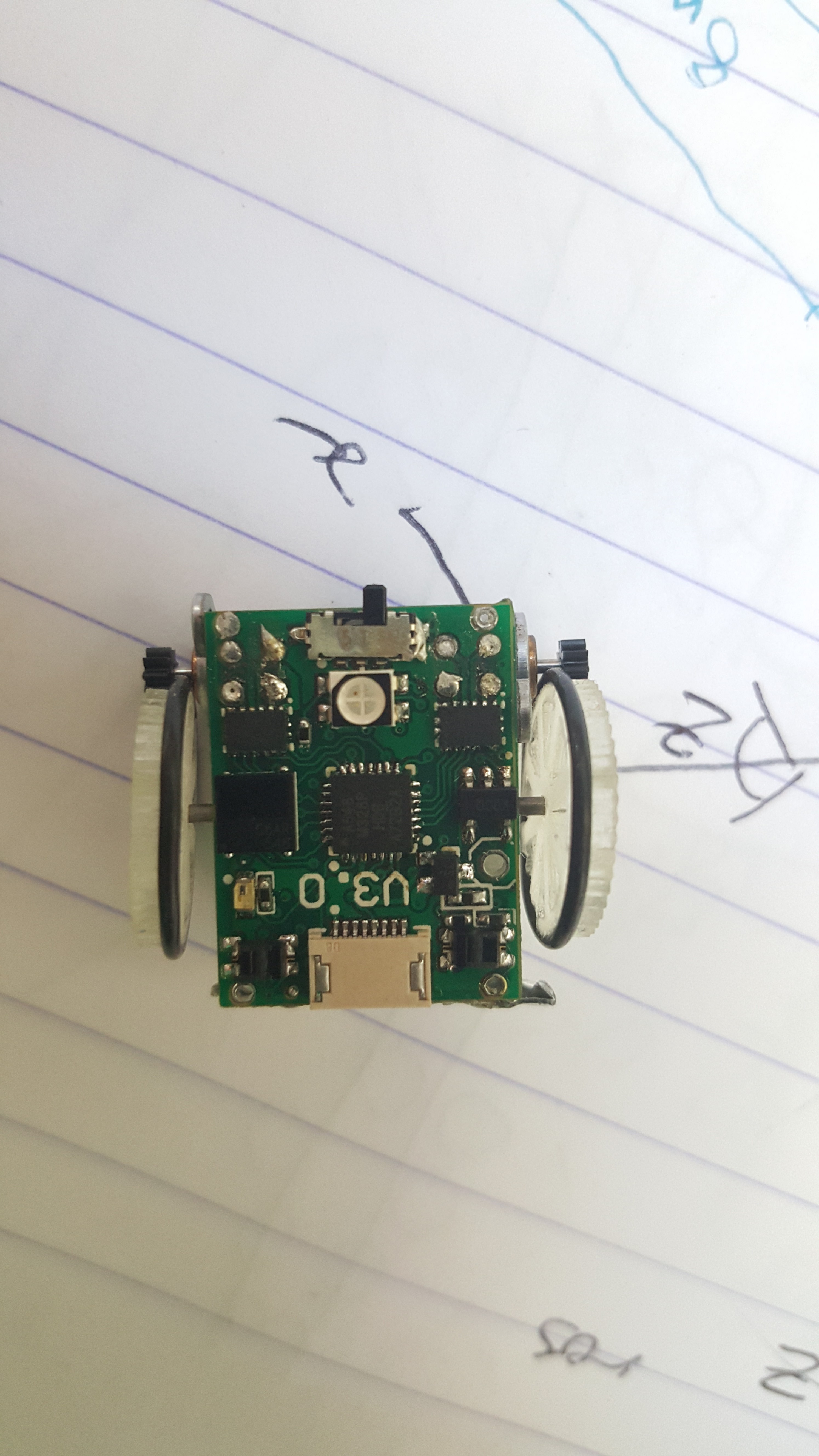

An interesting thing to note about this design of wheels is that they do not need to have a retaining clip on the shaft to stop them slipping off. The rubber o-ring is behind the pinion gear on the motor, the pinion then does not allow the wheel to move sidways.

This image shows an interesting point about the DLP printing process. It is important to avoid having any critical components touching the build plate. Before we had the gear teeth touching the bed in order to have a boss to lengthen the bore on the other side. This time the side retaining the o-ring was against the build plate, and look how sharp those teeth look! Satisfying! Consequently these new wheels are much more consistent with each other and run much more smoothly.

The wheel attempts are racking up, but I think we are nearly there. The current wheels will do for now, later we might make the bore more tight to the axle, but that is mostly for aesthetics.

Joshua Elsdon

Joshua Elsdon

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Wow, I love the wheels! 25 bots-worth in 1 hour seems like pretty reasonable fabrication time to me. And they're big enough that an enterprising could easily print out an encoder wheel and hack in some position monitoring.

Wheels, and specifically connecting them to the motor, have always been my achilles heel in robot building.

Are you sure? yes | no

Yes, as you can see we have spent lots of time getting the wheels to work. It is especially difficult due to the tiny torques involved. Assuming the wheels don't jam there is no need for an encoder, the motors we are using are stepper motors, so we know their position in an open loop way (slipping on the floor is not seen by encoders either). Closed loop positioning will be introduced later using an overhead camera.

Are you sure? yes | no